Deformation control and analysis of pre-stressed fish-belly beem steel support system pit

-

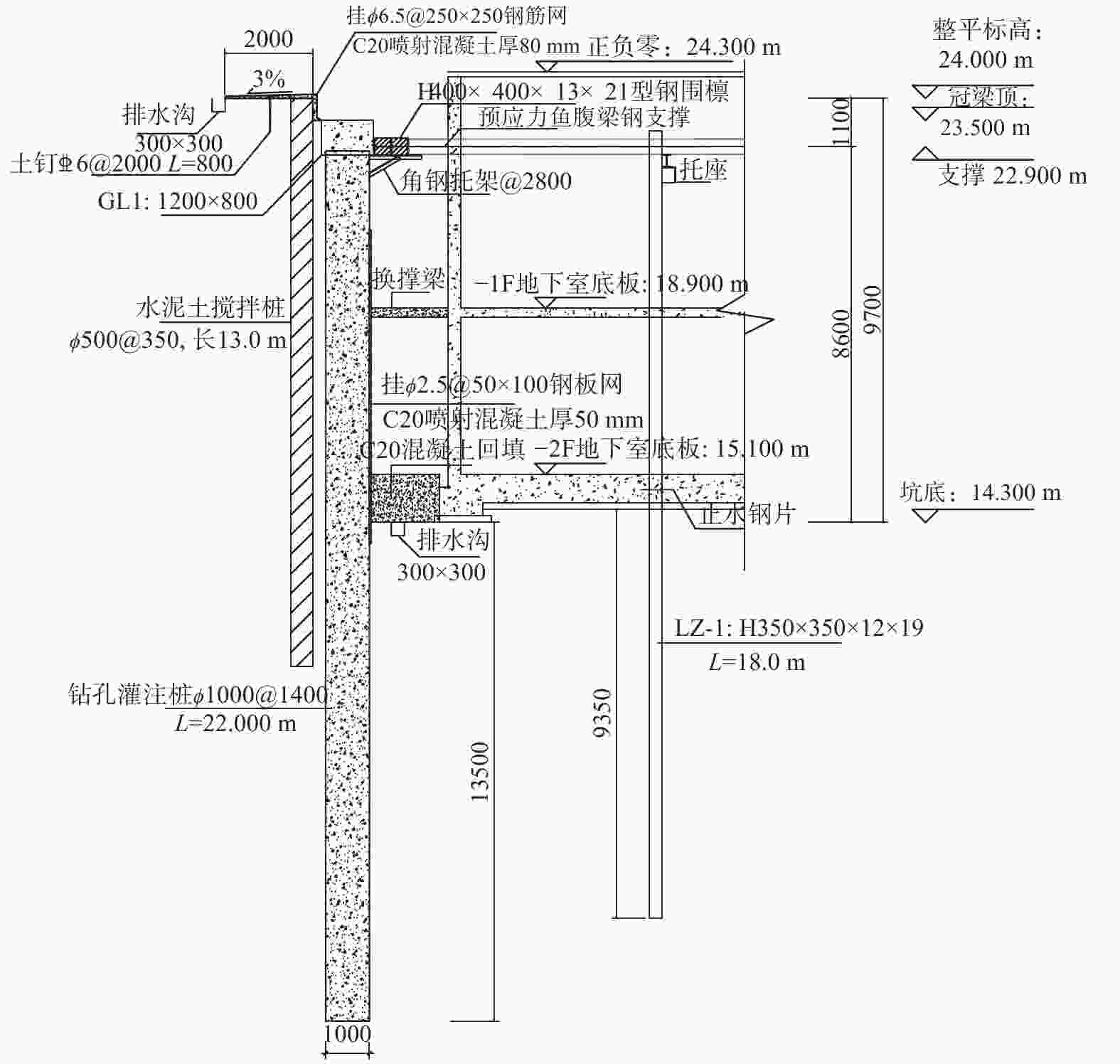

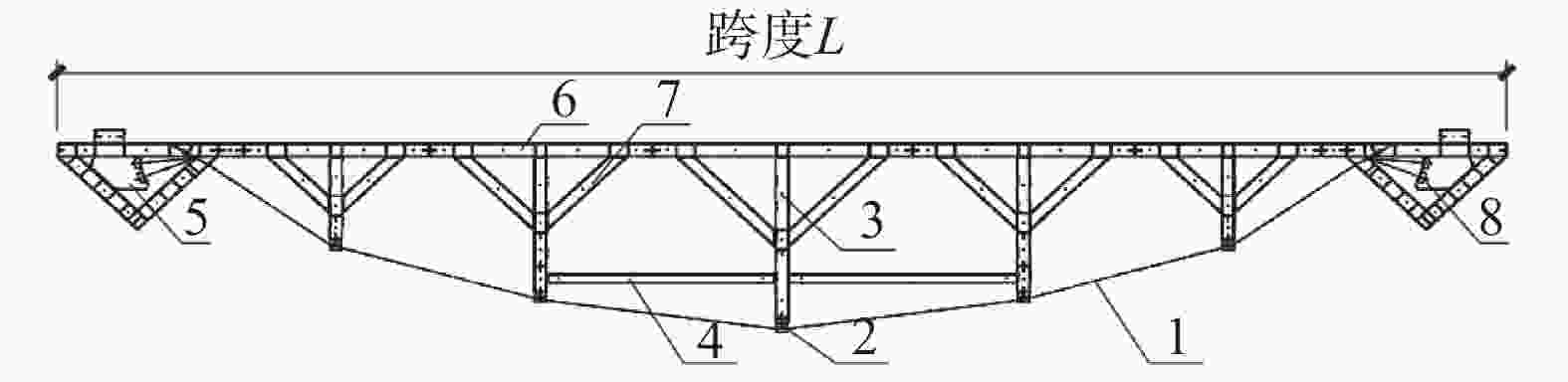

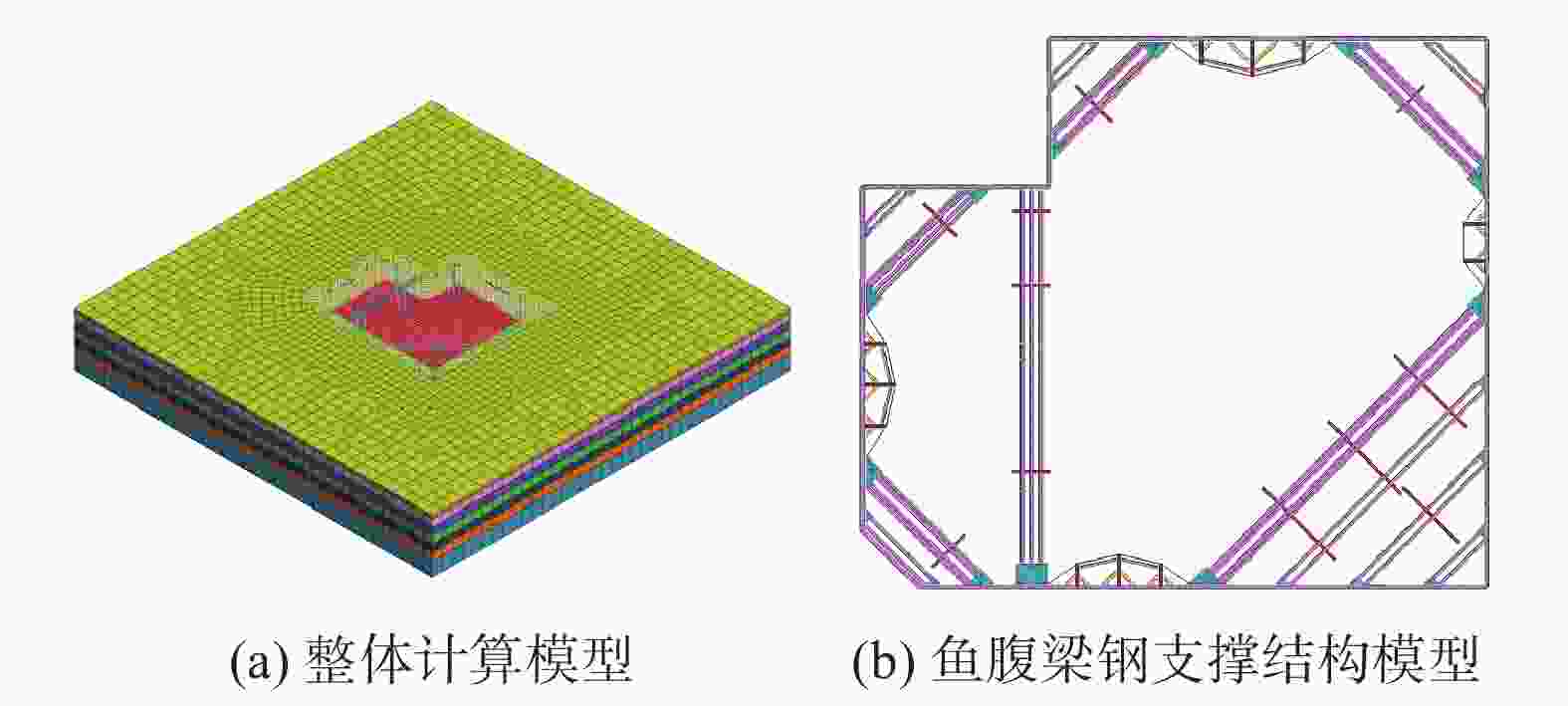

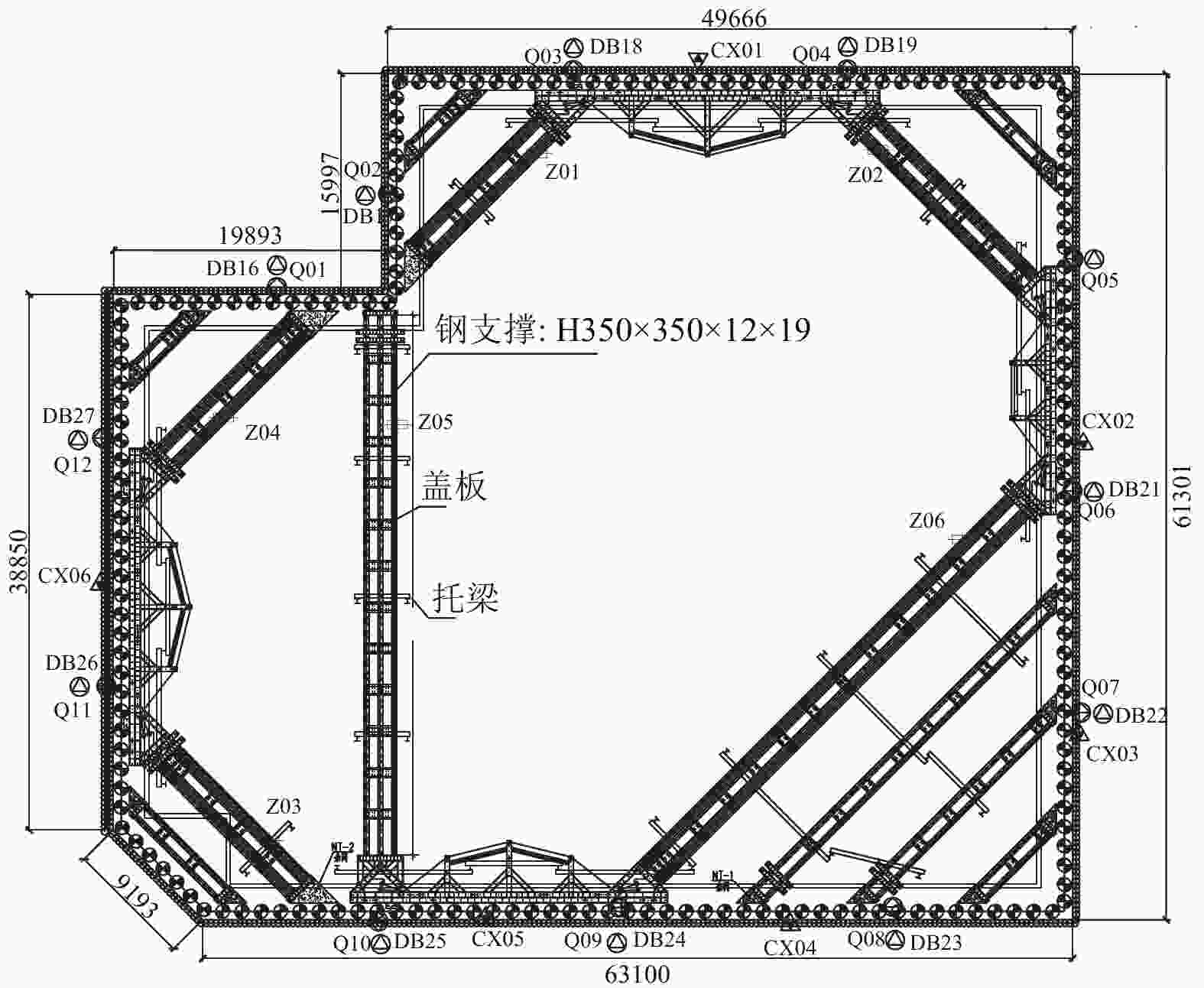

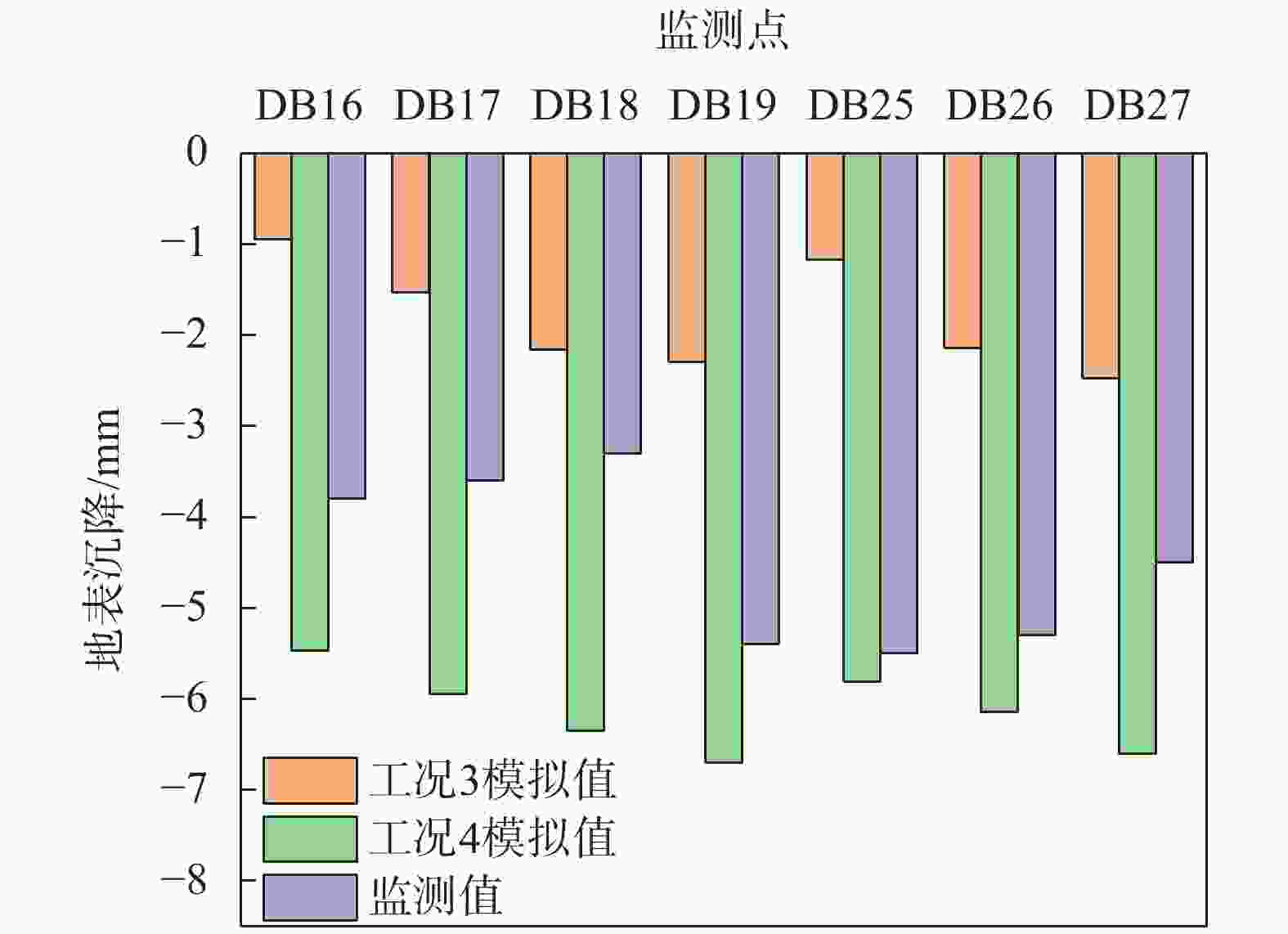

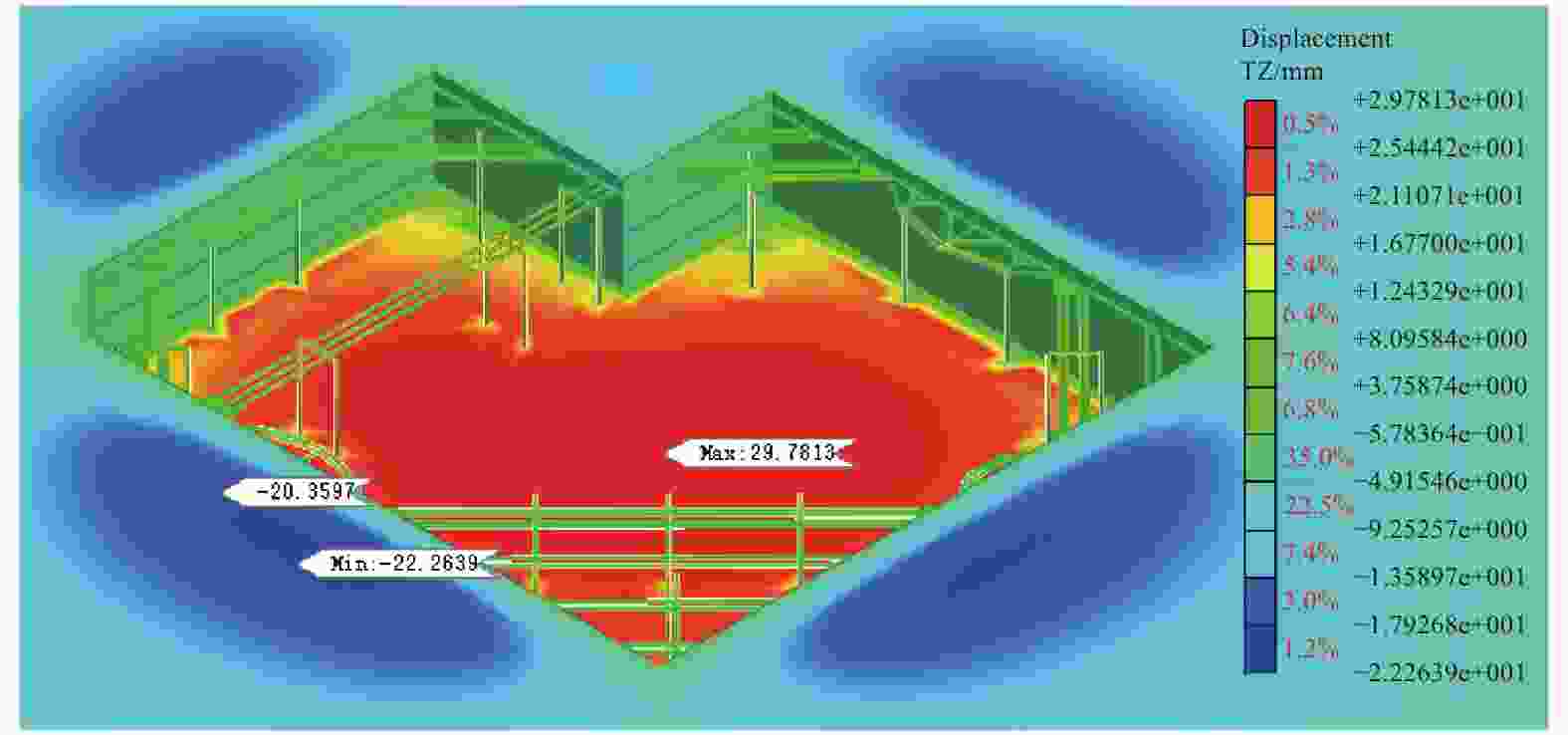

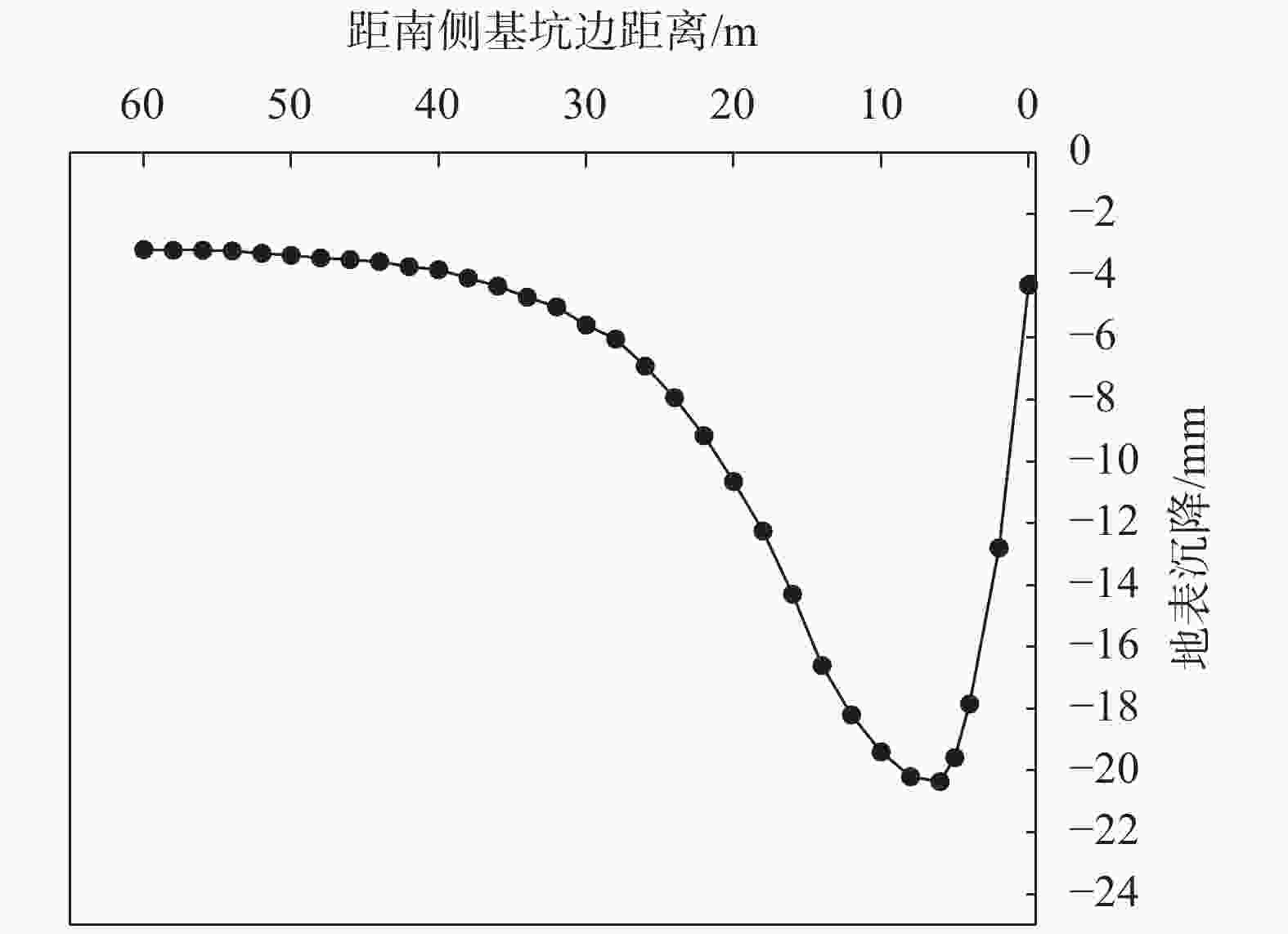

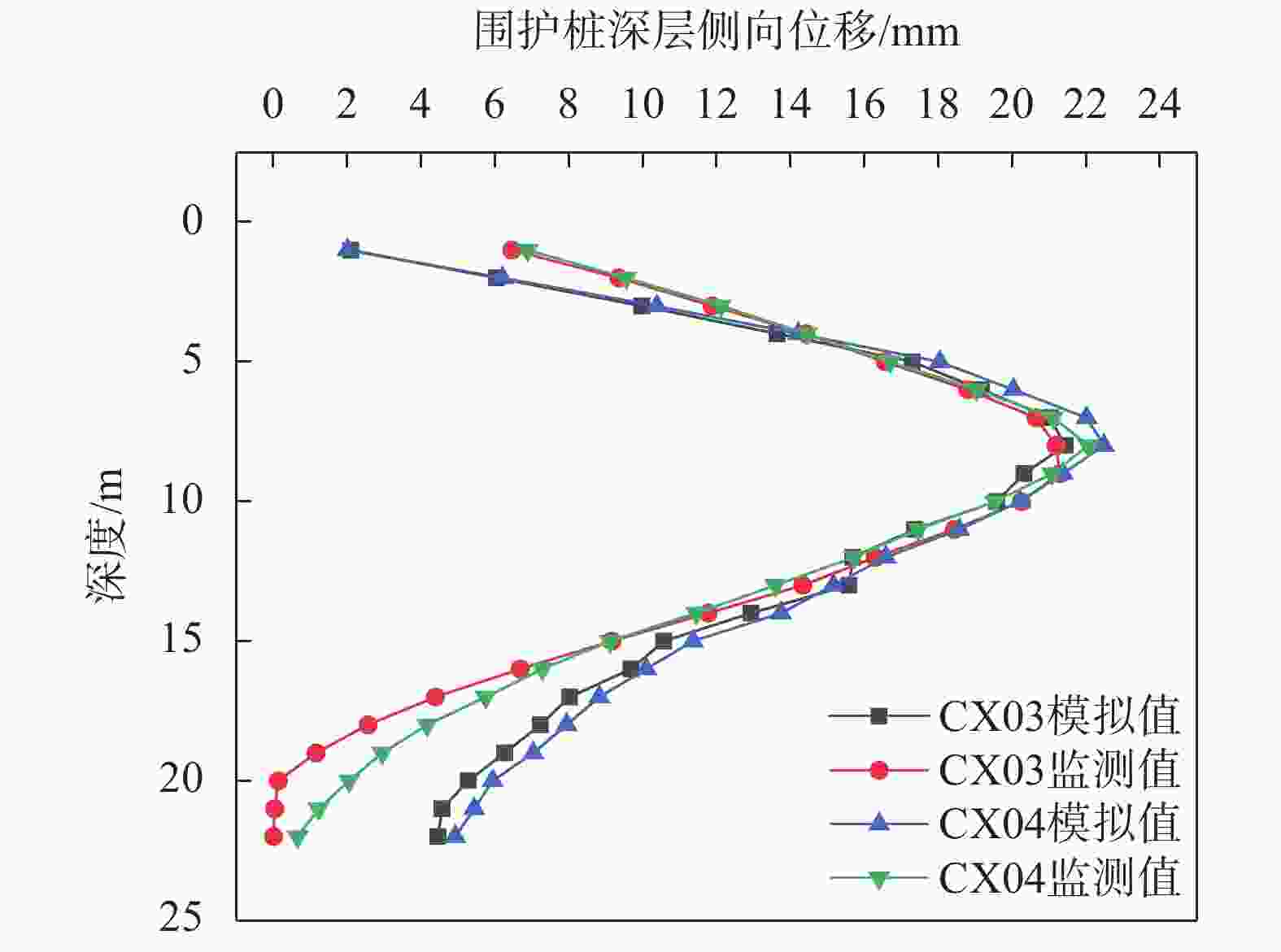

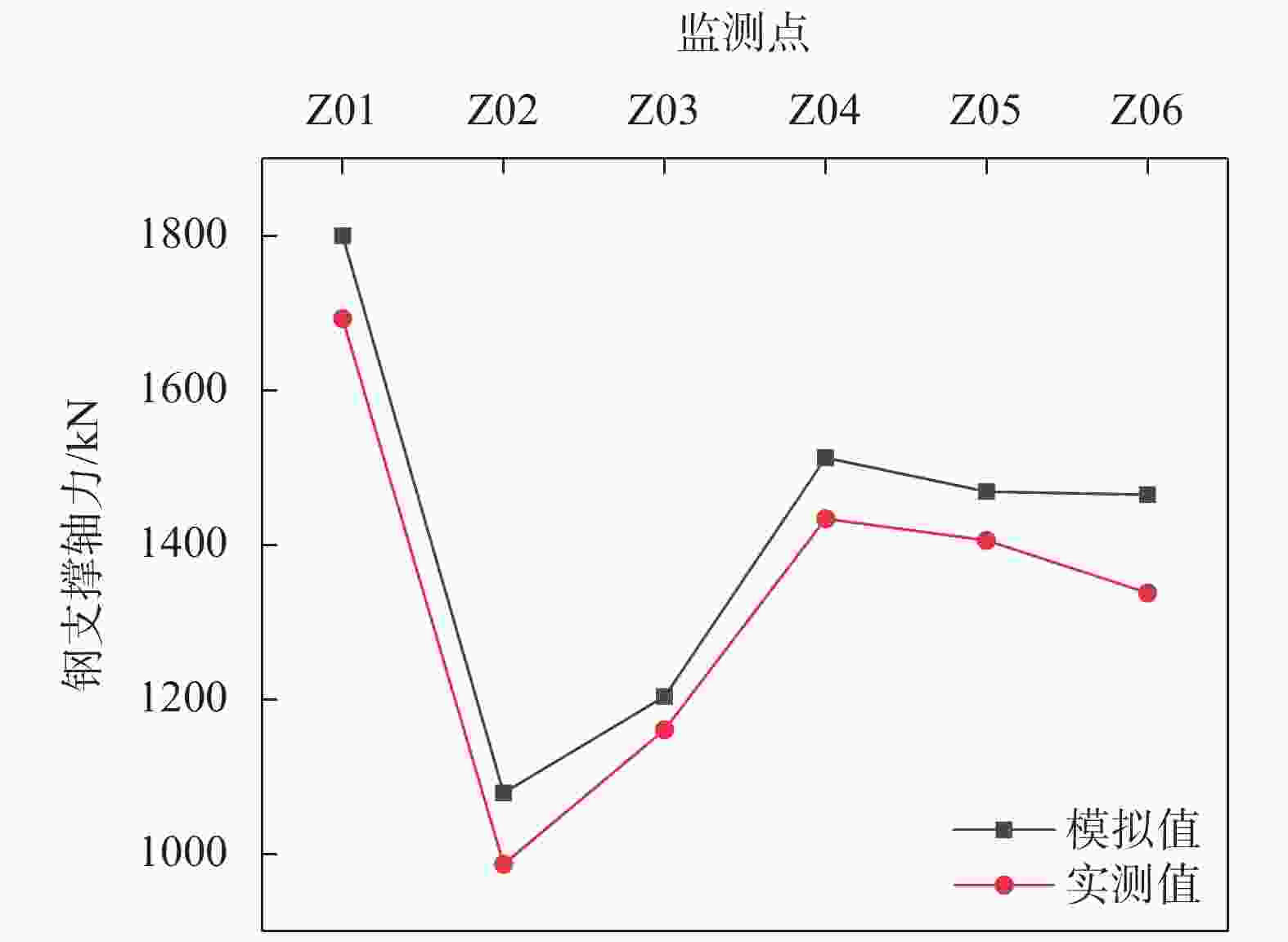

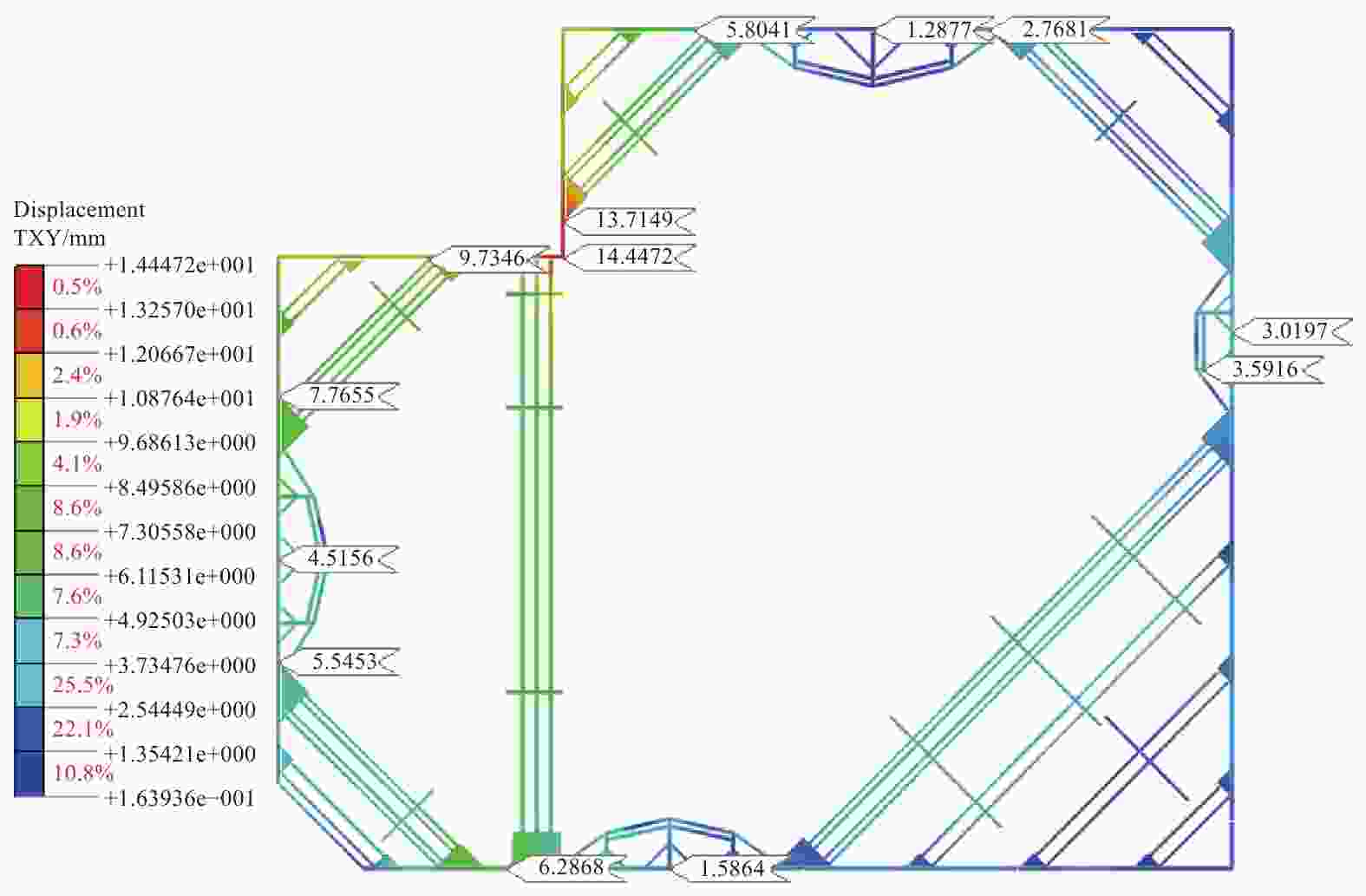

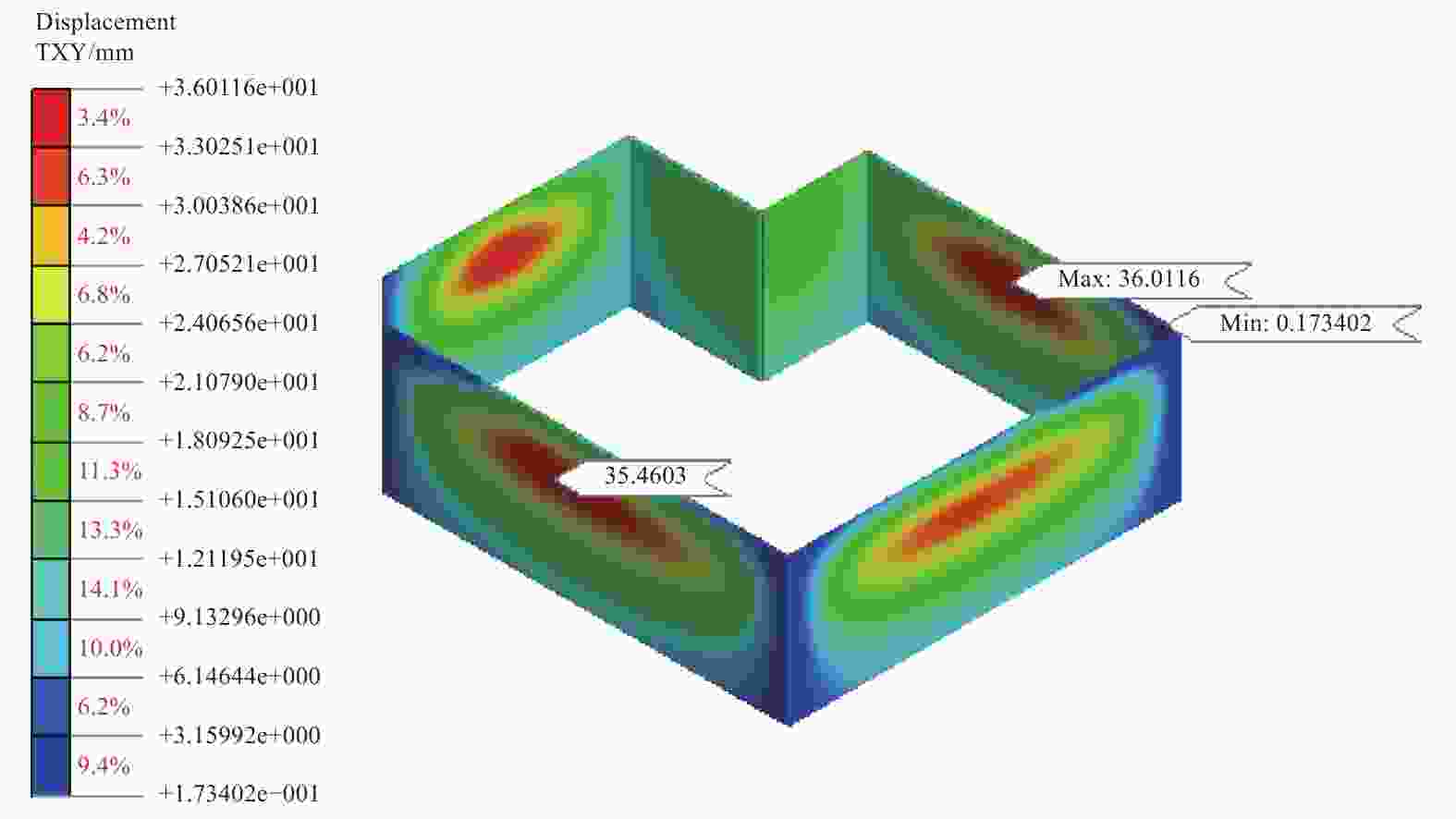

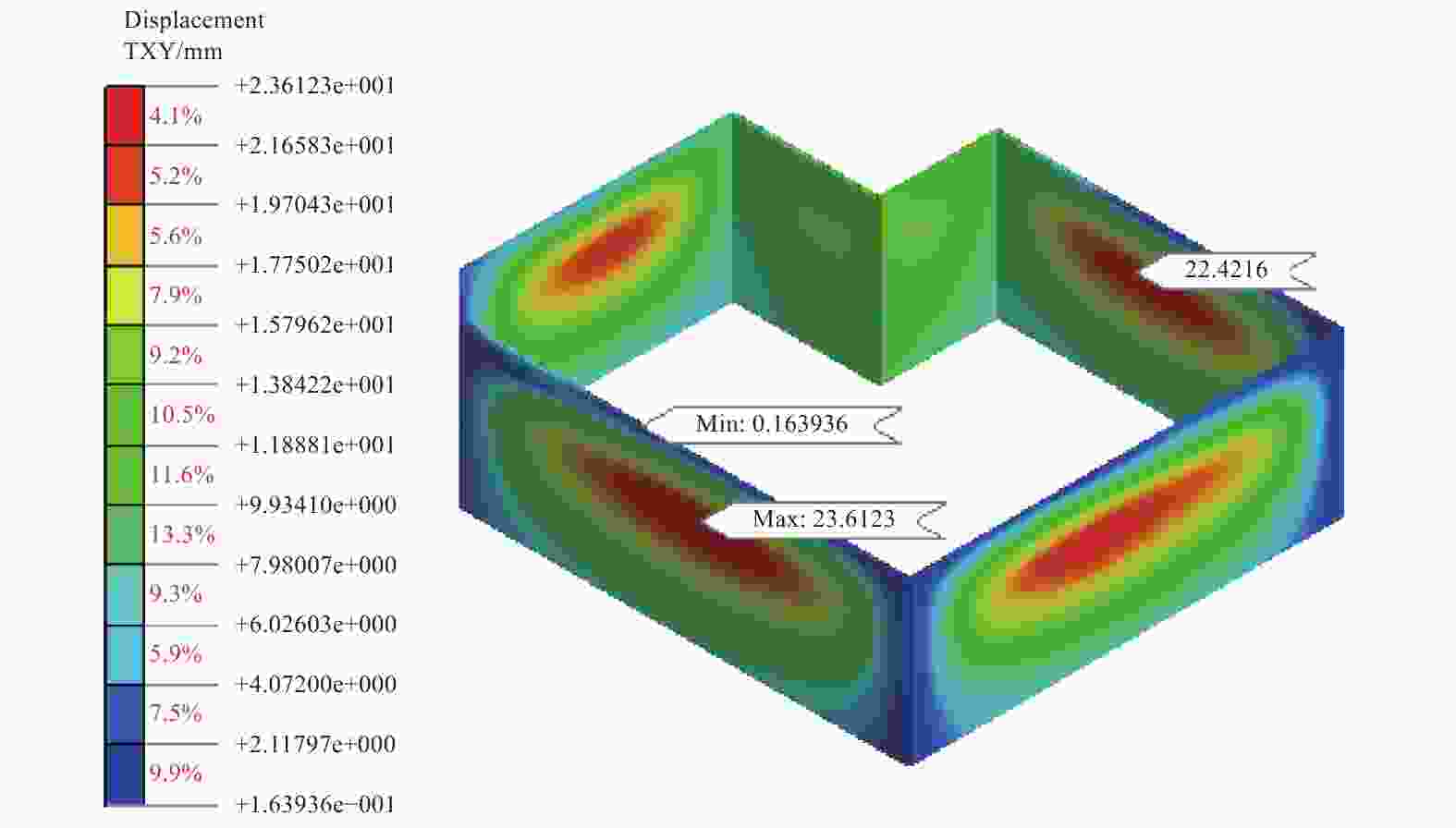

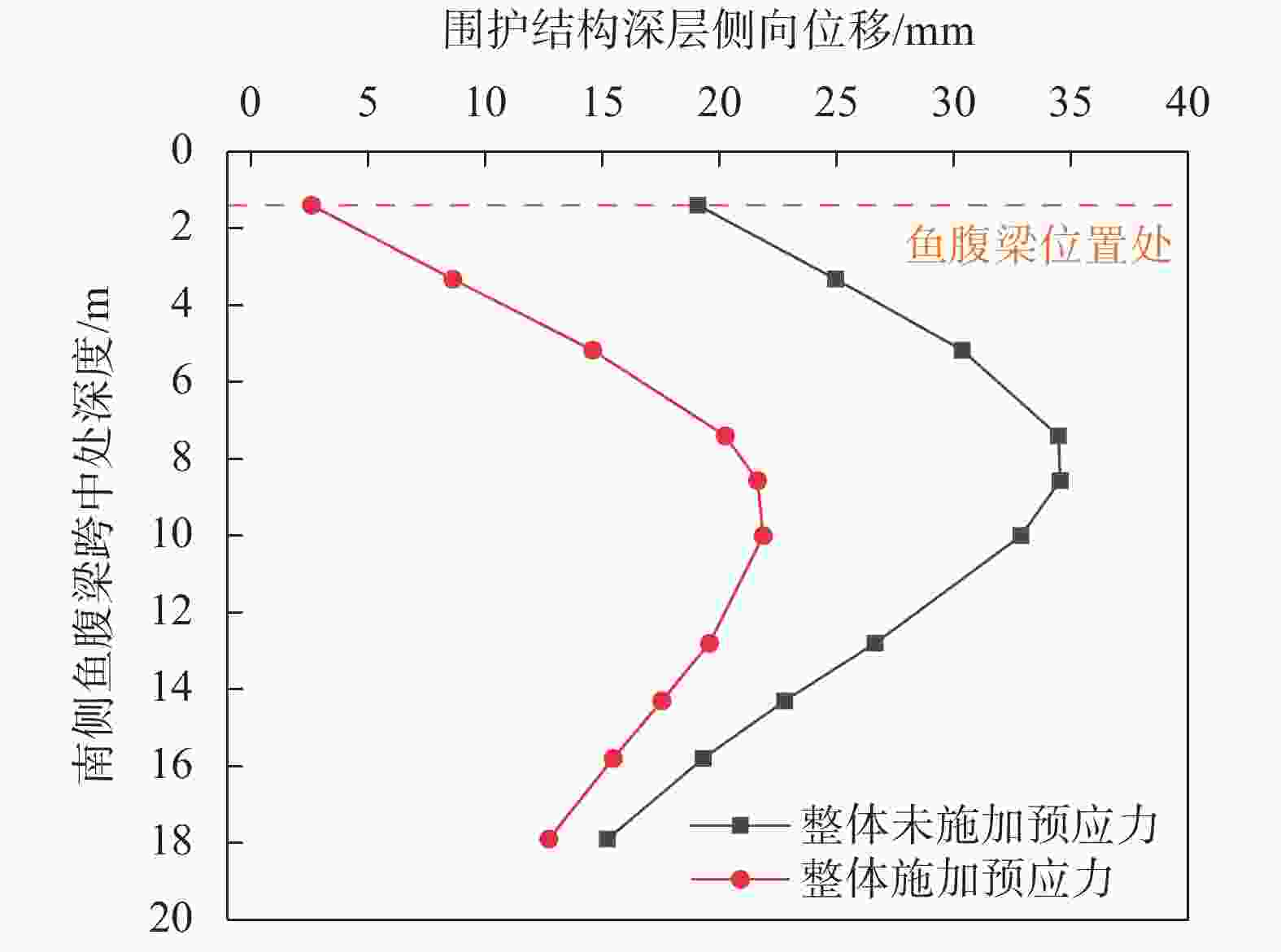

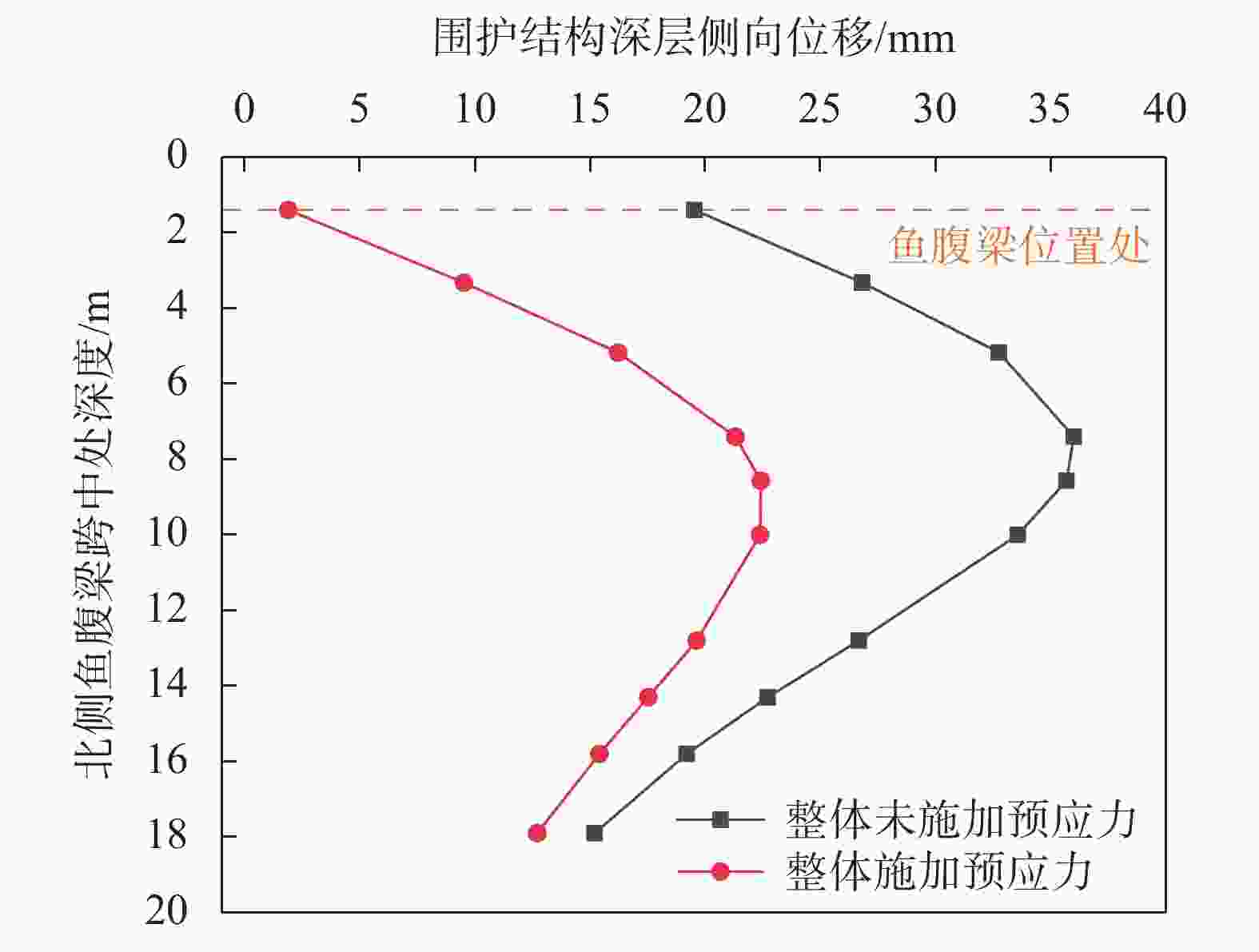

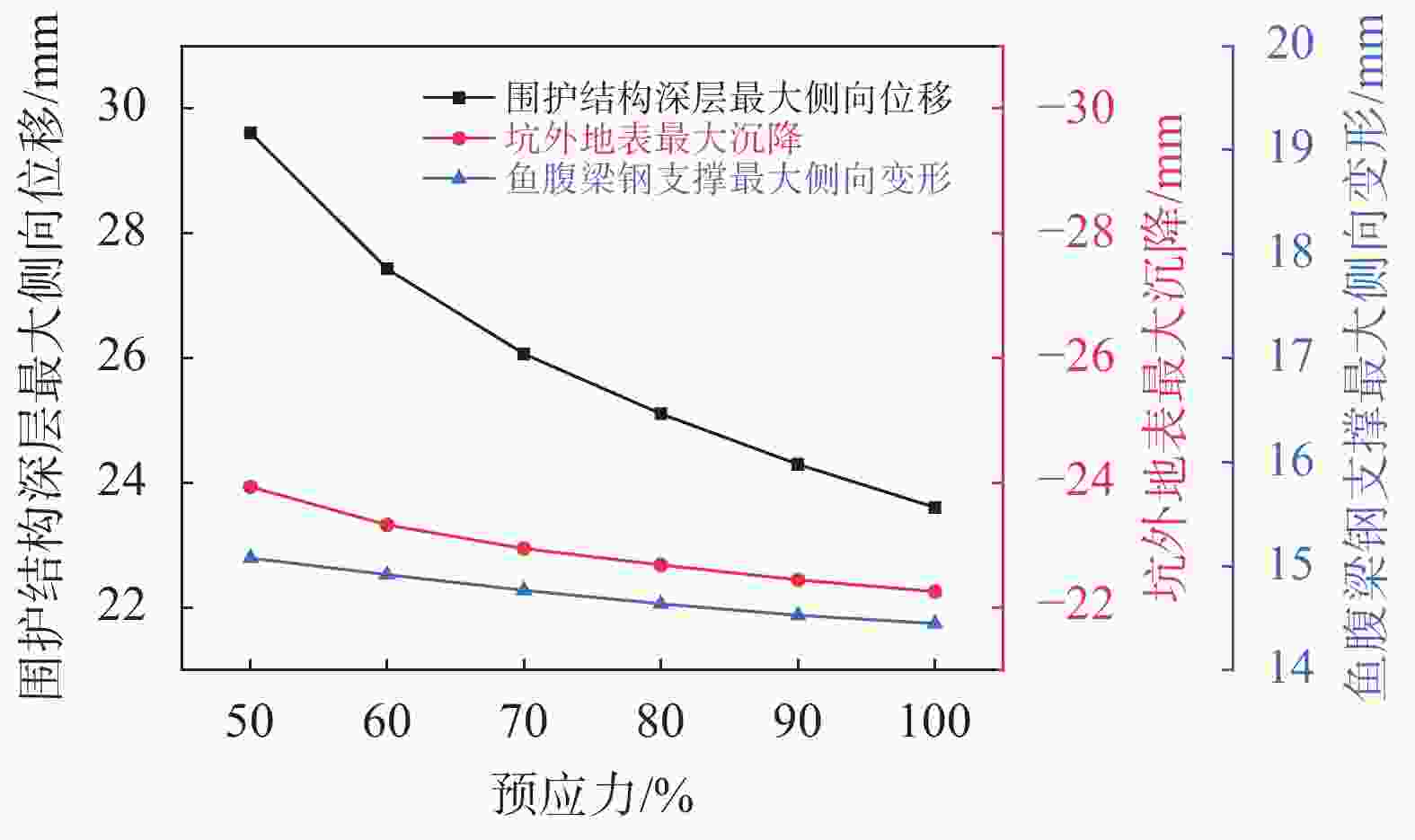

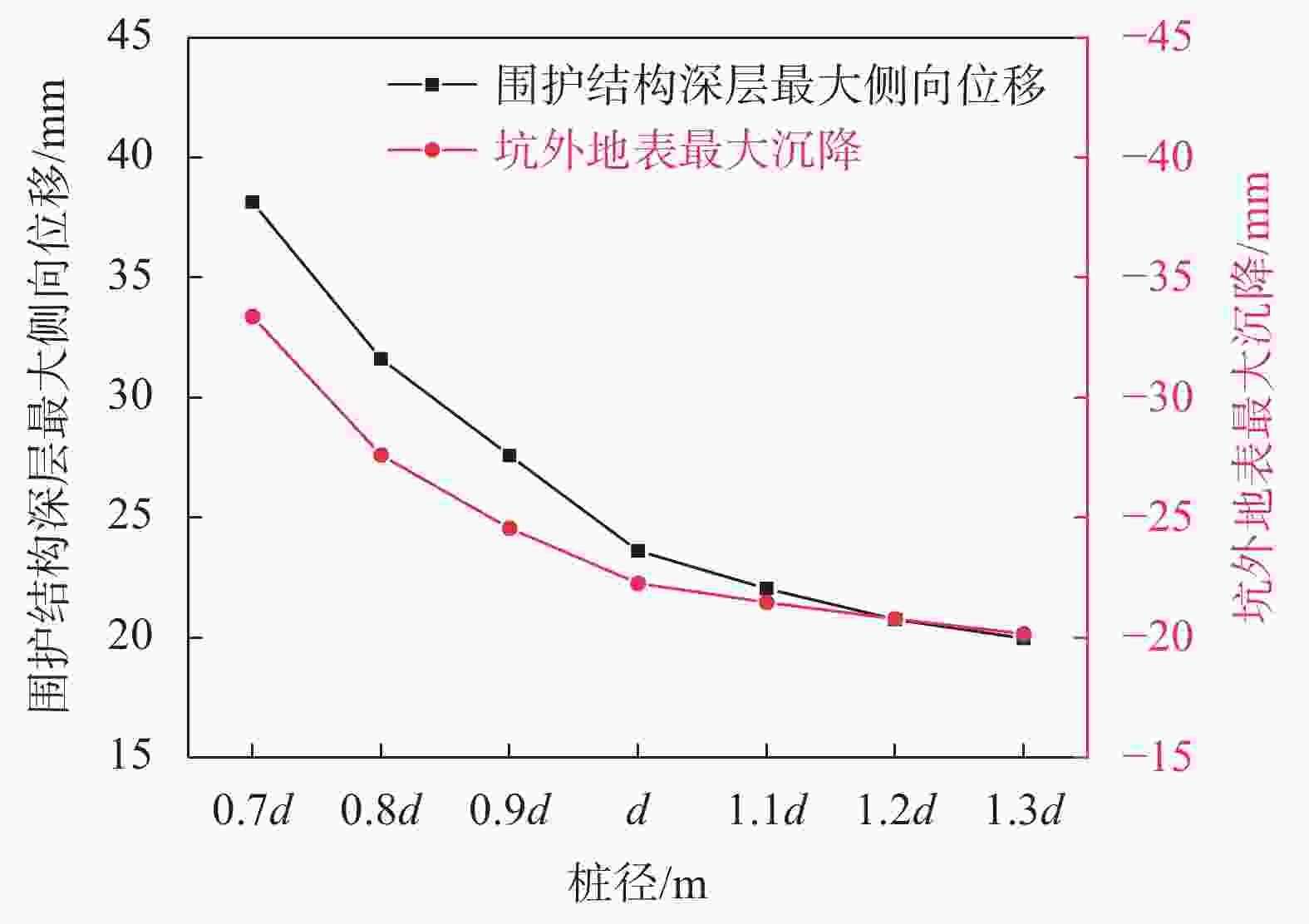

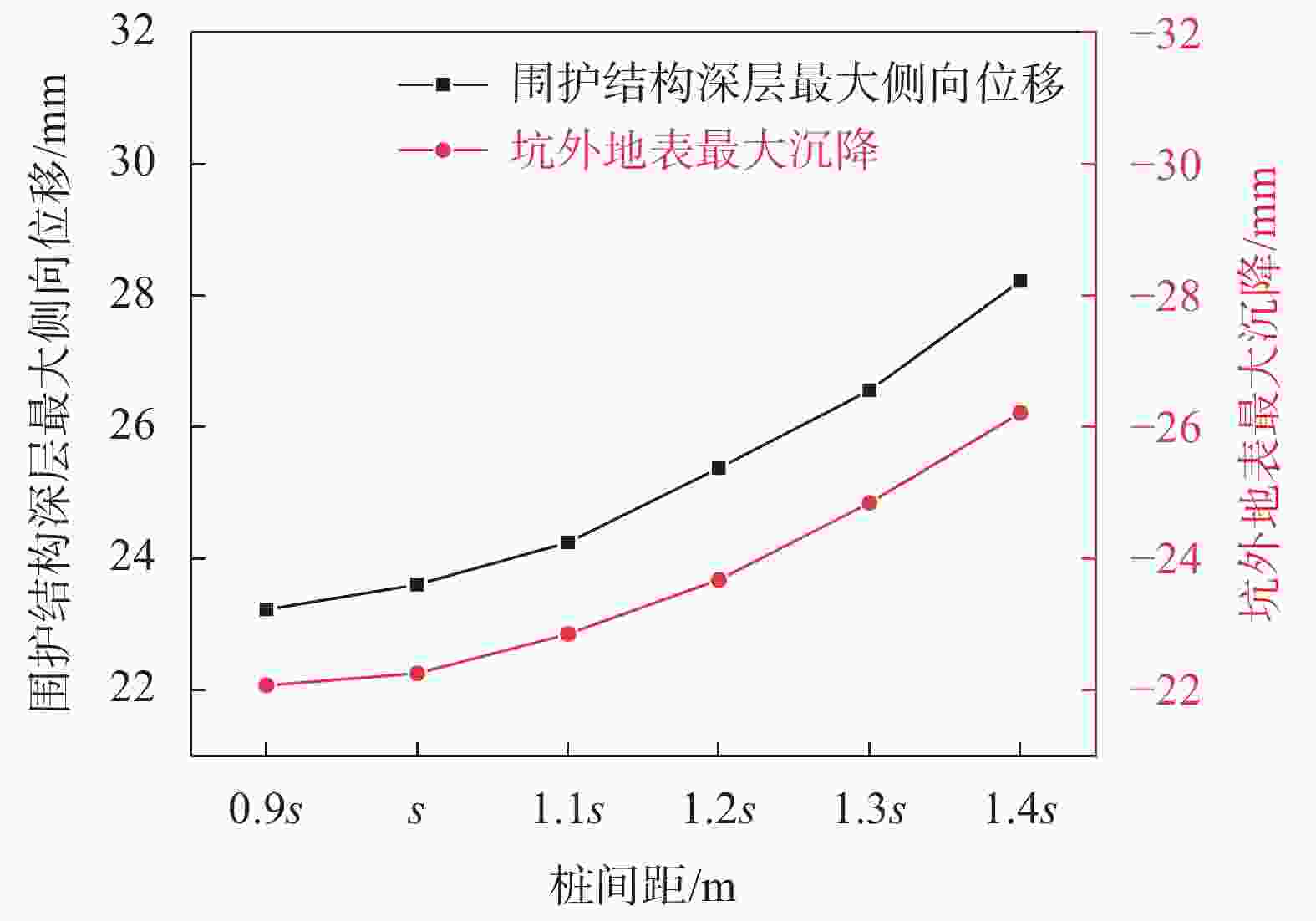

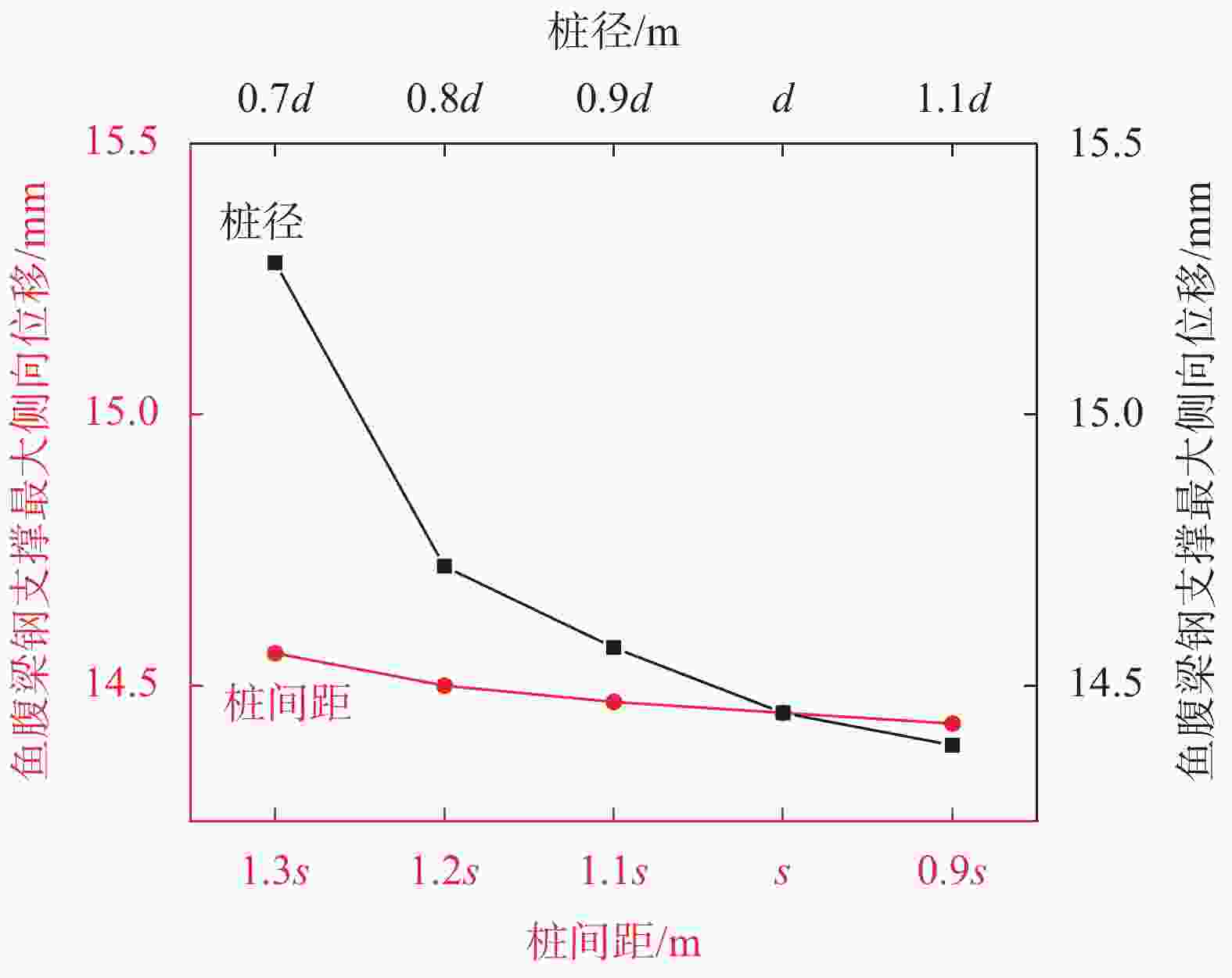

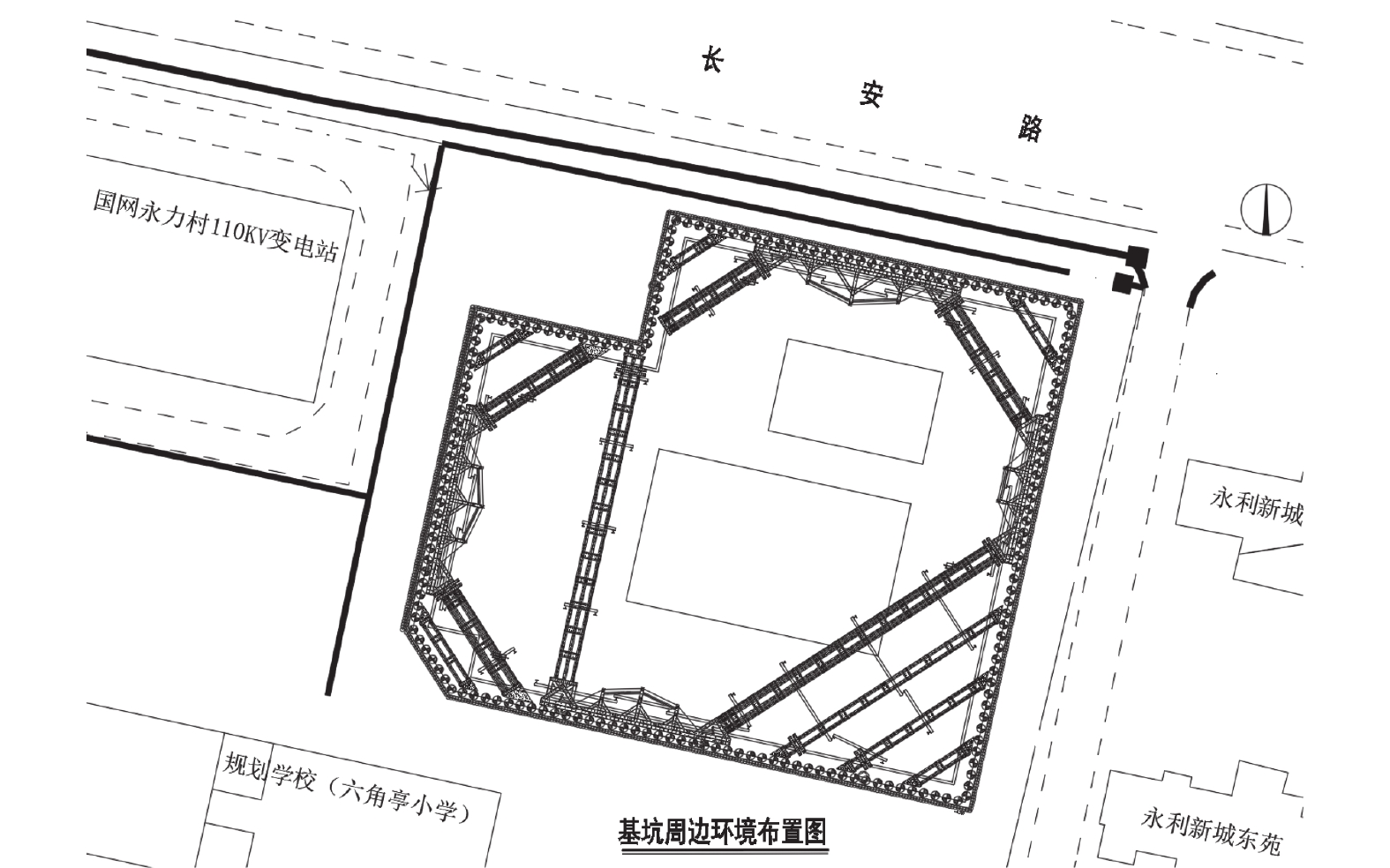

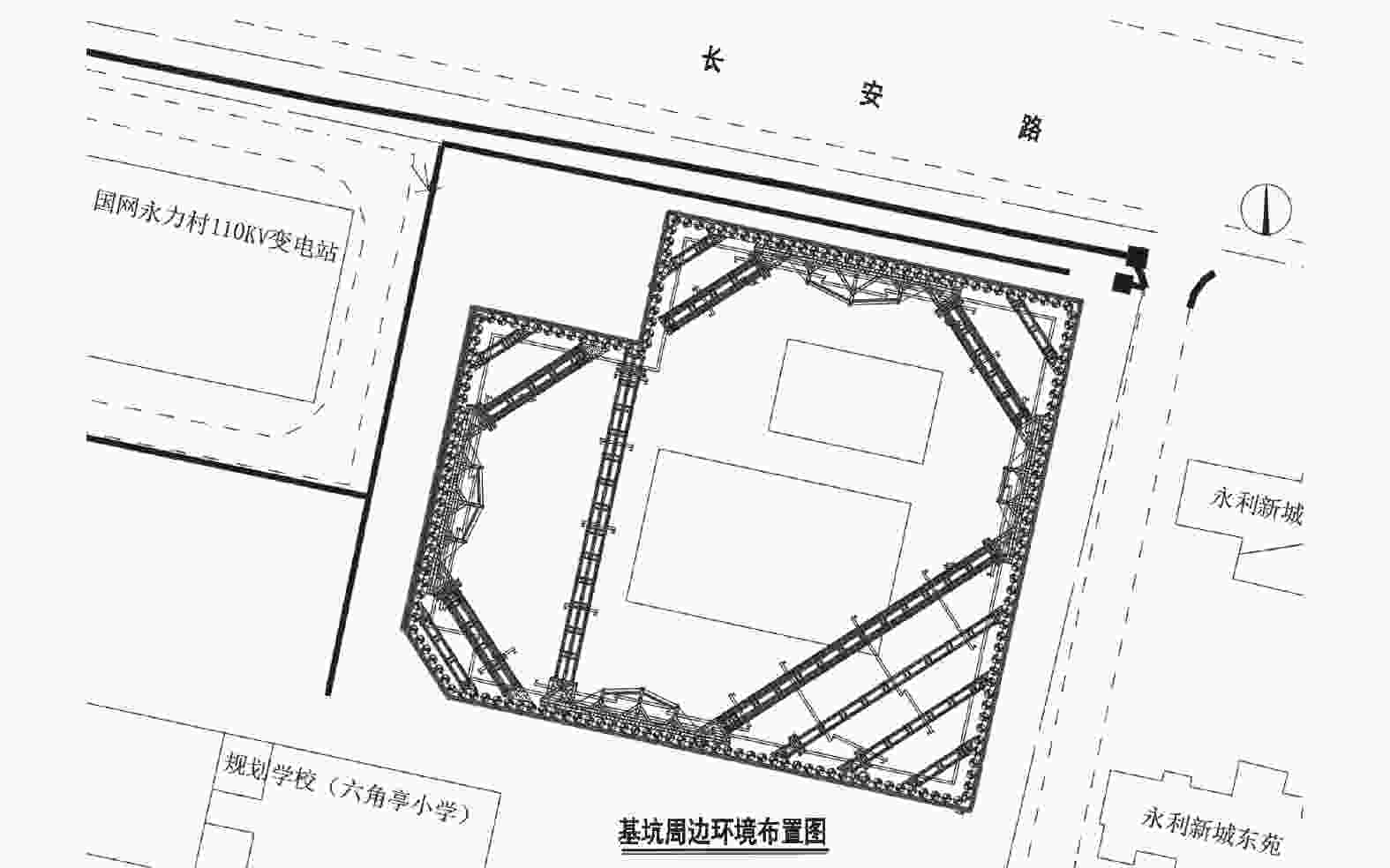

摘要: 以武汉市某深基坑为例,分析预应力鱼腹梁钢支撑体系对基坑整体变形的控制效果,并在此基础上研究预应力、围护桩桩径和桩间距等因素对鱼腹梁钢支撑体系基坑变形的影响程度。研究表明:鱼腹梁钢支撑结构体系侧向变形、围护结构深层侧向位移以及坑外地表沉降均未超过基坑预警值,预应力的施加能够有效控制围护结构最大侧向位移,且在鱼腹梁位置处控制效果较好,基坑整体施工安全性大大提高;增大预应力、增大围护桩桩径、减小桩间距,均能在一定程度上减小基坑整体变形。在合理范围内,相较于围护桩桩间距,桩径的改变对鱼腹梁钢支撑体系最大侧向变形、围护结构深层最大侧向位移以及坑外地表最大沉降影响程度更大,对基坑整体变形影响效果更为显著。Abstract: Taking a deep foundation pit in Wuhan as an example, the control effectiveness of the pre-stressed fish-bellied beam steel support system on the overall deformation was analyzed. The influence of the degree of pre-stress, the pile diameter of the enclosing piles and the spacing of the piles on the deformation of the fish-belly beam steel support system was studied. The study shows that: the lateral deformation of the steel support structure system of the fish-belly beam, the deep lateral displacement of the enclosure structure and the ground settlement outside the pit do not exceed the warning value of the pit, and the application of pre-stress can effectively control the maximum lateral displacement of the enclosure structure, and the control effect is better at the position of the fish-belly beam, and the overall safety of the construction of the pit is greatly improved. Increasing the degree of pre-stress, the diameter of the enclosing piles, and reducing the pile spacing can reduce the overall deformation of the foundation pit to a certain extent. Within a reasonable range, compared with the spacing of the enclosing piles, the change of pile diameter has a greater influence on the maximum lateral deformation of the fish-belly beam steel support system, the maximum lateral displacement of the deep layer of the enclosing structure, and the maximum settlement of the ground surface outside the pit, which has a more significant effect on the overall deformation of the foundation pit.

-

表 1 地层主要物理力学参数

土层 平均

厚度/m重度

γ/(kN·m−3)内摩擦角

φ/(°)黏聚力

c/kPa渗透系数

k/(cm·s−1)(1)素填土 1.47 17.0 18 8 1.0×10−4 (2-1)粉质黏土 3.70 19.3 10 19 2.0×10−5 (2a)粉质黏土 3.40 19.3 6.5 15 2.2×10−5 (3-1)粉质黏土 4.20 19.3 10 19 2.4×10−5 (3-2)粉质黏土 3.00 19.3 10.5 21 2.8×10−5 (4-1)粉砂夹粉黏 4.30 20.1 15 10 6.0×10-4 (4-2)粉砂 10.00 20.0 32 0 6.5×10-4 表 2 支护构件参数

构件

名称截面尺寸

/mm弹性模量

E/MPa泊松比

v重度

γ/(kN·m−³)钢围檩 H400×400×13×21 206000 0.3 78.5 钢支撑 H350×350×12×19 206000 0.3 78.5 托梁 H300×300×10×15 206000 0.3 78.5 立柱 H350×350×12×19 206000 0.3 78.5 表 3 预应力鱼腹梁系统参数及预应力设计值

鱼腹梁体系 钢绞线规格 预应力设计值/kN 北侧鱼腹梁 26ϕs15.2 3380 南侧鱼腹梁 22ϕs15.2 2860 西侧鱼腹梁 22ϕs15.2 2860 东侧鱼腹梁 14ϕs15.2 1820 角撑 1200 对撑 900 -

[1] 刘发前, 卢永成. 预应力装配式鱼腹梁内支撑的刚度分析[J]. 城市道桥与防洪, 2016(2): 154-156, 168. (LIU F Q, LU Y C. Stiffness analysis of prestressed assembled fish belly beam with internal supports[J]. Urban Roads, Bridges and Flood Control, 2016(2): 154-156, 168. (in Chinese)LIU F Q, LU Y C. Stiffness analysis of prestressed assembled fish belly beam with internal supports[J]. Urban Roads, Bridges and Flood Control, 2016(2): 154-156, 168. (in Chinese) [2] 黄鸿超. 预应力鱼腹梁装配式钢支撑在基坑围护支撑体系中的应用[J]. 建筑技术开发,2018,45(8):14-15. (HUANG H C. Steel beam assembly type prestressed fishbelly support in foundation pit support system in application[J]. Building Technology Development,2018,45(8):14-15. (in Chinese) doi: 10.3969/j.issn.1001-523X.2018.08.008HUANG H C. Steel beam assembly type prestressed fishbelly support in foundation pit support system in application[J]. Building Technology Development, 2018, 45(8): 14-15. (in Chinese) doi: 10.3969/j.issn.1001-523X.2018.08.008 [3] 沙敏军, 赵骏强. 装配式预应力鱼腹梁钢支撑受力机理研究[J]. 施工技术, 2019, 48(S1): 1305-1308. (SHA M J, ZHAO J Q. Study on the mechanism of load bearing of prestressed fish belly beam steel support in prefabricated construction[J]. Construction Technology, 2019, 48(S1): 1305-1308. (in Chinese)SHA M J, ZHAO J Q. Study on the mechanism of load bearing of prestressed fish belly beam steel support in prefabricated construction[J]. Construction Technology, 2019, 48(S1): 1305-1308. (in Chinese) [4] 易振华. 鱼腹梁钢支撑在基坑工程中的实践与分析[J]. 岩土工程技术,2022,36(1):26-30. (YI Z H. Practice and analysis of fish-belly beam steel support in foundation pit[J]. Geotechnical Engineering Technique,2022,36(1):26-30. (in Chinese) doi: 10.3969/j.issn.1007-2993.2022.01.005YI Z H. Practice and analysis of fish-belly beam steel support in foundation pit[J]. Geotechnical Engineering Technique, 2022, 36(1): 26-30. (in Chinese) doi: 10.3969/j.issn.1007-2993.2022.01.005 [5] 王寿生, 张银屏, 王明卓. 新型绿色基坑支撑技术研究及设计实例[J]. 中国市政工程,2016(3):82-84,88,127. (WANG S S, ZHANG Y P, WANG M Z. Study & design case of innovative green support technology for foundation pit engineering[J]. China Municipal Engineering,2016(3):82-84,88,127. (in Chinese) doi: 10.3969/j.issn.1004-4655.2016.03.025WANG S S, ZHANG Y P, WANG M Z. Study & design case of innovative green support technology for foundation pit engineering[J]. China Municipal Engineering, 2016(3): 82-84,88,127. (in Chinese) doi: 10.3969/j.issn.1004-4655.2016.03.025 [6] 余 旭, 刘 成, 秦文明, 等. IPS预应力鱼腹梁体系受力机理和有限元分析[J]. 安徽建筑大学学报,2017,25(2):1-5. (YU X, LIU C, QIN W M, et al. The stress mechanism and finite element analysis of IPS system[J]. Journal of Anhui Jianzhu University,2017,25(2):1-5. (in Chinese) doi: 10.11921/j.issn.2095-8382.20170201YU X, LIU C, QIN W M, et al. The stress mechanism and finite element analysis of IPS system[J]. Journal of Anhui Jianzhu University, 2017, 25(2): 1-5. (in Chinese) doi: 10.11921/j.issn.2095-8382.20170201 [7] 王荣勇. 软土地层深基坑鱼腹梁支撑体系受力及稳定性[D]. 上海: 上海交通大学, 2021. (WANG R Y. Research on the mechanical and stability behavior of the innovative prestressed support system for deep foundation pots in the soft soil stratum[D]. Shanghai: Shanghai Jiao Tong University, 2021. (in Chinese)WANG R Y. Research on the mechanical and stability behavior of the innovative prestressed support system for deep foundation pots in the soft soil stratum[D]. Shanghai: Shanghai Jiao Tong University, 2021. (in Chinese) [8] 胡廖琪. 预应力鱼腹梁钢支撑控制围护桩变形理论研究[J]. 地下空间与工程学报,2021,17(S1):141-149. (HU L Q. Theoretical study on the deformation control of retaining piles by steel support of prestressed fish-bellied beams[J]. Chinese Journal of Underground Space and Engineering,2021,17(S1):141-149. (in Chinese)HU L Q. Theoretical study on the deformation control of retaining piles by steel support of prestressed fish-bellied beams[J]. Chinese Journal of Underground Space and Engineering, 2021, 17(S1): 141-149. (in Chinese) [9] 周紫情, 张铭杰. 鱼腹式基坑支撑体系设计优化[C]//北京力学会. 北京力学会第二十八届学术年会论文集(下). 北京: 中国矿业大学, 2022. (ZHOU Z Q, ZHANG M J. Design and optimization of fish-belly foundation pit support system[C]//Beijing Mechanical Society. Proceedings of the 28th Annual Conference of Beijing Force Society (II). Beijing: China University of Mining and Technology, 2022. (in Chinese)ZHOU Z Q, ZHANG M J. Design and optimization of fish-belly foundation pit support system[C]//Beijing Mechanical Society. Proceedings of the 28th Annual Conference of Beijing Force Society (II). Beijing: China University of Mining and Technology, 2022. (in Chinese) [10] 周冠南. 预应力鱼腹梁支撑体系在异形基坑中的应用与研究[J]. 施工技术,2014,43(17):7-10. (ZHOU G N. Application and research of innovative prestressed support system in special-shaped foundation excavation[J]. Construction Technology,2014,43(17):7-10. (in Chinese)ZHOU G N. Application and research of innovative prestressed support system in special-shaped foundation excavation[J]. Construction Technology, 2014, 43(17): 7-10. (in Chinese) [11] 李立风. 某深基坑工程施工监测及数值模拟研究[D]. 武汉: 湖北工业大学, 2016. (LI L F. Construction monitoring and numerical simulation of deep excavation[D]. Wuhan: Hubei University of Technology, 2016. (in Chinese)LI L F. Construction monitoring and numerical simulation of deep excavation[D]. Wuhan: Hubei University of Technology, 2016. (in Chinese) -

下载:

下载: