Construction scheme comparison of tunnel structure simulation comprehensive test platform

-

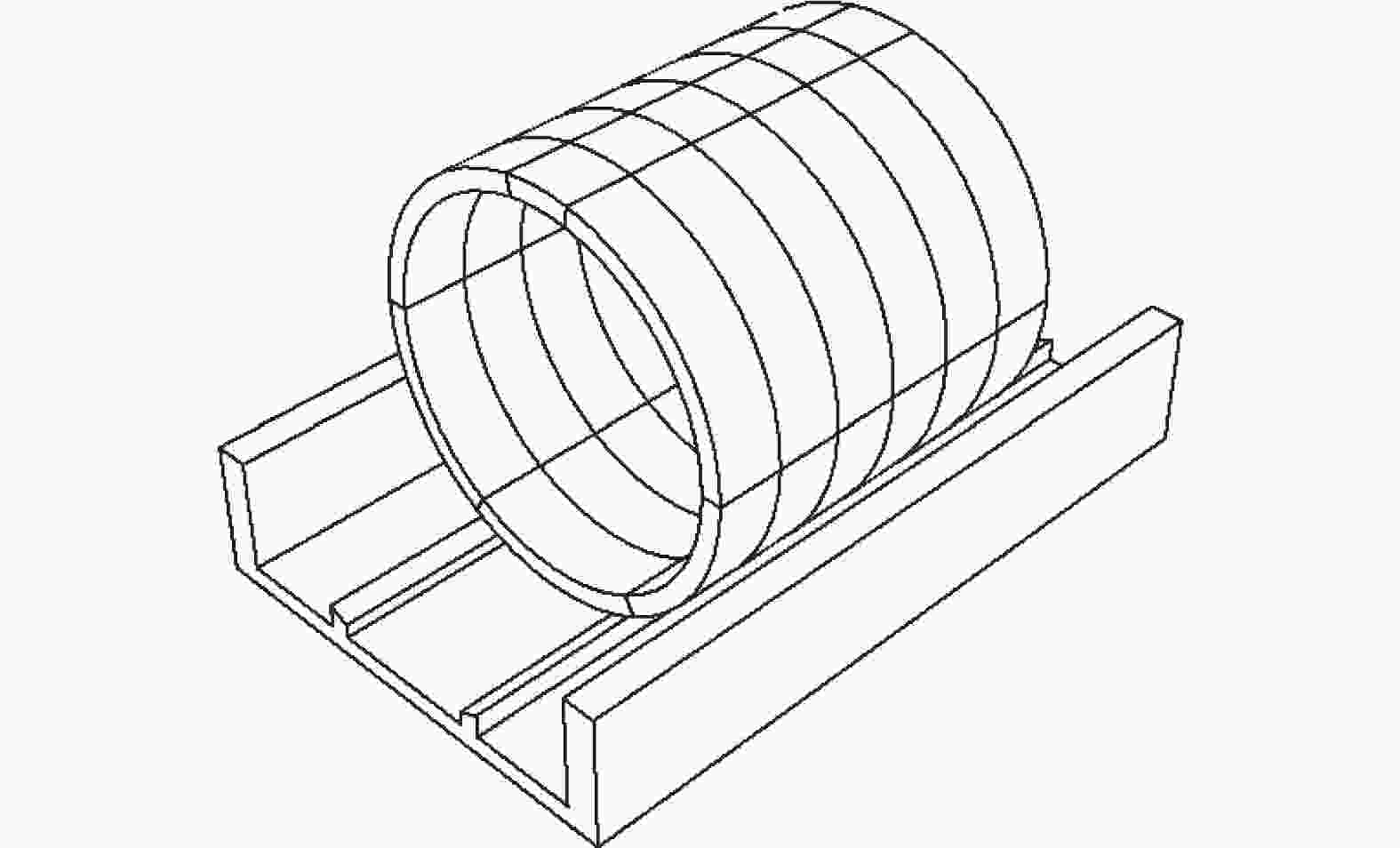

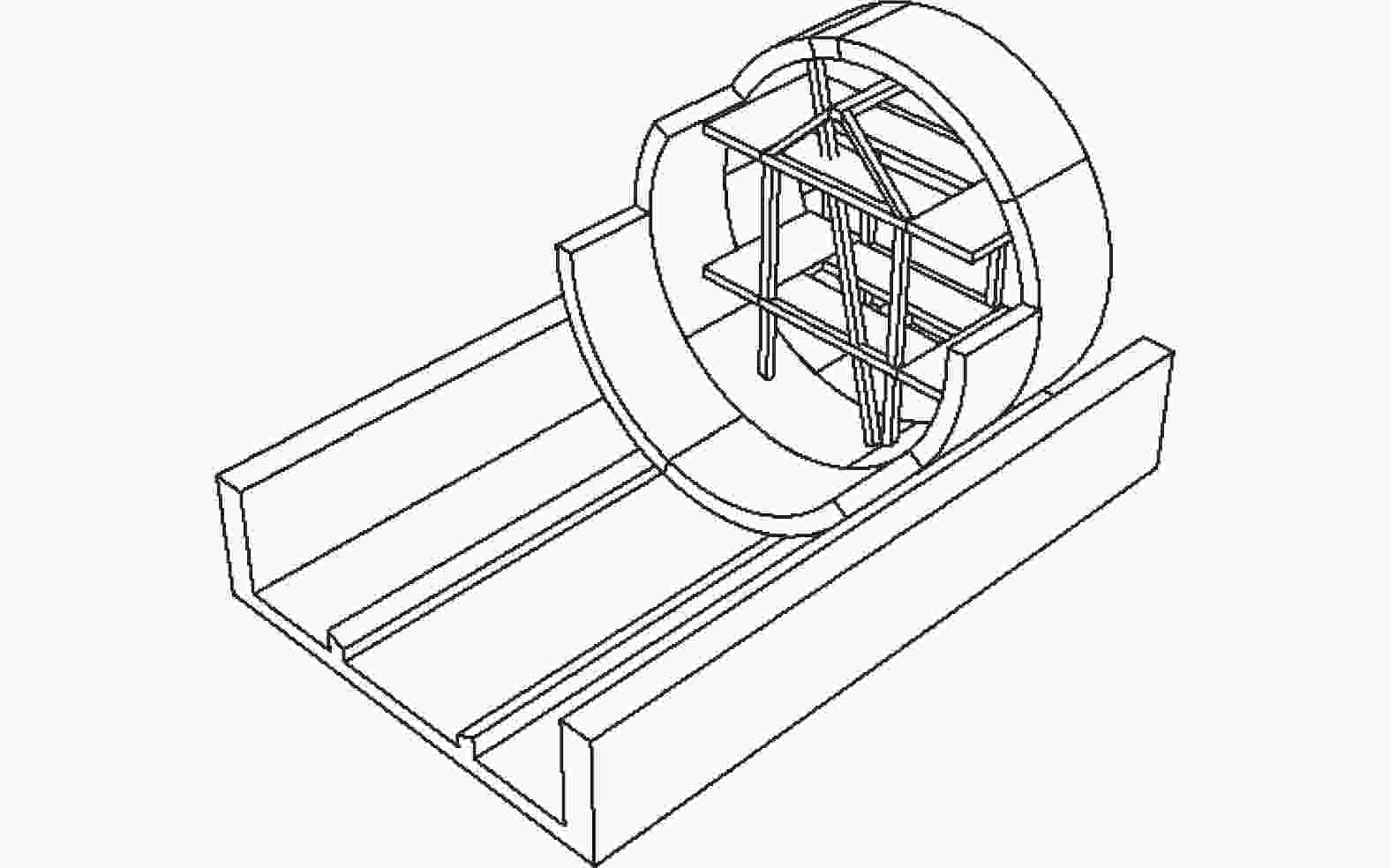

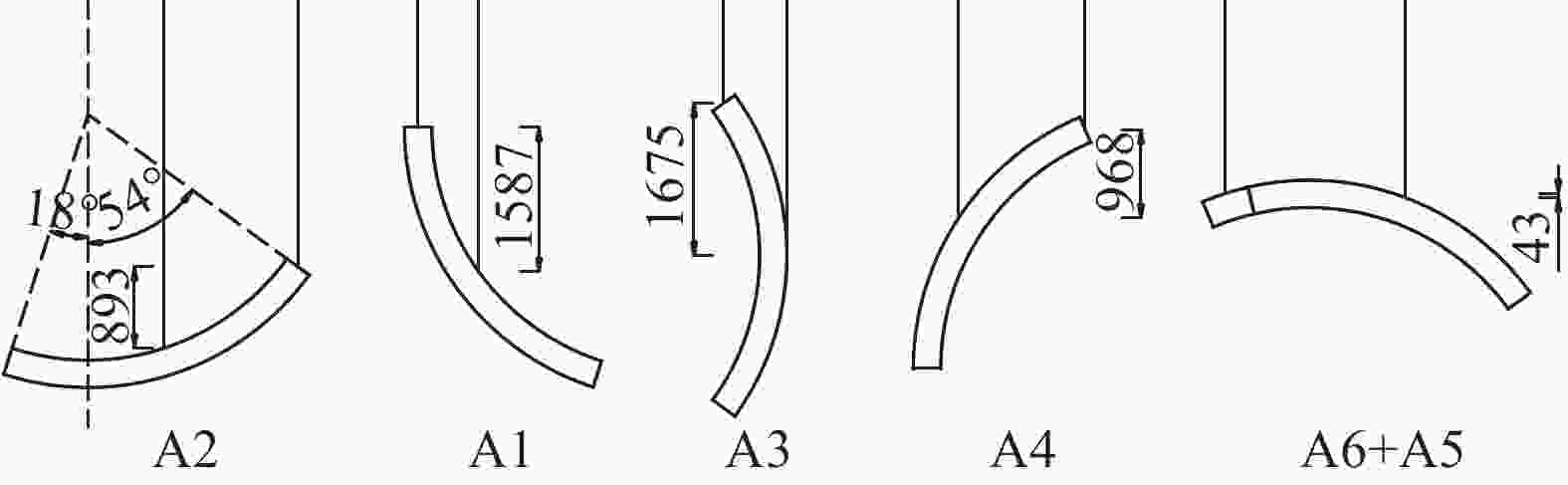

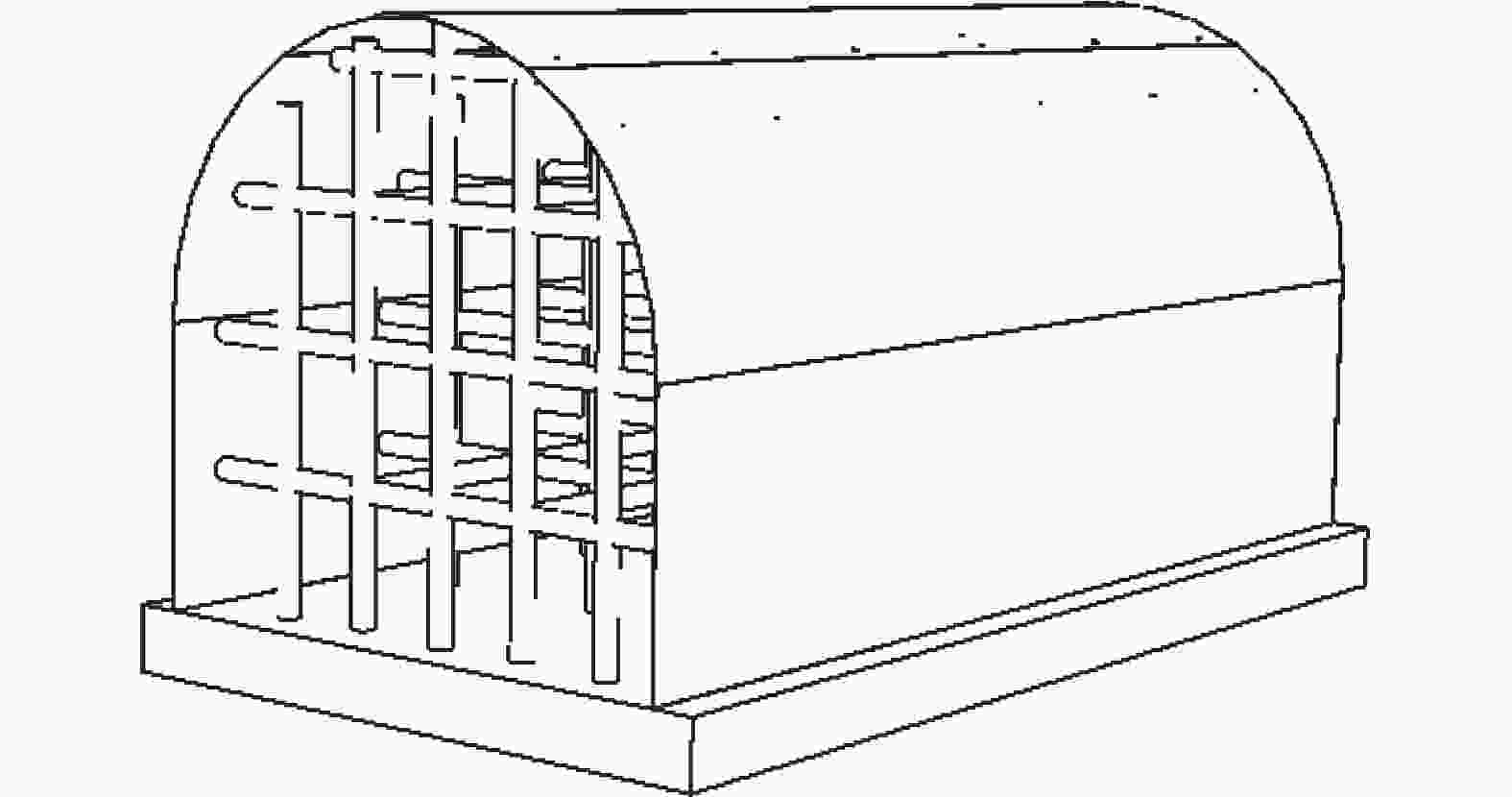

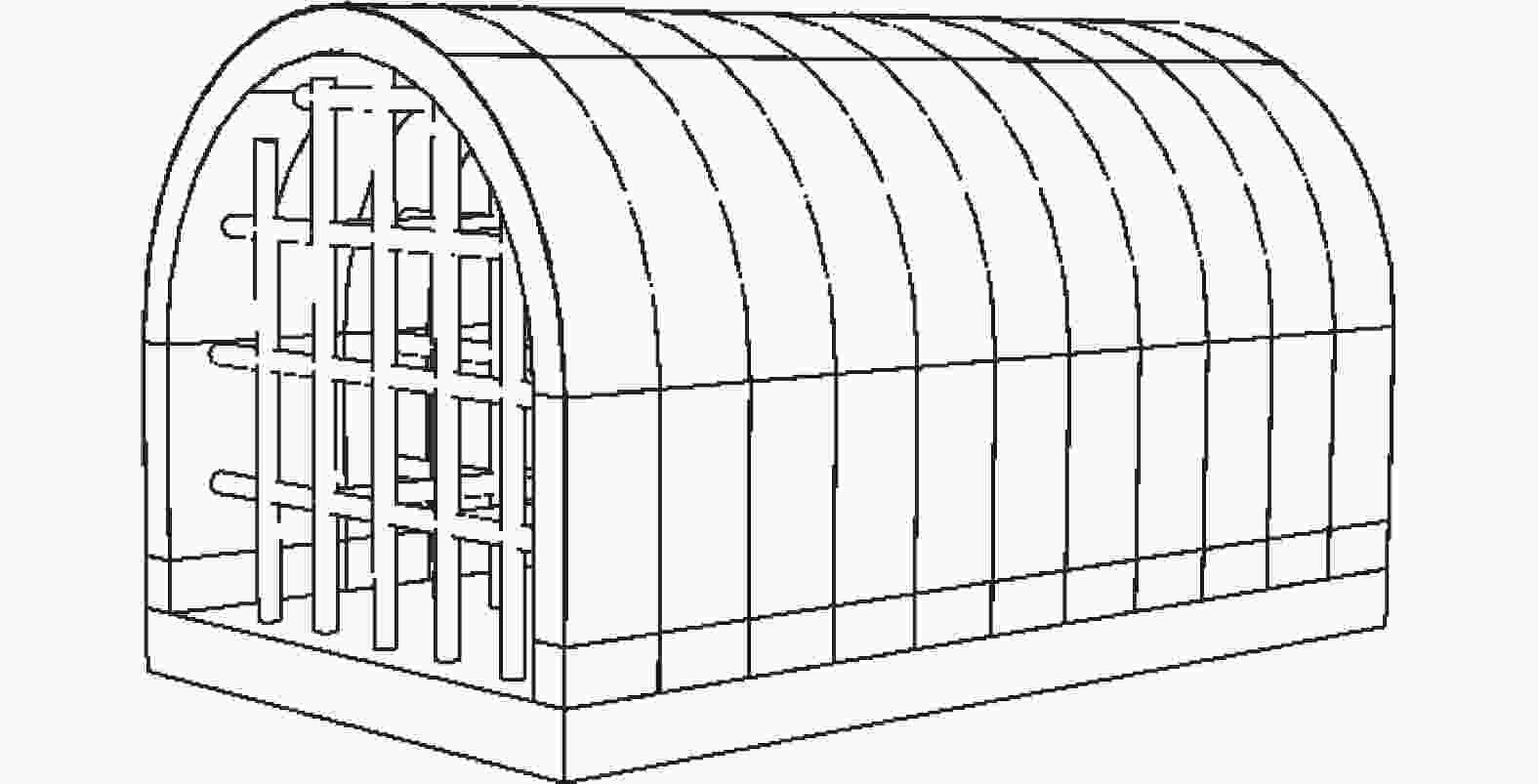

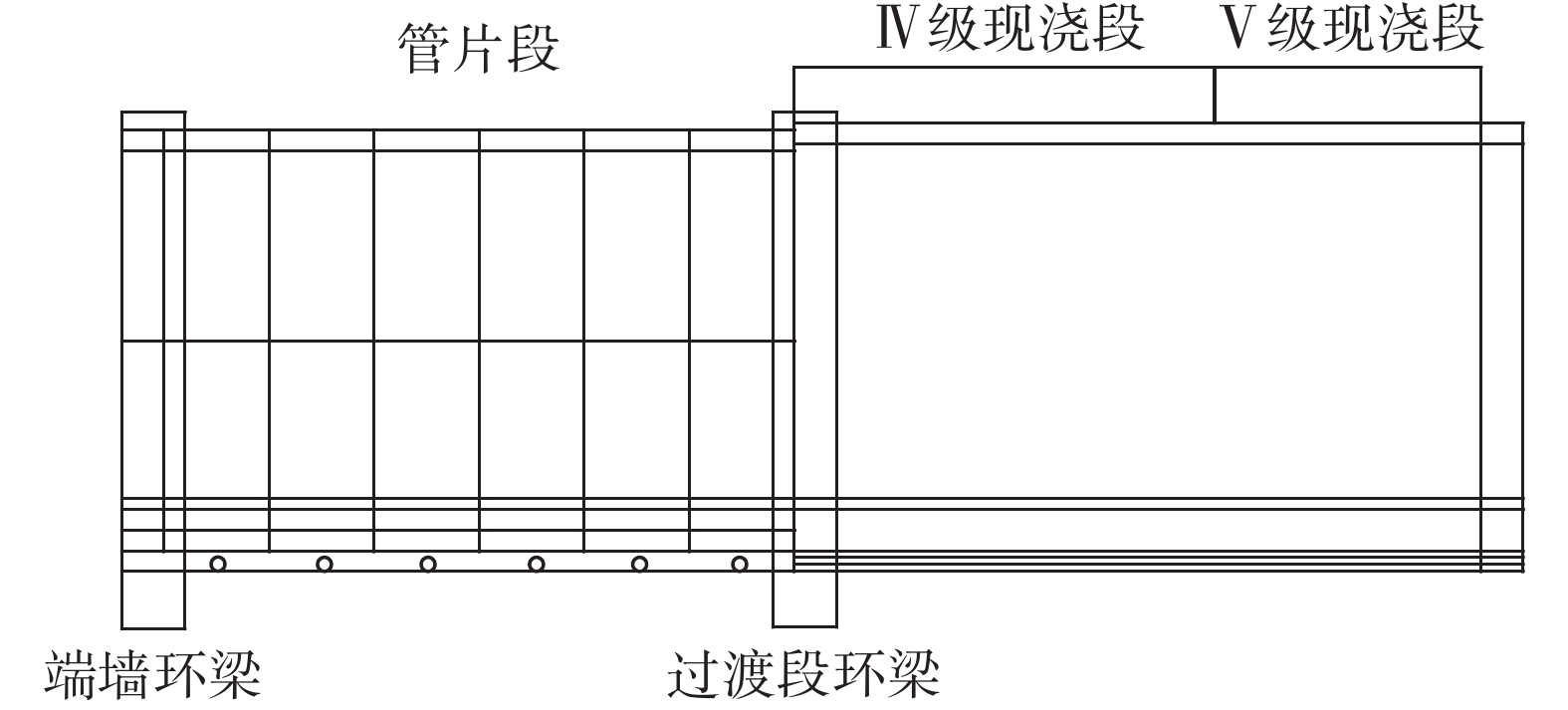

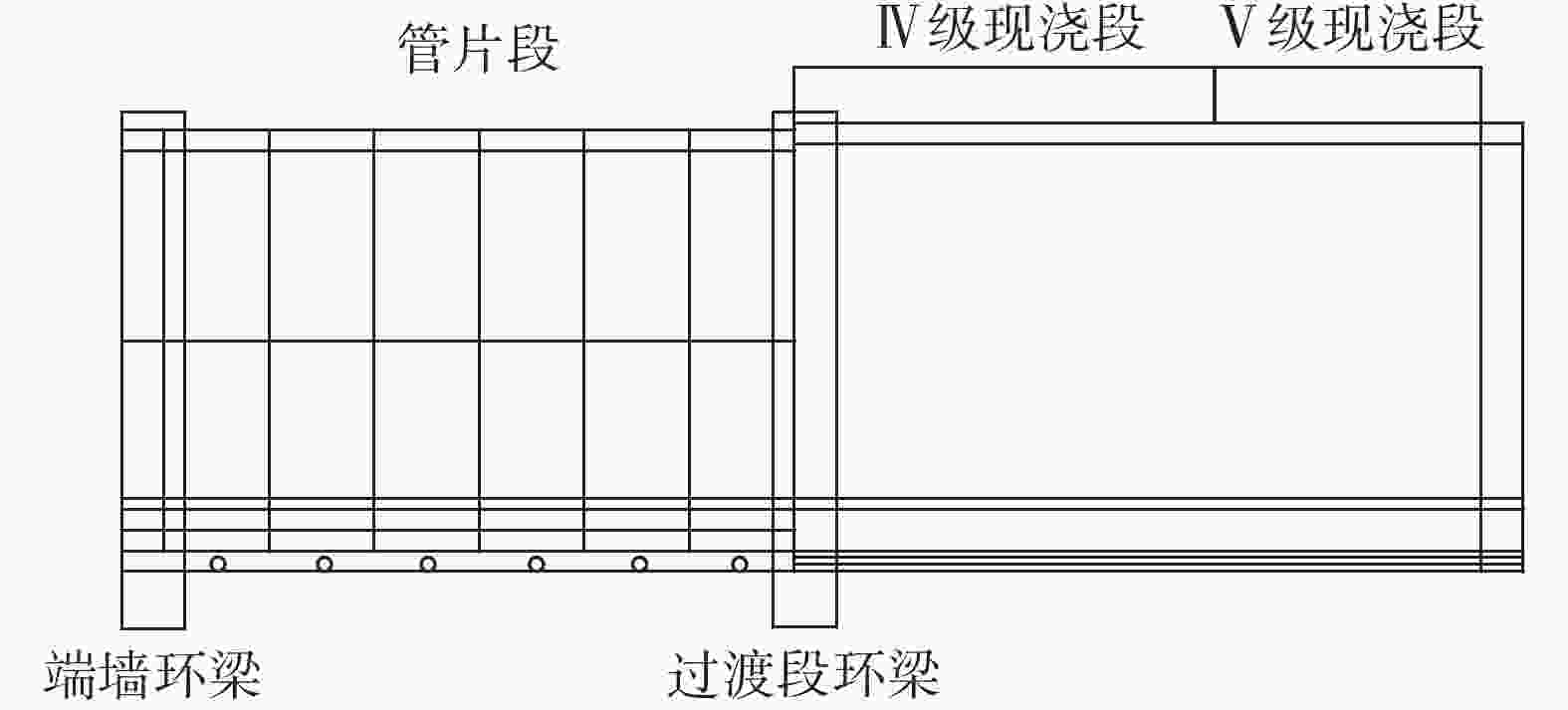

摘要: 为了搭建对隧道病害模拟与治理考虑更充分的隧道结构模拟综合试验平台,发明了一种管片段与现浇混凝土段组合结构,针对管片段与现浇段分别设计两种具体施工方案,结合计算工期、价格和所需机械数量,同时考虑了现场条件与需求优先级,比选确定了施工方案。结果表明:管片段采用错缝拼接施工方案搭接紧密,受力合理;现浇段采用脚手架+木模施工方案价格最优、运输方便。该隧道结构模拟综合试验平台施工方案可为其他试验平台的施工提供参考。Abstract: To build a comprehensive test platform for tunnel structure simulation with more consideration for tunnel disease simulation and treatment, a composite structure of pipe segment and cast-in-place concrete segment was invented. Two specific construction schemes were designed for the pipe segment and cast-in-place concrete segment respectively, and the construction scheme was determined by comparing and selecting according to the calculation of time limit, price, and quantity of machinery required, as well as the site condition and demand priority. The results show that the staggered splicing construction scheme of the pipe segment is tightly bonded and has reasonable structural force. The construction scheme of scaffold + wood formwork in cast-in-place concrete segment has the best price and convenient transportation. The construction scheme of the tunnel structure simulation comprehensive test platform can provide a reference for the construction of other test platforms.

-

Key words:

- tunnel /

- test platform /

- construction scheme

-

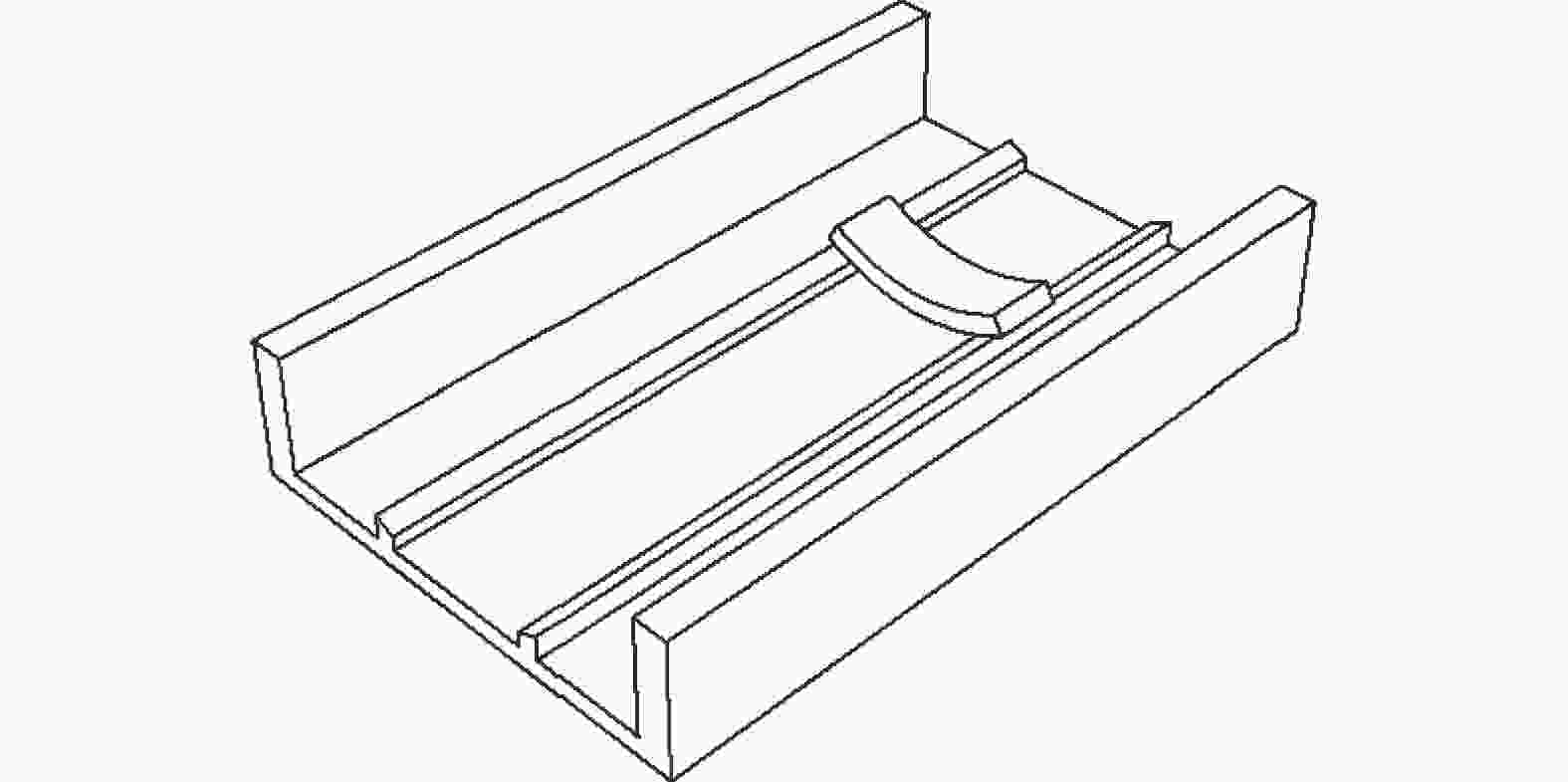

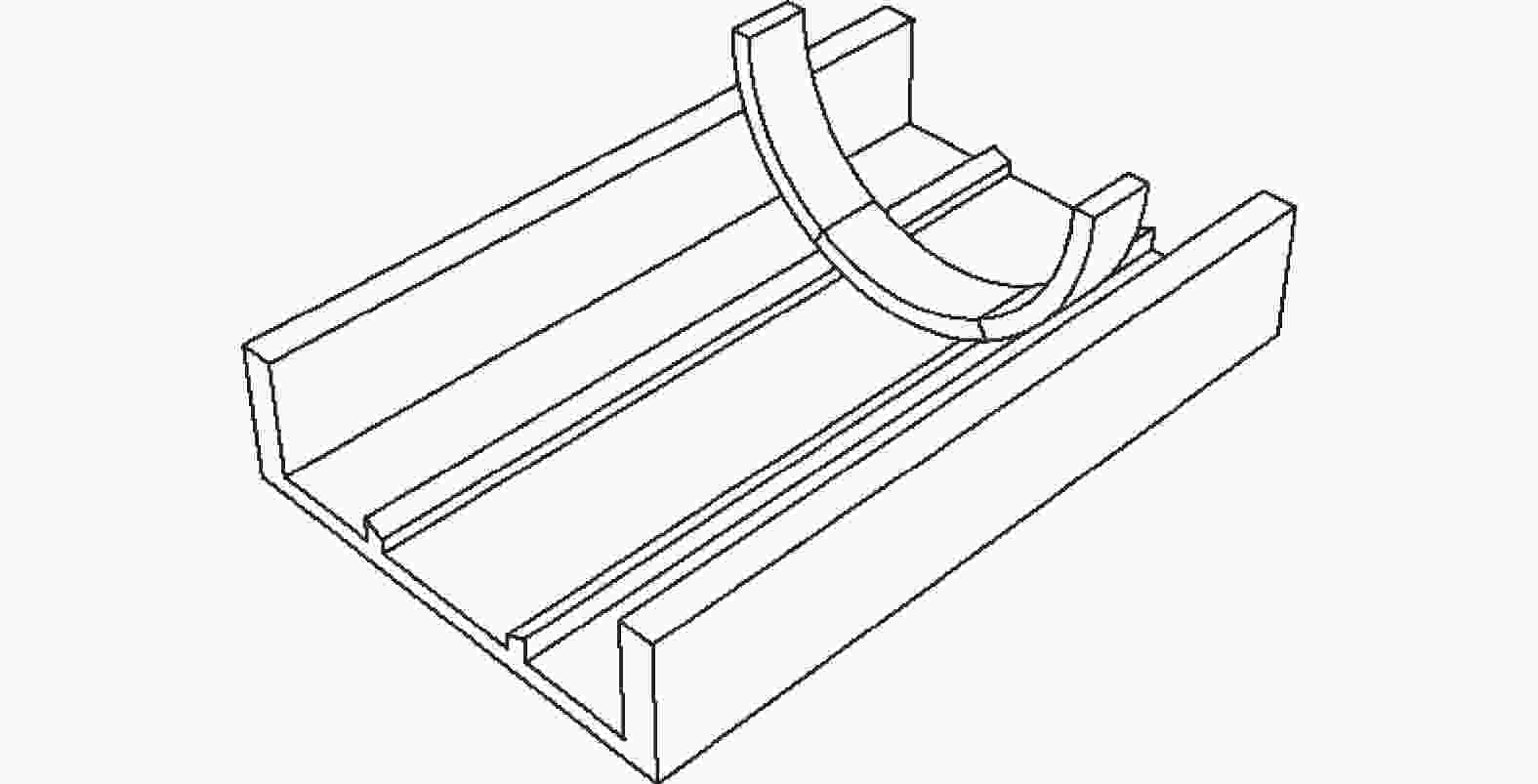

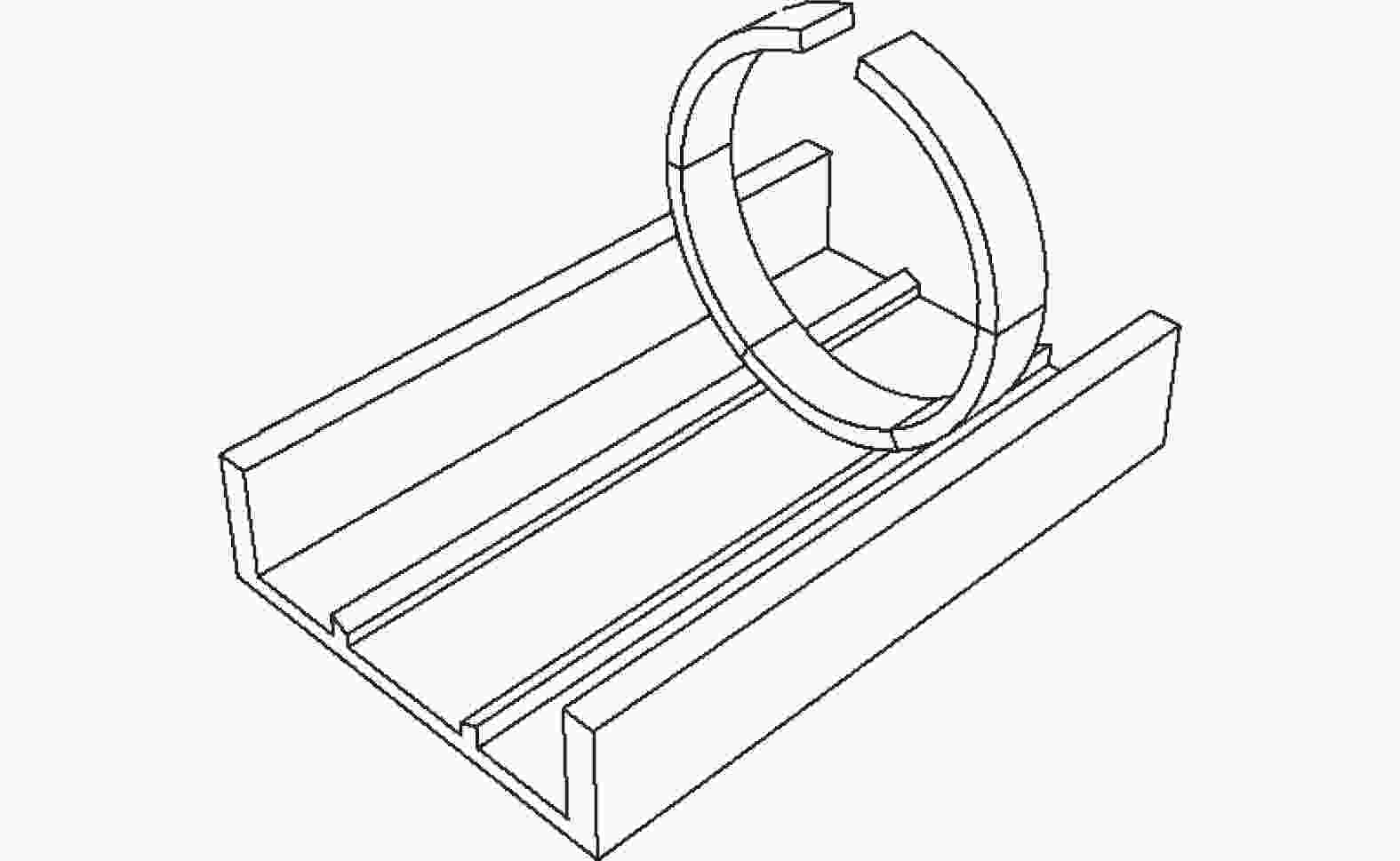

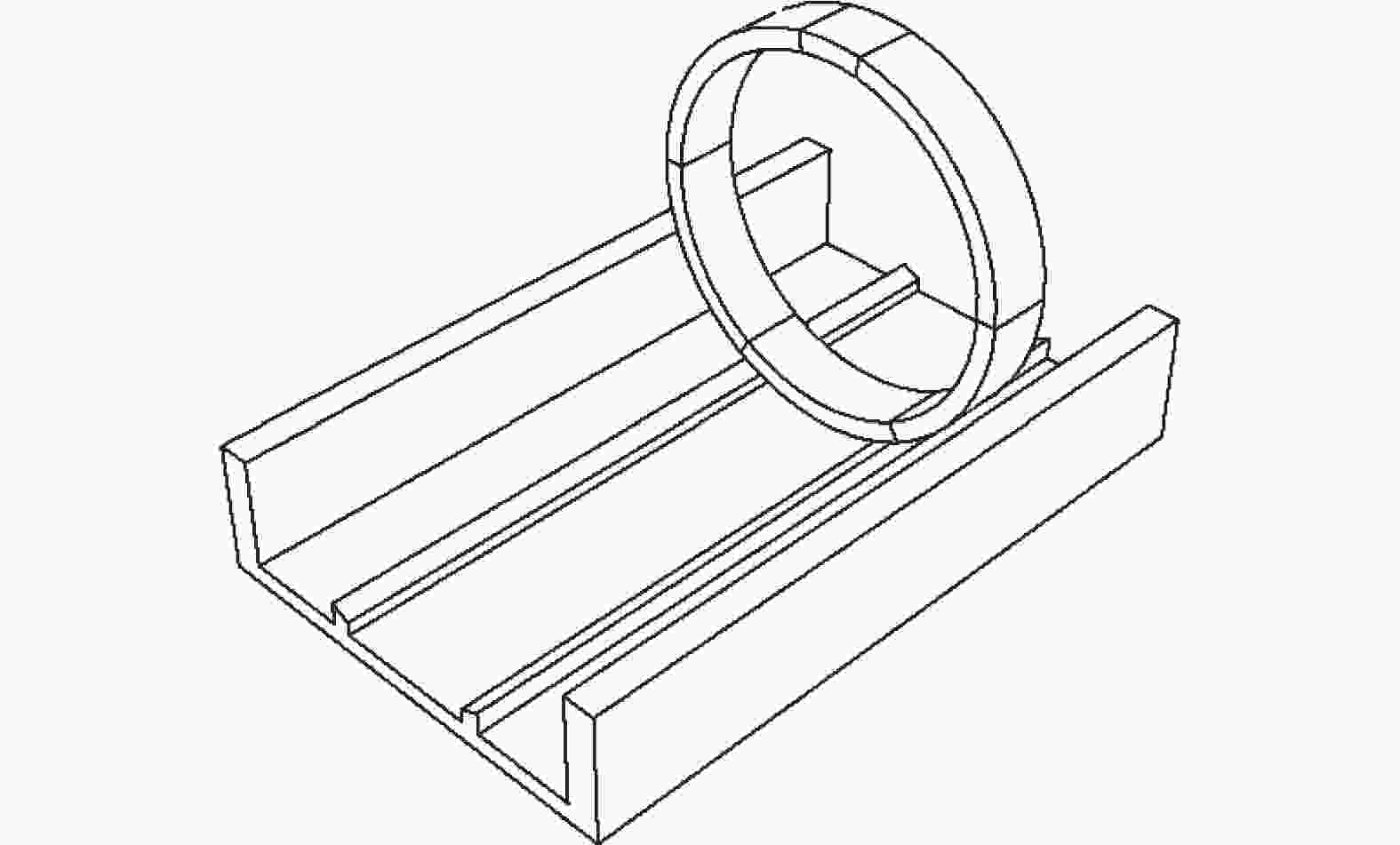

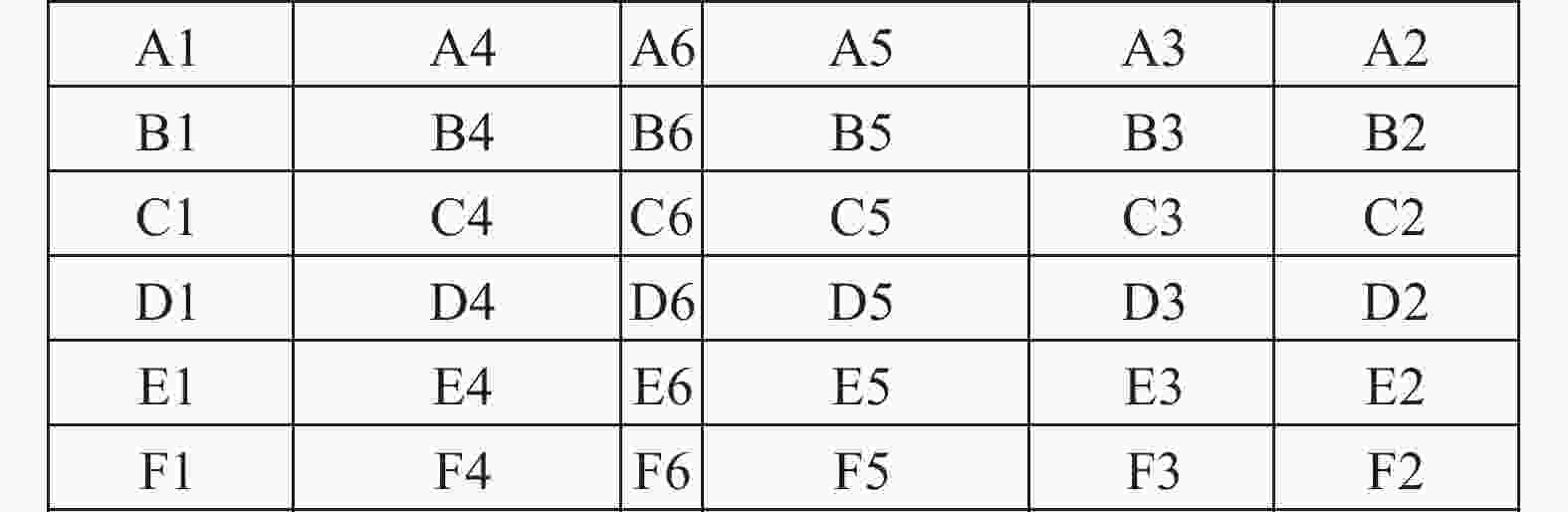

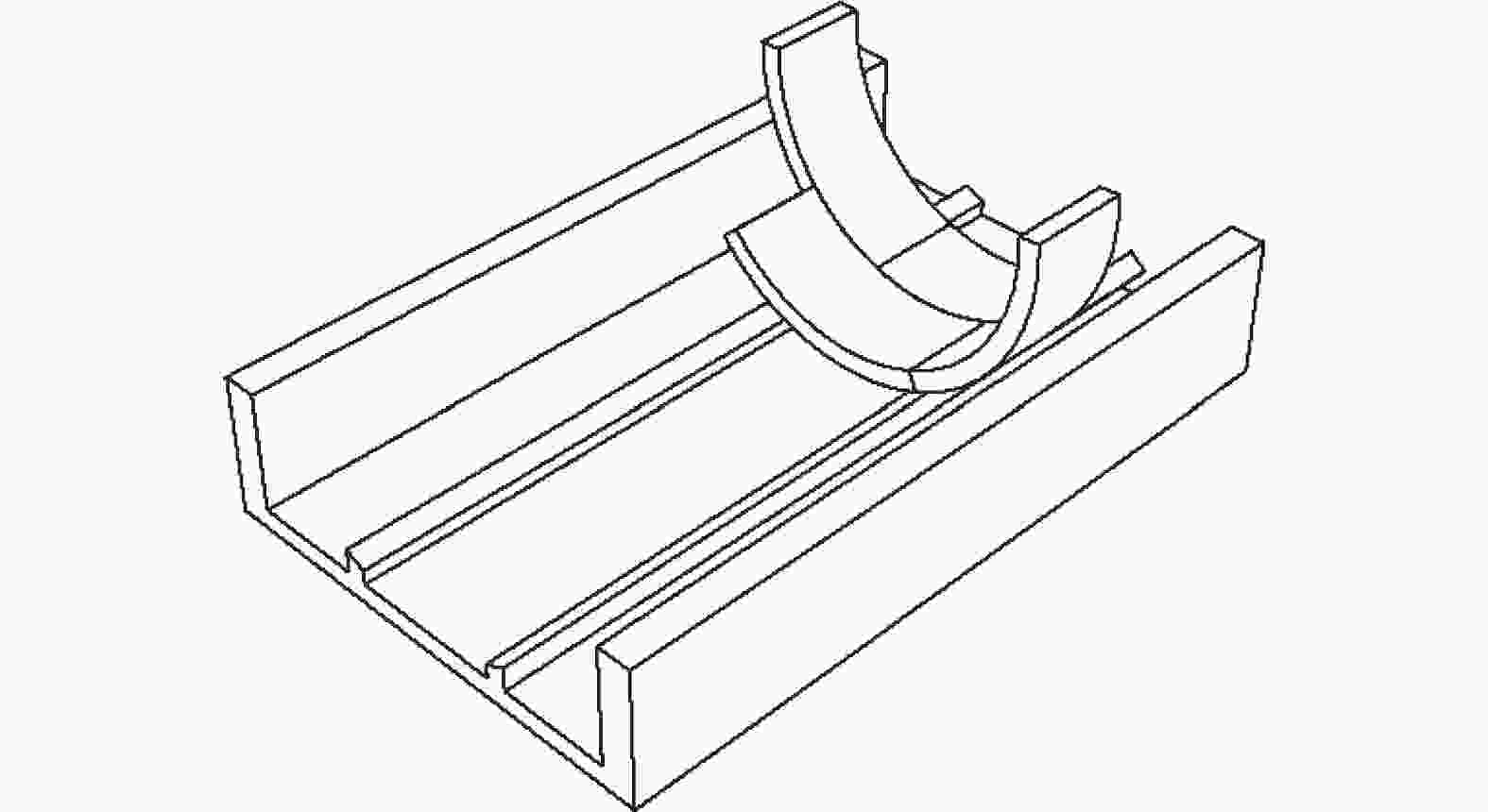

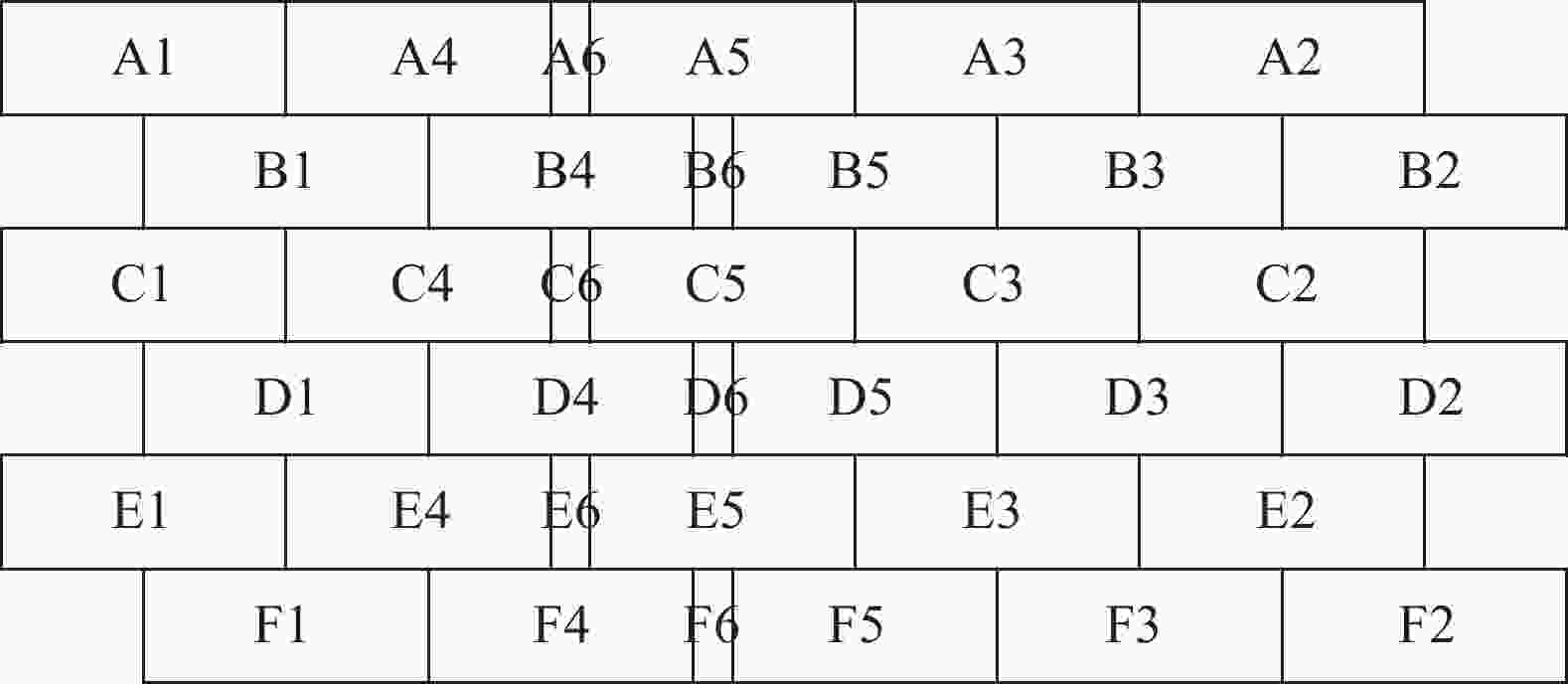

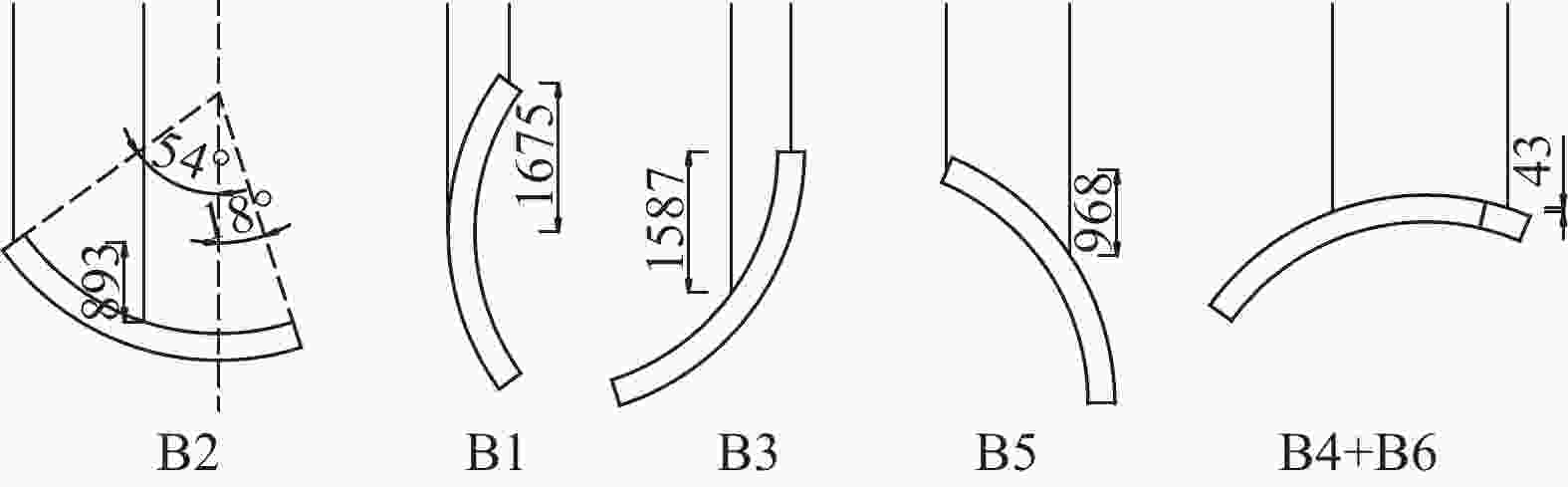

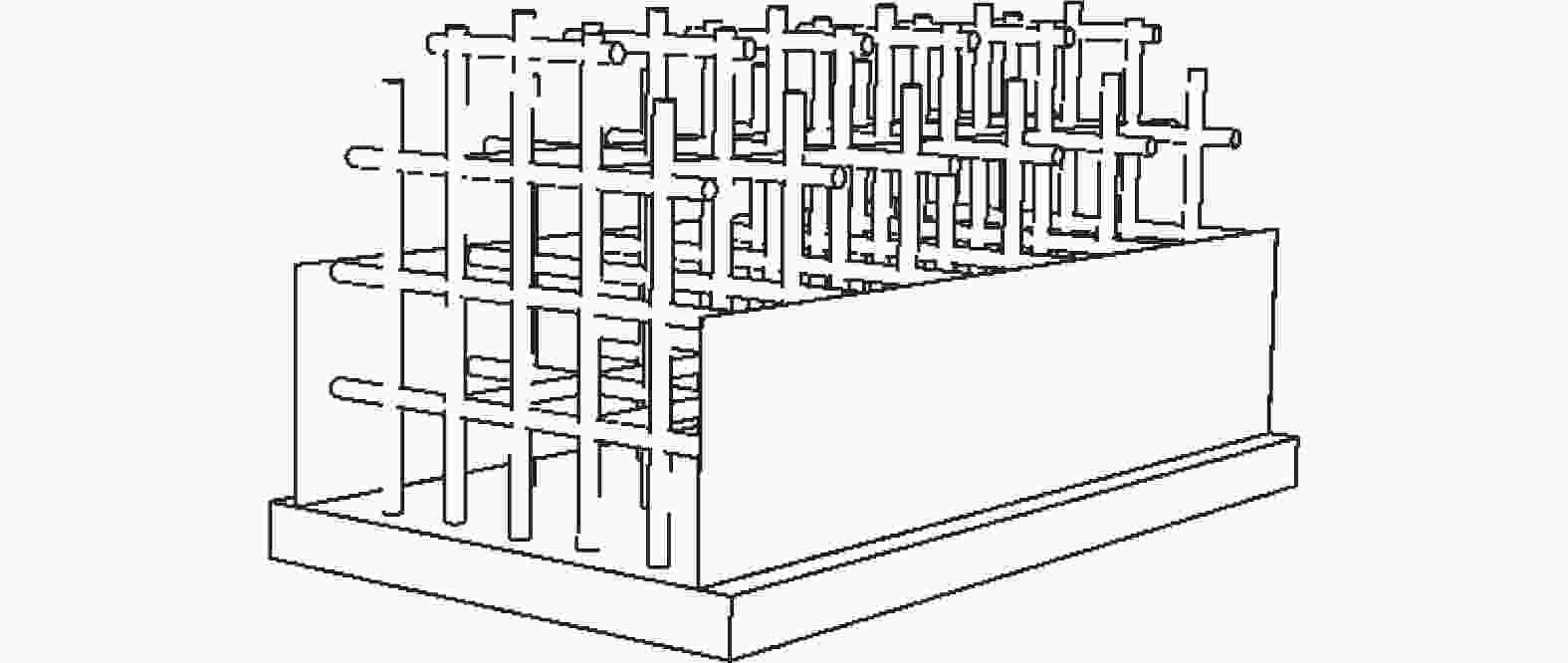

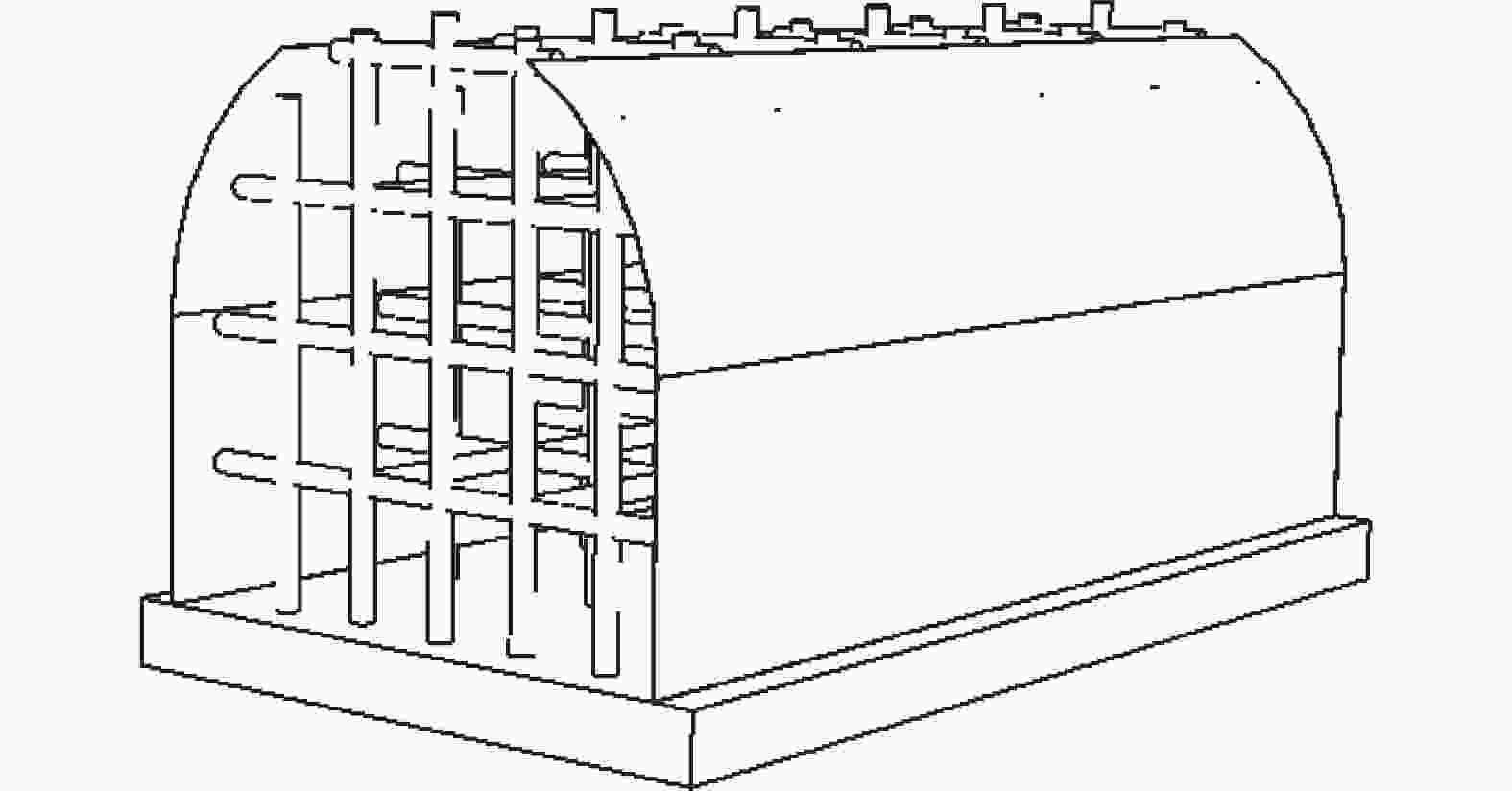

表 1 管片段施工方案比选表

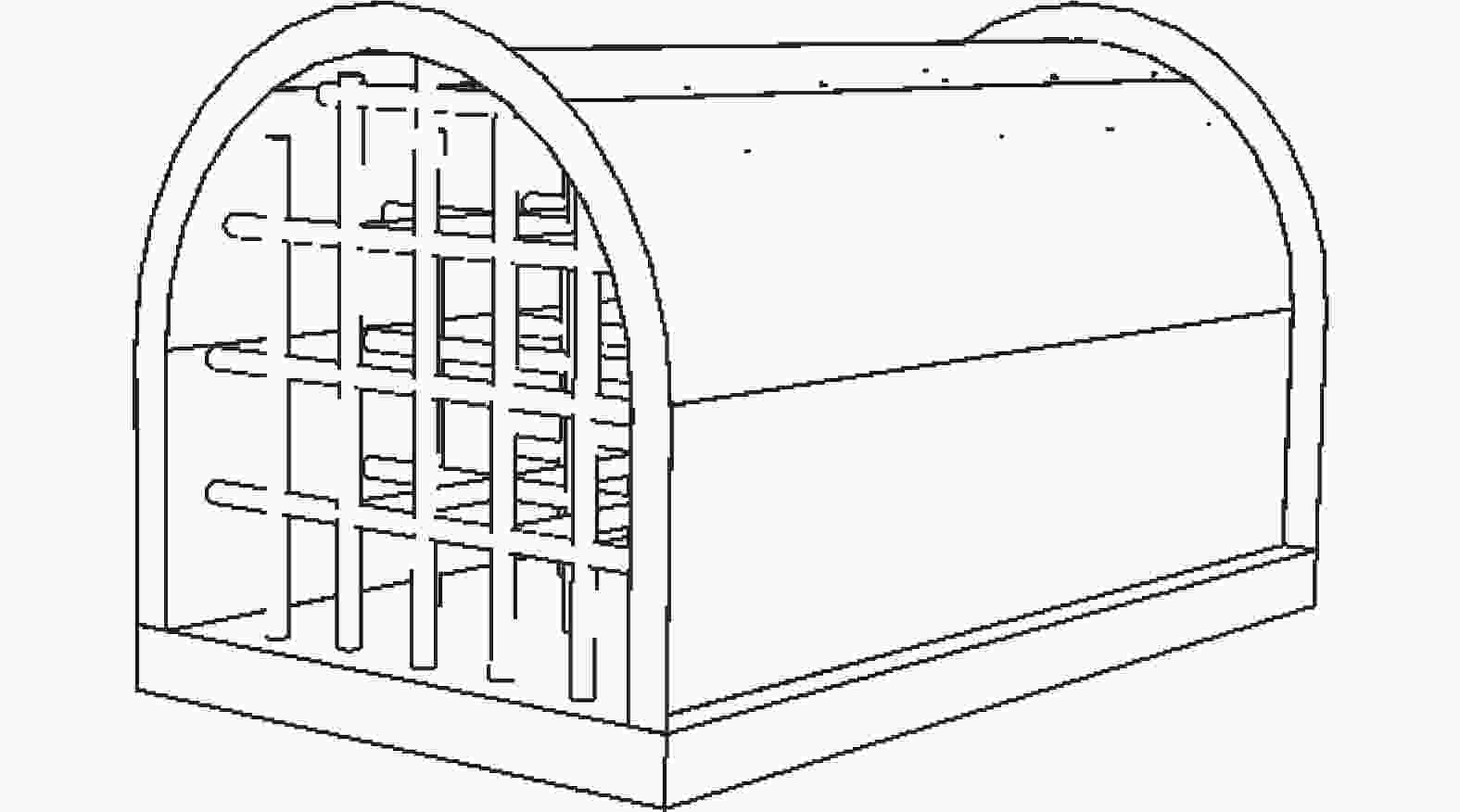

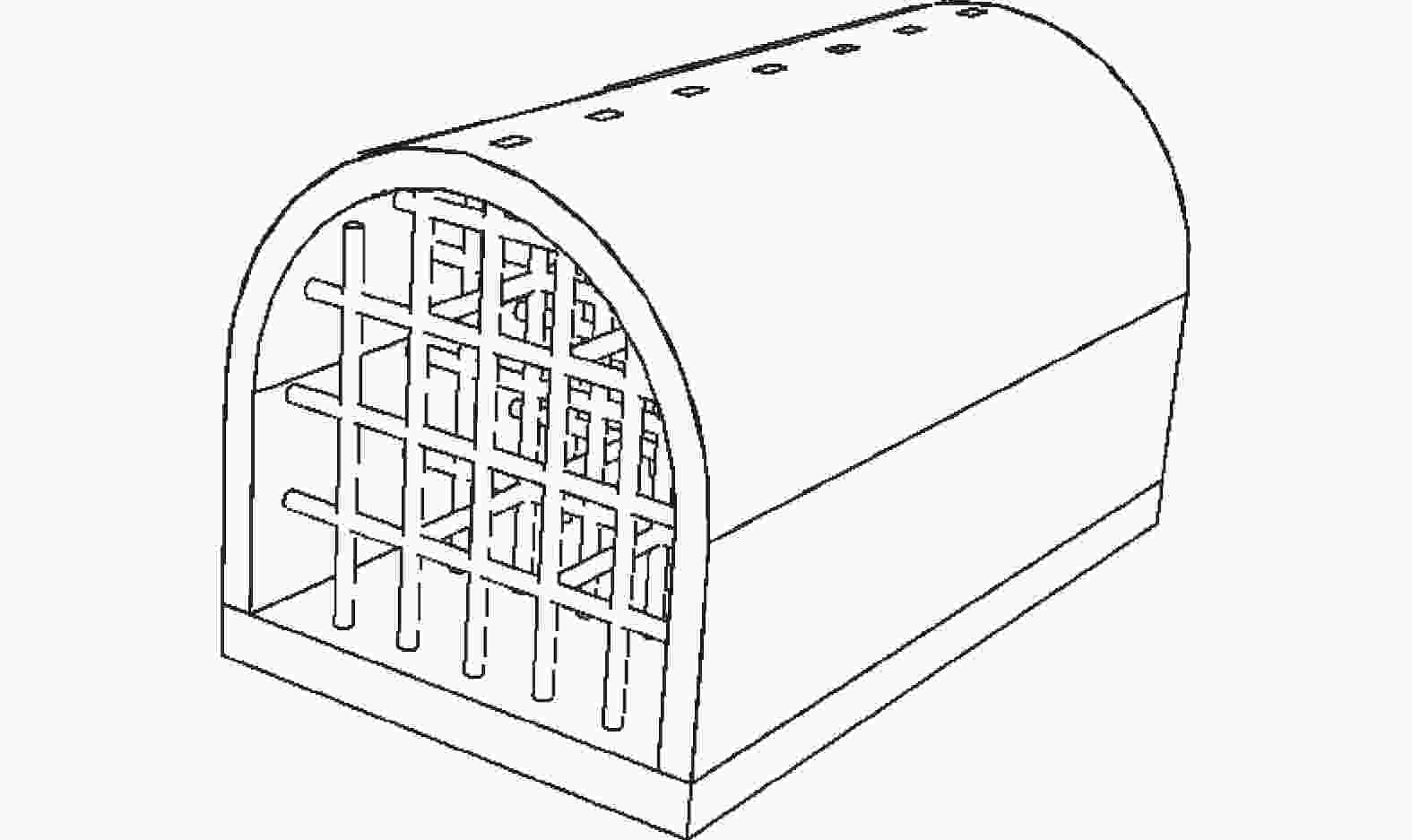

方案 长度 工期 造价 所需设备 示意图 方案1—通缝拼装 9 m 16 d(底座制作10 d+拼装6 d) 46万元 2台汽车吊35 t、1台高空作业车27 m、

1套非标工具、1套常规工具、1套吊具

方案2—错缝拼装 9 m 9 d(托梁制作2 d+拼装7 d) 40万元 QE32+10 t+16.5 m A5型吊钩桥式起重机,

主吊起重重量32 t,副吊起重重量10 t

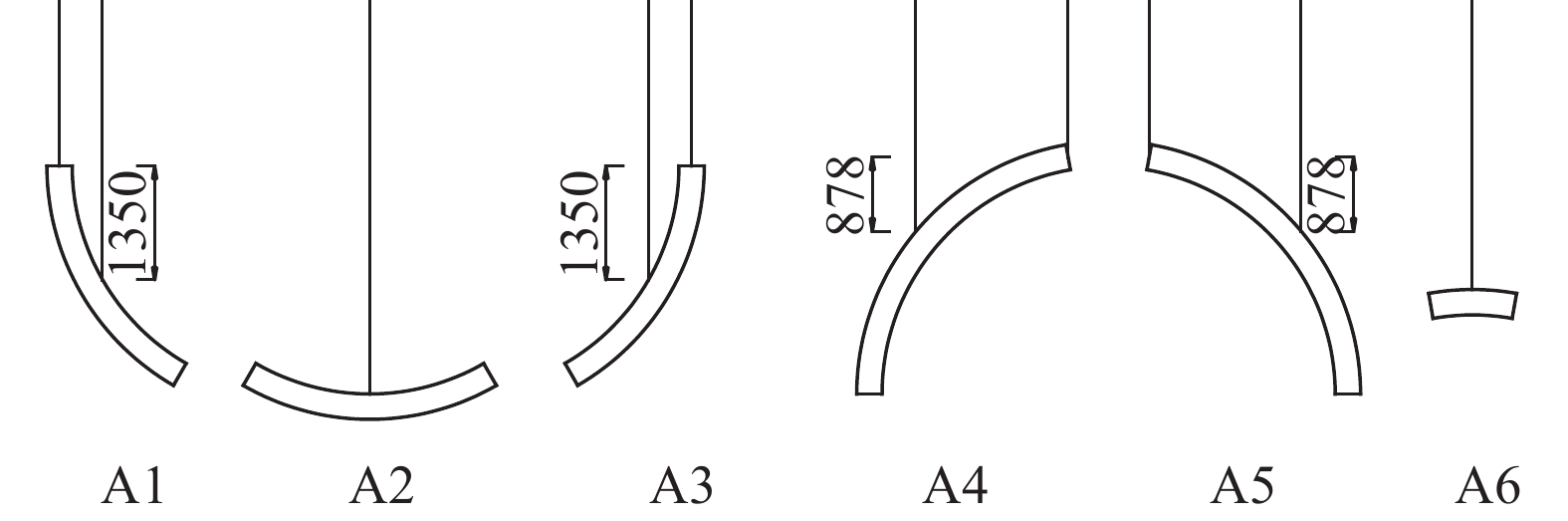

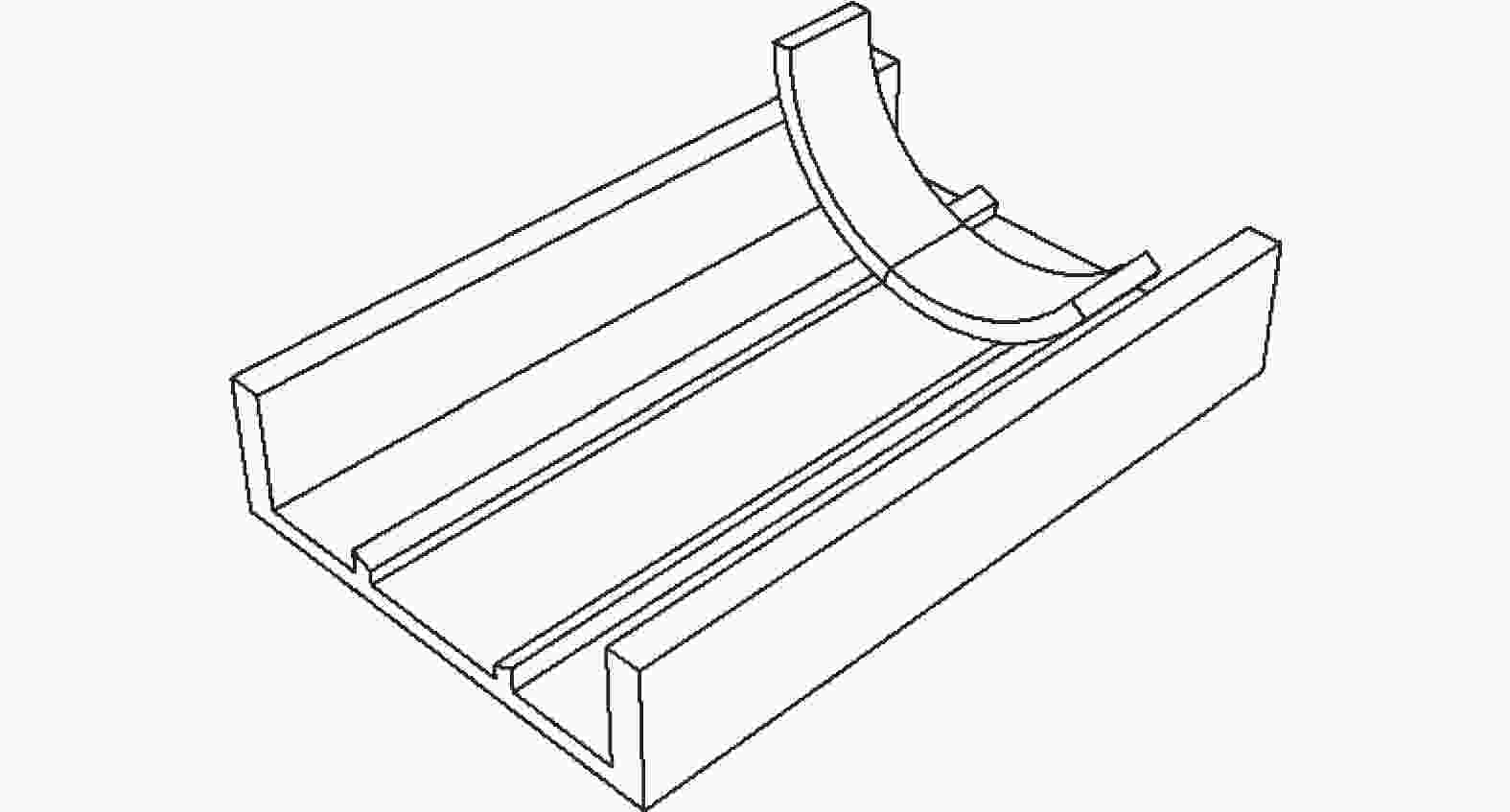

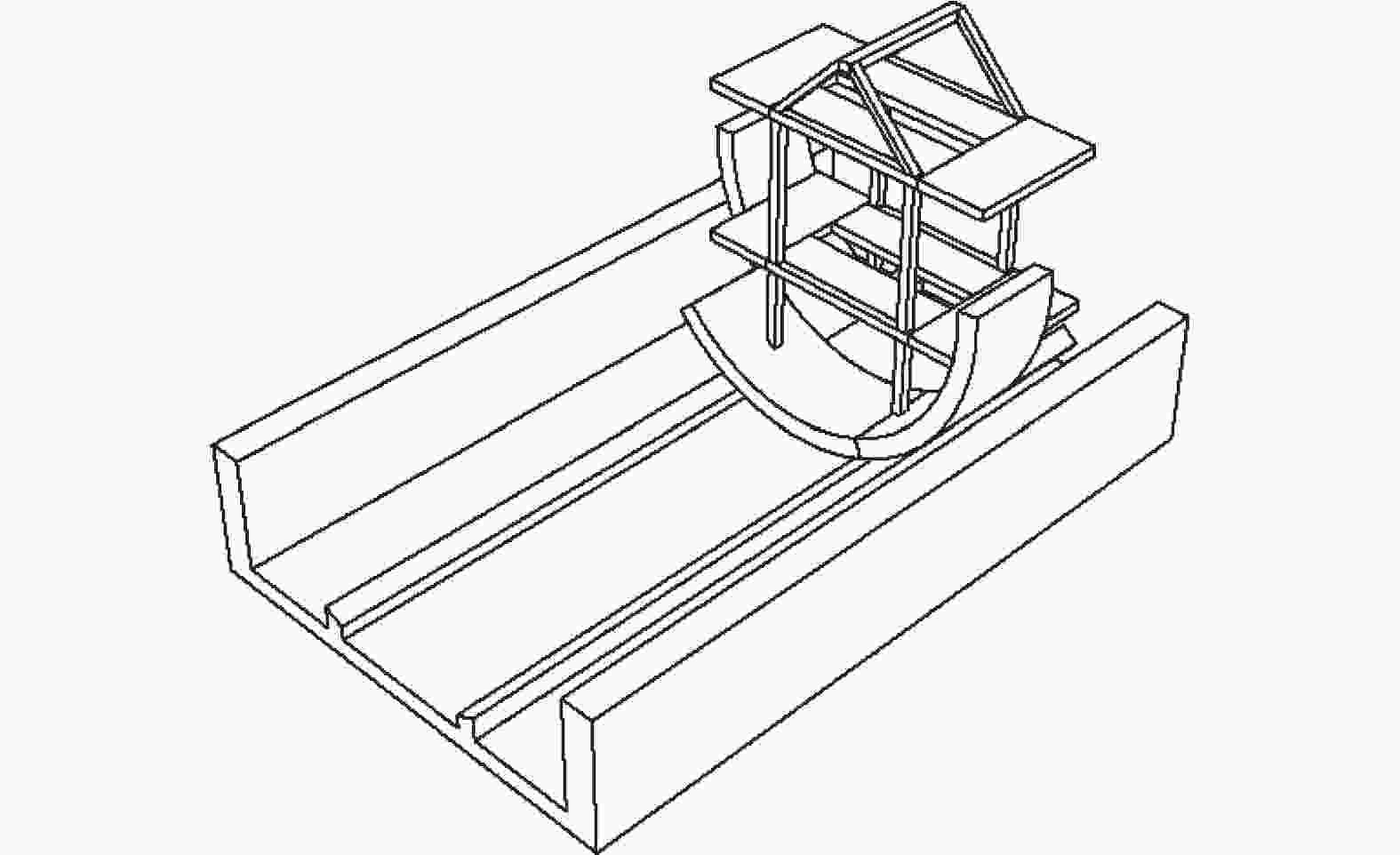

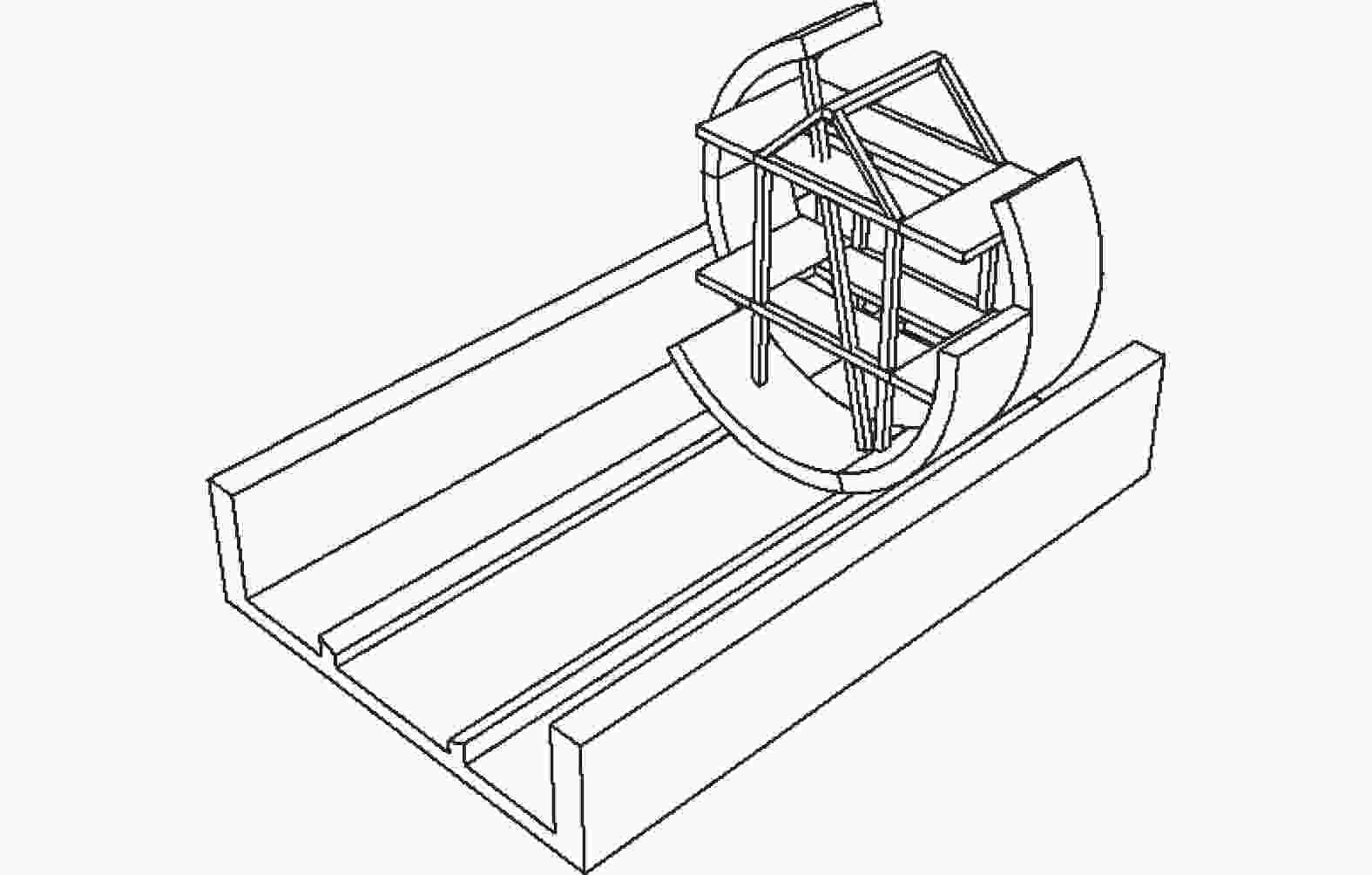

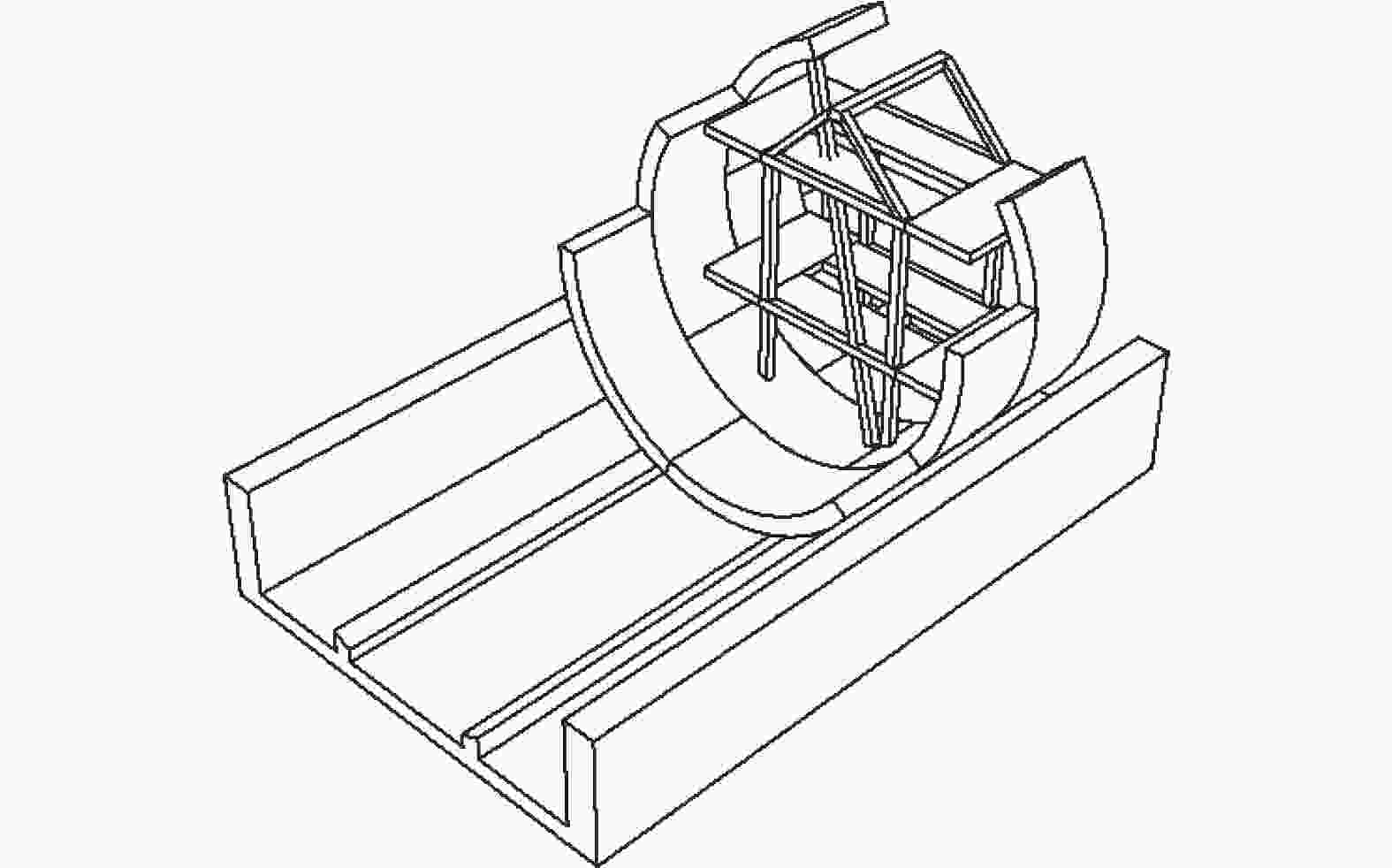

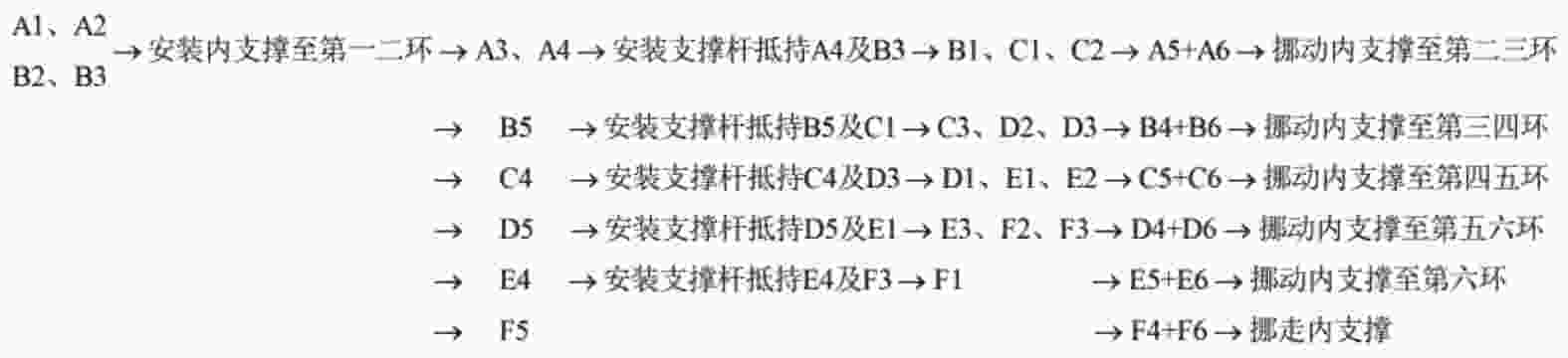

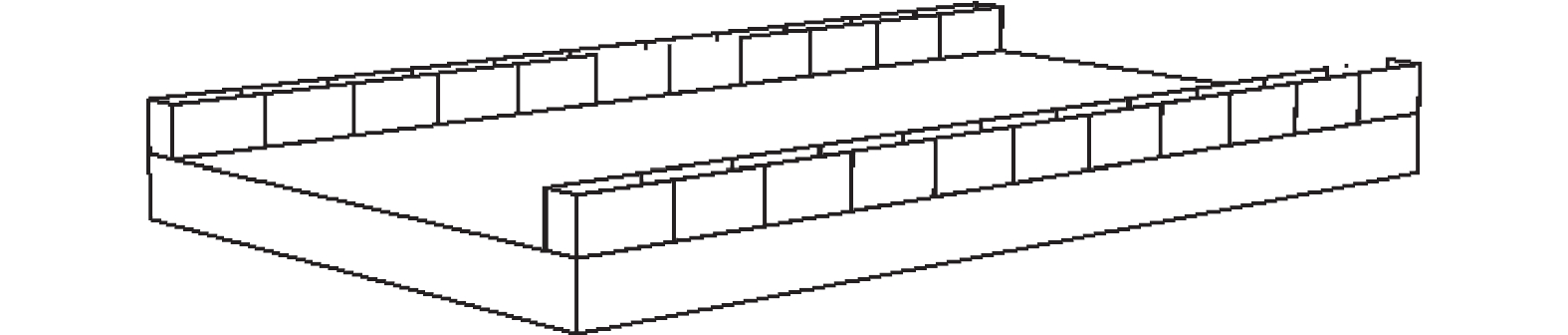

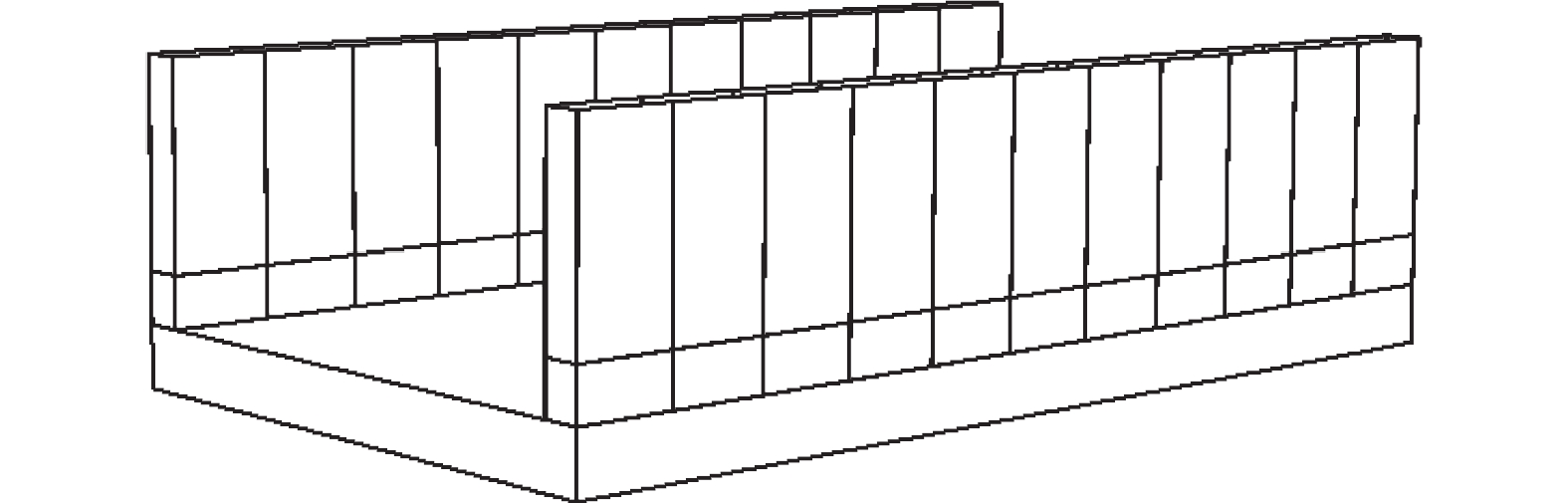

表 2 现浇段施工方案比选表

方案 长度 工期 造价 所需设备 示意图 方案1—脚手架+钢模 11 m 19 d(钢模加工10 d+一次性拼装2 d+

钢模立模、混凝土浇筑、拆模共7 d)35万元 QE32+10 t+16.5 m A5型吊钩桥式起重机、

混凝土输送泵车

方案2—脚手架+木模 11 m 17 d(底板施工3 d+侧墙施工7 d+

拱顶施工7 d)30万元 QE32+10 t+16.5 m A5型吊钩桥式起重机、

混凝土输送泵车

-

[1] 王 华, 路耀邦, 冯国峰, 等. 隧道结构健康管理大数据平台研发及应用[J]. 隧道建设(中英文),2023,43(8):1425-1437. (WANG H, LU Y B, FENG G F, et al. Development and application of big data platform for tunnel structure health management[J]. Tunnel Construction,2023,43(8):1425-1437. (in Chinese)WANG H, LU Y B, FENG G F, et al. Development and application of big data platform for tunnel structure health management[J]. Tunnel Construction, 2023, 43(8): 1425-1437. (in Chinese) [2] 刘德军, 仲 飞, 黄宏伟, 等. 运营隧道衬砌病害诊治的现状与发展[J]. 中国公路学报,2021,34(11):178-199. (LIU D J, ZHONG F, HUANG H W, et al. Present status and development trend of diagnosis and treatment of tunnel lining diseases[J]. China Journal of Highway and Transport,2021,34(11):178-199. (in Chinese)LIU D J, ZHONG F, HUANG H W, et al. Present status and development trend of diagnosis and treatment of tunnel lining diseases[J]. China Journal of Highway and Transport, 2021, 34(11): 178-199. (in Chinese) [3] 仇文革. 地下工程近接施工力学原理与对策的研究[D]. 成都: 西南交通大学, 2003. (QIU W G. The study on mechanics principle and countermeasure of approaching excavation in underground works[D]. Chengdu: Southwest Jiaotong University, 2003. (in Chinese)QIU W G. The study on mechanics principle and countermeasure of approaching excavation in underground works[D]. Chengdu: Southwest Jiaotong University, 2003. (in Chinese) [4] 兰 宇. 高速公路隧道维护加固对策的模型试验研究[D]. 成都: 西南交通大学, 2005. (LAN Y. Model test of expressway tunnel for maintenance and reinforcement strategies[D]. Chengdu: Southwest Jiaotong University, 2005. (in Chinese)LAN Y. Model test of expressway tunnel for maintenance and reinforcement strategies[D]. Chengdu: Southwest Jiaotong University, 2005. (in Chinese) [5] 王金明. 地铁隧道施工引起的地表沉降及变形研究[D]. 长沙: 中南大学, 2009. (WANG J M. Research on surface subsidence and deformation caused by subway tunnel construction[D]. Changsha: Central South University, 2009. (in Chinese)WANG J M. Research on surface subsidence and deformation caused by subway tunnel construction[D]. Changsha: Central South University, 2009. (in Chinese) [6] 周 乾. 基于尖点突变理论的城区孕育型土洞地陷判据研究[D]. 长沙: 湖南大学, 2019. (ZHOU Q. Study on the criterion of ground subsidence of pregnant soil cave in urban area based on cusp catastrophe theory[D]. Changsha: Hunan University, 2019. (in Chinese)ZHOU Q. Study on the criterion of ground subsidence of pregnant soil cave in urban area based on cusp catastrophe theory[D]. Changsha: Hunan University, 2019. (in Chinese) [7] 王建宁, 窦远明, 田贵州, 等. 圆形隧道衬砌背后空洞对隧道结构影响的振动台模型试验[J]. 工业建筑,2017,47(3):117-123,146. (WANG J N, DOU Y M, TIAN G Z, et al. Shaking table model test study of the effect on tunnel structure existing void behind lining of circular tunnel[J]. Industrial Construction,2017,47(3):117-123,146. (in Chinese)WANG J N, DOU Y M, TIAN G Z, et al. Shaking table model test study of the effect on tunnel structure existing void behind lining of circular tunnel[J]. Industrial Construction, 2017, 47(3): 117-123,146. (in Chinese) [8] 阿卜杜拉-穆塔里伯·凯特玛斯, 田 雨, 路德春, 等. 围岩相对密实度对隧道掘进时地层沉降的影响[J]. 工业建筑,2021,51(7):11-17. (ABDUL M K, TIAN Y, LU D C, et al. Influence of relative densities for surrounding rocks on stratum subsidence during tunnelling[J]. Industrial Construction,2021,51(7):11-17. (in Chinese)ABDUL M K, TIAN Y, LU D C, et al. Influence of relative densities for surrounding rocks on stratum subsidence during tunnelling[J]. Industrial Construction, 2021, 51(7): 11-17. (in Chinese) [9] 赵彦君, 张永谋, 吴红刚, 等. Ⅳ级砂岩隧道开挖掌子面与土体变形规律研究[J]. 工业建筑,2023,53(S2):548-552. (ZHAO Y J, ZHANG Y M, WU H G, et al. Study on the deformation rule of the tunnel face and soil mass in the excavation of Ⅳ grade sandstone tunnel[J]. Industrial Construction,2023,53(S2):548-552. (in Chinese)ZHAO Y J, ZHANG Y M, WU H G, et al. Study on the deformation rule of the tunnel face and soil mass in the excavation of Ⅳ grade sandstone tunnel[J]. Industrial Construction, 2023, 53(S2): 548-552. [10] 牛富生, 卓 越, 张 懿, 等. 一种用于隧道模型试验平台的管片段与现浇混凝土段组合结构: 202311855254.7[P]. 2024-03-15. (NIU F S, ZHUO Y, ZHANG Y, et al. Pipe segment and cast-in-place concrete segment combined structure for tunnel model test platform: 202311855254.7[P]. 2024-03-15. (in Chinese)NIU F S, ZHUO Y, ZHANG Y, et al. Pipe segment and cast-in-place concrete segment combined structure for tunnel model test platform: 202311855254.7[P]. 2024-03-15. (in Chinese) [11] 陈 欣, 胡 洋, 刘榆嵩, 等. 管片衬砌结构及其施工方法: 202310830489.4[P]. 2023-08-22. (CHEN X, HU Y, LIU Y S, et al. Segment lining structure and construction method thereof: 202310830489.4[P]. 2023-08-22. (in Chinese)CHEN X, HU Y, LIU Y S, et al. Segment lining structure and construction method thereof: 202310830489.4[P]. 2023-08-22. (in Chinese) [12] 王 华, 牛富生, 张 懿, 等. 一种钻爆法隧道结构模型的施工方法: 202410091093.7[P]. 2024-03-22. (WANG H, NIU F S, ZHANG Y, et al. Construction method of drilling and blasting method tunnel structure model: 202410091093.7[P]. 2024-03-22. (in Chinese)WANG H, NIU F S, ZHANG Y, et al. Construction method of drilling and blasting method tunnel structure model: 202410091093.7[P]. 2024-03-22. (in Chinese) -

下载:

下载: