Influence caused by reinforcement range of connecting passage on main tunnels

-

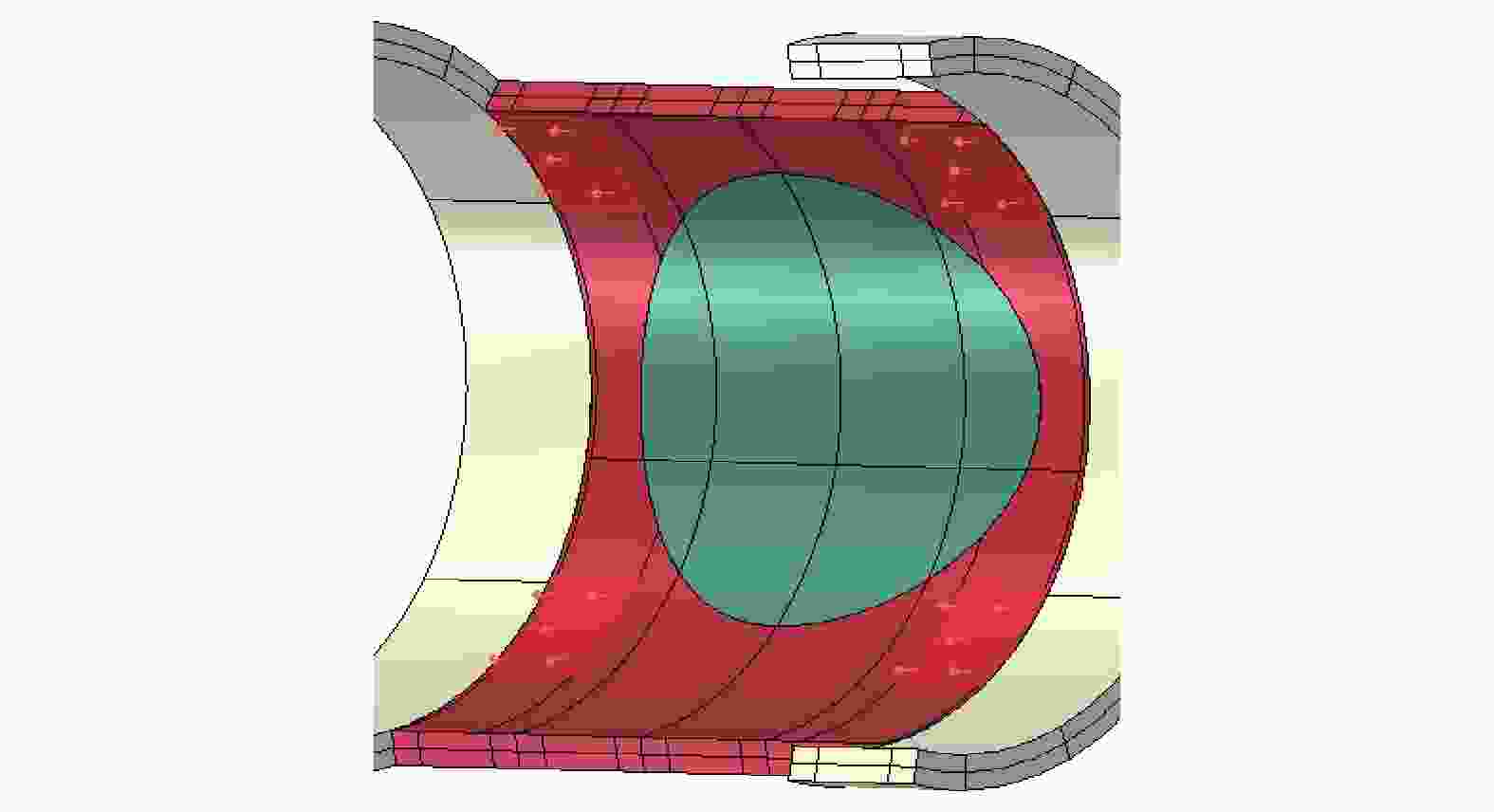

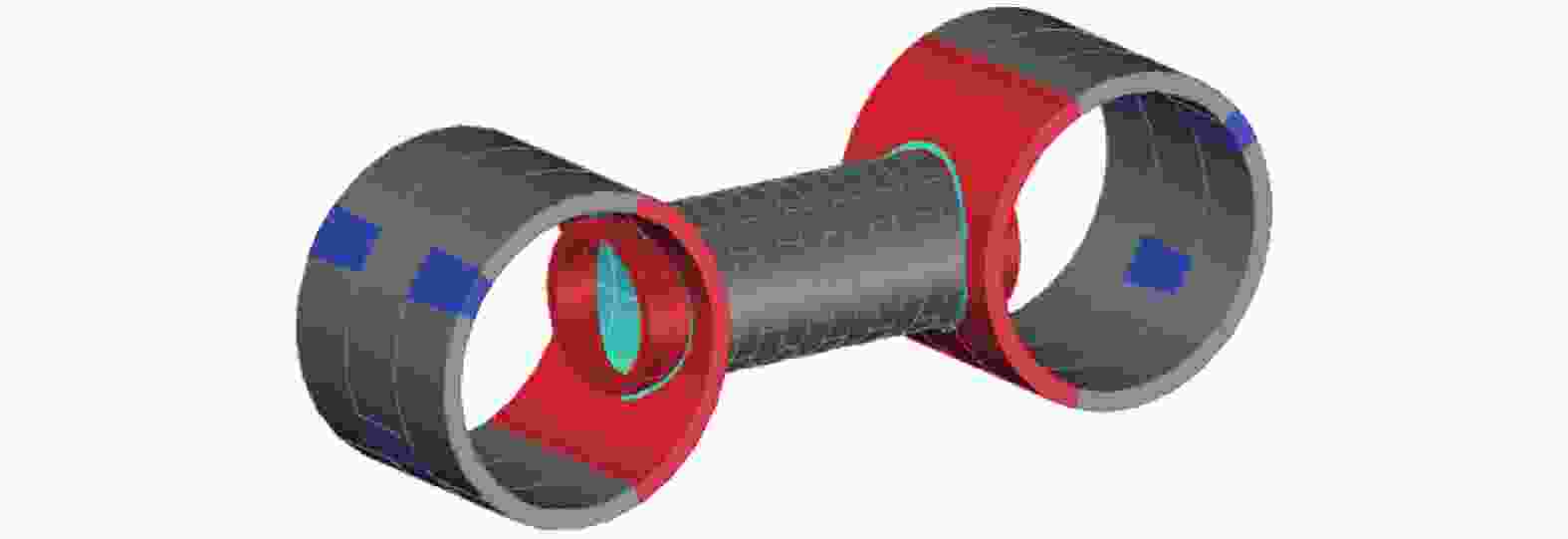

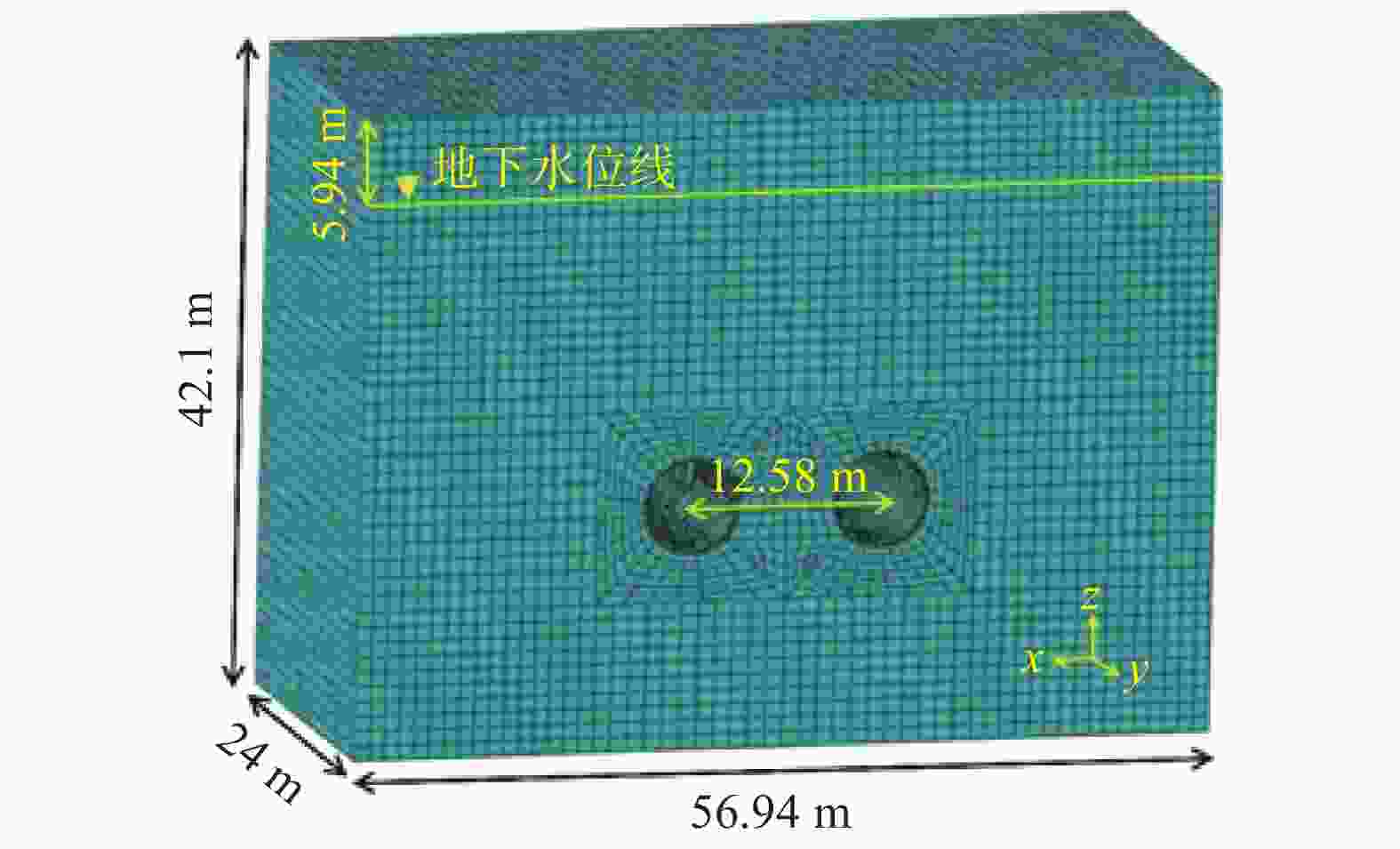

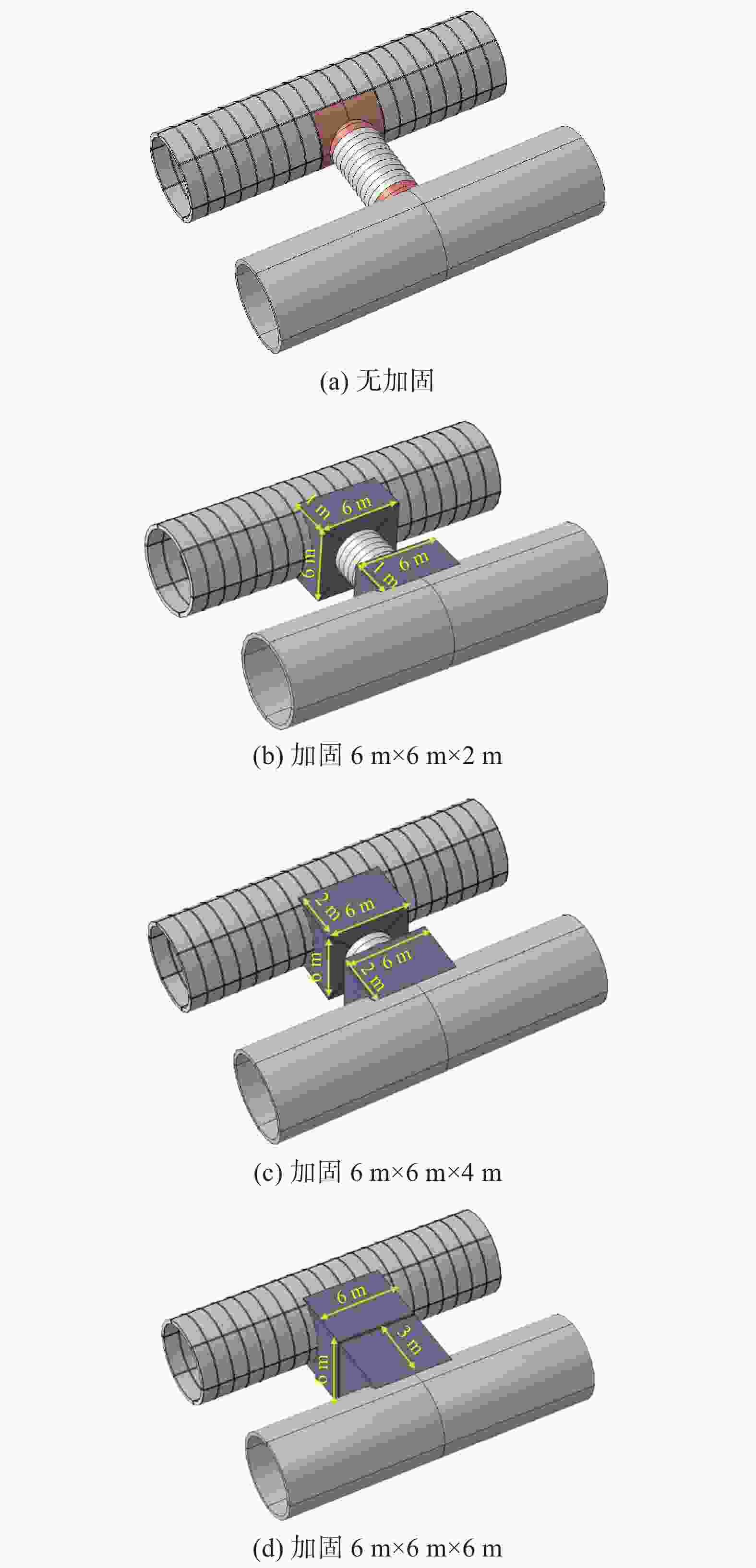

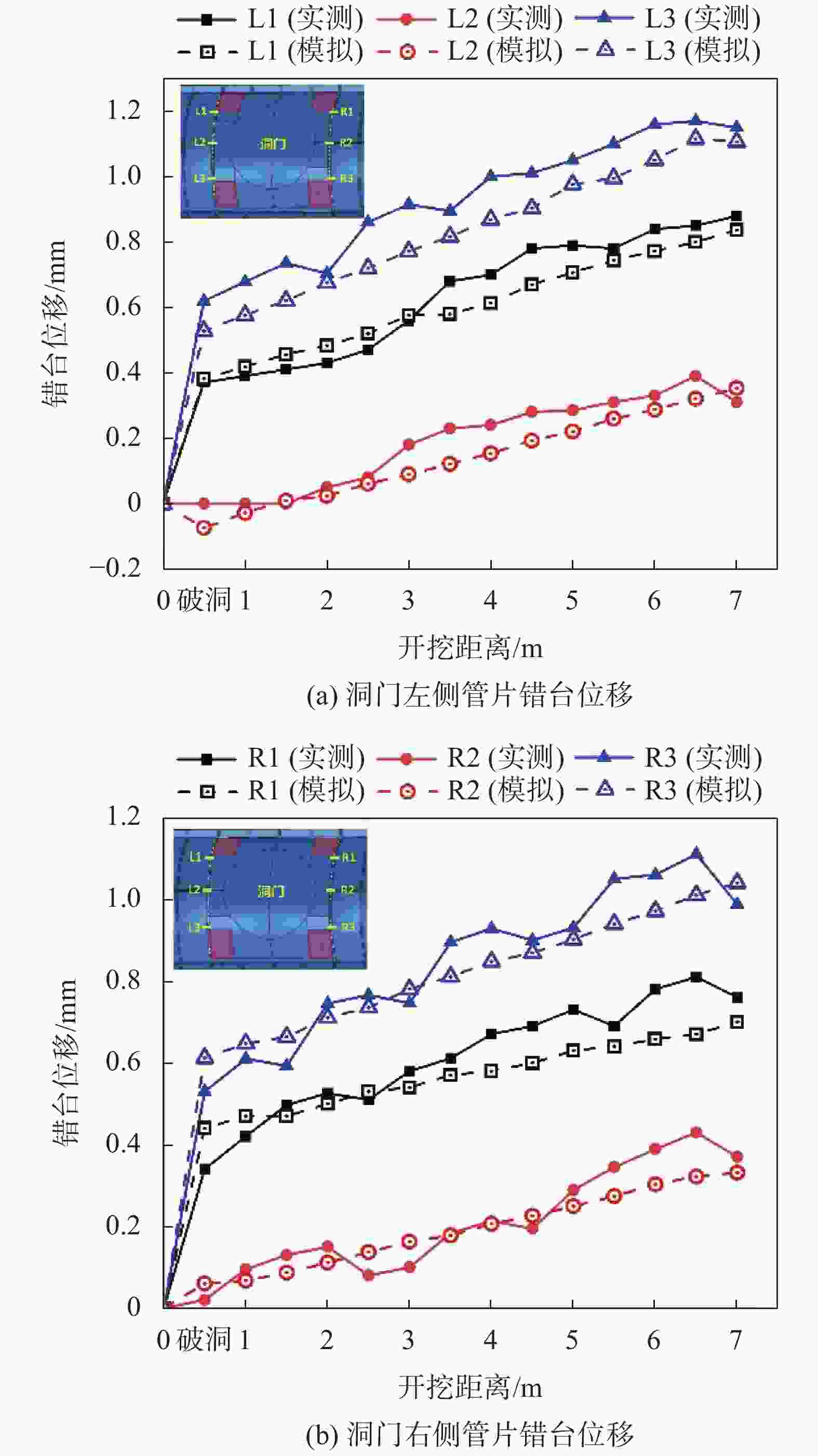

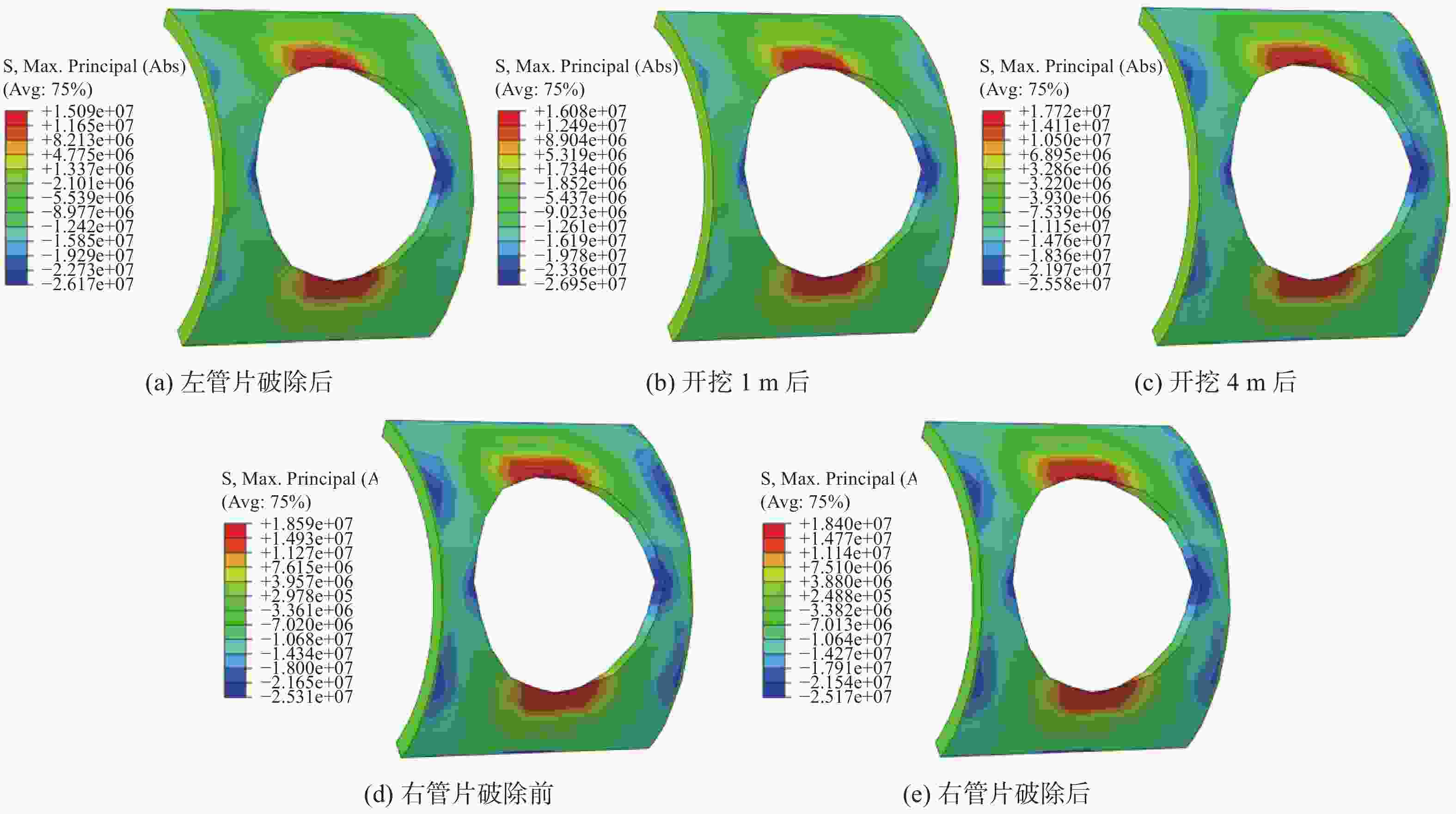

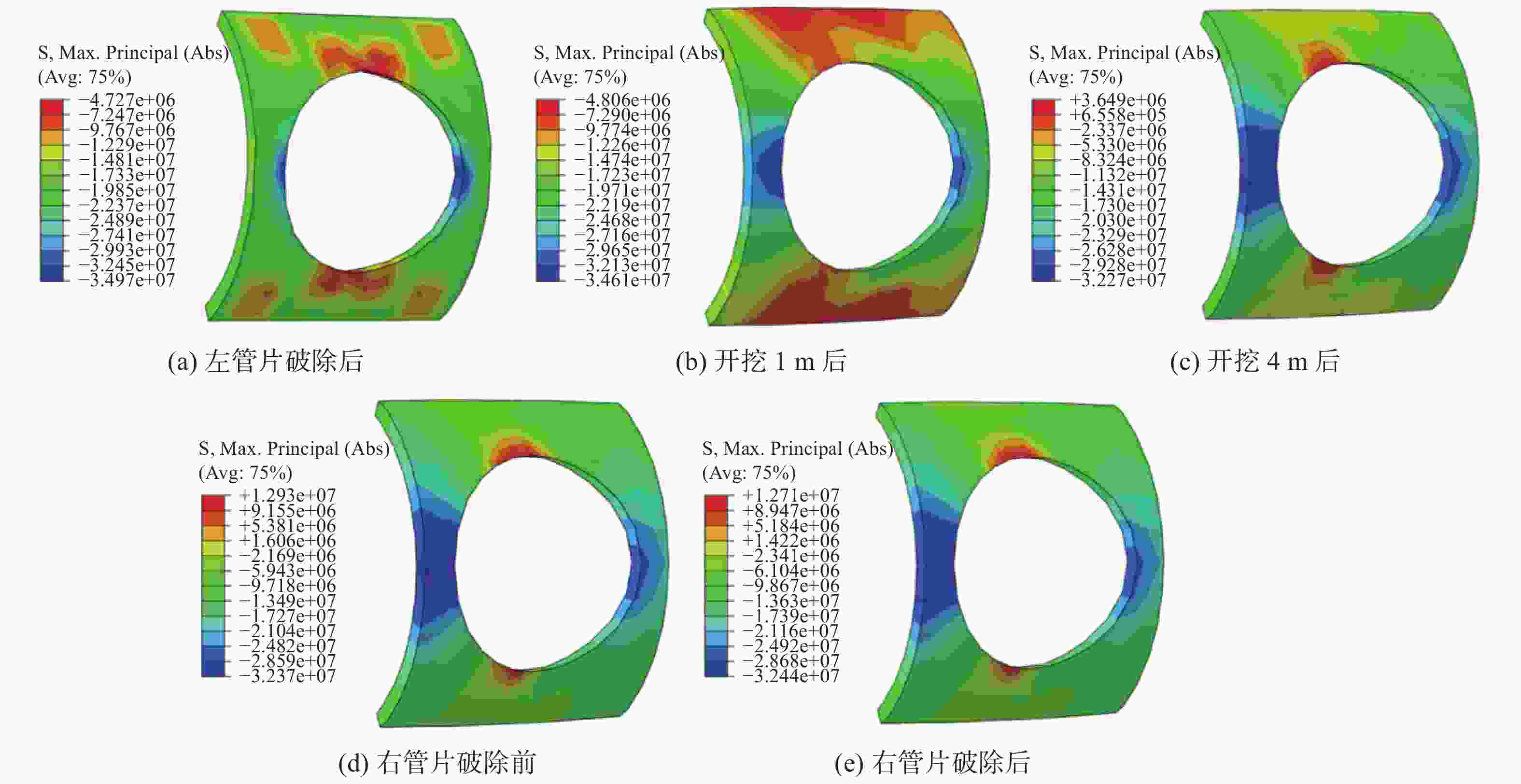

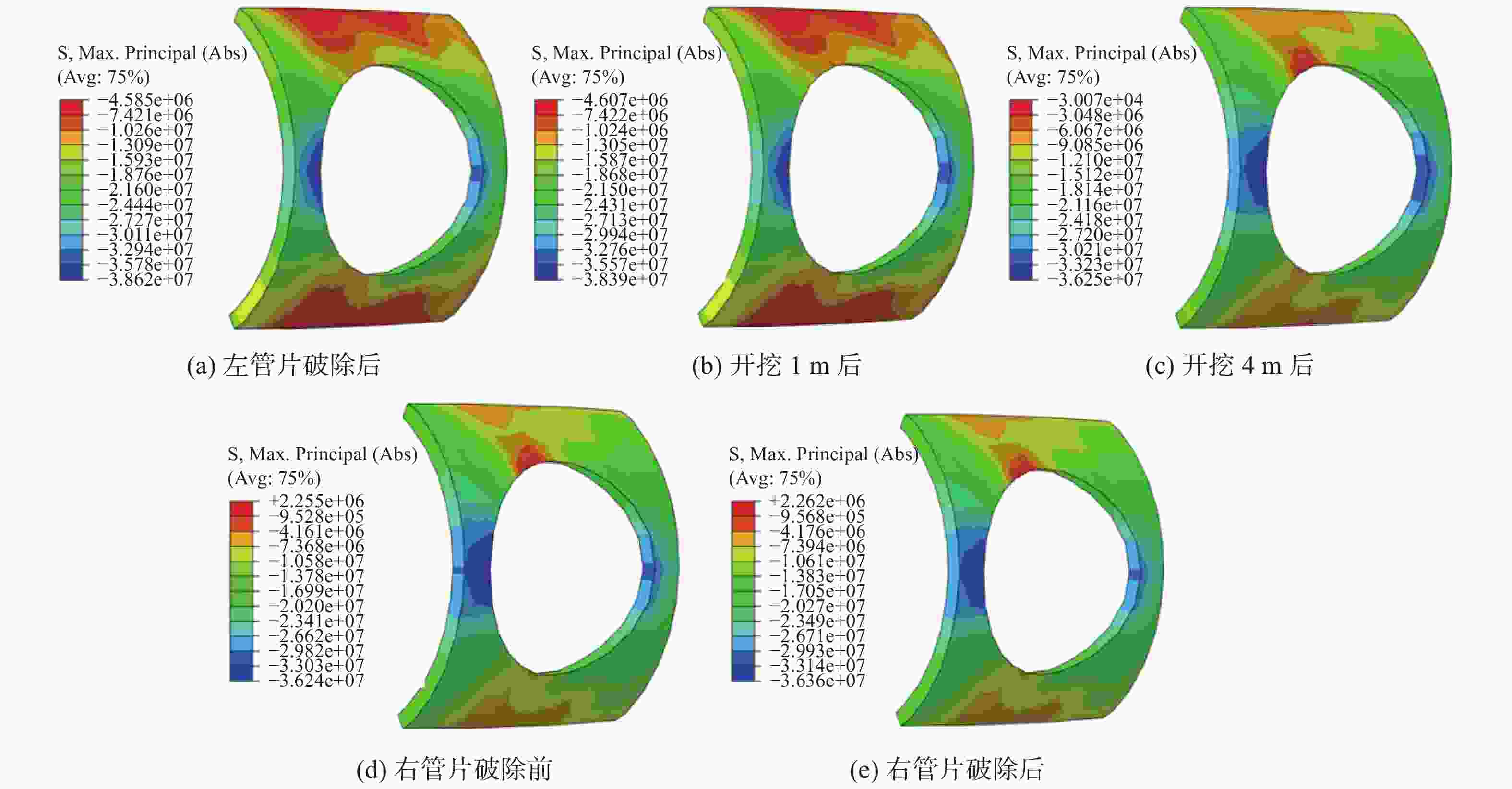

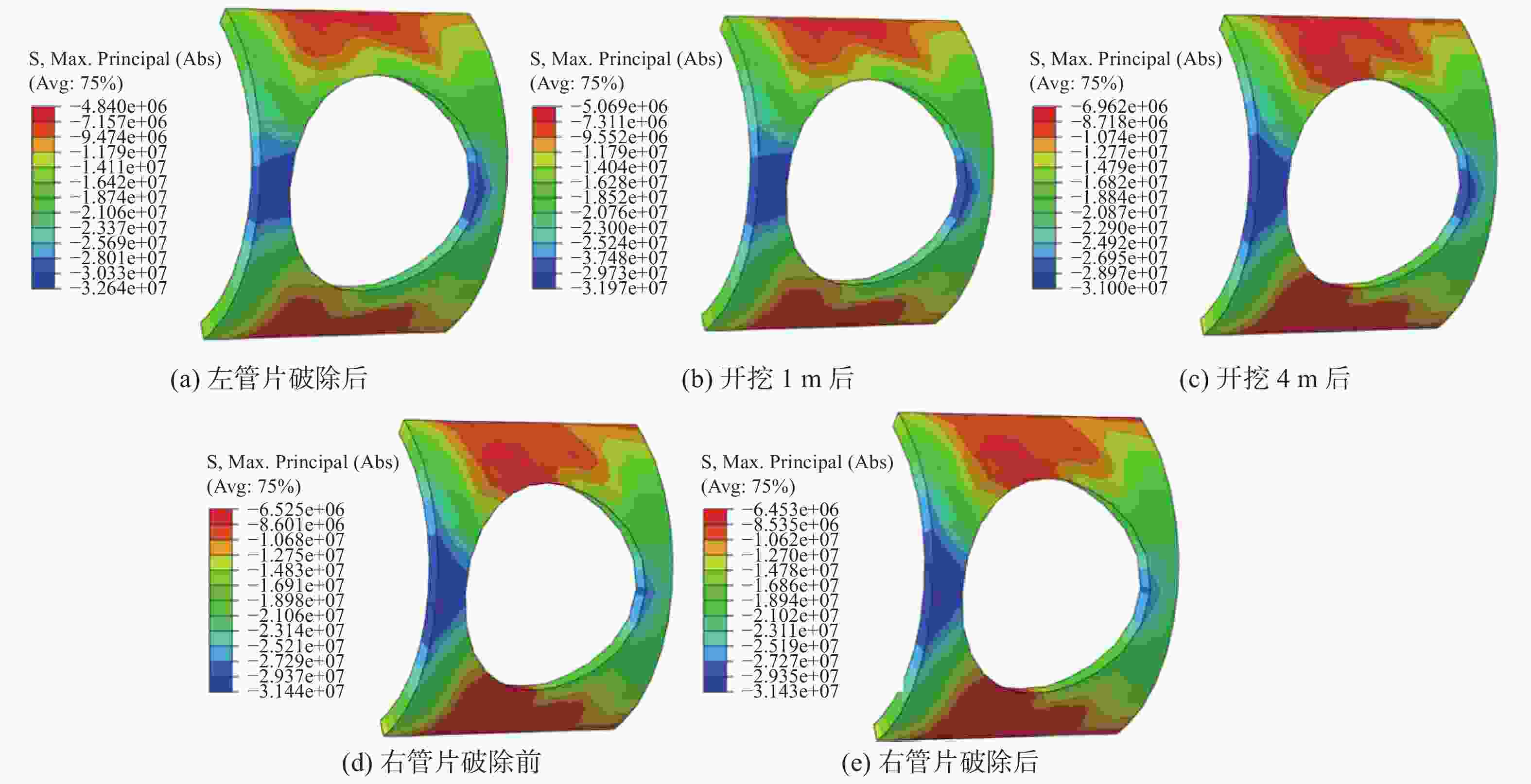

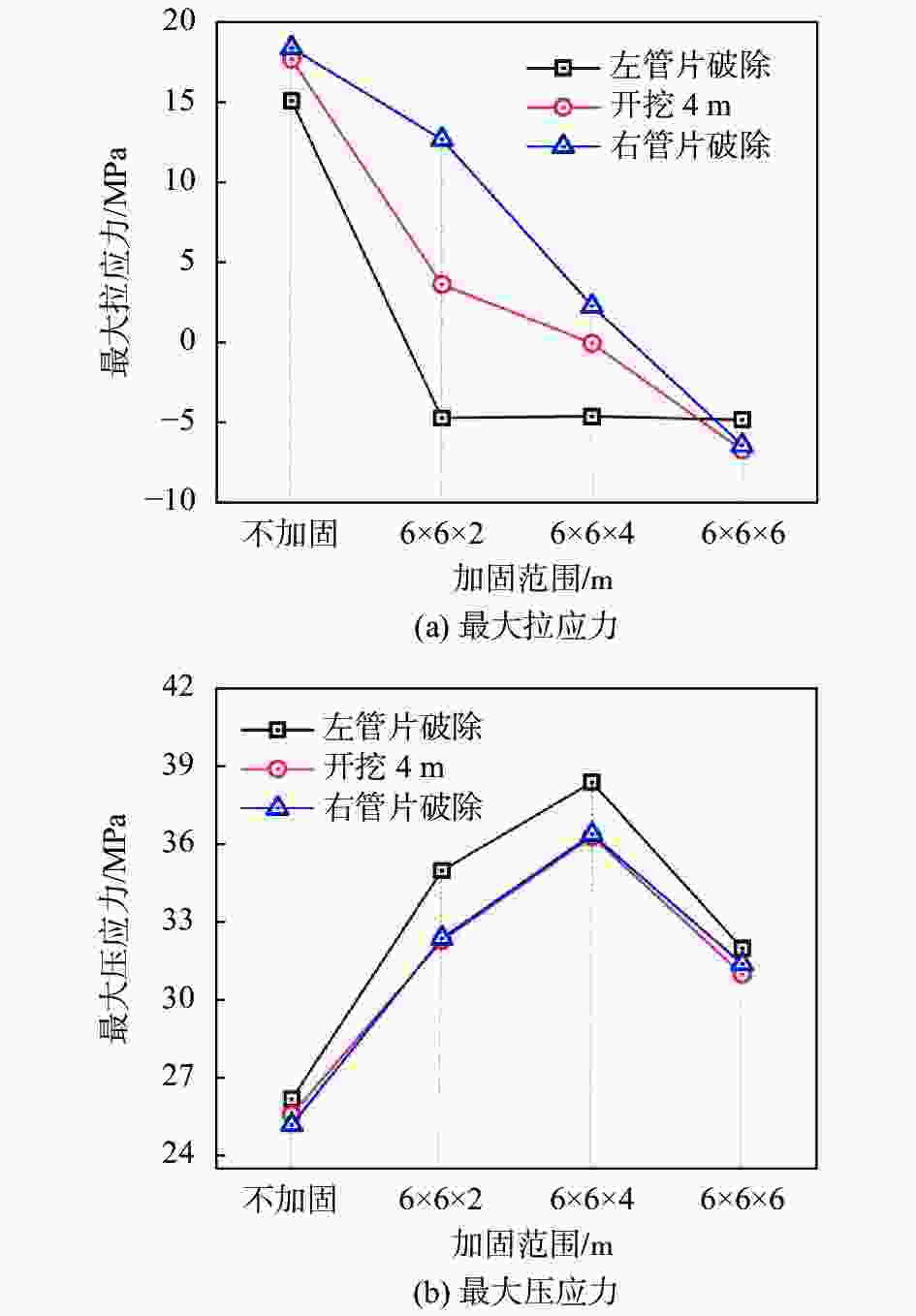

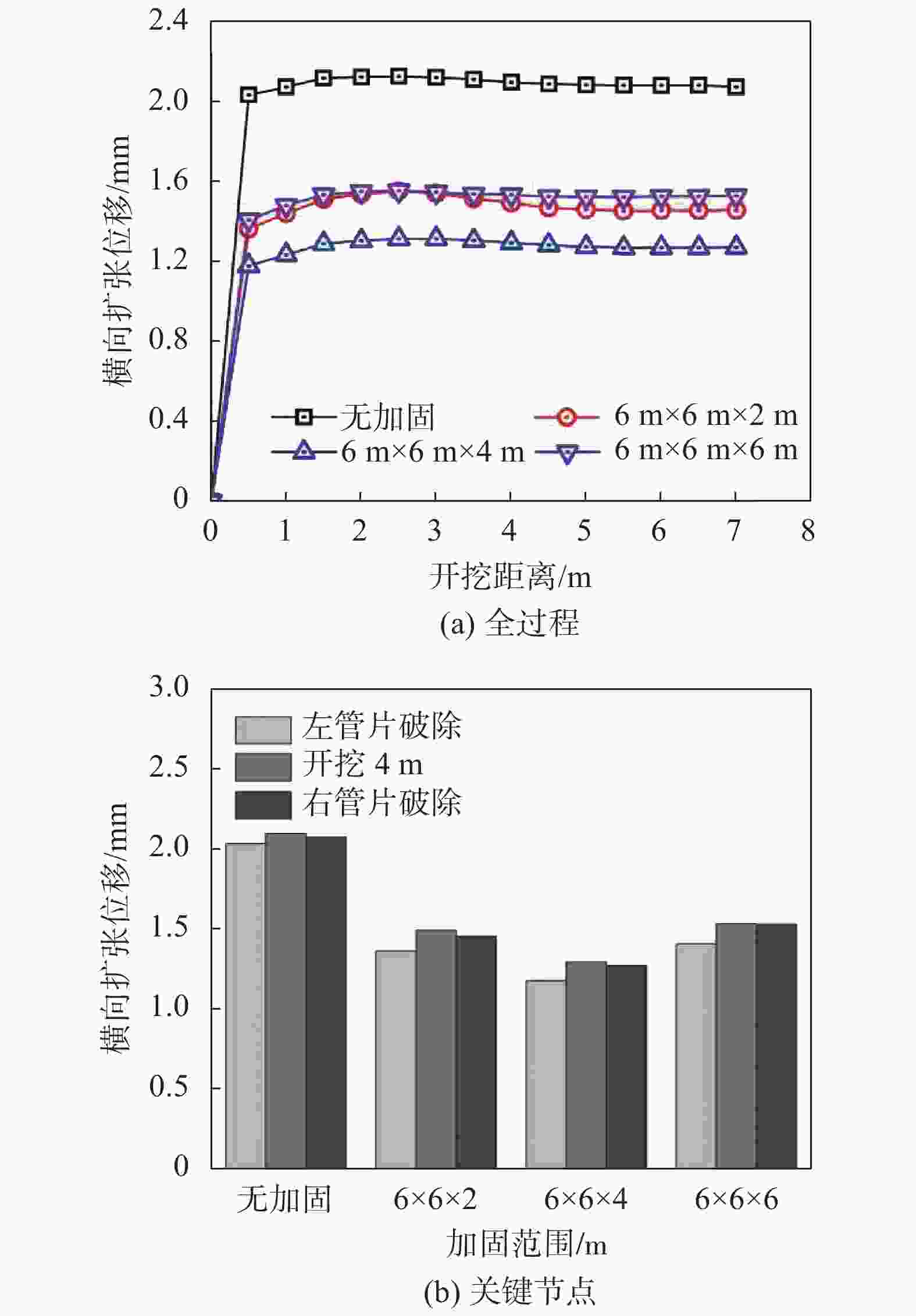

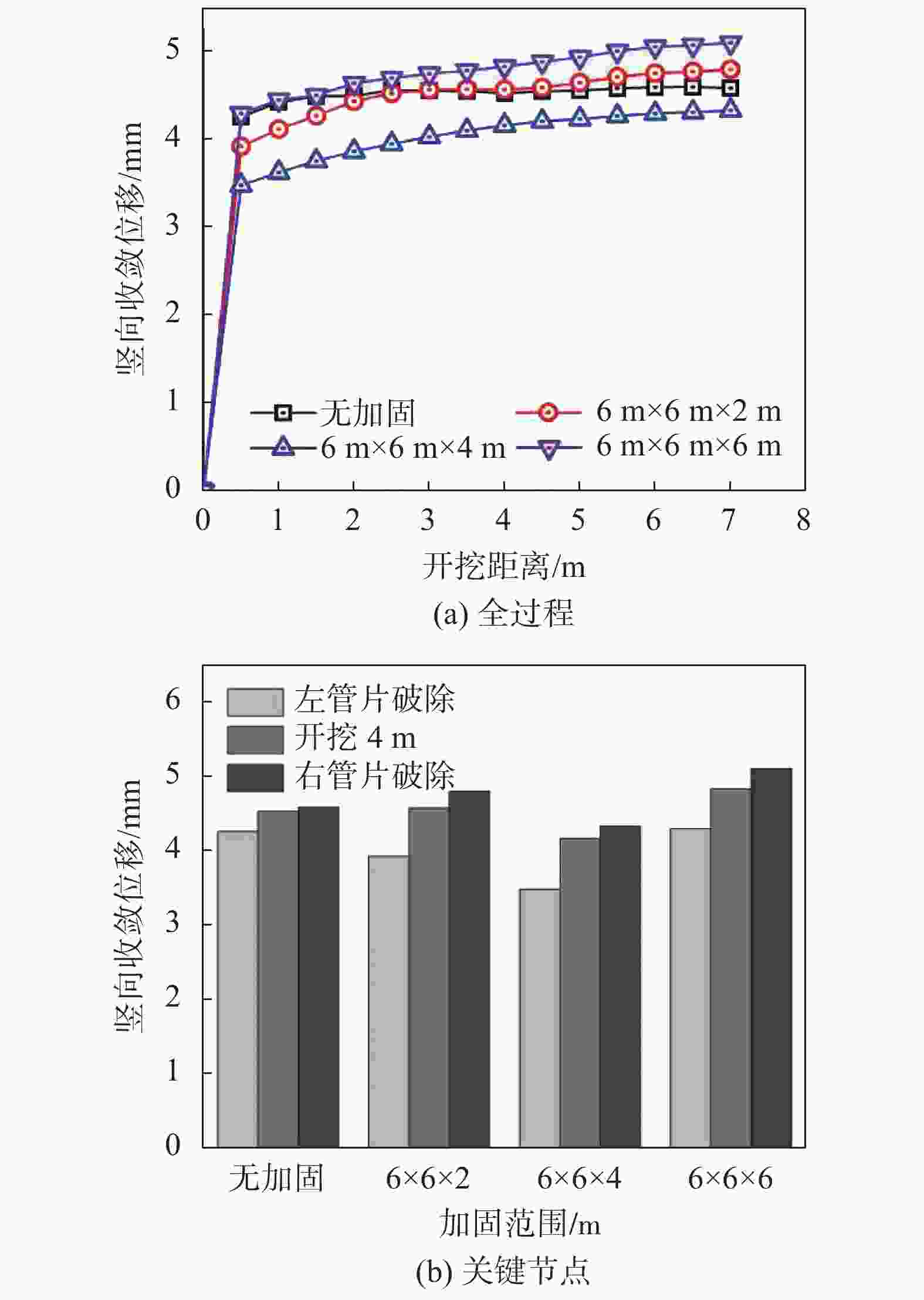

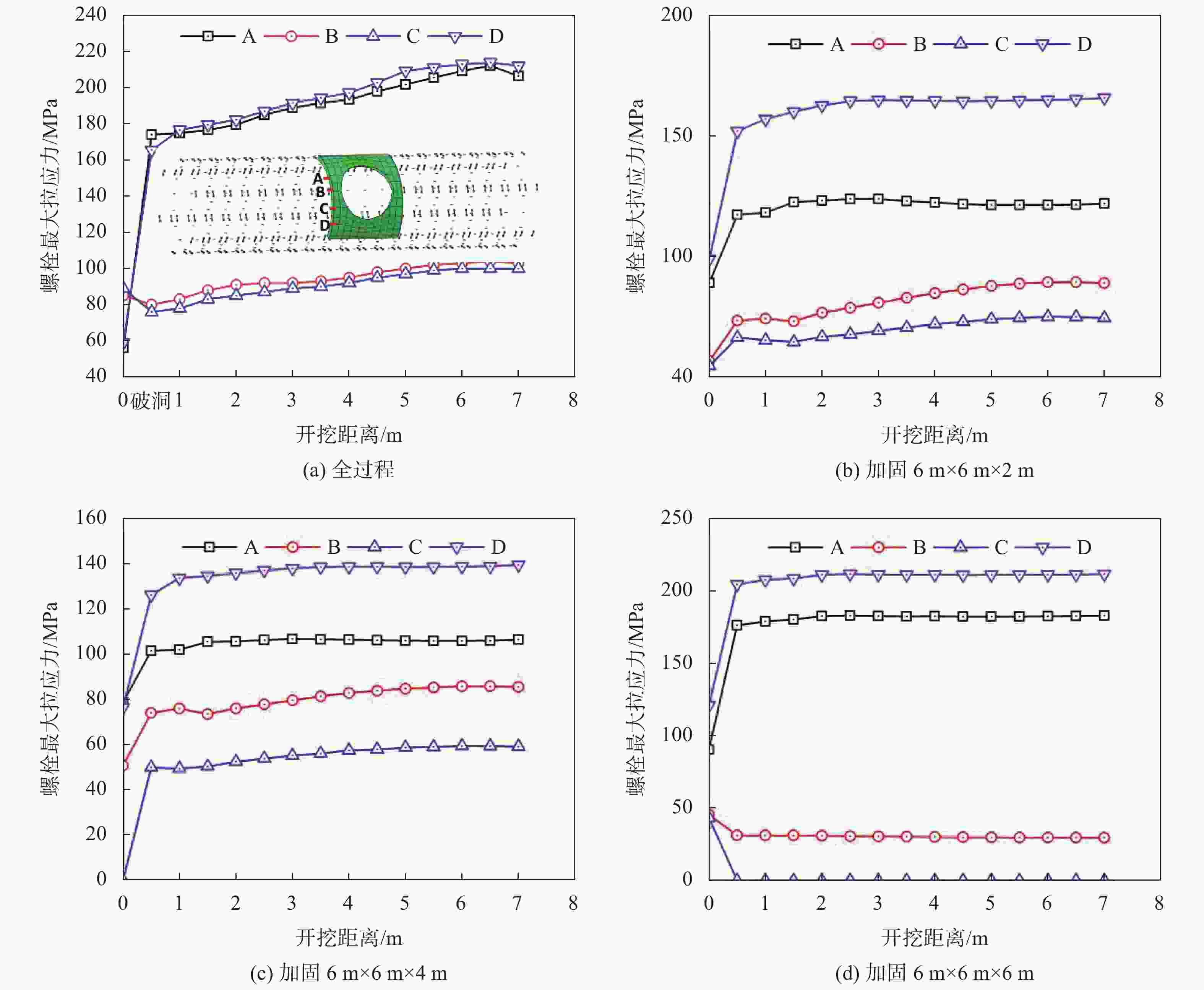

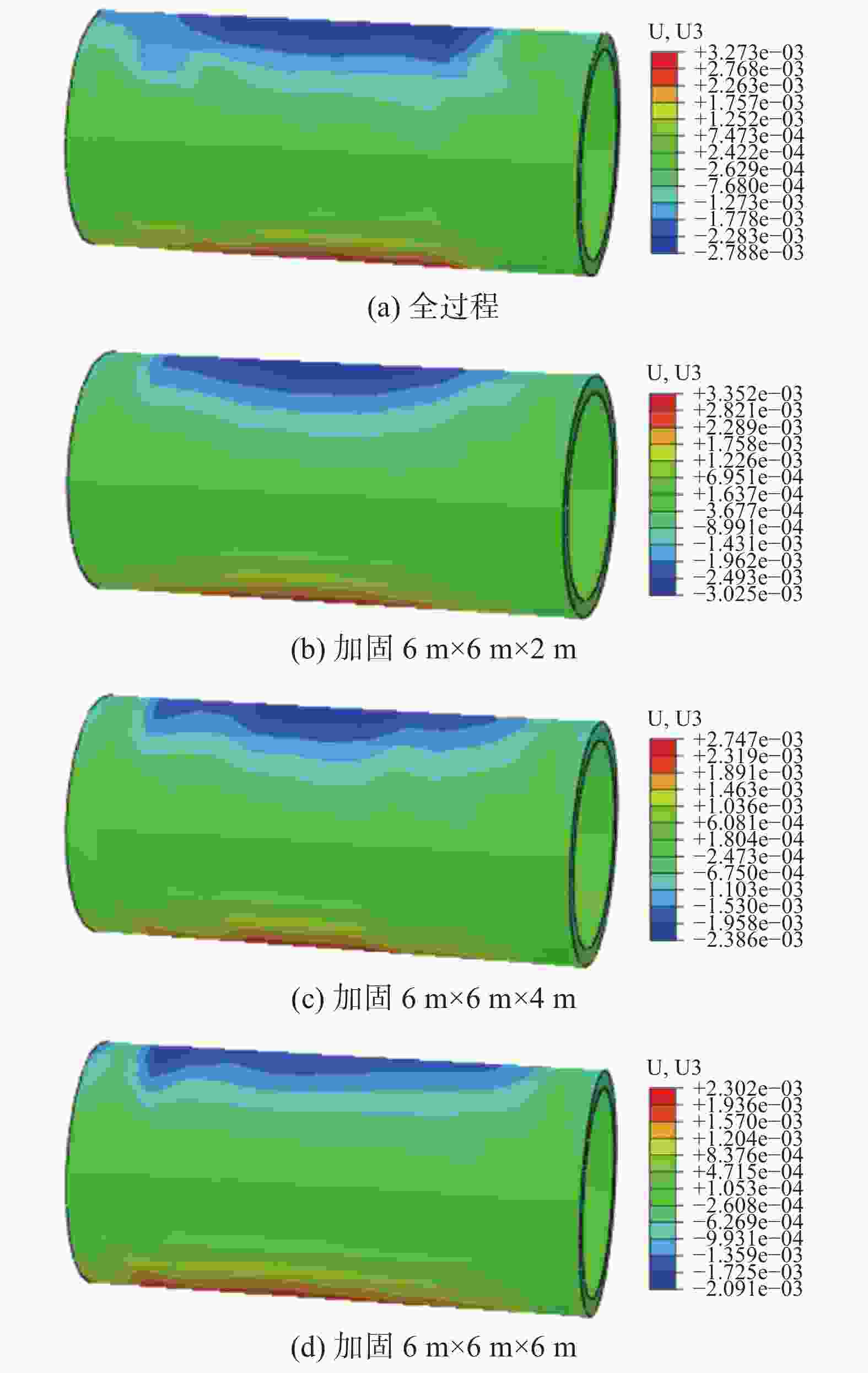

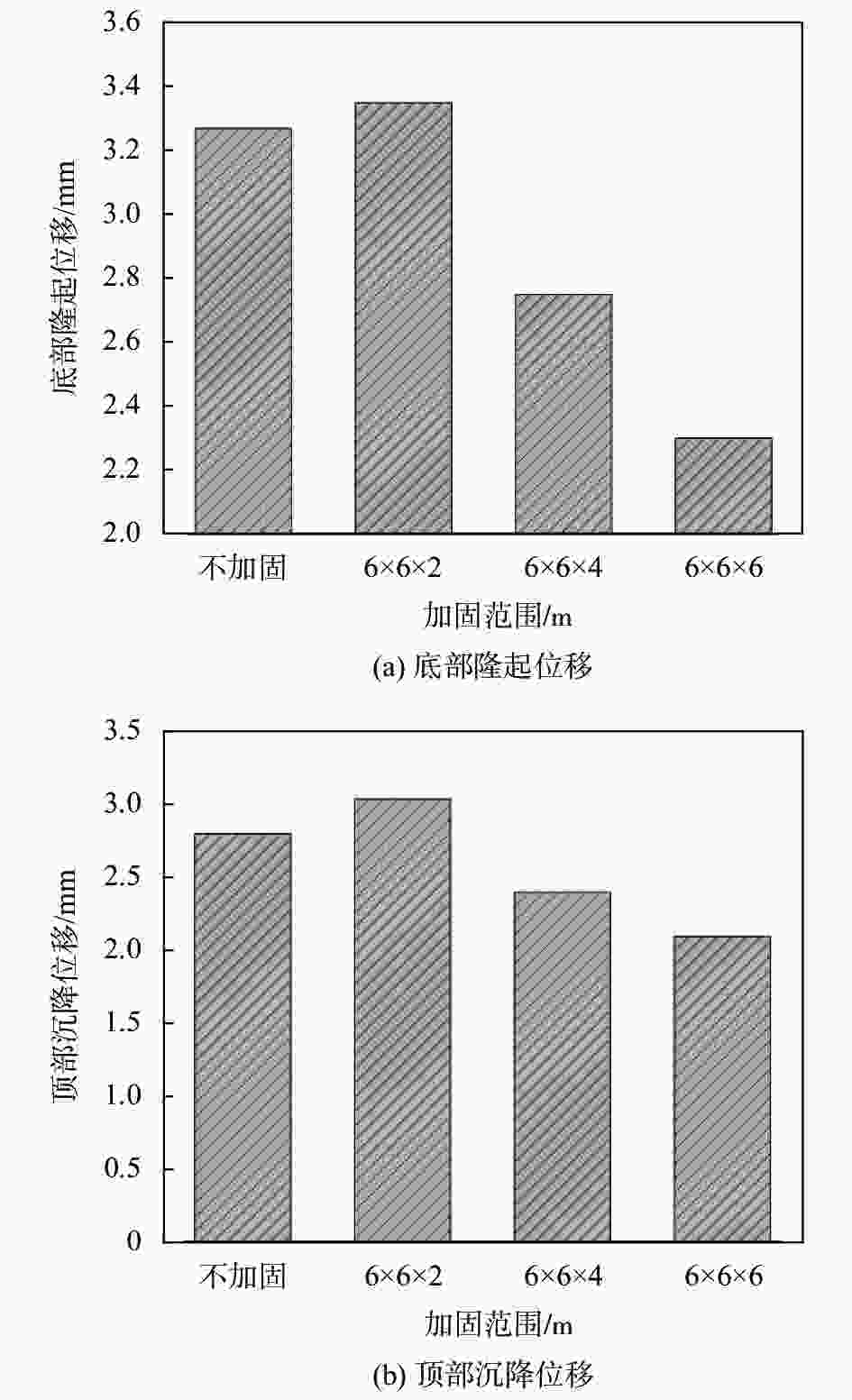

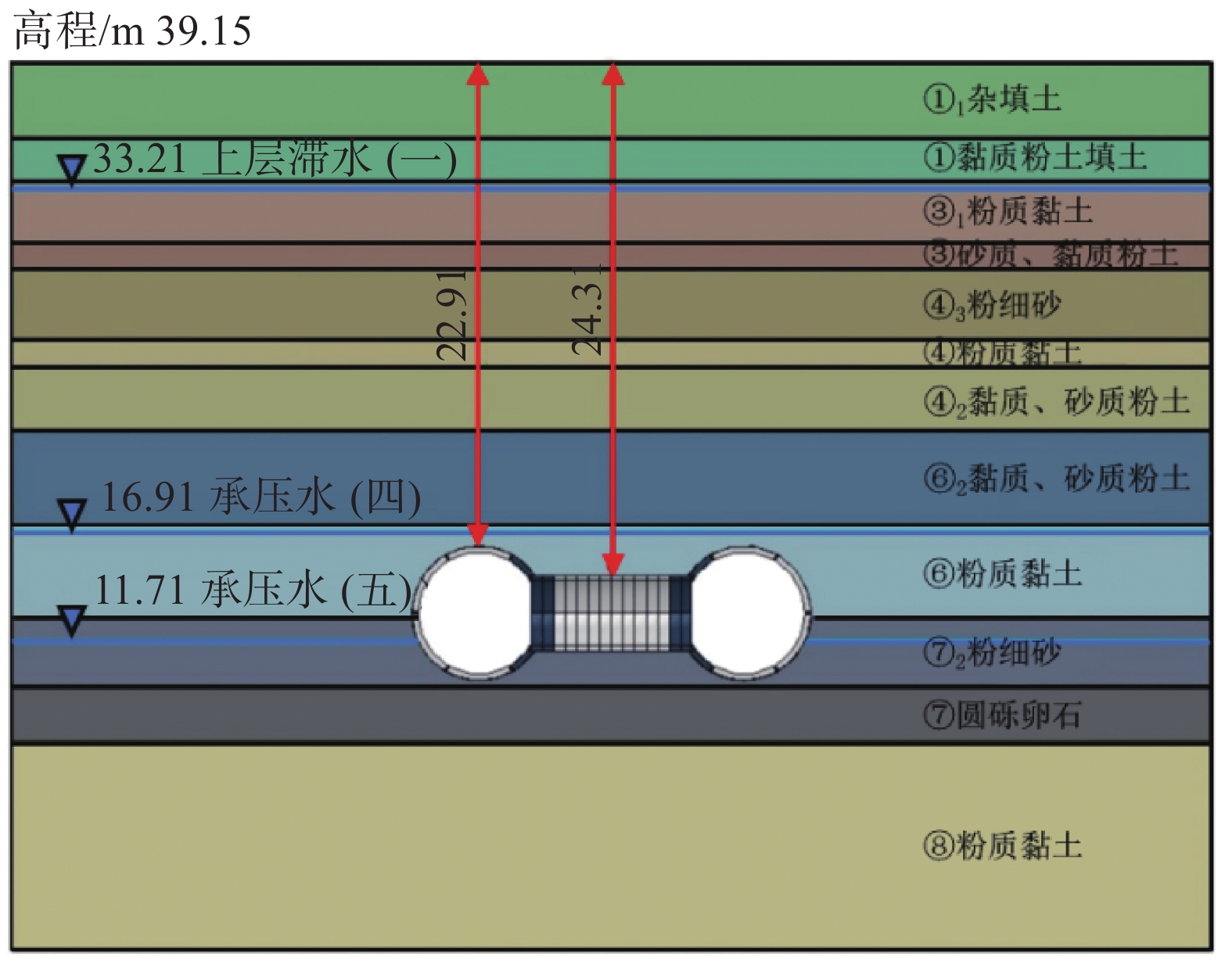

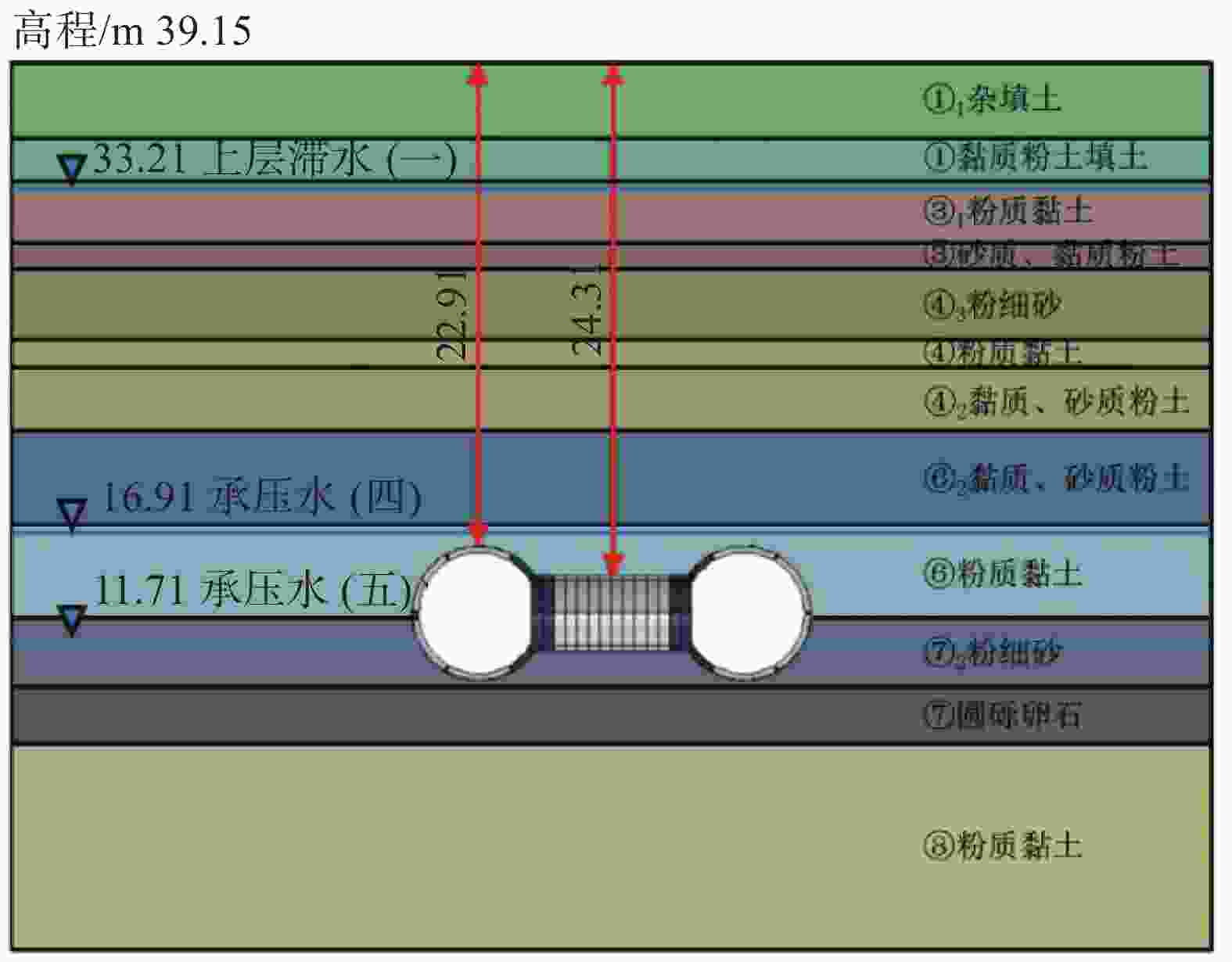

摘要: 深入研究了地铁盾构隧道联络通道施工过程中地层加固范围对主隧道的影响规律。通过数值模拟的方法,全面分析了地层加固范围对主隧道管片总体变形、特殊管片应力及位移、特殊与普通管片间螺栓受力状态等力学行为的影响规律。研究结果表明:(1)进行地层加固可显著降低特殊管片最大拉应力,但会导致其最大压应力明显增大,同时对横向扩张位移与竖向收敛位移控制效果有限;(2)适当地进行地层加固可明显降低螺栓最大拉应力,大幅降低横通道的顶部沉降位移,小幅减小底部隆起位移,有利于横通道整体变形控制;(3)当地层加固范围过大时,螺栓最大拉应力出现显著回升,综合考虑经济性、施工效果等因素,应避免通长加固。Abstract: The influence caused by the reinforcement range of the connecting passage on the main tunnel during the construction process of the connecting passage of subway shield tunnels was investigated. Through numerical simulation, the influence of the reinforcement range of the stratum on the mechanical behavior of the main tunnel segment, such as the overall deformation of the main tunnel segment, the stress and displacement of the special segment, and the stress state of the bolts between the special and ordinary segments, was comprehensively analyzed. The results show that: (1) Ground reinforcement can significantly reduce the maximum tensile stress of special segments, but it will significantly increase the maximum compressive stress, and the control effect on lateral expansion displacement and vertical convergence displacement was limited. (2) Proper reinforcement can significantly reduce the maximum tensile stress of the bolt, greatly reduce the top settlement displacement of the transverse channel, and slightly reduce the bottom uplift displacement, which is conducive to the overall deformation control of the transverse channel. However, when the reinforcement range is too large, the maximum tensile stress of the bolt rises significantly. Considering the factors such as the economy and construction effect, full-length reinforcement should be avoided.

-

Key words:

- subway shield tunnel /

- connecting passage /

- reinforcement range /

- numerical simulation

-

表 1 地层力学性能

地层名称 弹性模量

E/MPa泊松比

v黏聚力

c/kPa内摩擦角

$\varphi $/(°)密度

$\rho $/(kg·m−3)①1杂填土 15 0.25 0 10 1600 ①黏质粉土填土 13 0.26 8 10 1650 ③1粉质黏土 4.8 0.34 29 14 1860 ③砂质、黏质粉土 10 0.23 13 26 2000 ④3粉细砂 30 0.29 0 28 2050 ④粉质黏土 9.2 0.43 26 15 2010 ④2黏质、砂质粉土 13 0.26 15 25 2060 ⑥2黏质、砂质粉土 17.3 0.29 14.5 26 2050 ⑥粉质黏土 11.9 0.26 27 15 1980 ⑦2粉细砂 35 0.28 0 30 2050 ⑦圆砾卵石 55 0.23 0 40 2150 ⑧粉质黏土 15.8 0.31 28 16 1950 表 2 材料力学性能

名称 弹性模量

/MPa密度

/(kg·m−3)屈服强度

/MPa极限强度

/MPaC50混凝土 34500 2400 Q235B管片 200000 7850 235 420 M24螺栓 210000 7850 640 800 -

[1] 卫佳莺, 马永政, 莫振泽, 等. 机械法联络通道T接施工地层隆沉变化特征研究——以无锡地铁3号线顶管法联络通道T接施工示范工程为例[J]. 隧道建设(中英文),2020,40(S2):136-143. (WEI J Y, MA Y Z, MO Z Z, et al. Study on influence of ground settlement in T-joint connecting passage with mechanical pipe jacking method: With the example of the demonstration project of T-joint construction of connecting passage with pipe jacking method in Wuxi Metro Line 3[J]. Tunnel Construction,2020,40(S2):136-143. (in Chinese)WEI J Y, MA Y Z, MO Z Z, et al. Study on influence of ground settlement in T-joint connecting passage with mechanical pipe jacking method: With the example of the demonstration project of T-joint construction of connecting passage with pipe jacking method in Wuxi Metro Line 3[J]. Tunnel Construction, 2020, 40(S2): 136-143. (in Chinese) [2] 胡 威, 黄 强, 李海波, 等. 机械法联络通道施工对T接部位沉降影响的实测与数值分析[J]. 施工技术(中英文),2022,51(13):68-74,80. (HU W, HUANG Q, LI H B, et al. Actual measurement and numerical analysis of influence of mechanical connection channel construction on settlement of T-junction[J]. Construction Technology,2022,51(13):68-74,80. (in Chinese)HU W, HUANG Q, LI H B, et al. Actual measurement and numerical analysis of influence of mechanical connection channel construction on settlement of T-junction[J]. Construction Technology, 2022, 51(13): 68-74,80. (in Chinese) [3] 丁剑敏, 董子博, 莫振泽, 等. 顶管法T接隧道现场试验研究分析[J]. 隧道建设(中英文),2020,40(1):28-34. (DING J M, DONG Z B, MO Z Z, et al. Field Experimental study on t-connected tunnel with pipe jacking method[J]. Tunnel Construction,2020,40(1):28-34. (in Chinese)DING J M, DONG Z B, MO Z Z, et al. Field Experimental study on t-connected tunnel with pipe jacking method[J]. Tunnel Construction, 2020, 40(1): 28-34. (in Chinese) [4] 刘明高, 马连友, 陆 平, 等. 超大直径盾构隧道机械法施工联络通道结构力学响应分析[J]. 特种结构,2021,38(5):106-111. (LIU G M, MA L Y, LU P, et al. Structural mechanical response impact of cross-passages mechanical construction on super-large diameter shield tunnel[J]. Special Structures,2021,38(5):106-111. (in Chinese)LIU G M, MA L Y, LU P, et al. Structural mechanical response impact of cross-passages mechanical construction on super-large diameter shield tunnel[J]. Special Structures, 2021, 38(5): 106-111. (in Chinese) [5] 赵泽昌, 霍永鹏, 李河山, 等. 机械法开挖地铁联络通道的施工力学响应分析[J]. 市政技术,2022,40(1):1-6. (ZHAO Z C, HUO Y P, LI H S, et al. Analysis of mechanical response of metro connecting channel by mechanical construction[J]. Municipal Engineering Technology,2022,40(1):1-6. (in Chinese)ZHAO Z C, HUO Y P, LI H S, et al. Analysis of mechanical response of metro connecting channel by mechanical construction[J]. Municipal Engineering Technology, 2022, 40(1): 1-6. (in Chinese) [6] 张 磊, 李 帆, 张秉鹤, 等. 机械法联络通道主隧道特殊管片结构安全性数值分析[J]. 施工技术(中英文),2022,51(10):29-34. (ZHANG L, LI F, ZHANG B H, et al. Numerical analysis on safety of special segment structure of main tunnel in mechanical connecting aisle[J]. Construction Technology,2022,51(10):29-34. (in Chinese)ZHANG L, LI F, ZHANG B H, et al. Numerical analysis on safety of special segment structure of main tunnel in mechanical connecting aisle[J]. Construction Technology, 2022, 51(10): 29-34. (in Chinese) [7] 朱瑶宏, 高一民, 董子博, 等. 盾构法T接隧道结构受力现场试验研究——以宁波轨道交通3号线联络通道为例[J]. 隧道建设(中英文),2019,39(11):1759-1768. (ZHU Y H, GAO Y M, DONG Z B, et al. Field test on structural mechanism of T-connected shield tunnel: a case study of connecting passage on Ningbo Metro Line No. 3[J]. Tunnel Construction,2019,39(11):1759-1768. (in Chinese)ZHU Y H, GAO Y M, DONG Z B, et al. Field test on structural mechanism of T-connected shield tunnel: a case study of connecting passage on Ningbo Metro Line No. 3[J]. Tunnel Construction, 2019, 39(11): 1759-1768. (in Chinese) [8] 王 军, 李海峰, 李克金, 等. 盾构隧道联络通道钢管片快速开口施工技术研究[J]. 隧道建设(中英文),2021,41(S2):551-557. (WANG J, LI H F, LI K J, et al. Rapid opening technology of steel pipe sheet for connecting gallery of shield tunnel[J]. Tunnel Construction,2021,41(S2):551-557. (in Chinese)WANG J, LI H F, LI K J, et al. Rapid opening technology of steel pipe sheet for connecting gallery of shield tunnel[J]. Tunnel Construction, 2021, 41(S2): 551-557. (in Chinese) [9] 张付林, 刘正好, 朱瑶宏, 等. 机械法联络通道T接部位受力特性及弱化分析[J]. 岩土工程学报,2022,44(S2):116-119. (ZHANG F L, LIU Z H, ZHU Y H, et al. Stress characteristics and weakening analysis of T-joint of connection passage by mechanical excavation method[J]. Chinese Journal of Geotechnical Engineering,2022,44(S2):116-119. (in Chinese)ZHANG F L, LIU Z H, ZHU Y H, et al. Stress characteristics and weakening analysis of T-joint of connection passage by mechanical excavation method[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(S2): 116-119. (in Chinese) [10] 杨佳栋, 郑荣跃, 郑诗怡, 等. 机械法联络通道T接部位接收端切削模型试验研究[J]. 施工技术(中英文),2022,51(3):12-17. (YANG J D, ZHENG R Y, ZHENG S Y, et al. Experimental study on cutting model of receiving end of T-joint part of mechanical connection channels[J]. Construction Technology,2022,51(3):12-17. (in Chinese)YANG J D, ZHENG R Y, ZHENG S Y, et al. Experimental study on cutting model of receiving end of T-joint part of mechanical connection channels[J]. Construction Technology, 2022, 51(3): 12-17. (in Chinese) [11] 顾沉颖. NOMJS联络通道施工新工艺研究[J]. 隧道建设,2015,35(7):716-720. (GU C Y. NOMJS: A new technology for construction of connection passages of shield-bored tunnels[J]. Tunnel Construction,2015,35(7):716-720. (in Chinese) doi: 10.3973/j.issn.1672-741X.2015.07.016GU C Y. NOMJS: A new technology for construction of connection passages of shield-bored tunnels[J]. Tunnel Construction, 2015, 35(7): 716-720. (in Chinese) doi: 10.3973/j.issn.1672-741X.2015.07.016 [12] 柳 献, 郭振坤, 伍鹏李, 等. 通道开口对超大直径盾构法车站结构力学行为影响研究及结构优化[J]. 土木工程学报,2021,54(7):114-122. (LIU X, GUO Z K, WU P L, et al. Study on influence of passage opening on the mechanical behavior of super large diameter shield tunnel station structure and structural optimization[J]. China Civil Engineering Journal,2021,54(7):114-122. (in Chinese)LIU X, GUO Z K, WU P L, et al. Study on influence of passage opening on the mechanical behavior of super large diameter shield tunnel station structure and structural optimization[J]. China Civil Engineering Journal, 2021, 54(7): 114-122. (in Chinese) [13] 王 龙. 盾构隧道与联络通道交叉部位管片力学行为研究[D]. 石家庄: 石家庄铁道大学, 2018. (WANG L. The mechanical behavior study of intersecting segment of shield tunnel and contact channel[D]. Shijiazhuang: Shijiazhuang Railway University, 2018. (in Chinese)WANG L. The mechanical behavior study of intersecting segment of shield tunnel and contact channel[D]. Shijiazhuang: Shijiazhuang Railway University, 2018. (in Chinese) [14] LU P, YUAN D J, JIN D L, et al. Centrifugal model tests on the structural response of the shield tunnel when constructing cross passages by mechanical methods[J]. Tunnelling and Underground Space Technology,2022,128:104621. doi: 10.1016/j.tust.2022.104621 [15] 张明聚, 康 博, 李鹏飞, 等. 反拉式顶管法施工联络通道对地铁盾构隧道力学性能影响[J]. 隧道建设(中英文),2024,44(6):1165-1173. (ZHANG M J, KANG B, LI P F, et al. Influence of cross-passage construction using front-traction pipe jacking method on mechanical properties of metro shield tunnel[J]. Tunnel Construction,2024,44(6):1165-1173. (in Chinese)ZHANG M J, KANG B, LI P F, et al. Influence of cross-passage construction using front-traction pipe jacking method on mechanical properties of metro shield tunnel[J]. Tunnel Construction, 2024, 44(6): 1165-1173. (in Chinese) -

下载:

下载: