Shape optimization of tunnel section based on the homogenization distribution of surrounding rock strain energy

-

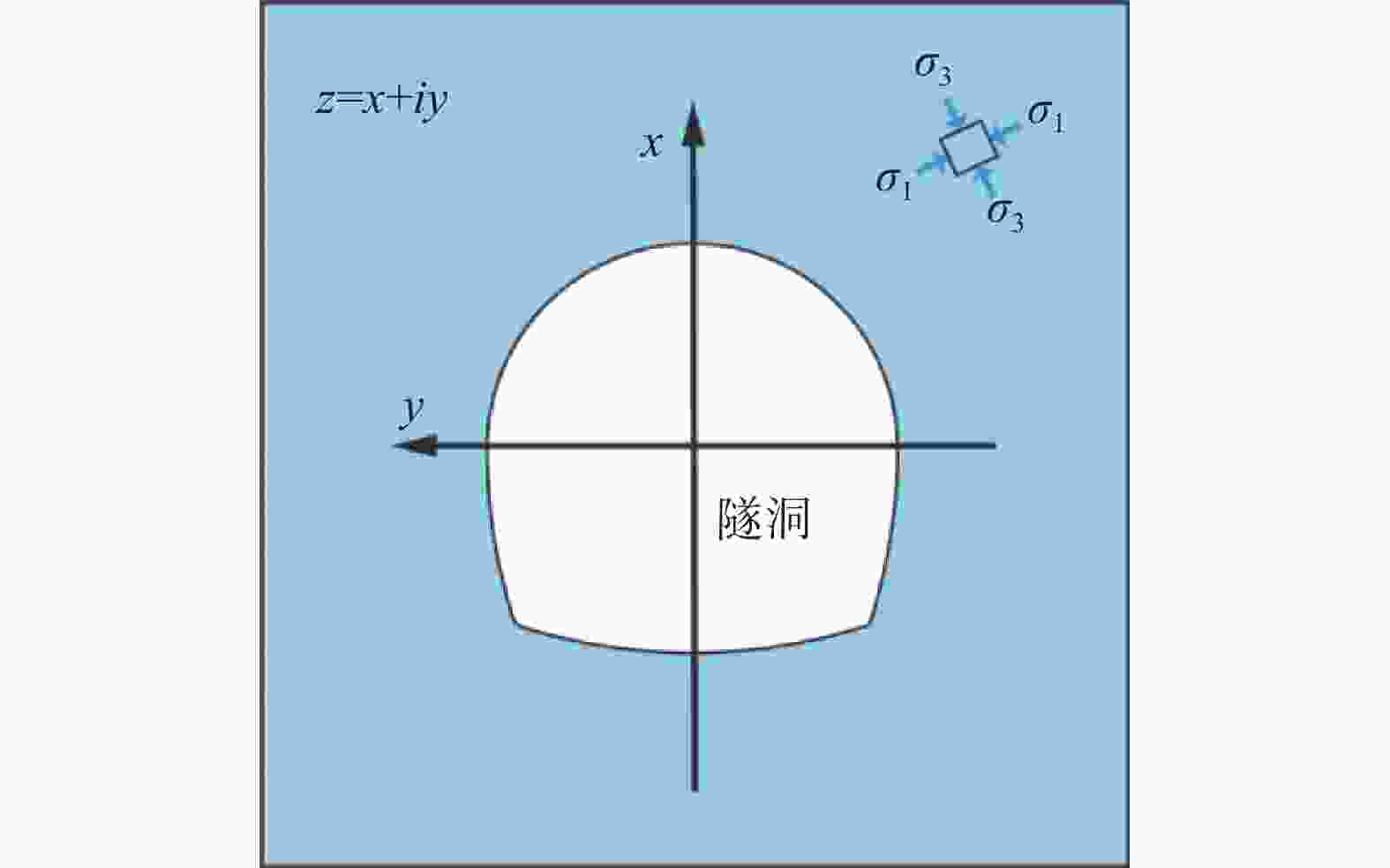

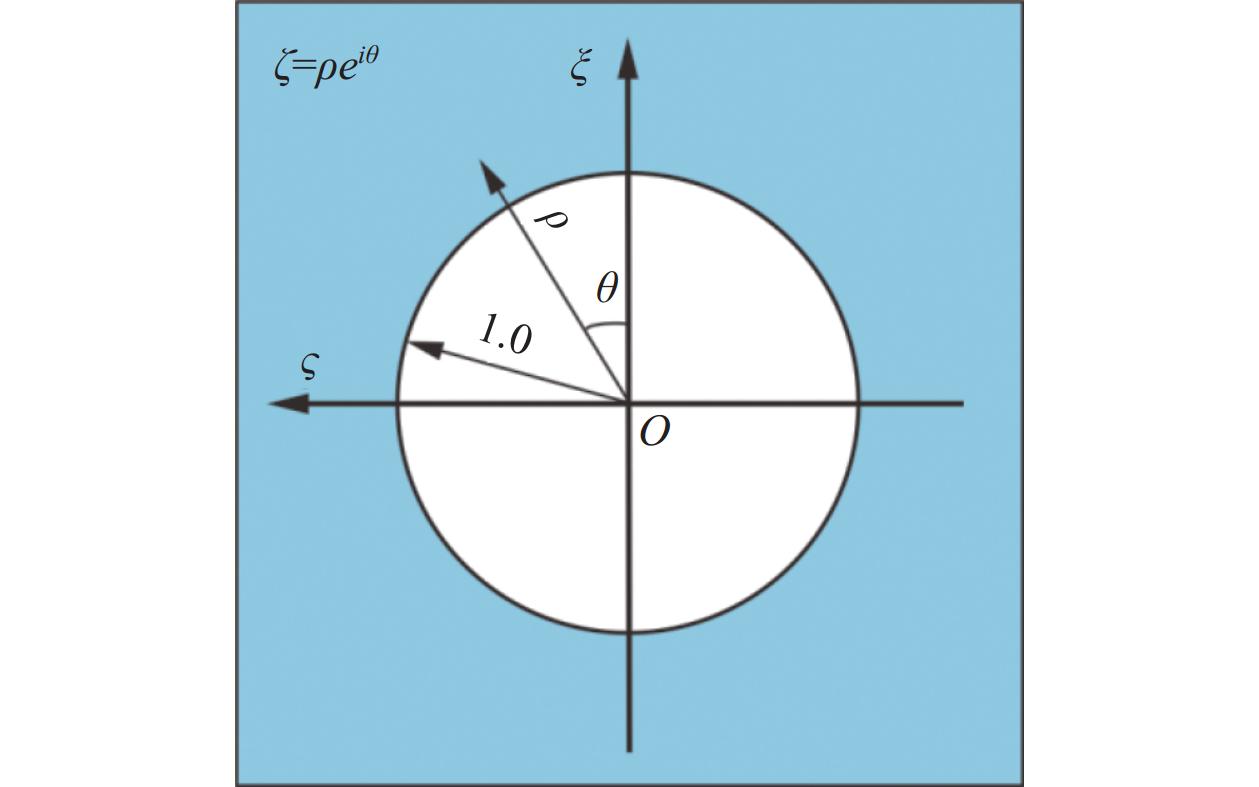

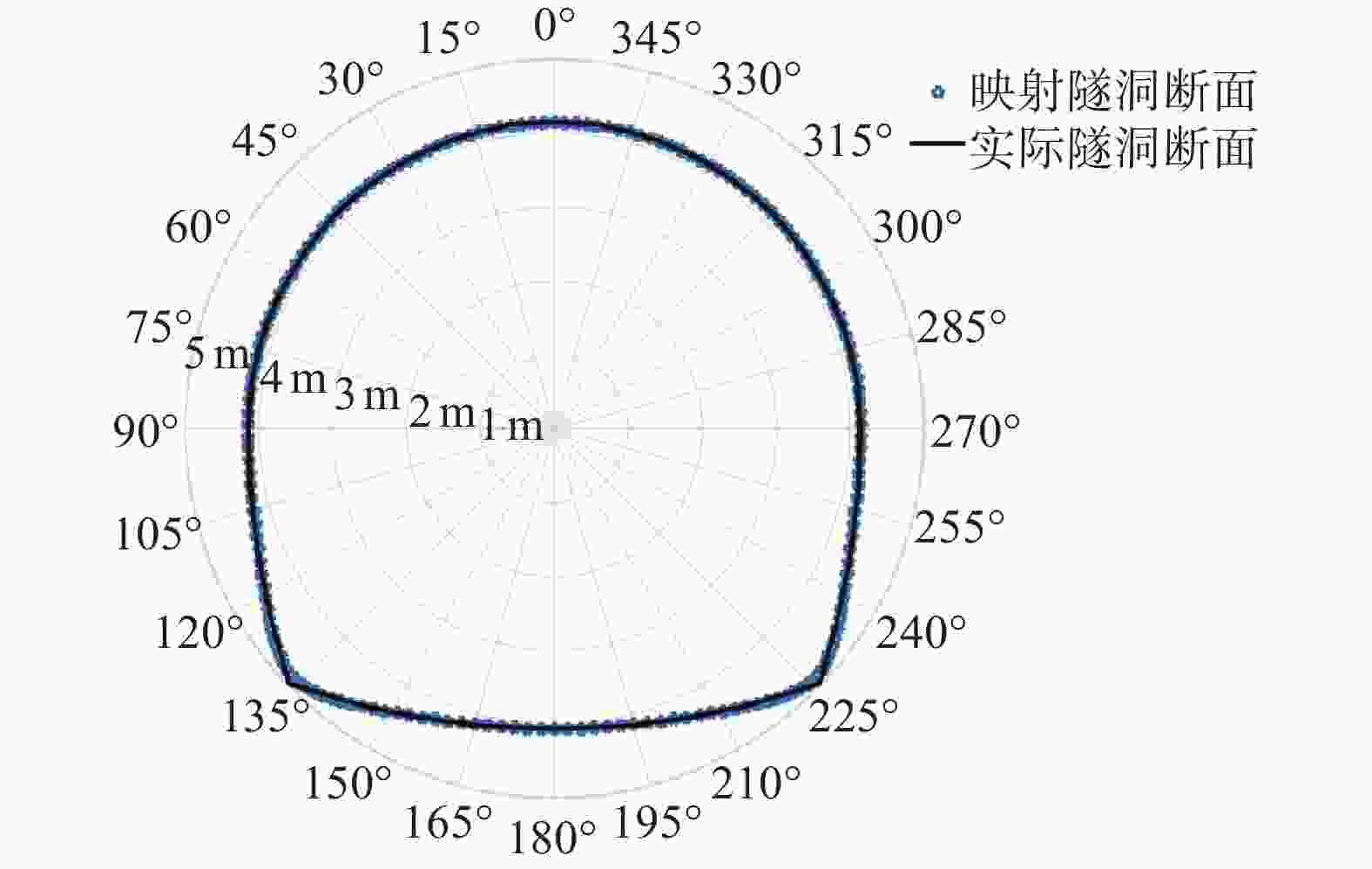

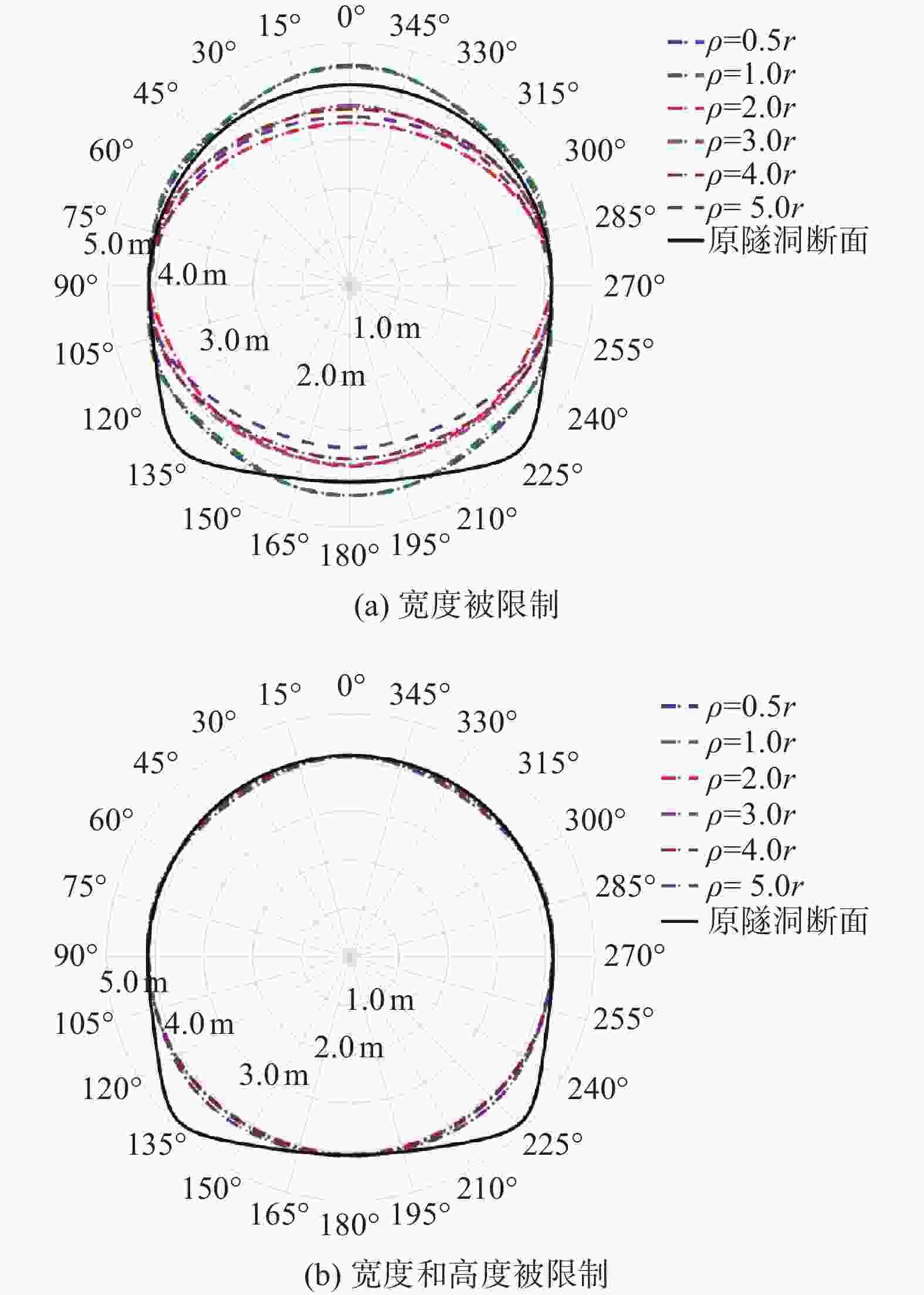

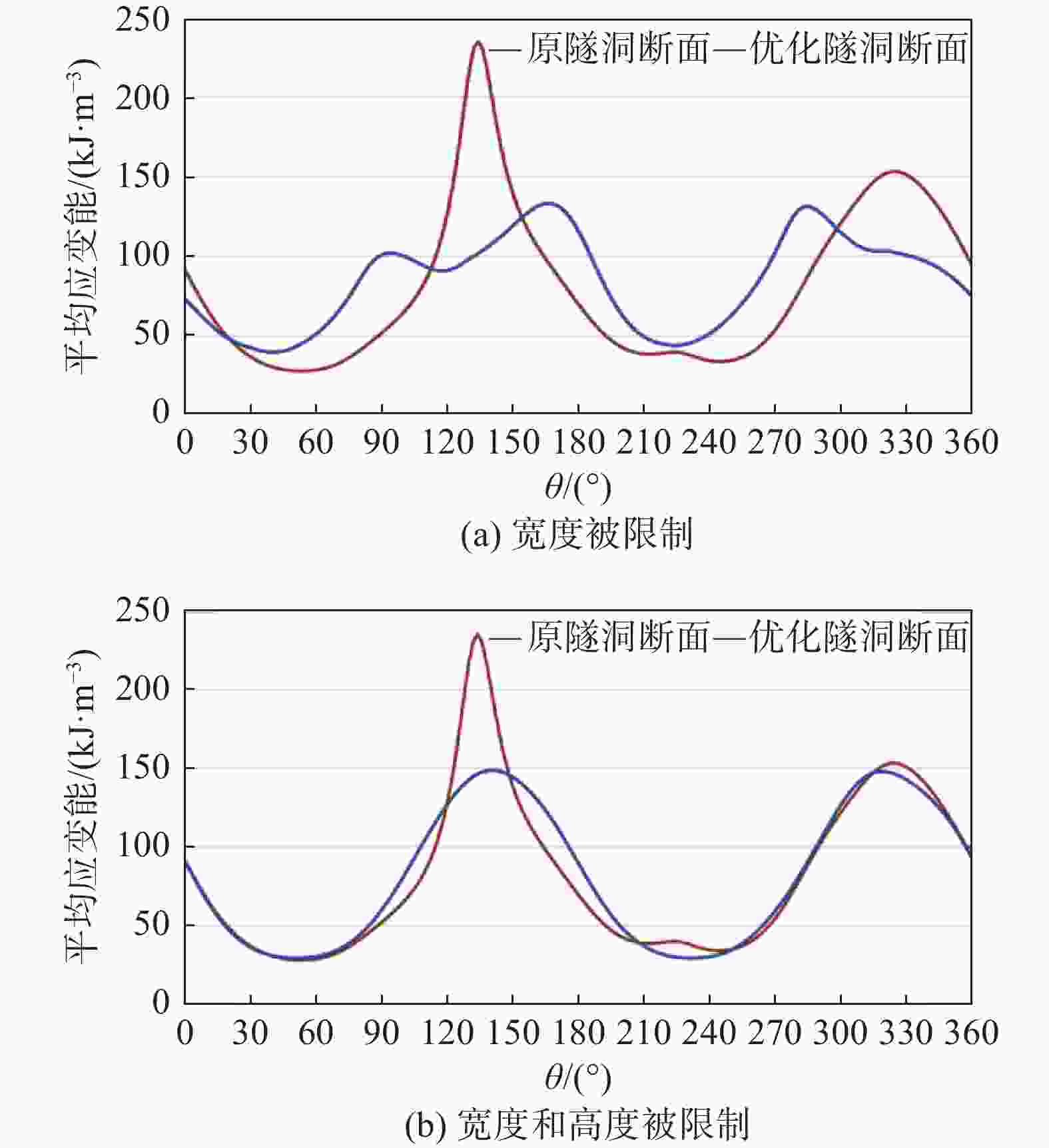

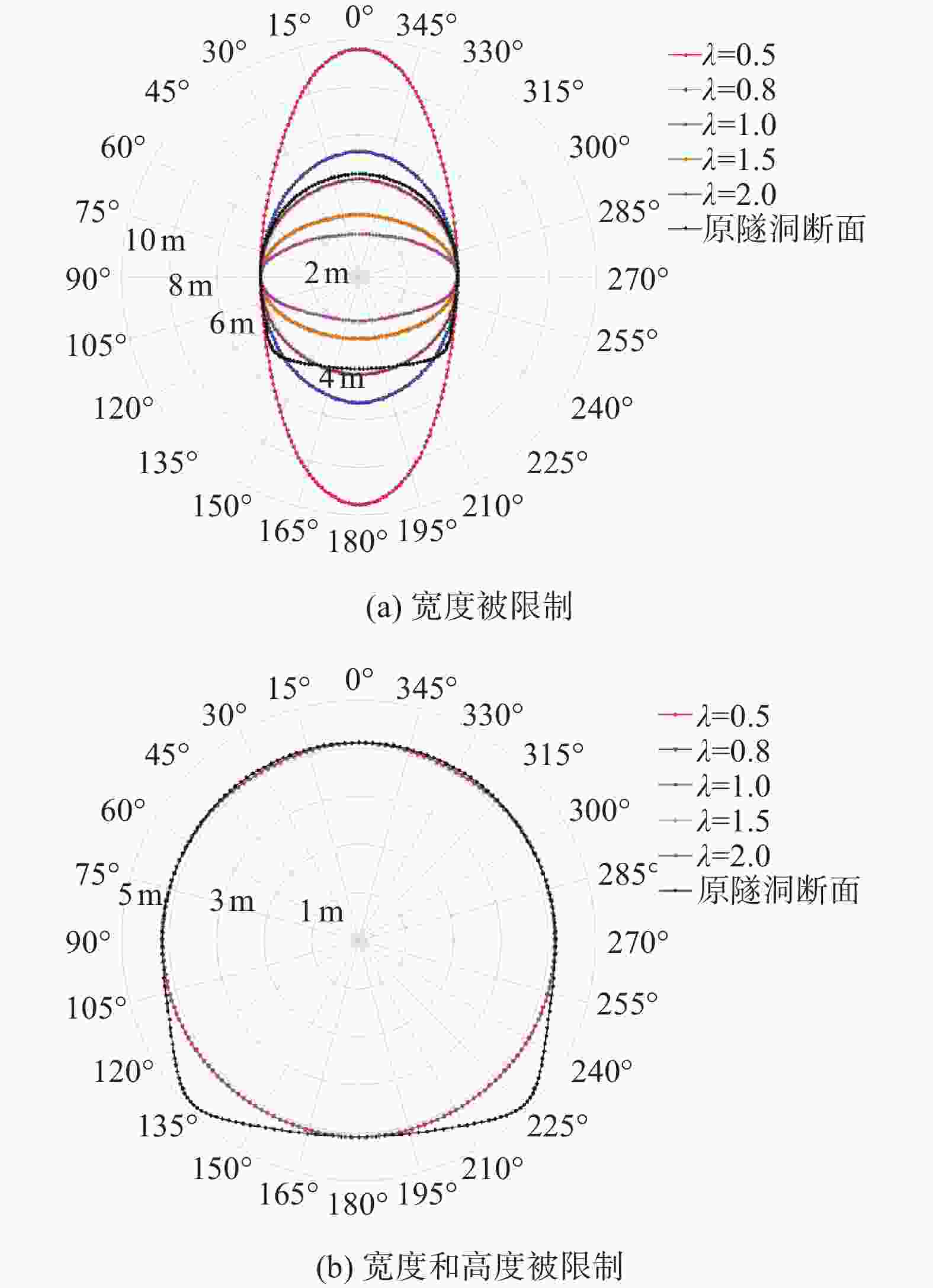

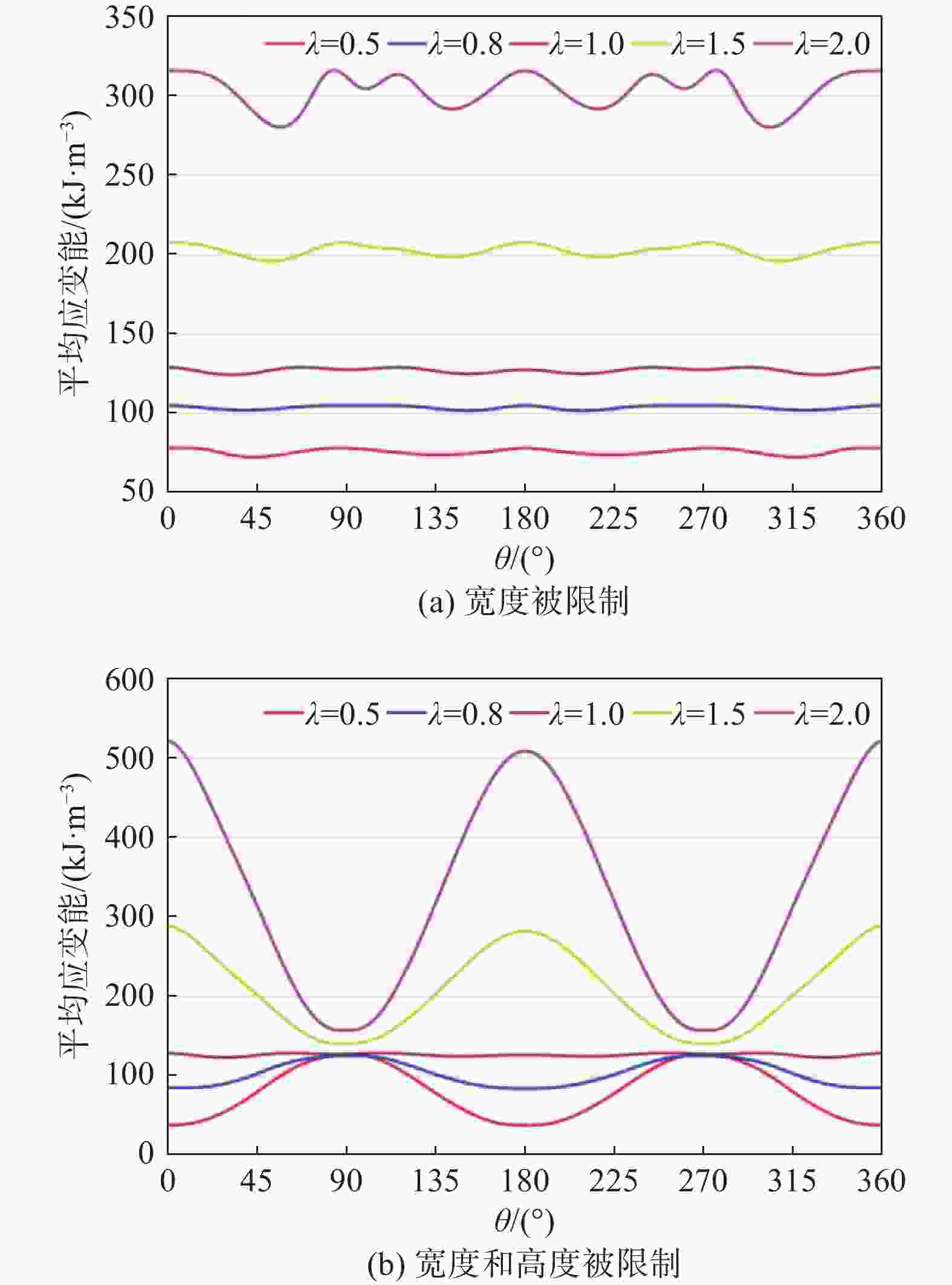

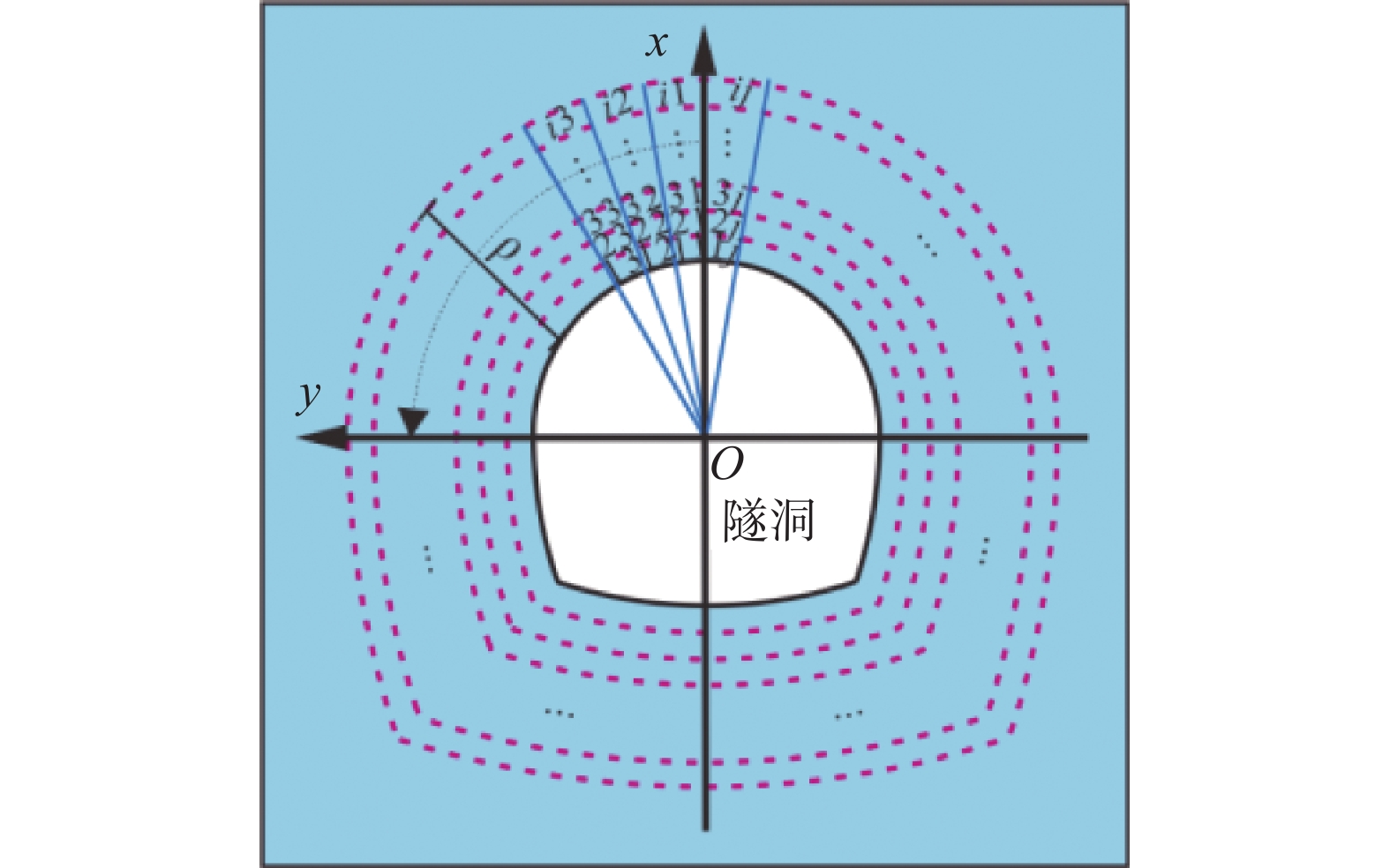

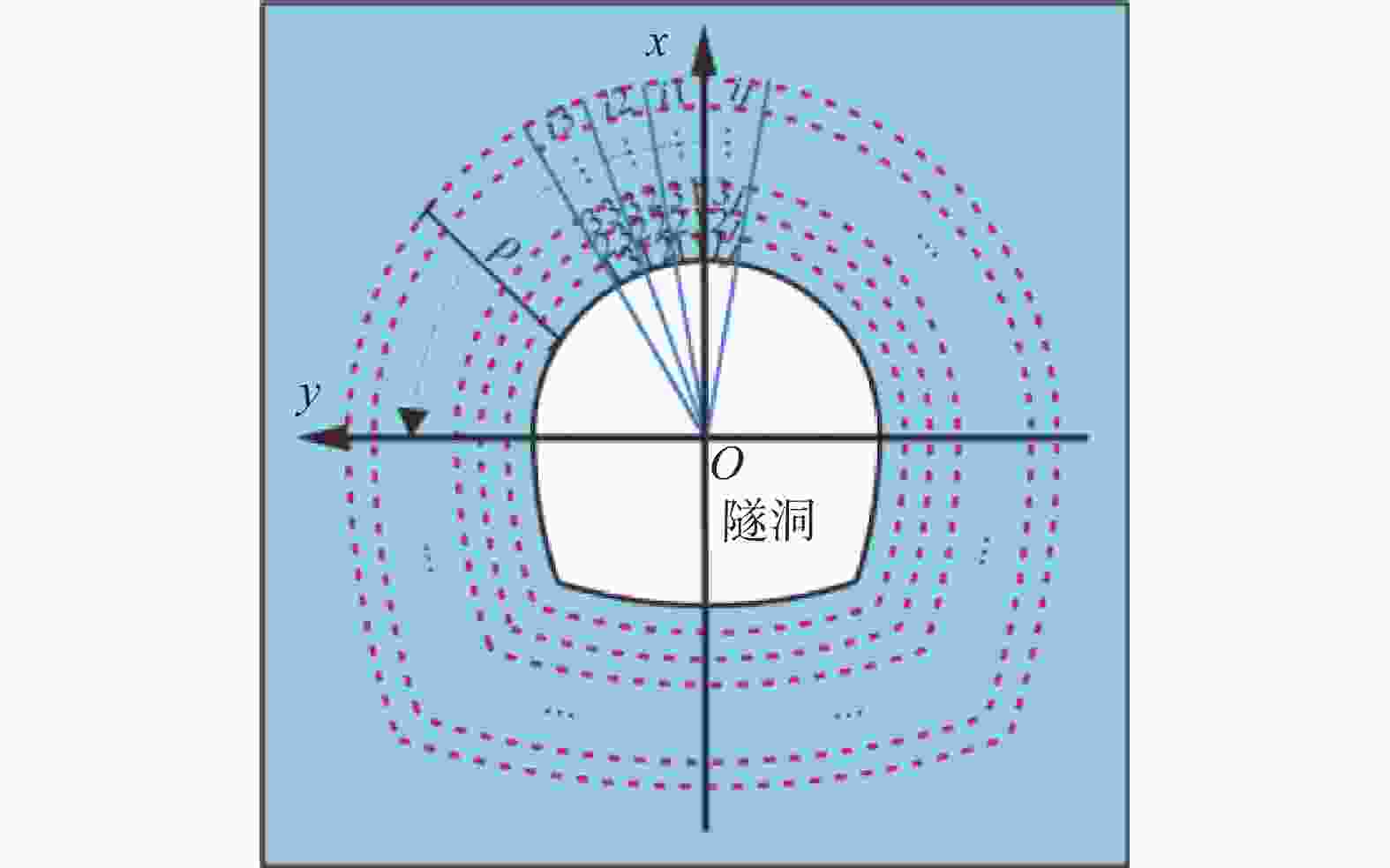

摘要: 隧洞断面形状的选型直接影响其围岩稳定性。基于复变函数理论和混合罚函数法,从隧洞围岩应变能分布与其病害之间的关系出发,提出了一种隧洞断面平均应变能最大达到最小化的断面形状优化准则,依托引汉济渭深部硬岩隧洞工程,研究了隧洞径向应变能计算范围与地应力对优化断面形状的影响。结果表明:采用提出的断面形状优化准则对深部马蹄形隧洞断面优化时,径向应变能计算范围取2.0倍隧洞最大半径以上即可。当隧洞断面宽度受限时,该优化准则可显著改善隧洞断面应变能的不均匀分布,且侧压力系数对优化断面形状及其围岩平均应变能整体分布值的影响也较大。当隧洞断面宽度和高度受限时,该优化准则对改善隧洞断面应变能不均匀分布作用有限,且侧压力系数对其优化断面形状的影响也较小,但对其围岩平均应变能整体分布值影响较大。Abstract: The selection of tunnel section shape directly affects the stability of its surrounding rock. Based on the complex variable function theory and the mixed penalty function method, a shape optimization criterion was proposed that the maximum average strain energy of the tunnel reached the minimum from the perspective of the relationship between the strain energy distribution of the tunnel and its failure characteristics. Combined with the engineering geological data of the deep hard rock tunnel from Hanjiang River to Weihe River, the effects of the radial strain energy calculation range and ground stress on the optimized tunnel section shape were investigated. The results show that: when using the shape optimization criteria developed to optimize the deep horseshoe tunnel, the radial strain energy calculation range should exceed 2.0 times the maximum tunnel radius. For tunnels with limited section width, the criterion significantly improved the uneven strain energy distribution, and the lateral pressure coefficient exhibited a stronger influence on the optimized section shape and overall distribution of surrounding rock average strain energy. When the width and height of the tunnel section are limited, this optimization criterion has limited effect on improving the uneven distribution of the surrounding rock strain energy of the tunnel, and the lateral pressure coefficient has little effect on the optimized section shape, but has a greater impact on the overall distribution of the surrounding rock average strain energy.

-

Key words:

- tunnel engineering /

- deep tunnel /

- strain energy /

- shape optimization

-

表 1 秦岭岭北段地应力测试结果

σx/MPa σy/MPa τxy/MPa 弹性模量/GPa 泊松比 41.2 49.6 16.7 32.835 0.18 -

[1] 梁伟章, 赵国彦. 深部硬岩长短期岩爆风险评估研究综述[J]. 岩石力学与工程学报,2022,41(1):19-39. (LIANG W Z, ZHAO G Y. A review of long-term and short-term rockburst risk evaluations in deep hard rock[J]. Chinese Journal of Rock Mechanics and Engineering,2022,41(1):19-39. (in Chinese)LIANG W Z, ZHAO G Y. A review of long-term and short-term rockburst risk evaluations in deep hard rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(1): 19-39. (in Chinese) [2] 张 超, 吴 华, 姜同虎. 钓鱼台隧道洞口崩塌成因分析与处治措施研究[J]. 岩土工程技术,2024,38(1):58-64. (ZHANG C, WU H, JIANG T H. Cause analysis and treatment measures for the collapse at the entrance of Diaoyutai tunnel[J]. Geotechnical Engineering Technique,2024,38(1):58-64. (in Chinese) doi: 10.3969/j.issn.1007-2993.2024.01.010ZHANG C, WU H, JIANG T H. Cause analysis and treatment measures for the collapse at the entrance of Diaoyutai tunnel[J]. Geotechnical Engineering Technique, 2024, 38(1): 58-64. (in Chinese) doi: 10.3969/j.issn.1007-2993.2024.01.010 [3] 陈峰宾, 张顶立, 张素磊. 采用逐次渐进法求解非圆形地下洞室映射函数[J]. 中国铁道科学,2013,34(2):80-86. (CHEN F B, ZHANG D L, ZHANG S L. Solving the mapping function of noncircular underground cavern with the method of successive approximation[J]. China Railway Science,2013,34(2):80-86. (in Chinese) doi: 10.3969/j.issn.1001-4632.2013.02.14CHEN F B, ZHANG D L, ZHANG S L. Solving the mapping function of noncircular underground cavern with the method of successive approximation[J]. China Railway Science, 2013, 34(2): 80-86. (in Chinese) doi: 10.3969/j.issn.1001-4632.2013.02.14 [4] 白强强, 陈 健. 基于合理拱轴线的偏压隧道最优断面研究[J]. 岩石力学与工程学报,2023,42(S1):3160-3168. (BAI Q Q, CHEN J. Study on the optimal shape of biased-pressure tunnel based on rational arch axis[J]. Chinese Journal of Rock Mechanics and Engineering,2023,42(S1):3160-3168. (in Chinese)BAI Q Q, CHEN J. Study on the optimal shape of biased-pressure tunnel based on rational arch axis[J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(S1): 3160-3168. (in Chinese) [5] JAFARI M, MOUSSAVIAN H, CHALESHTARI M H B. Optimum design of perforated orthotropic and laminated composite plates under in-plane loading by genetic algorithm[J]. Structural and Multidisciplinary Optimization,2018,57(1):341-357. doi: 10.1007/s00158-017-1758-5 [6] RICHARDS R JR, BJORKMAN G S JR. Optimum shapes for unlined tunnels and cavities[J]. Engineering Geology,1978,12:171-179. doi: 10.1016/0013-7952(78)90010-8 [7] LU A Z, YIN C L, ZHANG N. Analytic stress solutions for a lined circular tunnel under frictional slip contact conditions[J]. European Journal of Mechanics - A/Solids,2019,75:10-20. doi: 10.1016/j.euromechsol.2019.01.008 [8] CHEREPANOV G P. Inverse problems of the plane theory of elasticity[J]. Journal of Applied Mathematics and Mechanics,1974,38(6):915-931. doi: 10.1016/0021-8928(75)90085-4 [9] VIGDERGAUZ S B, CHERKAYEV A V. A hole in a plate, optimal for its biaxial extension - compression[J]. Journal of Applied Mathematics and Mechanics,1986,50(3):401-404. doi: 10.1016/0021-8928(86)90141-3 [10] BJORKMAN G S JR, RICHARDS R JR. Harmonic holes-an inverse problem in elasticity[J]. Journal of Applied Mechanics,1976,43(3):414-418. doi: 10.1115/1.3423882 [11] DHIR S K. Optimization in a class of hole shapes in plate structures[J]. Journal of Applied Mechanics,1981,48(4):905-908. doi: 10.1115/1.3157754 [12] 孙焕纯, 张巨勇, 严国梅, 等. 弹性平面孔洞形状优化复变函数方法[J]. 应用数学和力学,1987,8(2):133-142. (SUN H C, ZHANG J Y, YAN G M, et al. Complex variable function method for hole shape optimization in an elastic plane[J]. Applied Mathematics and Mechanics,1987,8(2):133-142. (in Chinese)SUN H C, ZHANG J Y, YAN G M, et al. Complex variable function method for hole shape optimization in an elastic plane[J]. Applied Mathematics and Mechanics, 1987, 8(2): 133-142. (in Chinese) [13] 吕爱钟. 以孔边绝对值最大的切向应力最小为优化准则的孔洞形状优化[J]. 固体力学学报,1996,17(1):73-76. (LV A Z. Optimization of hole shapes based on optimality criterion-minization of the maximally tangential stress (absolute value) on the boundary of hole[J]. Acta Mechanica Solida Sinica,1996,17(1):73-76. (in Chinese)LV A Z. Optimization of hole shapes based on optimality criterion-minization of the maximally tangential stress (absolute value) on the boundary of hole[J]. Acta Mechanica Solida Sinica, 1996, 17(1): 73-76. (in Chinese) [14] WANG S J, LU A Z, ZHANG X L, et al. Shape optimization of the hole in an orthotropic plate[J]. Mechanics Based Design of Structures and Machines,2018,46(1):23-37. doi: 10.1080/15397734.2016.1261036 [15] MIRSALIMOV V M. Optimal hole shape in plate with cracks taking into account body forces[J]. Mechanics Based Design of Structures and Machines,2022,50(10):3475-3490. doi: 10.1080/15397734.2020.1809453 [16] VIGDERGAUZ S, ELISHAKOFF I. Energy-maximizing holes in an elastic plate under remote loading[J]. Journal of Mechanics of Materials and Structures,2019,14(1):139-154. doi: 10.2140/jomms.2019.14.139 [17] VIGDERGAUZ S. Simply and doubly periodic arrangements of the equi-stress holes in a perforated elastic plane: The single-layer potential approach[J]. Mathematics and Mechanics of Solids,2018,23(5):805-819. doi: 10.1177/1081286517691807 [18] 王午阳, 王华宁, 蒋明镜. 基于解析解和新准则的深埋隧道断面形状优化[J]. 力学季刊,2022,43(2):227-238. (WANG W Y, WANG H N, JIANG M J. Shape optimization of the section of deep-buried tunnel based on analytical solution and new criterion[J]. Chinese Quarterly of Mechanics,2022,43(2):227-238. (in Chinese)WANG W Y, WANG H N, JIANG M J. Shape optimization of the section of deep-buried tunnel based on analytical solution and new criterion[J]. Chinese Quarterly of Mechanics, 2022, 43(2): 227-238. (in Chinese) [19] 方星桦, 杨 曾, 阳军生, 等. 高地应力隧道蚀变花岗岩地层围岩大变形特征及控制措施[J]. 中国铁道科学,2020,41(5):92-101. (FANG X H, YANG Z, YANG J S, et al. Large deformation characteristics and control measures of surrounding rock in altered granite stratum of high ground stress tunnel[J]. China Railway Science,2020,41(5):92-101. (in Chinese) doi: 10.3969/j.issn.1001-4632.2020.05.11FANG X H, YANG Z, YANG J S, et al. Large deformation characteristics and control measures of surrounding rock in altered granite stratum of high ground stress tunnel[J]. China Railway Science, 2020, 41(5): 92-101. (in Chinese) doi: 10.3969/j.issn.1001-4632.2020.05.11 [20] 梁 宁, 伍法权, 王云峰, 等. 大埋深高地应力关山隧道围岩变形破坏分析[J]. 岩土力学,2016,37(S2):329-336. (LIANG N, WU F Q, WANG Y F, et al. Analysis of deformation and failure of rock mass of deep Guanshan tunnel under high in situ stress[J]. Rock and Soil Mechanics,2016,37(S2):329-336. (in Chinese)LIANG N, WU F Q, WANG Y F, et al. Analysis of deformation and failure of rock mass of deep Guanshan tunnel under high in situ stress[J]. Rock and Soil Mechanics, 2016, 37(S2): 329-336. (in Chinese) [21] 韩现民, 孙明磊. 雁门关隧道挤压性围岩变形控制技术[J]. 现代隧道技术,2017,54(3):174-180. (HAN X M, SUN M L. Deformation control techniques for the Yanmenguan tunnel in squeezing surrounding rocks[J]. Modern Tunnelling Technology,2017,54(3):174-180. (in Chinese)HAN X M, SUN M L. Deformation control techniques for the Yanmenguan tunnel in squeezing surrounding rocks[J]. Modern Tunnelling Technology, 2017, 54(3): 174-180. (in Chinese) [22] 王智阳, 王浩杰, 张晓平. 大埋深高地应力硬岩TBM隧洞围岩破裂变形规律研究[J]. 工程地质学报,2022,30(5):1678-1688. (WANG Z Y, WANG H J, ZHANG X P. Fracturing and deformation mechanism of surrounding rock of deep-buried and high in-situ stress hard rock TBM tunnel[J]. Journal of Engineering Geology,2022,30(5):1678-1688. (in Chinese)WANG Z Y, WANG H J, ZHANG X P. Fracturing and deformation mechanism of surrounding rock of deep-buried and high in-situ stress hard rock TBM tunnel[J]. Journal of Engineering Geology, 2022, 30(5): 1678-1688. (in Chinese) [23] 刘 宁, 张春生, 单治钢, 等. 深埋硬岩隧洞开挖响应合理解译与监测优化[J]. 岩石力学与工程学报,2020,39(S1):2818-2827. (LIU N, ZHANG C S, SHAN Z G, et al. Reasonable interpretation and monitoring optimization on excavation response of deep buried tunnel in hard rock[J]. Chinese Journal of Rock Mechanics and Engineering,2020,39(S1):2818-2827. (in Chinese)LIU N, ZHANG C S, SHAN Z G, et al. Reasonable interpretation and monitoring optimization on excavation response of deep buried tunnel in hard rock[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(S1): 2818-2827. (in Chinese) [24] 杜小洲, 胡志平, 王振林, 等. 非圆形隧洞解析应力空间分布特征[J]. 科学技术与工程, 2022, 22(27): 12175-12182. (DU X Z, HU Z P, WANG Z L, et al. Spatial distribution characteristics of analytical stress on a non-circular tunnel[J]. Science Technology and Engineering, 2020, 39(S1): 12175-12182. (in Chinese)DU X Z, HU Z P, WANG Z L, et al. Spatial distribution characteristics of analytical stress on a non-circular tunnel[J]. Science Technology and Engineering, 2020, 39(S1): 12175-12182. (in Chinese) [25] AN X X, HU Z P, SU Y, et al. Initial support distance of a non-circular tunnel based on convergence constraint method and integral failure criteria of rock[J]. Journal of Central South University,2022,29(11):3732-3744. doi: 10.1007/s11771-022-5186-3 [26] LU A Z, CHEN H Y, QIN Y, et al. Shape optimisation of the support section of a tunnel at great depths[J]. Computers and Geotechnics,2014,61:190-197. doi: 10.1016/j.compgeo.2014.05.011 -

下载:

下载: