Comparative experimental study on grouting of fine cement and ordinary cement in underground engineering

-

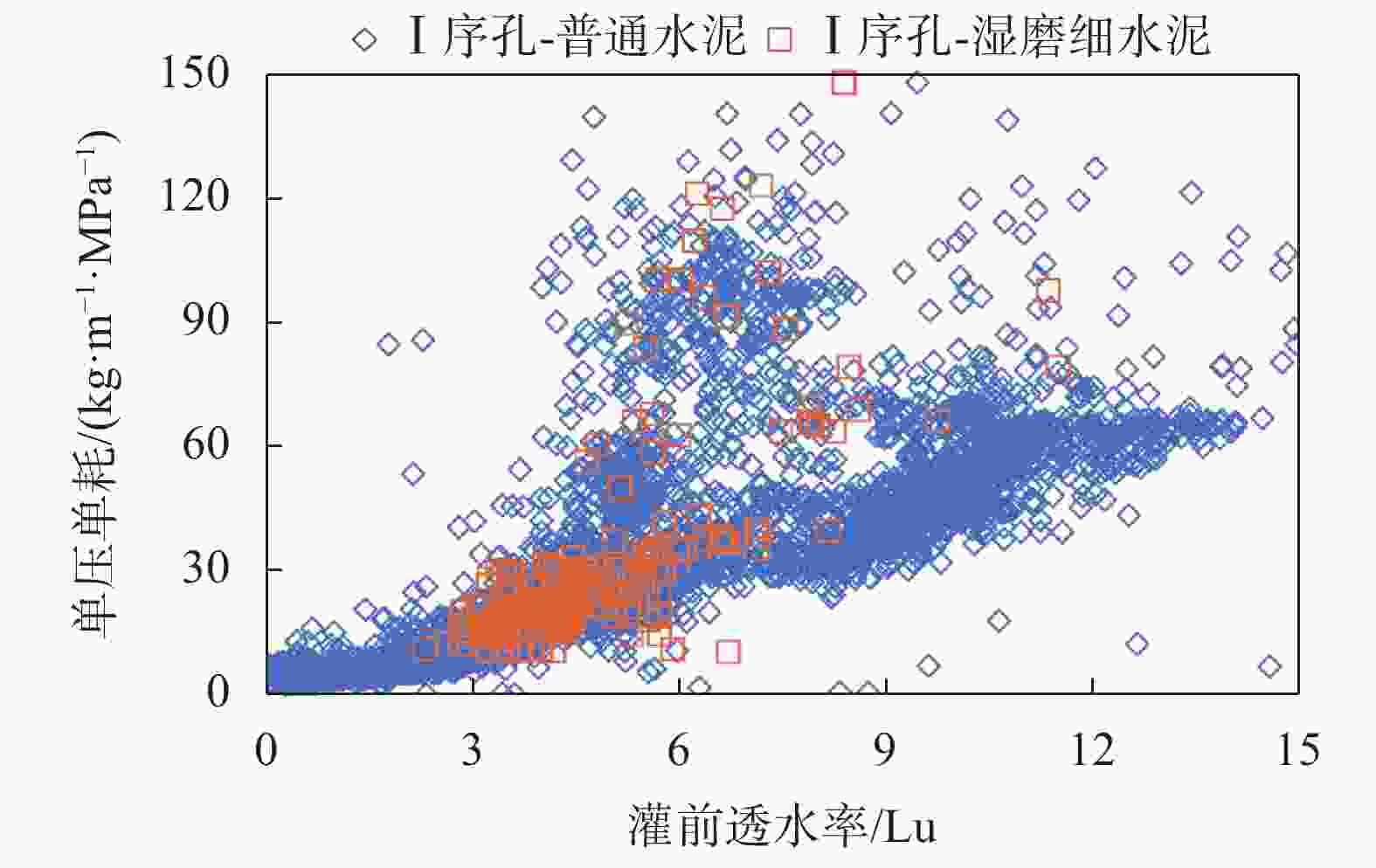

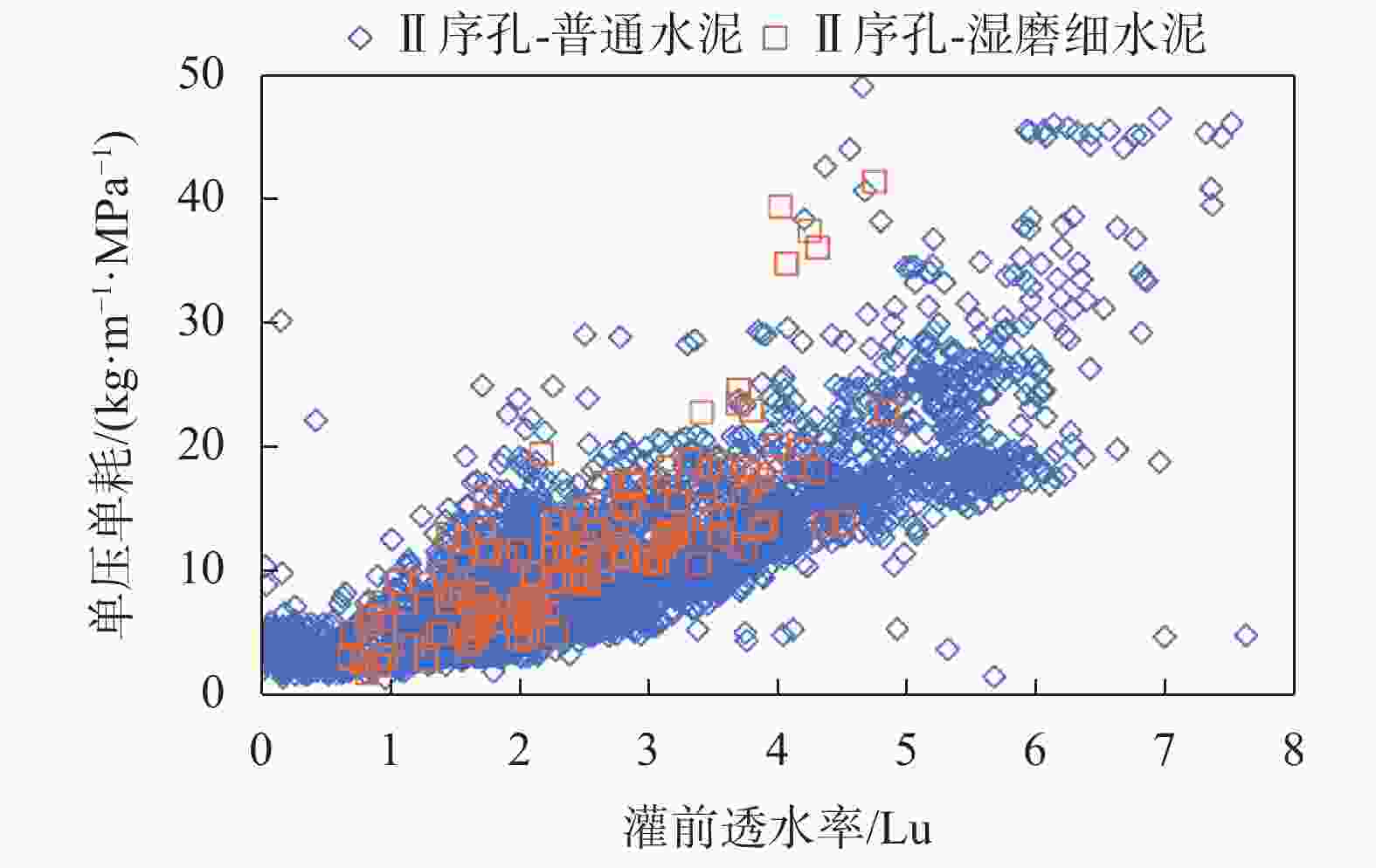

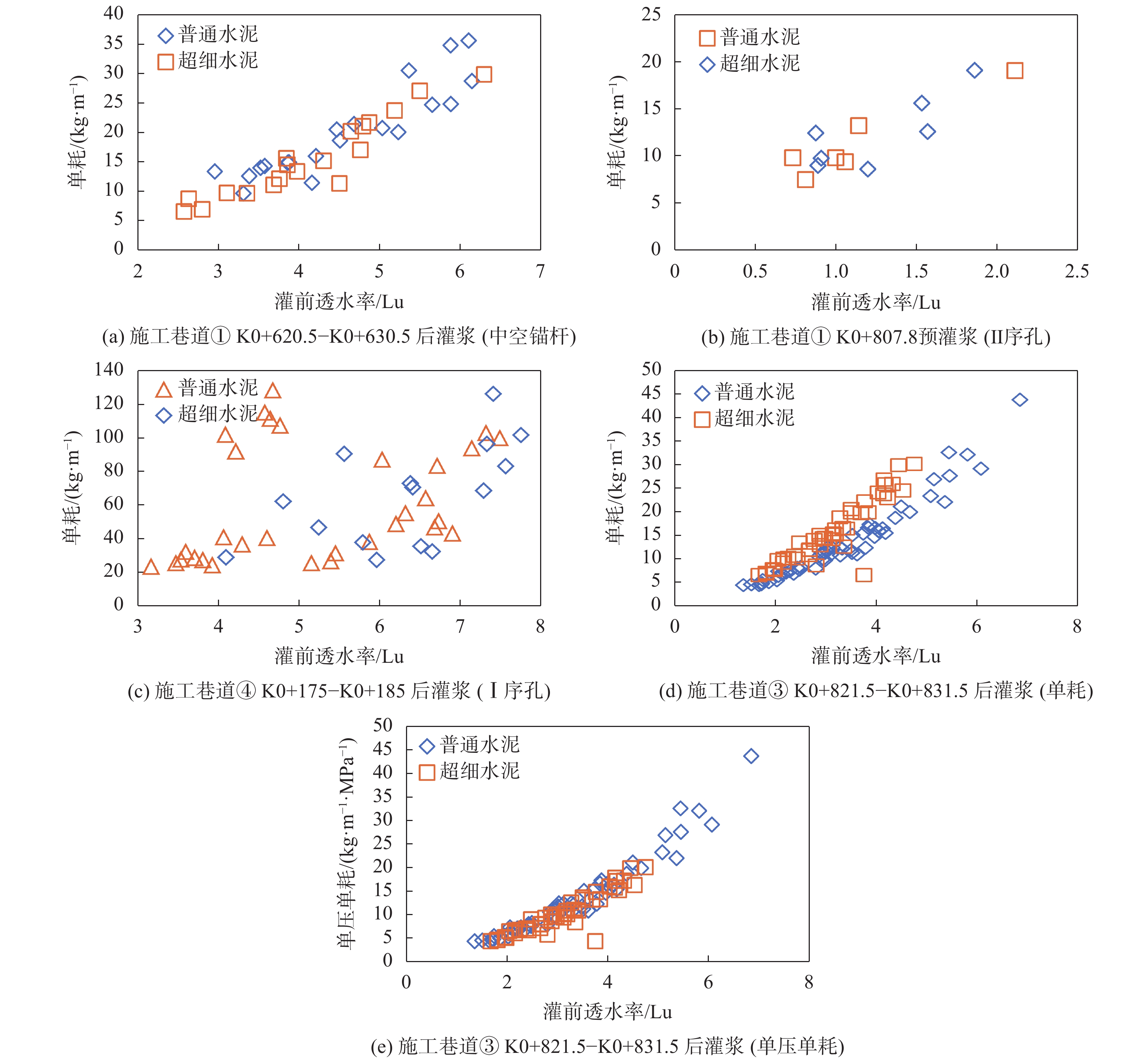

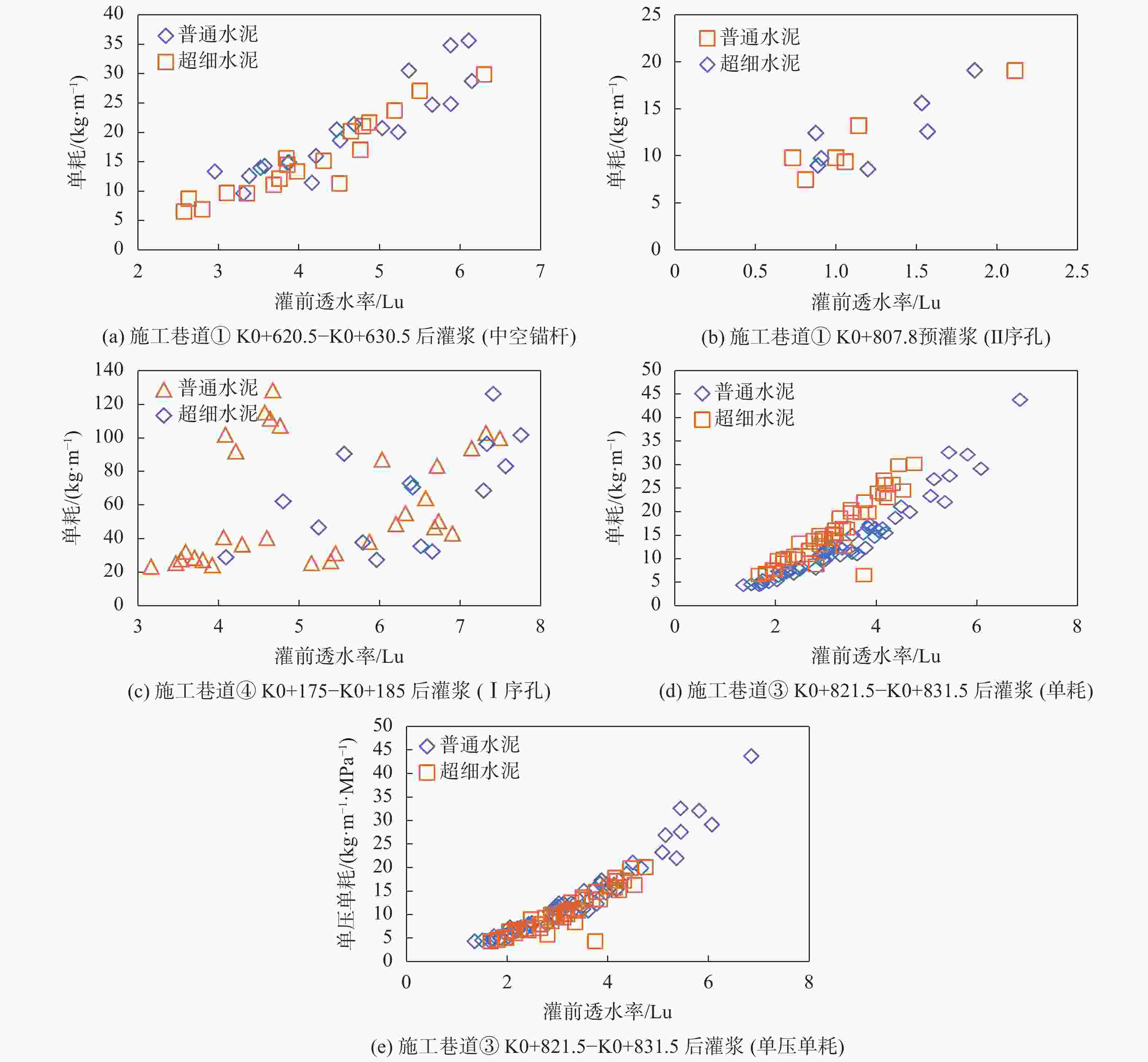

摘要: 水封洞库、储气库、引水隧洞等地下工程对区域渗流场控制均有严格要求,灌浆是控制工程区域渗流场的重要方式。不同地质条件下的岩体可灌性不同,对灌浆材料的粒径敏感性也不同,需要开展相关试验论证,为工程施工提供科学依据。依托某水封洞库灌浆施工,通过开展超细水泥、湿磨细水泥与普通水泥灌浆对比试验,研究不同类型灌浆材料在该工程中的适用性。试验结果表明:当岩体透水率较大时,超细水泥、湿磨细水泥与普通水泥三种灌浆材料渗控效果差异不明显,相同岩体透水率条件下,采用不同材料灌浆,单位耗灰量总体一致;灌浆压力增大,灌浆孔的单位耗灰量显著增加,灌浆实施效果显著提升;当岩体透水率很小,采用超细水泥或湿磨细水泥能够进一步降低围岩渗水量。因此,在依托工程中无需大范围采用超细水泥和湿磨细水泥进行灌浆,在普通水泥可灌性不强的特殊情况下,建议采用超细水泥和湿磨细水泥灌浆,同时合理调节灌浆压力,以显著改善灌浆效果。Abstract: Underground projects such as water-sealed caverns, gas storages, and diversion tunnels have strict requirements for the control of regional seepage fields. Grouting is an important way to control the seepage field in the engineering area. The groutability under different geological conditions is different, and the sensitivity to the particle size of grouting material is different. It is necessary to carry out relevant experimental demonstrations to provide a scientific basis for engineering construction. Based on the grouting construction of a water-sealed cavern, and by conducting comparative experiments of ultra-fine cement, wet grinding fine cement, and ordinary cement grouting, the applicability of different types of grouting materials was studied in the project. The test results show that when the rock permeability is high, there is no obvious difference in the seepage control effect of the three grouting materials. Under the condition of the same permeability of rock mass, different materials were used for grouting, and the unit ash consumption was generally the same. With the increase in grouting pressure, the unit ash consumption of the grouting hole increased significantly, and the effect of grouting was significantly improved. When the rock permeability is very low, using ultra-fine cement or wet-grinding fine cement can further reduce the seepage of the surrounding rock. Therefore, there is no need to use ultra-fine cement and wet grinding fine cement for grouting on a large scale in this project. In special cases where the groutability of ordinary cement is not good, it is recommended to use ultra-fine cement and wet-ground fine cement and to reasonably adjust the grouting pressure to significantly improve the grouting effect.

-

Key words:

- underground engineering /

- grouting test /

- ordinary cement /

- ultra-fine cement /

- wet grinding fine cement

-

表 1 超细水泥灌浆试验灌浆孔信息表

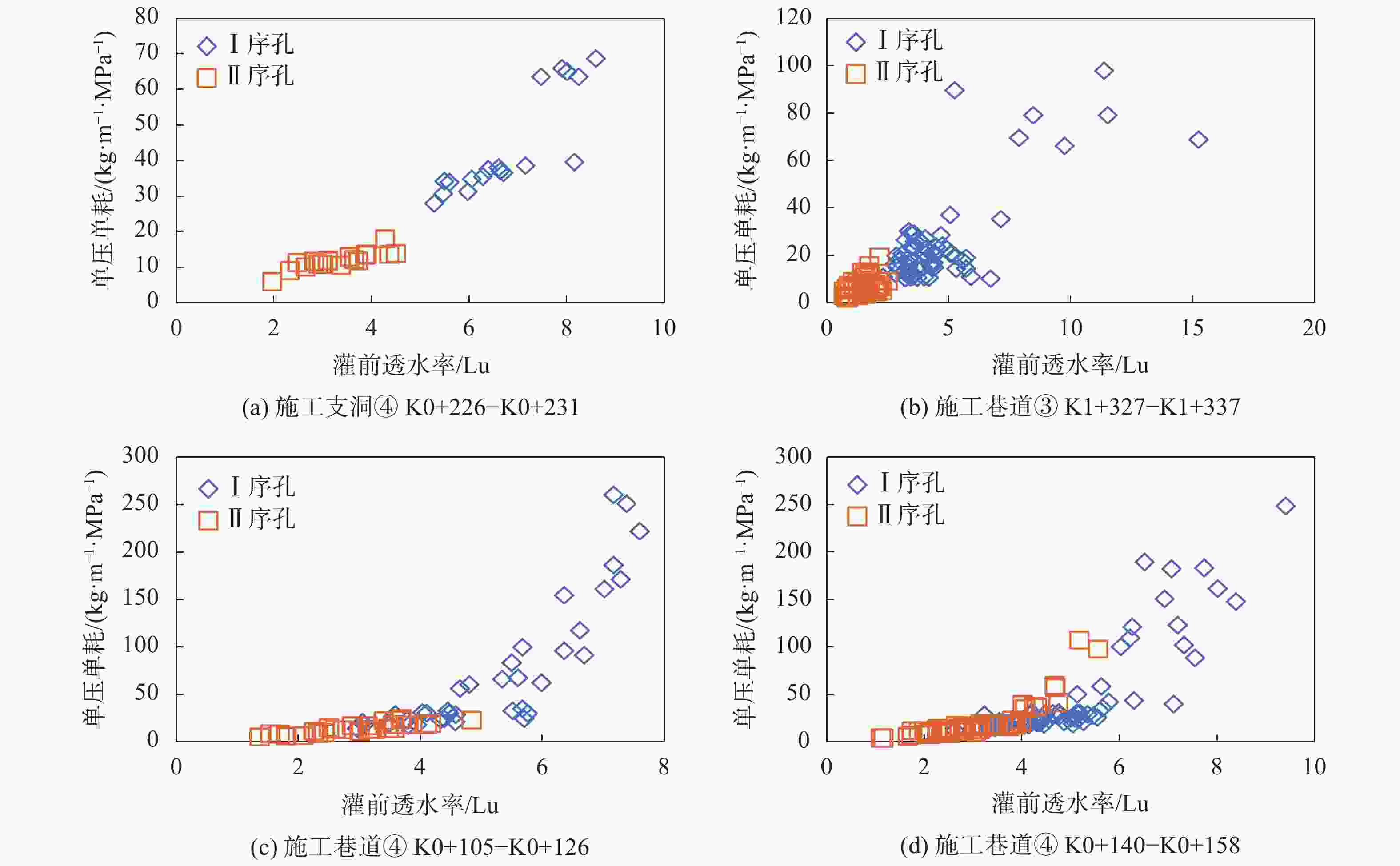

序号 部位 孔序 围岩类型 孔数/个 孔深/m 灌浆压力/MPa 灌浆材料 1 施工巷道①K0+620.5—K0+630.5 Ⅲ2 18 4.5 1.5 普通水泥 Ⅲ2 22 4.5 1.5 超细水泥 2 施工巷道①K0+807.8 Ⅱ Ⅲ2 7 15 2.2 普通水泥 Ⅱ Ⅲ2 7 15 2.2 超细水泥 3 施工巷道④K0+175—K0+185 Ⅰ Ⅲ2 31 6 1.05 普通水泥 Ⅰ Ⅲ2 15 6 1.05 超细水泥 4 施工巷道③K0+821.5—K0+831.5 Ⅰ Ⅲ2 55 6 1.0 普通水泥 Ⅱ Ⅲ2 44 6 1.5 超细水泥 表 2 湿磨细水泥灌浆试验灌浆孔信息表

序号 部位 孔序 孔数

/个孔深

/m耗灰量

/kg灌浆类型及材料 1 施工巷道④

K0+226—K0+231Ⅰ 18 6 4704 后灌浆、湿磨细水泥 Ⅱ 18 6 1928 2 施工巷道③

K1+327—K1+337Ⅰ 60 6 11239 Ⅱ 50 6 3667 3 施工巷道④

K0+105—K0+126Ⅰ 37 6 16862 Ⅱ 30 6 3850 4 施工巷道④

K0+140—K0+158Ⅰ 68 6 20298 Ⅱ 55 6 9921 -

[1] 左 崇, 张继勋, 任旭华, 等. 围岩灌浆深度对水封石油洞库水封效果的影响[J]. 三峡大学学报(自然科学版),2020,42(1):30-35. (ZUO C, ZHANG J X, REN X H, et al. Effect of rock grouting depth on containment property of containment oil storage cavern[J]. Journal of China Three Gorges University (Natural Sciences),2020,42(1):30-35. (in Chinese)ZUO C, ZHANG J X, REN X H, et al. Effect of rock grouting depth on containment property of containment oil storage cavern[J]. Journal of China Three Gorges University (Natural Sciences), 2020, 42(1): 30-35. (in Chinese) [2] 秦之勇, 高锡敏. 我国水封石洞油库研究现状及思考[J]. 长江科学院院报,2019,36(5):141-148. (QIN Z Y, GAO X M. Research status and thinking about underground oil storage in rock caverns in China[J]. Journal of Yangtze River Scientific Research Institute,2019,36(5):141-148. (in Chinese)QIN Z Y, GAO X M. Research status and thinking about underground oil storage in rock caverns in China[J]. Journal of Yangtze River Scientific Research Institute, 2019, 36(5): 141-148. (in Chinese) [3] 彭振华, 李俊彦, 孙承志, 等. 地下水封洞库的库址选择研究[J]. 油气储运,2008,27(1):60-62. (PENG Z H, LI J Y, SUN C Z, et al. Site determination on underground water-sealing oil storage in Rock Caverns[J]. Oil & Gas Storage and Transportation,2008,27(1):60-62. (in Chinese)PENG Z H, LI J Y, SUN C Z, et al. Site determination on underground water-sealing oil storage in Rock Caverns[J]. Oil & Gas Storage and Transportation, 2008, 27(1): 60-62. (in Chinese) [4] 蒋中明, 钟 兵, 万 发. 水封石油洞库污染物运移规律研究[J]. 岩土工程学报,2023,45(12):2529-2536. (JIANG Z M, ZHONG B, WAN F. Migration laws of pollutants in surrounding rock of underground oil storage caverns[J]. Chinese Journal of Geotechnical Engineering,2023,45(12):2529-2536. (in Chinese)JIANG Z M, ZHONG B, WAN F. Migration laws of pollutants in surrounding rock of underground oil storage caverns[J]. Chinese Journal of Geotechnical Engineering, 2023, 45(12): 2529-2536. (in Chinese) [5] 邵晓妹, 卢其波, 李发权. 地下水封洞库水泥–水玻璃防渗灌浆材料耐久性试验研究[J]. 长江科学院院报,2018,35(8):154-158. (SHAO X M, LU Q B, LI F Q. Experimental study on durability of grouting material composed of cement and water glass for underground water-sealed cavern[J]. Journal of Yangtze River Scientific Research Institute,2018,35(8):154-158. (in Chinese)SHAO X M, LU Q B, LI F Q. Experimental study on durability of grouting material composed of cement and water glass for underground water-sealed cavern[J]. Journal of Yangtze River Scientific Research Institute, 2018, 35(8): 154-158. (in Chinese) [6] 王者超, 张振杰, 李术才, 等. 基于离散裂隙网络法的地下石油洞库洞室间水封性评价[J]. 山东大学学报(工学版),2016,46(2):94-100,115. (WANG Z C, ZHANG Z J, LI S C, et al. Assessment of inter-cavern containment property for underground oil storage caverns using discrete fracture networks[J]. Journal of Shandong University (Engineering Science),2016,46(2):94-100,115. (in Chinese)WANG Z C, ZHANG Z J, LI S C, et al. Assessment of inter-cavern containment property for underground oil storage caverns using discrete fracture networks[J]. Journal of Shandong University (Engineering Science), 2016, 46(2): 94-100,115. (in Chinese) [7] 温毓繁, 余 雷, 孔琼菊. 地下水封石油洞库工程的灌浆参数模拟分析[J]. 水资源与水工程学报,2017,28(2):168-172. (WEN Y F, YU L, KONG Q J. The simulation of grouting parameters of underground petroleum storage caverns project[J]. Journal of Water Resources and Water Engineering,2017,28(2):168-172. (in Chinese)WEN Y F, YU L, KONG Q J. The simulation of grouting parameters of underground petroleum storage caverns project[J]. Journal of Water Resources and Water Engineering, 2017, 28(2): 168-172. (in Chinese) [8] 李术才, 张 立, 马秀媛, 等. 大型地下水封石油洞库渗流场时空演化特征研究[J]. 岩土力学,2013,34(7):1979-1986. (LI S C, ZHANG L, MA X Y, et al. Space-time evolution behaviour of seepage field around a large underground petroleum storage caverns with groundwater curtaining[J]. Rock and Soil Mechanics,2013,34(7):1979-1986. (in Chinese)LI S C, ZHANG L, MA X Y, et al. Space-time evolution behaviour of seepage field around a large underground petroleum storage caverns with groundwater curtaining[J]. Rock and Soil Mechanics, 2013, 34(7): 1979-1986. (in Chinese) [9] 黄志驹, 王 志, 李 领. 地下水封石油洞库竖井地面预注浆技术应用[J]. 红水河,2022,41(5):121-124. (HUANG Z J, WANG Z, LI L. Technology application on Pre-Grouting from the surface of shaft in underground water-sealed oil storage cavern[J]. Hongshui River,2022,41(5):121-124. (in Chinese)HUANG Z J, WANG Z, LI L. Technology application on Pre-Grouting from the surface of shaft in underground water-sealed oil storage cavern[J]. Hongshui River, 2022, 41(5): 121-124. (in Chinese) [10] 吴 波, 王 凯, 郭 钊. 地下水封洞库灌浆止水施工技术及应用[J]. 水利建设与管理,2022,42(10):48-51,65. (WU B, WANG K, GUO Z. Construction technology and application of grouting and water stop for underground water-sealed cave depot[J]. Water Conservancy Construction and Management,2022,42(10):48-51,65. (in Chinese)WU B, WANG K, GUO Z. Construction technology and application of grouting and water stop for underground water-sealed cave depot[J]. Water Conservancy Construction and Management, 2022, 42(10): 48-51,65. (in Chinese) [11] 白文军. 水封洞库工程预灌浆策略及实施要点[J]. 水利水电技术(中英文),2022,53(S2):200-204. (BAI W J. Pre-excavation grouting strategy and implementation points of water sealed cavern project[J]. Water Resources and Hydropower Engineering,2022,53(S2):200-204. (in Chinese)BAI W J. Pre-excavation grouting strategy and implementation points of water sealed cavern project[J]. Water Resources and Hydropower Engineering, 2022, 53(S2): 200-204. (in Chinese) [12] 杨培洲, 孙起军, 李丰年, 等. 雅砻江两河口水电站大坝灌浆技术[J]. 水利水电快报,2023,44(1):54-58. (YANG P Z, SUN Q J, LI F N, et al. Grouting technology for dam of Lianghekou Hydropower Station on Yalong River[J]. Express Water Resources & Hydropower Information,2023,44(1):54-58. (in Chinese)YANG P Z, SUN Q J, LI F N, et al. Grouting technology for dam of Lianghekou Hydropower Station on Yalong River[J]. Express Water Resources & Hydropower Information, 2023, 44(1): 54-58. (in Chinese) [13] 卢晓鹏. 水库试蓄水过程中坝基局部渗漏分析及处理[J]. 人民长江,2021,52(S2):91-94. (LU X P. Analysis and treatment of dam foundation local leakage in reservoir trial storage process[J]. Yangtze River,2021,52(S2):91-94. (in Chinese)LU X P. Analysis and treatment of dam foundation local leakage in reservoir trial storage process[J]. Yangtze River, 2021, 52(S2): 91-94. (in Chinese) -

下载:

下载: