Conservation method of relics soil based on carbonization principle

-

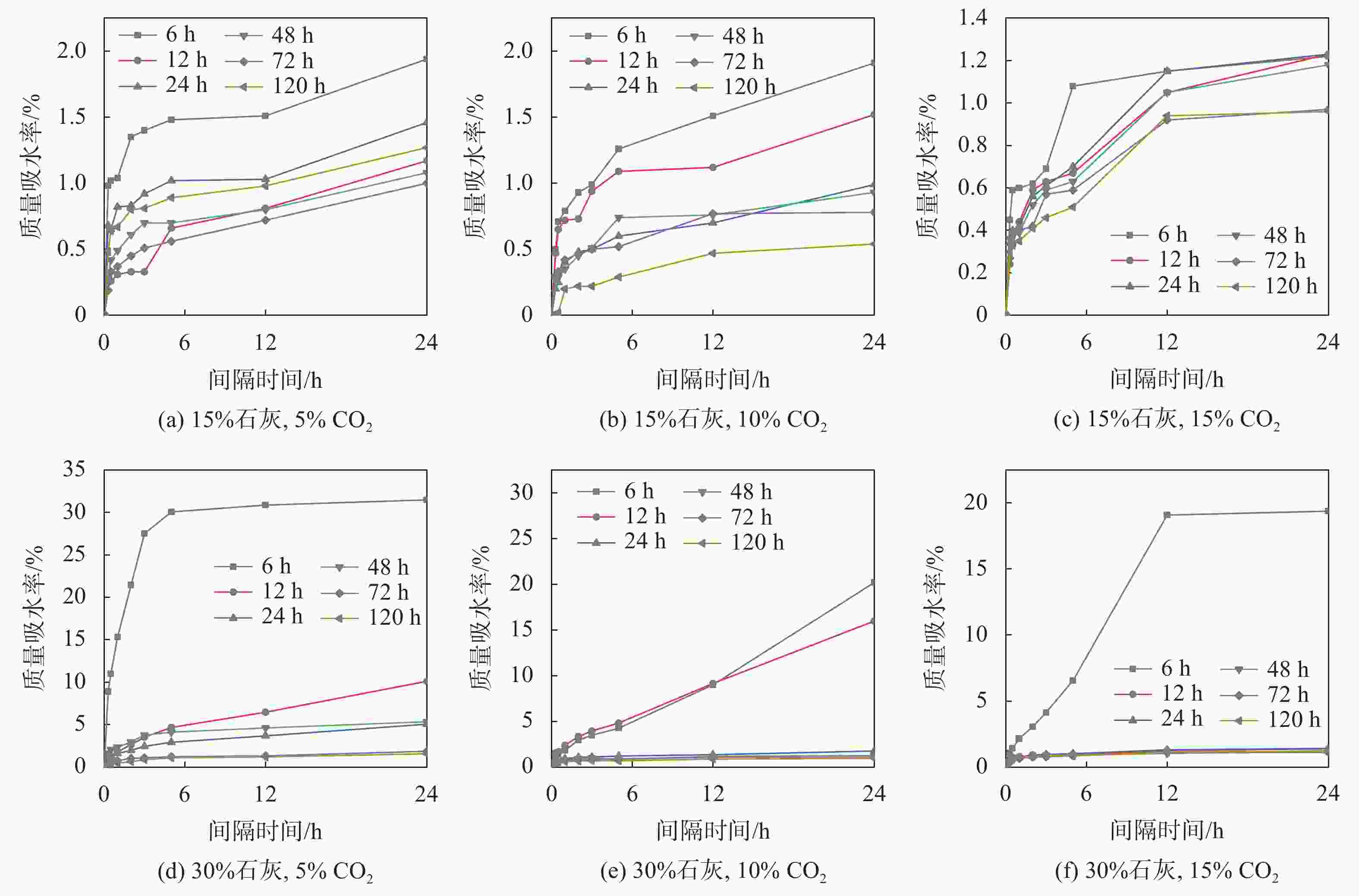

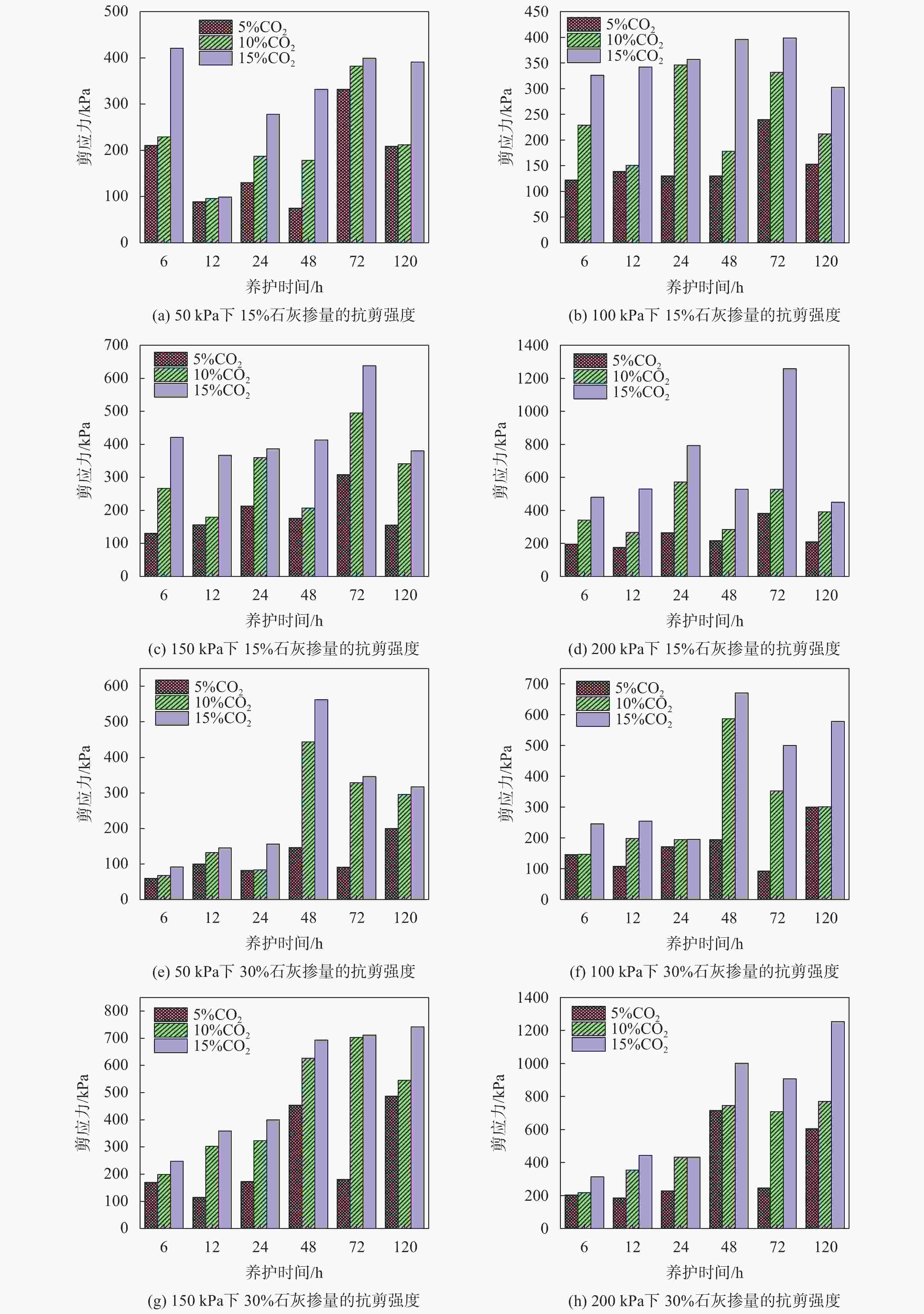

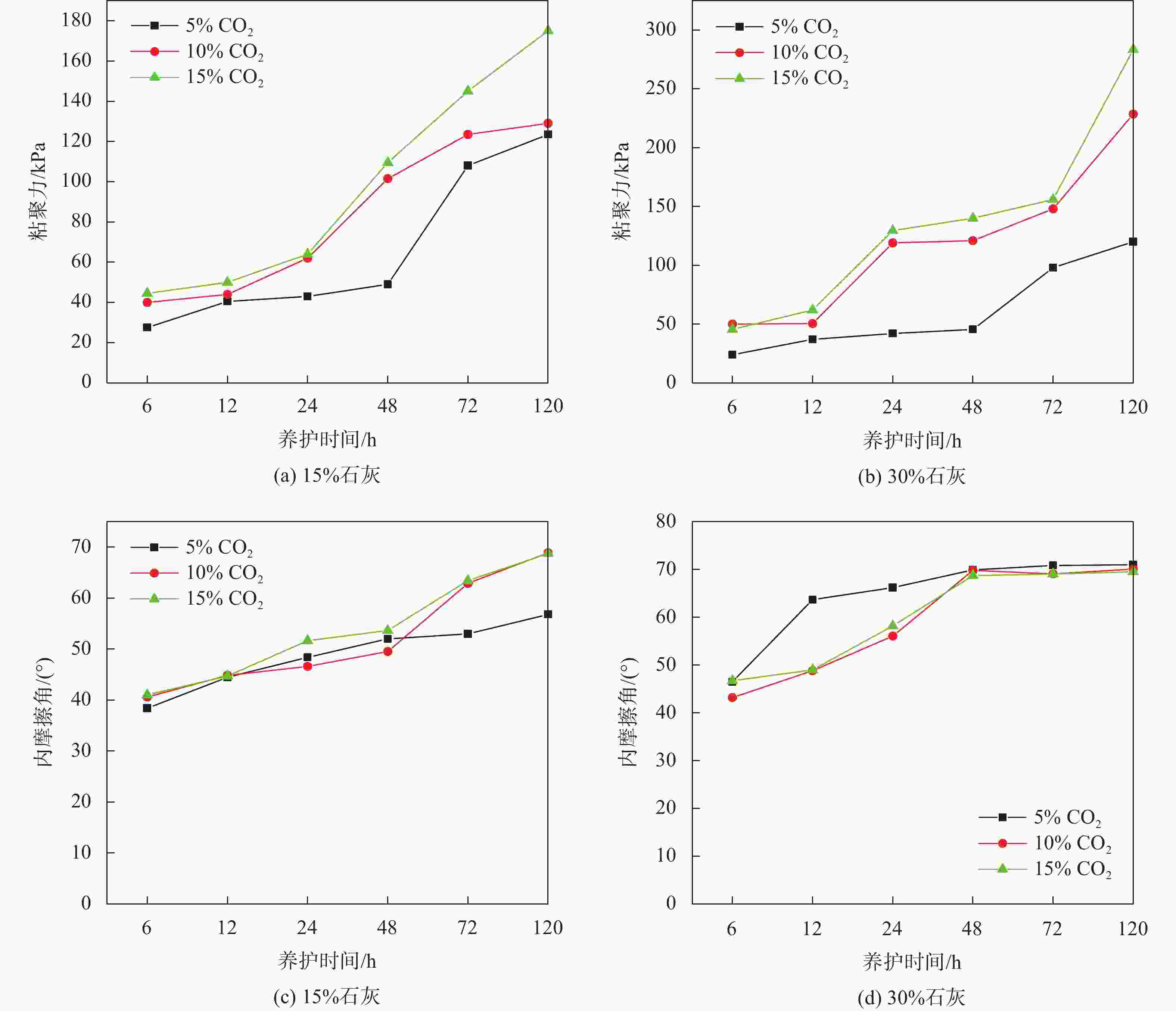

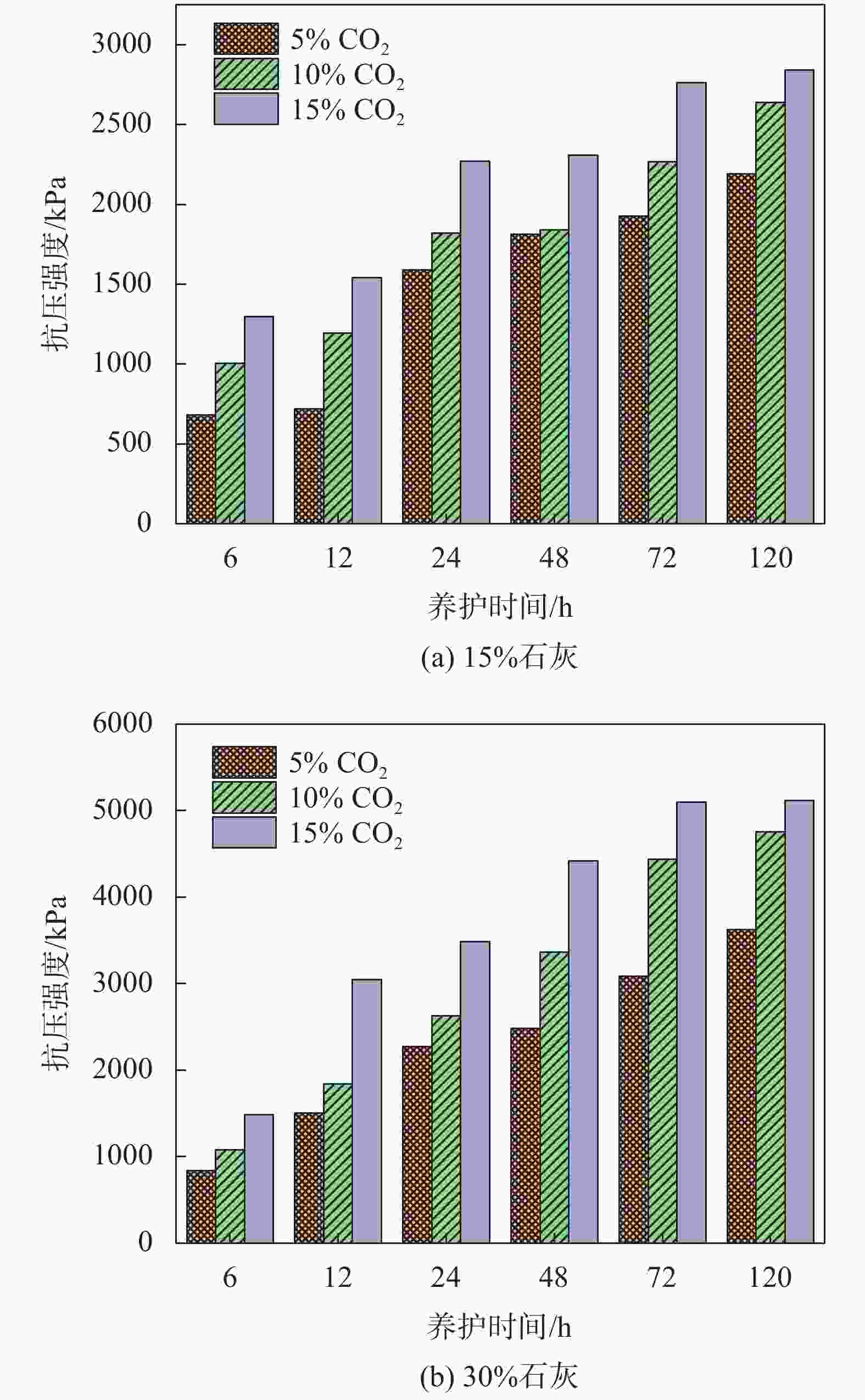

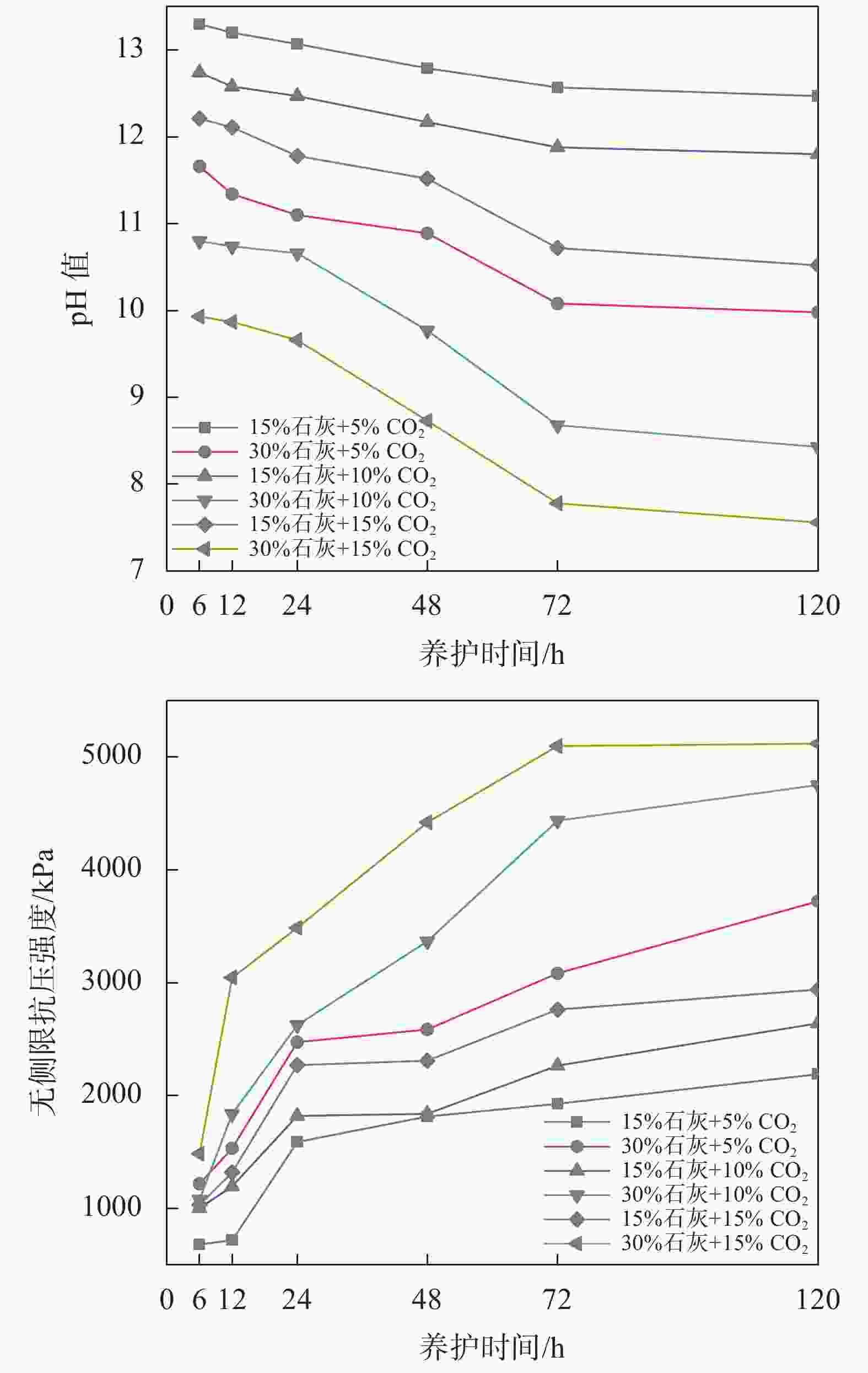

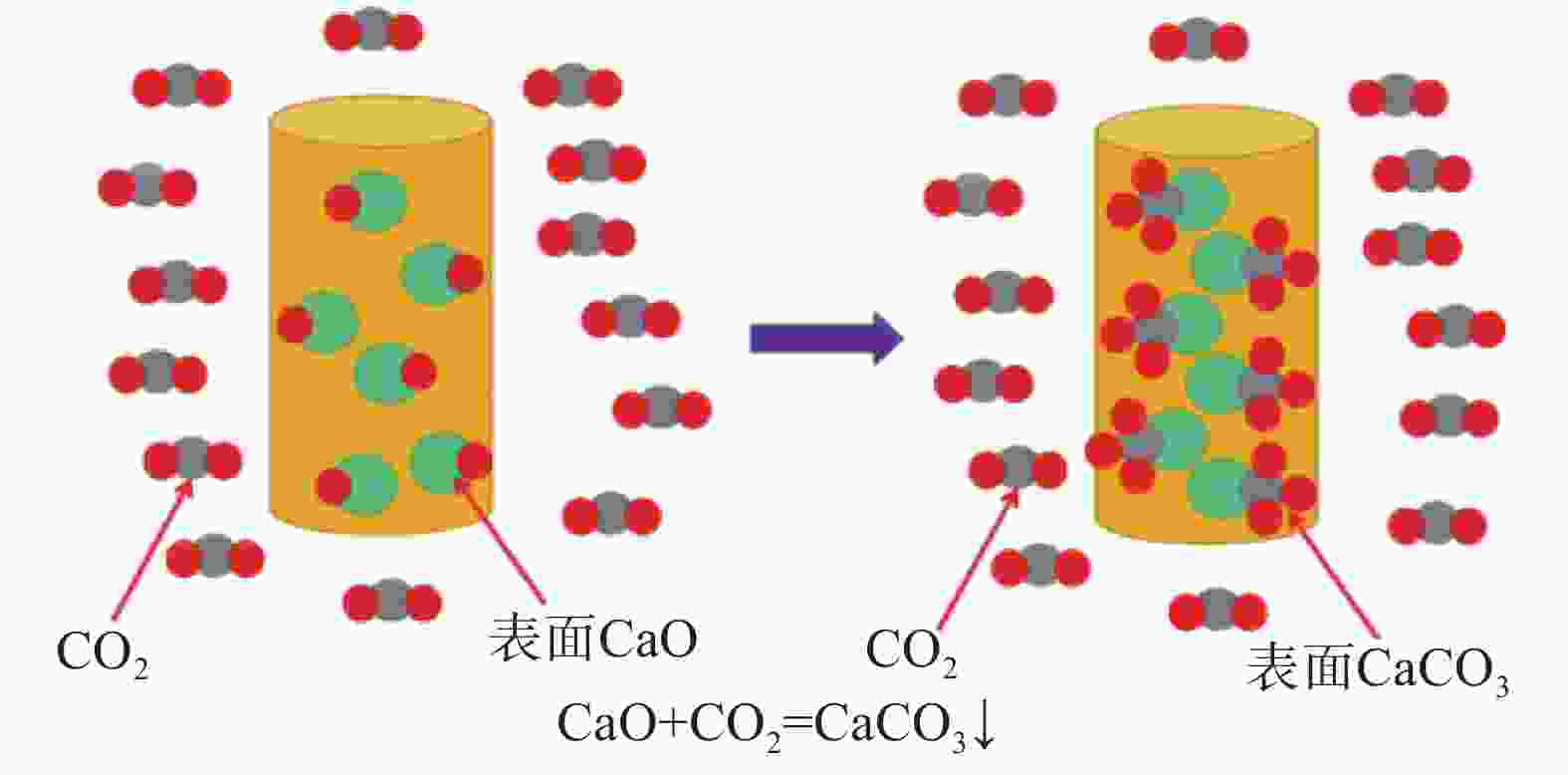

摘要: 土遗址修复后表层易开裂脱落,且与旧遗址相比外观质量欠佳。依托开封城墙遗址修复工程,针对新修复土遗址常见病害,结合机械施工要求,对仿遗址土添加2%浓度甲基硅酸钠(防水剂)后,基于石灰碳化原理,对不同石灰掺量、CO2浓度和养护时间的仿遗址土试样进行力学与水理性能对比试验。试验研究结果表明:(1)添加石灰和甲基硅酸钠以后土样的水稳定性与崩解性能均更加理想,CO2浓度为5%条件下甲基硅酸钠与石灰基本完成了碳化,养护24 h可达到较好的毛细吸水性能,养护72 h时可达到较好的耐崩解性能;(2)增加石灰掺量、CO2浓度和养护时间,可使试样碳化后产生的CaCO3增多,从而提高其抗剪强度和抗压强度,且CO2浓度的贡献大于养护时间;(3)当空气中CO2浓度为15%时,养护时间超过72 h后试样抗压强度增长缓慢趋于稳定,即石灰与空气中充足的CO2发生充分反应(约72 h)之后,试样抗压强度接近最佳。研究成果可为土遗址保护提供新思路。Abstract: The phenomenon of surface cracking and falling off of newly restored soil sites, results in inferior appearance quality compared to old sites. In response to the diseases of newly restored soil sites, combined with the requirements of mechanical construction, a 2% concentration of sodium methylsilicate (waterproofing agent) was added to the simulated site soil. Based on the principle of lime carbonation, mechanical and hydraulic performance comparative tests were conducted on simulated site soil samples with different lime parameters, CO2 concentrations, and curing times. The experimental research results show that: (1) After adding lime and sodium methylsilicate, the water stability and disintegration performance of the soil sample are more ideal. Under the condition of CO2 concentration of 5%, sodium methylsilicate and lime have basically completed carbonization. After 24 hours of curing, good capillary water absorption performance can be achieved, and good disintegration resistance can be achieved after 72 hours of curing. (2) Increasing the lime content, CO2 concentration, and curing time can increase the amount of CaCO3 produced after sample carbonization, thereby improving its shear strength and compressive strength, and the contribution of CO2 concentration is greater than that of curing time. (3) When the concentration of CO2 in the air is 15%, the compressive strength of the sample increases slowly and tends to stabilize after a curing time of more than 72 hours. That is, after sufficient reaction between lime and sufficient CO2 in the air (about 72 hours), the compressive strength of the sample approaches the optimal level. This research could provide new ideas for the protection of soil sites.

-

Key words:

- imitative site soil /

- carbonization principle /

- water physical property /

- mechanical property /

- pH value

-

表 1 掺和配比设计

配合比组合 石灰/% 甲基硅酸钠浓度/% A1 15 2 A2 30 表 2 养护设计

CO2浓度/% 养护时间/h 6 12 24 48 72 120 5 B1C1 B1C2 B1C3 B1C4 B1C5 B1C6 10 B2C1 B2C2 B2C3 B2C4 B2C5 B2C6 15 B3C1 B3C2 B3C3 B3C4 B3C5 B3C6 -

[1] 陈 毅, 张虎元, 杨 龙. 遗址土劣化进程中微观结构变化的类比研究[J]. 岩土力学,2018,39(11):4117-4124,4141. (CHEN Y, ZHANG H Y, YANG L. Analogy study on evolution of microstructure of earthen monument during natural weathering process[J]. Rock and Soil Mechanics,2018,39(11):4117-4124,4141. (in Chinese)CHEN Y, ZHANG H Y, YANG L. Analogy study on evolution of microstructure of earthen monument during natural weathering process[J]. Rock and Soil Mechanics, 2018, 39(11): 4117-4124,4141. (in Chinese) [2] 刘 莉, 姜大伟, 于明波, 等. 千枚岩全风化土的持水特性研究[J]. 河南科技大学学报(自然科学版),2022,43(6):53-58. (LIU L, JIANG D W, YU M B, et al. Soil water retention characteristics of Phyllite completely weathered soil[J]. Journal of Henan University of Science and Technology (Natural Science),2022,43(6):53-58. (in Chinese)LIU L, JIANG D W, YU M B, et al. Soil water retention characteristics of Phyllite completely weathered soil[J]. Journal of Henan University of Science and Technology (Natural Science), 2022, 43(6): 53-58. (in Chinese) [3] 岳建伟, 李嘉乐, 王思远, 等. 定远营遗址稳定性和微观劣化的研究[J]. 科学技术与工程,2021,21(10):4159-4166. (YUE J W, LI J L, WANG S Y, et al. The stability and micro deterioration of Dingyuanying ruins[J]. Science Technology and Engineering,2021,21(10):4159-4166. (in Chinese) doi: 10.3969/j.issn.1671-1815.2021.10.043YUE J W, LI J L, WANG S Y, et al. The stability and micro deterioration of Dingyuanying ruins[J]. Science Technology and Engineering, 2021, 21(10): 4159-4166. (in Chinese) doi: 10.3969/j.issn.1671-1815.2021.10.043 [4] 任克彬, 王 博, 李新明, 等. 低应力水平下土遗址力学特性的干湿循环效应[J]. 岩石力学与工程学报,2019,38(2):376-385. (REN K B, WANG B, LI X M, et al. Effect of dry-wet cycles on the mechanical properties of earthen archaeological site under low stresses[J]. Chinese Journal of Rock Mechanics and Engineering,2019,38(2):376-385. (in Chinese)REN K B, WANG B, LI X M, et al. Effect of dry-wet cycles on the mechanical properties of earthen archaeological site under low stresses[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(2): 376-385. (in Chinese) [5] 袁志辉, 唐 春, 杨普济, 等. 干湿循环下原状黄土抗压强度试验研究[J]. 工程地质学报,2018,26(S1):155-161. (YUAN Z H, TANG C, YANG P J, et al. Experimental studies of compressive strength of undisturbed loess in drying-wetting cycle[J]. Journal of Engineering Geology,2018,26(S1):155-161. (in Chinese)YUAN Z H, TANG C, YANG P J, et al. Experimental studies of compressive strength of undisturbed loess in drying-wetting cycle[J]. Journal of Engineering Geology, 2018, 26(S1): 155-161. (in Chinese) [6] 张冬梅. 浅析建筑材料石灰的性能及应用[J]. 四川水泥, 2021(7): 105-106. (ZHANG D M. Analysis of the performance and application of building material lime[J]. Sichuan Cement, 2021(7): 105-106. (in Chinese)ZHANG D M. Analysis of the performance and application of building material lime[J]. Sichuan Cement, 2021(7): 105-106. (in Chinese) [7] 岳建伟, 杨 雪, 赵丽敏, 等. 开封城墙修复土配合比试验[J]. 建筑材料学报,2022,25(5):532-536,544. (YUE J W, YANG X, ZHAO L M, et al. Experimental on mix proportion of restoration soil for Kaifeng city wall[J]. Journal of Building Materials,2022,25(5):532-536,544. (in Chinese) doi: 10.3969/j.issn.1007-9629.2022.05.013YUE J W, YANG X, ZHAO L M, et al. Experimental on mix proportion of restoration soil for Kaifeng city wall[J]. Journal of Building Materials, 2022, 25(5): 532-536,544. (in Chinese) doi: 10.3969/j.issn.1007-9629.2022.05.013 [8] 郑 旭. 碳化固化土的耐久性能试验研究[D]. 南京: 东南大学, 2015. (ZHENG X. Experimental study on the durability of carbonated soils[D]. Nanjing: Southeast University, 2015. (in Chinese)ZHENG X. Experimental study on the durability of carbonated soils[D]. Nanjing: Southeast University, 2015. (in Chinese) [9] 秦 川. 软弱地基整体碳化固化工艺试验研究[D]. 南京: 东南大学, 2019. (QIN C. Experimental study on overall carbonization and solidification process of soft foundation[D]. Nanjing: Southeast University, 2019. (in Chinese)QIN C. Experimental study on overall carbonization and solidification process of soft foundation[D]. Nanjing: Southeast University, 2019. (in Chinese) [10] WANG D X, XIAO J, GAO X Y. Strength gain and microstructure of carbonated reactive MgO-fly ash solidified sludge from East Lake, China[J]. Engineering Geology,2019,251:37-47. doi: 10.1016/j.enggeo.2019.02.012 [11] LI W T, NI P P, YI Y L. Comparison of reactive magnesia, quick lime, and ordinary Portland cement for stabilization/solidification of heavy metal-contaminated soils[J]. Science of the Total Environment,2019,671:741-753. [12] LIU S Y, CAI G H, WANG L, et al. Treatment system and method for ex-situ carbonization and solidification of silt soil using active magnesium oxide: US20200115875A1[P]. 2020-04-16. [13] SILVA B A, PINTO A P F, GOMES A, et al. Effects of natural and accelerated carbonation on the properties of lime-based materials[J]. Journal of CO2 Utilization,2021,49:101552. doi: 10.1016/j.jcou.2021.101552 [14] LUO S R, WU W D, WU K Y. Effect of recycled coarse aggregates enhanced by CO2 on the mechanical properties of recycled aggregate concrete[J]. IOP Conference Series: Materials Science and Engineering,2018,431(10):102006. [15] ERGENÇ D, FORT R. Accelerating carbonation in lime-based mortar in high CO2 environments[J]. Construction and Building Materials,2018,188:314-325. [16] 岳建伟, 林 健, 王永锋, 等. 开封仿遗址土水理性质的改良研究[J]. 工程科学与技术,2020,52(1):46-55. (YUE J W, LIN J, WANG Y F, et al. Study on the improvement of soil water in Kaifeng imitation site[J]. Advanced Engineering Sciences,2020,52(1):46-55. (in Chinese)YUE J W, LIN J, WANG Y F, et al. Study on the improvement of soil water in Kaifeng imitation site[J]. Advanced Engineering Sciences, 2020, 52(1): 46-55. (in Chinese) [17] BOARDMAN D I, GLENDINNING S, ROGERS C D F. Development of stabilisation and solidification in lime-clay mixes[J]. Géotechnique,2001,51(6):533-543. [18] 张 铖, 王 玲, 姚 燕, 等. 逐层磨粉pH值法测定混凝土碳化深度的试验研究[J]. 材料导报,2022,36(7):168-171. (ZHANG C, WANG L, YAO Y, et al. Determination of concrete carbonation depth by testing the pH value of layer-by-layer grinding concrete samples[J]. Materials Reports,2022,36(7):168-171. (in Chinese)ZHANG C, WANG L, YAO Y, et al. Determination of concrete carbonation depth by testing the pH value of layer-by-layer grinding concrete samples[J]. Materials Reports, 2022, 36(7): 168-171. (in Chinese) [19] 徐树强, 王乐乐, 马清林, 等. 天然水硬性石灰在不同碳化条件下的水化反应[J]. 文物保护与考古科学,2017,29(4):1-8. (XU S Q, WANG L L, MA Q L, et al. Hydration of natural hydraulic lime pastes under different conditions of carbonation[J]. Sciences of Conservation and Archaeology,2017,29(4):1-8. (in Chinese)XU S Q, WANG L L, MA Q L, et al. Hydration of natural hydraulic lime pastes under different conditions of carbonation[J]. Sciences of Conservation and Archaeology, 2017, 29(4): 1-8. (in Chinese) [20] 蔡 奕, 施 斌, 刘志彬, 等. 团聚体大小对填筑土强度影响的试验研究[J]. 岩土工程学报,2005,27(12):1482-1486. (CAI Y, SHI B, LIU Z B, et al. Experimental study on effect of aggregate size on strength of filled soils[J]. Chinese Journal of Geotechnical Engineering,2005,27(12):1482-1486. (in Chinese) doi: 10.3321/j.issn:1000-4548.2005.12.022CAI Y, SHI B, LIU Z B, et al. Experimental study on effect of aggregate size on strength of filled soils[J]. Chinese Journal of Geotechnical Engineering, 2005, 27(12): 1482-1486. (in Chinese) doi: 10.3321/j.issn:1000-4548.2005.12.022 -

下载:

下载: