Analytical study on the crack limitation theory of permeable lining of diversion tunnels under high internal pressure

-

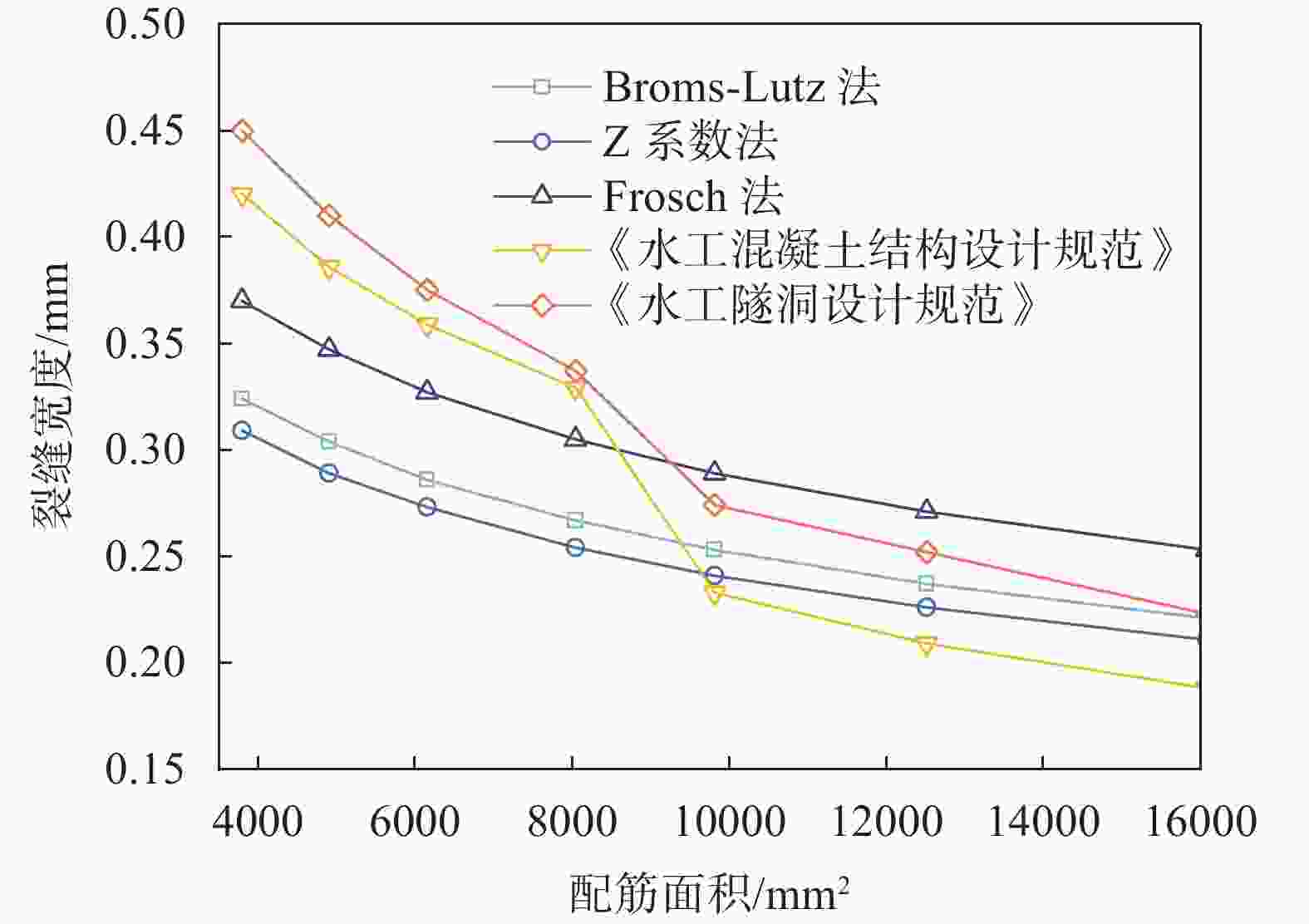

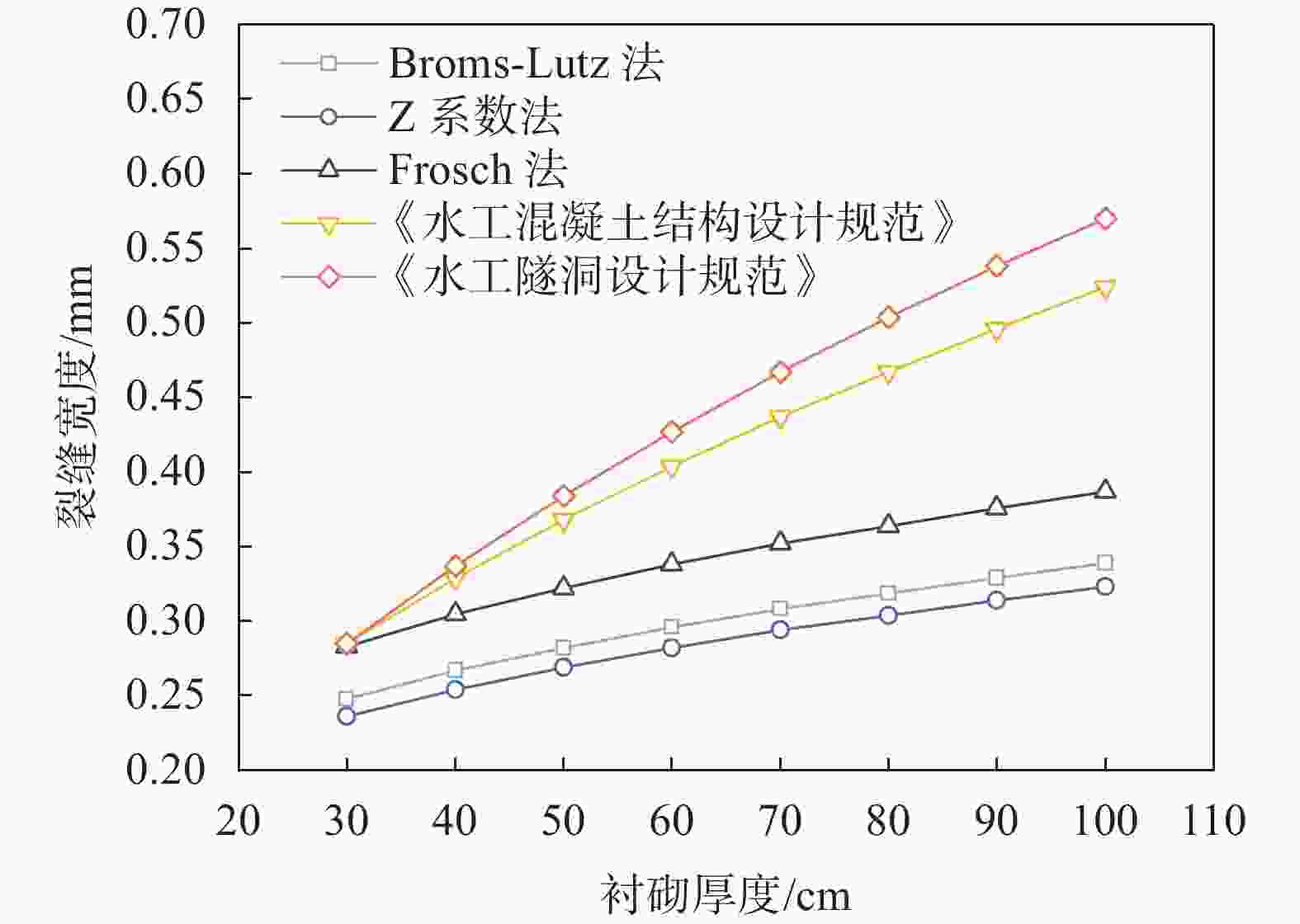

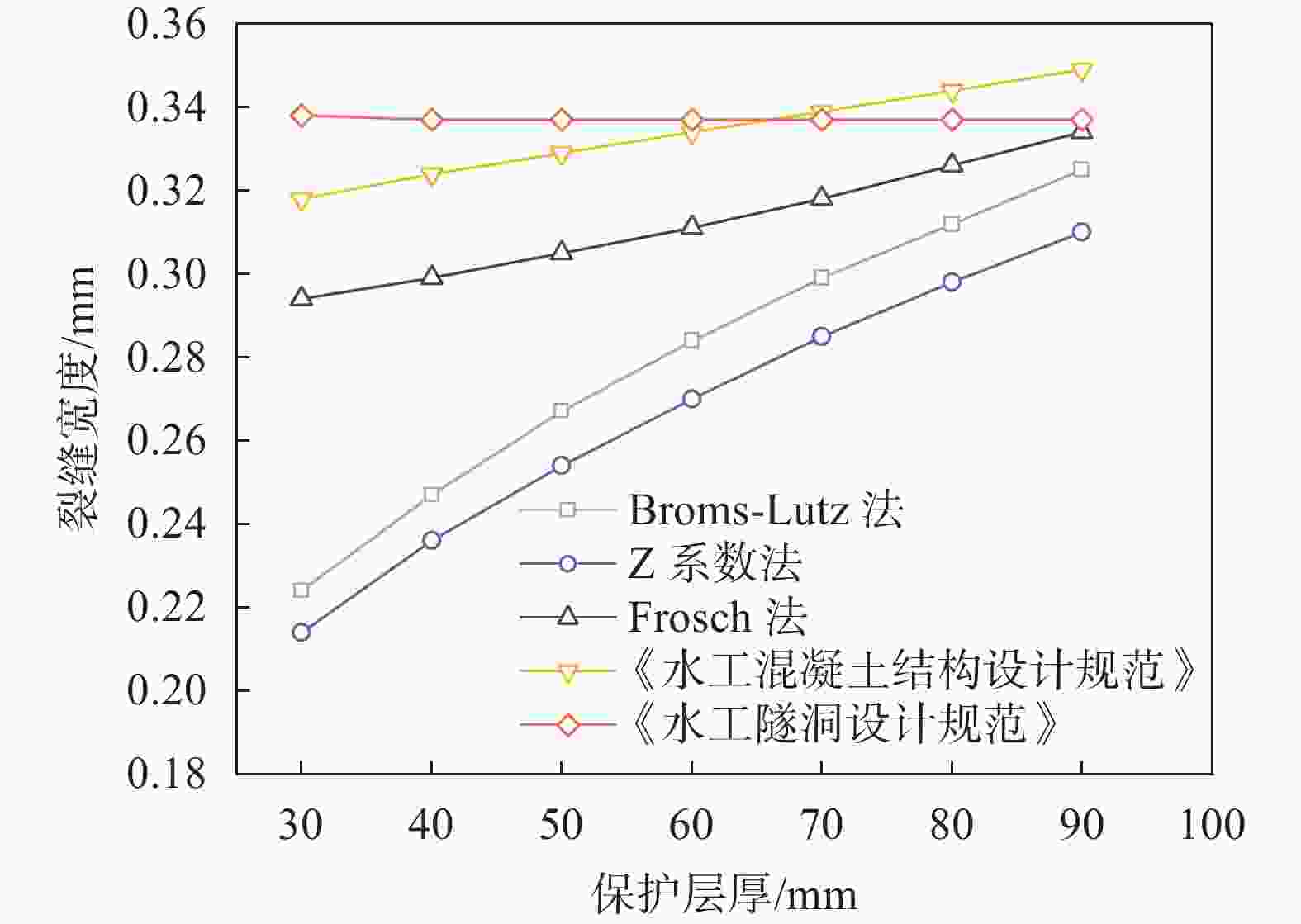

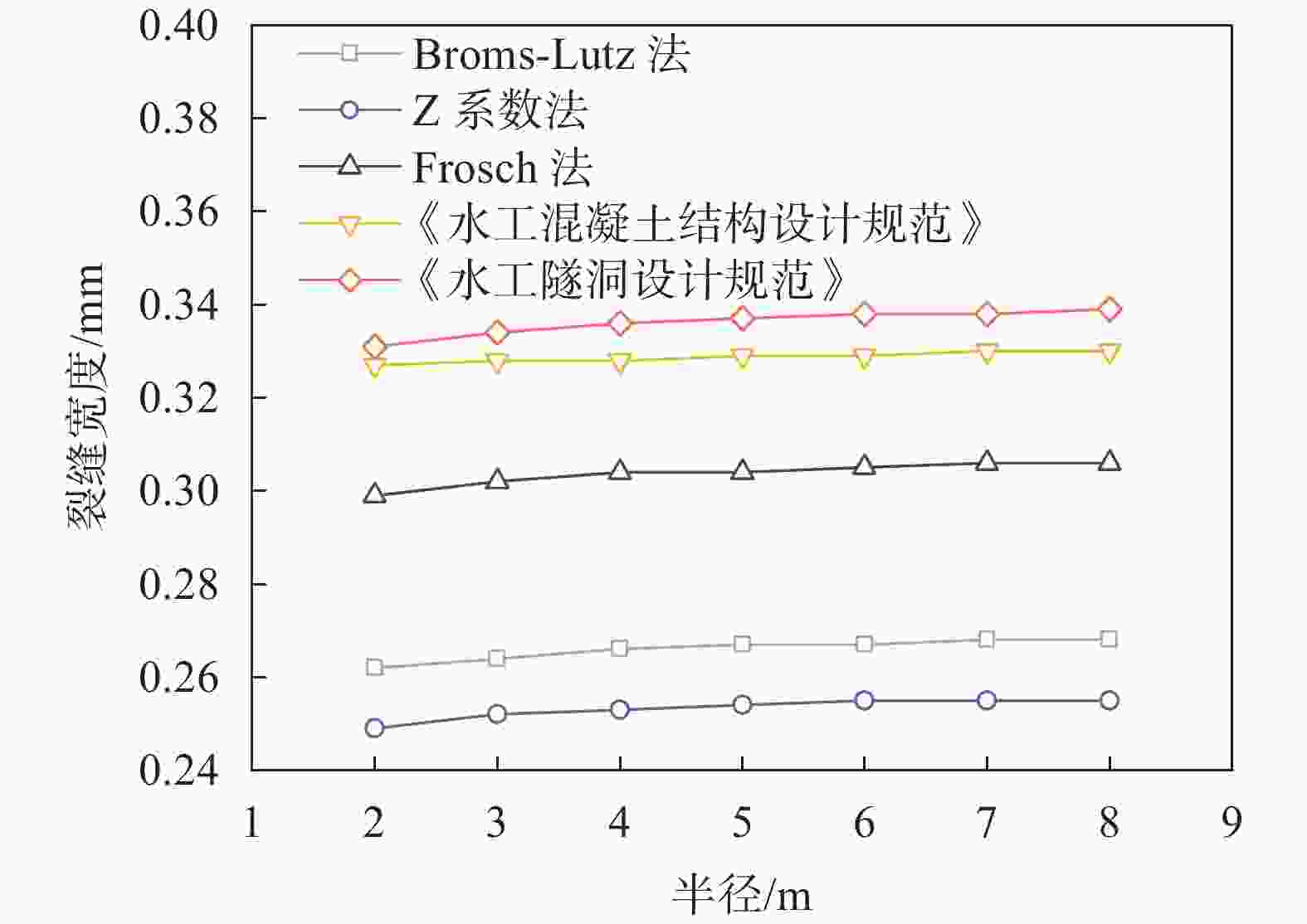

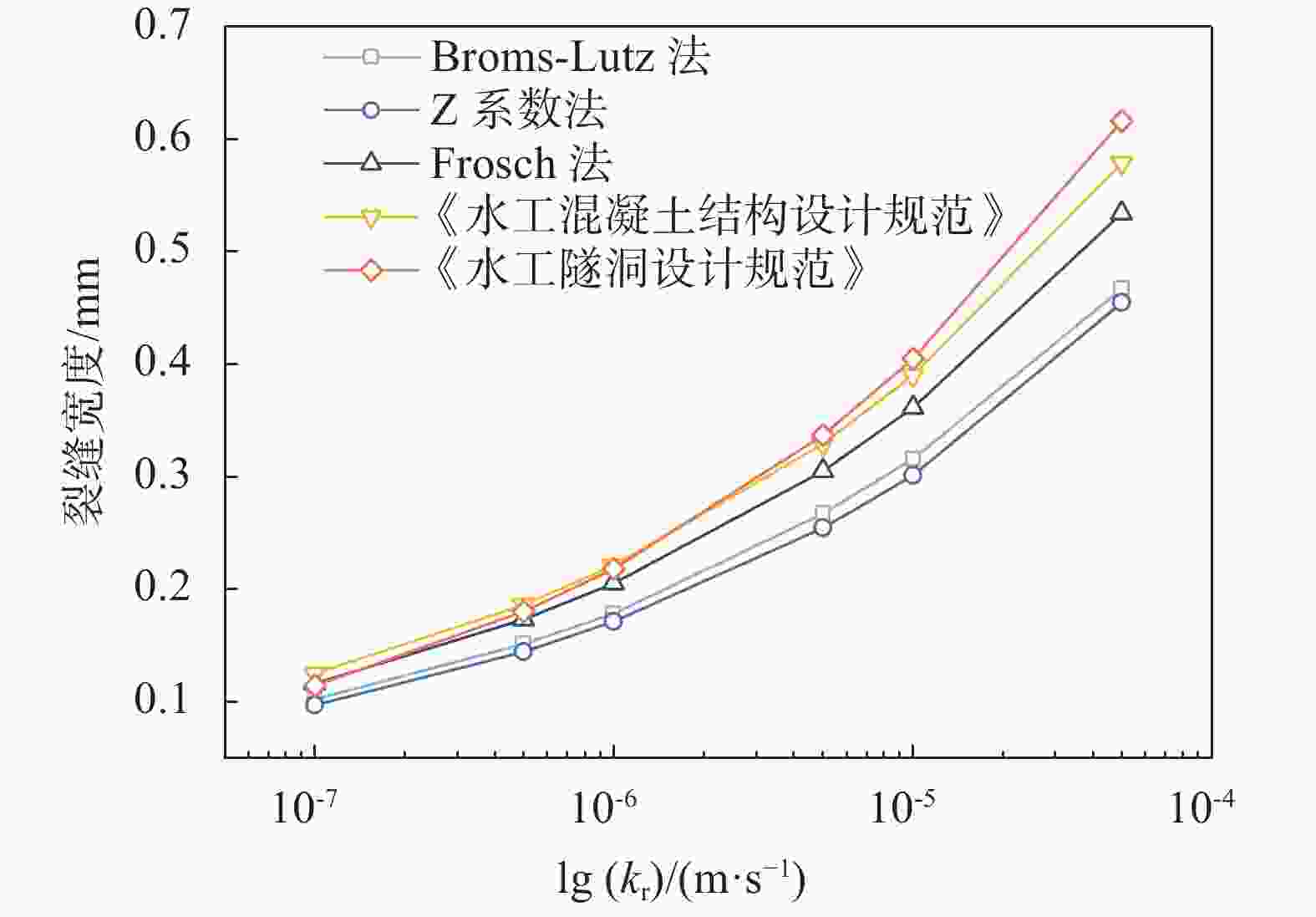

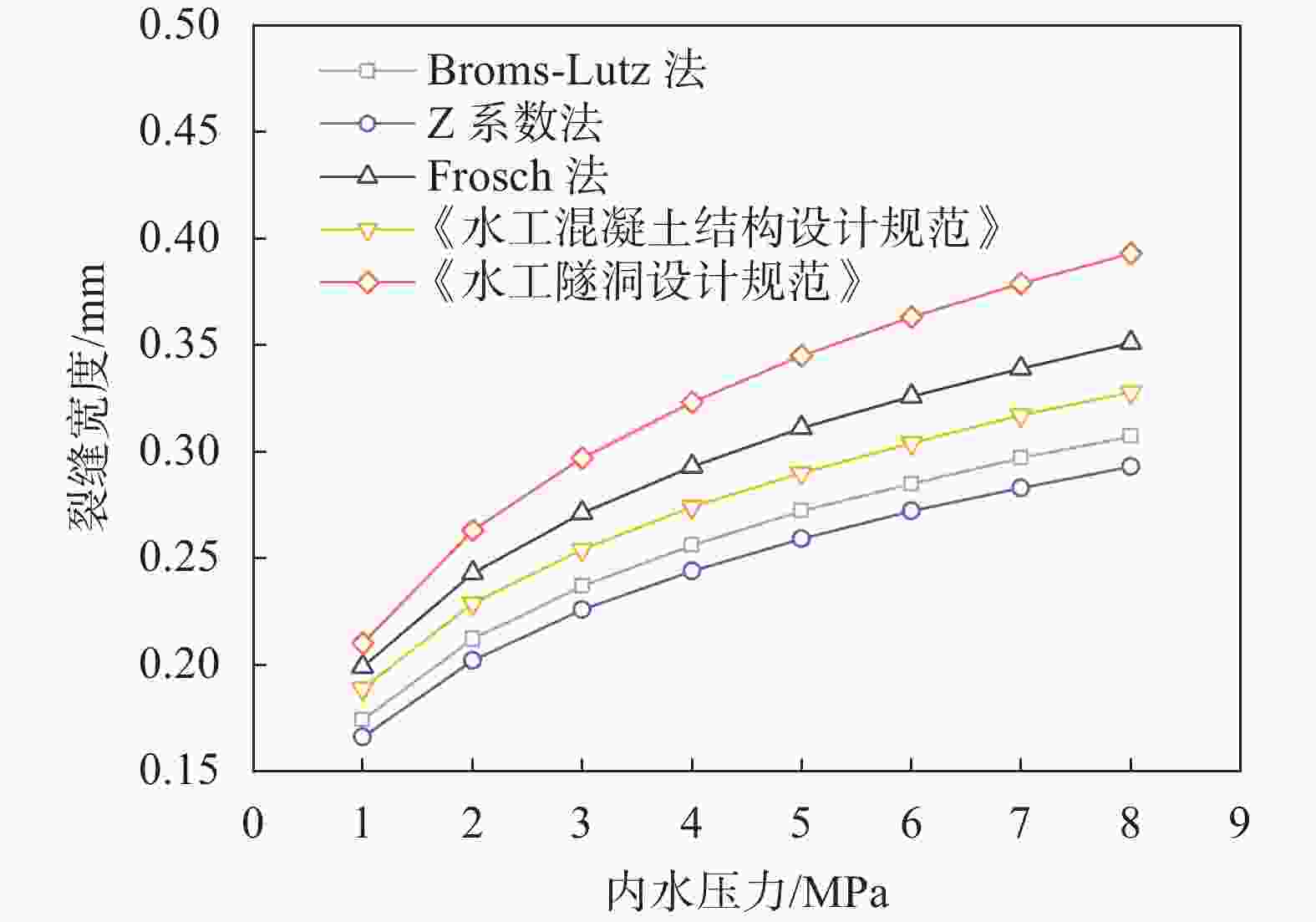

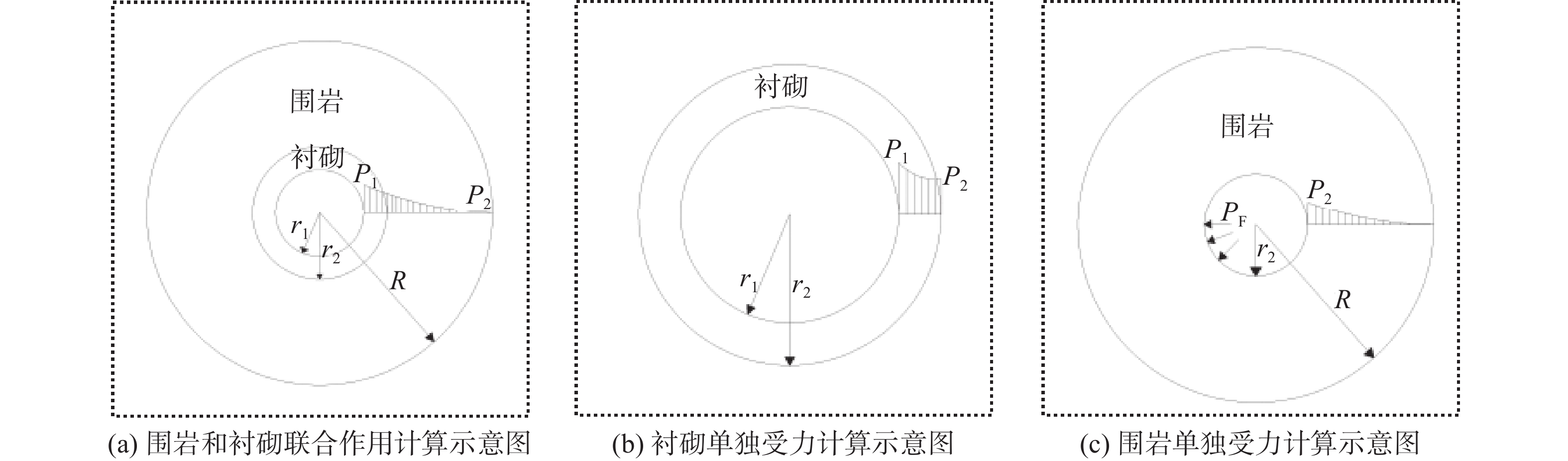

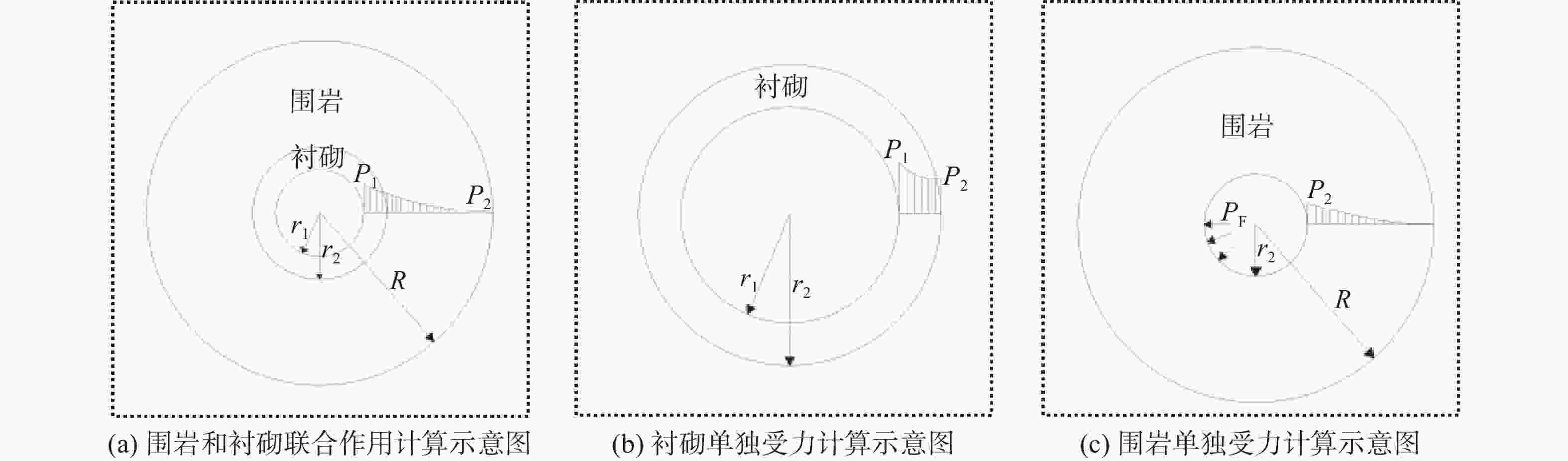

摘要: 为了研究高内水压力下引水隧洞衬砌开裂的影响因素,进而对衬砌限裂进行优化设计,基于透水衬砌理论确定了透水衬砌的设计步骤,并给出了钢筋混凝土衬砌不同裂缝宽度的计算公式,结合实际工程,分别采用中国规范和美国规范的裂缝宽度计算公式计算得到混凝土衬砌配筋方案,并对混凝土衬砌裂缝宽度的影响因素进行了分析。结果表明:(1)中国规范计算得到的配筋面积比美国规范要更大,钢筋的应力更小;(2)影响混凝土裂缝宽度的影响因素主要有内水压力、配筋面积、渗透系数和衬砌的厚度,可以通过调整这几种影响因素来限制混凝土开裂。Abstract: Based on the theory of permeable lining, the design steps of permeable lining were determined, and the calculation formula for solving different crack widths of pressure tunnel lining concrete was given. The reinforcement scheme was obtained by combining with the actual project using the crack width calculation formula in the Chinese and U.S. codes. The results show that: (1) the reinforcing area obtained through the Chinese code is larger than the American code, and the stress of the reinforcement is smaller. (2) The major influencing factors affecting the width of concrete cracks are internal water pressure, reinforcement area, permeability coefficient and the thickness of the lining, which can be adjusted to control the cracking of the concrete by these different influencing factors.

-

表 1 厚壁圆筒模型解析计算公式

计算工况 衬砌混凝土未开裂 衬砌混凝土已开裂 径向应力 $ \sigma\mathrm{_r}=\dfrac{(p_1-p_2)}{2(1-\mu)}\left(\dfrac{\mathrm{ln}\;\left(r_2/r\right)}{\mathrm{ln}\;t}+\dfrac{1-r_2^2/r^2}{t^2-1}\right) $ $ {\sigma }_{\rm{r}}=\dfrac{{(2-\mu )(p}_{1}-{p}_{2})}{3(1-\mu )}\left(\dfrac{1-{r}_{2}^{2}/{r}^{2}}{{t}^{2}-1}+\dfrac{{r}_{2}-r}{{r}_{2}-{r}_{1}}\right) $ 环向应力 $ \sigma{_{{\text{θ}}}}=\dfrac{(p_1-p_2)}{2(1-\mu)}\left(\dfrac{\mathrm{ln}\;\left(r_2/r\right)+1-2\mu}{\mathrm{ln}\;t}+\dfrac{1+r_2^2/r^2}{t^2-1}\right) $ $ \sigma_{{{\text{θ}}}}=\dfrac{(2-\mu)(p_1-p_2)}{3(1-\mu)}\left(\dfrac{1+r_2^2/r^2}{t^2-1}+\dfrac{r_2}{r_2-r_1}-\dfrac{(1+\mu)r}{(r_2-r_1)(2-\mu)}\right) $ 位移 $ {u}_{\rm{r}}=\dfrac{r{(p}_{1}-{p}_{2}\left)\right(1+\mu )}{2E(1-\mu )}\left(\dfrac{(1-2\mathrm{\mu })(\mathrm{l}\mathrm{n}\;\left({r}_{2}/r\right)+1-\mathrm{\mu })}{\mathrm{l}\mathrm{n}\; t}+\dfrac{1-2\mu +{r}_{2}^{2}/{r}^{2}}{{t}^{2}-1}\right) $ $ {u}_{\rm{r}}=\dfrac{r{(p}_{1}-{p}_{2}\left)\right(1+\mu \left)\right(2-\mu )}{3E(1-\mu )}\left(\dfrac{(1-2\mathrm{\mu })\left[\right(2-\mathrm{\mu }){r}_{2}-\mathrm{r}]}{({r}_{2}-{r}_{1})(2-\mu )}+\dfrac{1-2\mu +{r}_{2}^{2}/{r}^{2}}{{t}^{2}-1}\right) $ 表 2 中、美规范中混凝土最大裂缝计算公式

规范或方法 计算公式 《水工混凝土结构设计规范》

(SL 191—2008)[14]$ w\mathrm{_{\rm{max}}}=\alpha\dfrac{\sigma_{\mathrm{sk}}}{E_{\mathrm{s}}}\left(0.03+c+0.07\dfrac{d}{\rho_{\mathrm{te}}}\right) $ 《水工隧洞设计规范》

(SL 279—016)[15]$ w_{\mathrm{max}}=2\left(\dfrac{\sigma_{\mathrm{s}}}{E_{\mathrm{s}}}\phi-0.7\times10^{-4}\right)l_{\mathrm{f}} $ Z系数法[17] $ w_{\mathrm{max}}=1.1\beta f_{\mathrm{s}}\sqrt[3]{d\mathrm{_c}A}\times10^{-5} $ Frosch法[19] $ w\mathrm{_{\rm{max}}}=2\dfrac{f\mathrm{_s}}{E_{\mathrm{s}}}\beta\sqrt[]{d_{\mathrm{c}}^2+\left(\dfrac{s}{2}\right)^2} $ Broms-Lutz法[20] $ w\mathrm{_{\rm{max}}}=1.45\sigma_{\mathrm{s}}\sqrt[3]{d\mathrm{_c}A}\times10^{-5} $ 注:《水工混凝土结构设计规范》(SL 191—2008)中,$ \alpha $为考虑构件受力特征和荷载长期作用的综合影响系数,本文按轴心受拉计算,取$ \alpha $=2.4;$ \sigma\mathrm{_{sk}} $为纵向受拉钢筋的应力,MPa;$ E_{\mathrm{s}} $为钢筋的杨氏模量,$ \mathrm{M}\mathrm{P}\mathrm{a} $;$ c $为保护层厚度,mm;$ d $为钢筋的直径,mm;$ \rho\mathrm{_{te}} $为钢筋的配筋率。《水工隧洞设计规范》(SL279—2016)中,$ \sigma\mathrm{_s} $为纵向受拉钢筋的应力,MPa;$ E\mathrm{_s} $为钢筋的杨氏模量,MPa;$ \phi $为裂缝间纵向受拉钢筋应变不均匀系数,当$ \phi $<0.3时,取0.3;$ l\mathrm{_f} $为平均裂缝间距,m;Z系数法中,$ \beta $为钢筋到界面受拉边缘的应变梯度的影响,在本文中,近似取1.2;$ f\mathrm{_s} $为受拉钢筋应力,MPa;$ d\mathrm{_c} $从受拉区底面至最靠近该面的受拉钢筋界面形心的距离,mm;$ A $为包围一根钢筋的混凝土截面面积。Frosch法中,$ f\mathrm{_s},\beta,d_{\mathrm{c}},E\mathrm{_s} $均与上述相同,$ s $为钢筋的间距,mm;Broms-Lutz法中,参数含义均与上述相同。 表 3 计算参数

计算参数 取值 内水压力/MPa 1.3 衬砌外径/m 11.8 衬砌内径/m 11 保护层厚度/mm 25 围岩弹性模量/GPa 4 围岩泊松比 0.35 围岩渗透系数/(m·s–1) 5×10−6 单位弹抗系数/(MPa·cm–1) 12.5 衬砌混凝土弹性模量/GPa 28 衬砌混凝土泊松比 0.167 衬砌混凝土渗透系数/(m·s–1) 1×10−9 钢筋弹性模量/GPa 200 围岩渗透半径/m 118 表 4 采用 《水工隧洞设计规范》(SL 279—2016)限裂宽度计算公式透水衬砌配筋计算结果

钢筋的直径/m 钢筋的间距/m 钢筋的面积/mm2 脱开水头/MPa 衬砌与围岩接触面之间的水压力$ {p}_{2} $/MPa 钢筋应力/MPa 裂缝宽度/mm 0.020 0.200 1570.796 0.263 1.138 608.098 1.992 0.022 0.200 1900.664 0.267 1.134 516.325 1.520 0.025 0.200 2454.369 0.275 1.126 418.422 1.065 0.028 0.200 3078.761 0.284 1.117 350.858 0.782 0.030 0.200 3534.292 0.291 1.110 316.874 0.651 0.032 0.200 4021.239 0.299 1.103 289.206 0.549 0.036 0.200 5089.380 0.316 1.087 247.340 0.442 0.040 0.200 6283.185 0.337 1.068 217.603 0.414 0.020 0.100 3141.593 0.291 1.109 358.968 0.574 0.022 0.100 3801.327 0.303 1.097 314.452 0.450 0.025 0.100 4908.739 0.324 1.078 266.976 0.393 0.028 0.100 3141.593 0.350 1.056 234.094 0.366 0.030 0.100 3801.327 0.369 1.039 217.440 0.349 0.032 0.100 4908.738 0.390 1.022 203.771 0.333 0.036 0.100 6157.524 0.438 0.985 182.746 0.304 0.040 0.100 7068.583 0.495 0.944 167.350 0.279 表 5 工程案例1最终配筋方案对比

规范 配筋方案 钢筋应力

/MPa裂缝宽度

/mm《水工混凝土结构设计规范》

(SL 191—2008)ϕ36@100 155.197 0.291 《水工隧洞设计规范》

(SL 279—2016)ϕ40@100 167.350 0.279 Z系数法 ϕ30@100 262.525 0.173 Frosch法 ϕ25@100 214.545 0.265 Broms-Lutz法 ϕ25@200 274.932 0.251 表 6 工程案例2最终配筋方案对比

规范 配筋方案 钢筋应力

/MPa裂缝宽度

/mm《水工混凝土结构设计规范》

(SL 191—2008)ϕ40@100 142.002 0.284 《水工隧洞设计规范》

(SL 279—2016)ϕ40@100 181.325 0.298 Z系数法 ϕ36@200 287.680 0.239 Frosch法 ϕ28@100 237.806 0.294 Broms-Lutz法 ϕ30@100 282.616 0.205 -

[1] 侯 靖, 胡敏云. 水工高压隧洞结构设计中若干问题的讨论[J]. 水利学报,2001,32(7):36-40. (HOU J, HU M Y. Discussion on some problems in design of high pressure tunnel for hydro projects[J]. Journal of Hydraulic Engineering,2001,32(7):36-40. (in Chinese) doi: 10.3321/j.issn:0559-9350.2001.07.006HOU J, HU M Y. Discussion on some problems in design of high pressure tunnel for hydro projects[J]. Journal of Hydraulic Engineering, 2001, 32(7): 36-40. (in Chinese) doi: 10.3321/j.issn:0559-9350.2001.07.006 [2] 叶冀升. 广州抽水蓄能电站建设的科技进步成果[J]. 水力发电学报,1998,(3):87-97. (YE J S. Technological Advancements of GuangzhouPumped Storage Power Station[J]. Journal of Hydroelectric Engineering,1998,(3):87-97. (in Chinese)YE J S. Technological Advancements of GuangzhouPumped Storage Power Station[J]. Journal of Hydroelectric Engineering, 1998, (3): 87-97. [3] SU K, LI Y. Design of pressure tunnel with reinforcement concrete lining under consolidation grouting[J]. Advanced Materials Research,2012,446-449:2731-2735. doi: 10.4028/www.scientific.net/AMR.446-449.2731 [4] 张 巍, 黄立财, 陈世玉. 高压钢筋混凝土隧洞透水衬砌设计理论的进一步研究[J]. 广东水利水电,2008(9):1-4,18. (ZHANG W, HUANG L C, CHEN S Y. A further research of high pressure reinforced concrete tunnel permeable lining design theory[J]. Guangdong Water Resources and Hydropower,2008(9):1-4,18. (in Chinese) doi: 10.3969/j.issn.1008-0112.2008.09.001ZHANG W, HUANG L C, CHEN S Y. A further research of high pressure reinforced concrete tunnel permeable lining design theory[J]. Guangdong Water Resources and Hydropower, 2008(9): 1-4,18. (in Chinese) doi: 10.3969/j.issn.1008-0112.2008.09.001 [5] 何 敏, 户 莹, 李 宁, 等. 水工压力隧洞衬砌配筋的计算[J]. 西北农林科技大学学报(自然科学版),2018,46(9):131-138. (HE M, HU Y, LI Y, et al. Reinforcement calculation of hydraulic pressure tunnel lining[J]. Journal of Northwest A&F University (Natural Science Edition),2018,46(9):131-138. (in Chinese)HE M, HU Y, LI Y, et al. Reinforcement calculation of hydraulic pressure tunnel lining[J]. Journal of Northwest A&F University (Natural Science Edition), 2018, 46(9): 131-138. (in Chinese) [6] 钟建文, 谷兆祺, 彭守拙. 高压隧洞衬砌设计配筋研究[J]. 水力发电学报,2007,26(2):42-46,59. (ZHONG J W, GU Z Q, PENG S Z. Research on the reinforcement in the high pressure tunnel lining[J]. Journal of Hydroelectric Engineering,2007,26(2):42-46,59. (in Chinese) doi: 10.3969/j.issn.1003-1243.2007.02.009ZHONG J W, GU Z Q, PENG S Z. Research on the reinforcement in the high pressure tunnel lining[J]. Journal of Hydroelectric Engineering, 2007, 26(2): 42-46,59. (in Chinese) doi: 10.3969/j.issn.1003-1243.2007.02.009 [7] 吴俊杰, 潘旭东, 郭 宇, 等. 透水理论在阿尔塔什水电站发电洞混凝土衬砌设计中的应用[J]. 水利水电技术,2018,49(S1):87-91. (WU J J, PAN X D, GUO Y, et al. Application of permeable theory to design of concrete lining for power tunnel of Altash Hydropower Station[J]. Water Resources and Hydropower Engineering,2018,49(S1):87-91. (in Chinese)WU J J, PAN X D, GUO Y, et al. Application of permeable theory to design of concrete lining for power tunnel of Altash Hydropower Station[J]. Water Resources and Hydropower Engineering, 2018, 49(S1): 87-91. (in Chinese) [8] 文喜雨, 苏 凯, 周亚峰. 高压水工隧洞透水衬砌设计方法与理论研究[J]. 武汉大学学报(工学版),2016,49(6):824-830. (WEN X Y, SU K, ZHOU Y F. Research of pervious lining design and theory for high pressure hydraulic tunnel[J]. Engineering Journal of Wuhan University,2016,49(6):824-830. (in Chinese)WEN X Y, SU K, ZHOU Y F. Research of pervious lining design and theory for high pressure hydraulic tunnel[J]. Engineering Journal of Wuhan University, 2016, 49(6): 824-830. (in Chinese) [9] 周 利, 苏 凯, 周亚峰, 等. 高压水工隧洞透水衬砌渗流–应力–损伤耦合分析方法研究[J]. 水利学报,2018,49(3):313-322. (ZHOU L, SU K, ZHOU Y F, et al. Hydro-mechanical coupling analysis of pervious lining in high pressure hydraulic tunnel[J]. Journal of Hydraulic Engineering,2018,49(3):313-322. (in Chinese)ZHOU L, SU K, ZHOU Y F, et al. Hydro-mechanical coupling analysis of pervious lining in high pressure hydraulic tunnel[J]. Journal of Hydraulic Engineering, 2018, 49(3): 313-322. (in Chinese) [10] 张建伟, 刘 贺, 曹克磊, 等. TBM有压输水隧洞内张钢圈–管片–围岩组合结构联合承载力学特性分析[J]. 岩土力学,2024,45(4):1154-1169,1180. (ZHANG J W, LIU H, CAO K L, et al. Combined bearing mechanical characteristics of composite structure of inner tensioned steel ring-segment-surrounding rock in a TBM pressurized water conveyance tunnel[J]. Rock and Soil Mechanics,2024,45(4):1154-1169,1180. (in Chinese)ZHANG J W, LIU H, CAO K L, et al. Combined bearing mechanical characteristics of composite structure of inner tensioned steel ring-segment-surrounding rock in a TBM pressurized water conveyance tunnel[J]. Rock and Soil Mechanics, 2024, 45(4): 1154-1169,1180. (in Chinese) [11] DUAN S Q, JIANG X Q, JIANG Q, et al. Theoretical solution and failure analysis of water pressure on lining of deep-buried non-circular hydraulic tunnel based on the equivalent hydraulic radius method[J]. Engineering Failure Analysis,2023,148:107163. doi: 10.1016/j.engfailanal.2023.107163 [12] MIN B, ZHANG C P, WANG Y, et al. Experimental and numerical study on the failure performance of cracked tunnel linings[J]. Structures,2024,63:106357. doi: 10.1016/j.istruc.2024.106357 [13] CHEN J X, HU T T, HU X, et al. Study on the influence of crack depth on the safety of tunnel lining structure[J]. Tunnelling and Underground Space Technology,2024,143:105470. doi: 10.1016/j.tust.2023.105470 [14] 中华人民共和国水利部. 水工混凝土结构设计规范: SL 191—2008[S]. 北京: 中国水利水电出版社, 2009. (Ministry of Water Resources of the People’s Republic of China. Design code for hydraulic concrete structures: SL 191—2008[S]. Beijing: China Water & Power Press, 2009. (in Chinese)Ministry of Water Resources of the People’s Republic of China. Design code for hydraulic concrete structures: SL 191—2008[S]. Beijing: China Water & Power Press, 2009. (in Chinese) [15] 中华人民共和国水利部. 水工隧洞设计规范: SL 279—2016[S]. 北京: 中国水利水电出版社, 2016. (Ministry of Water Resources of the People’s Republic of China. Specification for design of hydraulic tunnel: SL 279—2016[S]. Beijing: China Water & Power Press, 2016. (in Chinese)Ministry of Water Resources of the People’s Republic of China. Specification for design of hydraulic tunnel: SL 279—2016[S]. Beijing: China Water & Power Press, 2016. (in Chinese) [16] 杜小凯, 任青文, 夏 宁. 高压引水隧洞若干问题的研究现状和存在的问题[J]. 水力发电,2007,33(6):65-68. (DU X K, REN Q W, XIA N. Status quo of the study on the several problems of high pressure diversion tunnel and its existing problems[J]. Water Power,2007,33(6):65-68. (in Chinese) doi: 10.3969/j.issn.0559-9342.2007.06.021DU X K, REN Q W, XIA N. Status quo of the study on the several problems of high pressure diversion tunnel and its existing problems[J]. Water Power, 2007, 33(6): 65-68. (in Chinese) doi: 10.3969/j.issn.0559-9342.2007.06.021 [17] GERGELY P, LUTZ L A. Maximum crack width in reinforced concrete flexural members[R]. 1968: 87-117. [18] 陈 飞, 赵 勇, 周建民. 美国规范ACI 318的裂缝控制方法评析[J]. 建筑科学,2009,25(7):102-105,93. (CHEN F, ZHAO Y, ZHOU J M. Review of crack control methods in ACI 318 code[J]. Building Science,2009,25(7):102-105,93. (in Chinese) doi: 10.3969/j.issn.1002-8528.2009.07.024CHEN F, ZHAO Y, ZHOU J M. Review of crack control methods in ACI 318 code[J]. Building Science, 2009, 25(7): 102-105,93. (in Chinese) doi: 10.3969/j.issn.1002-8528.2009.07.024 [19] FROSCH R J. Another look at cracking and crack control in reinforced concrete[J]. ACI Structural Journal,1999,96(3):437-442. [20] DARWIN D, SCANLON A, GERGELY P, et al. Cracking of concrete members in direct tension[J]. Journal of the American Concrete Institute, 1986, 83(1): 3-13. [21] SCHLEISS A J. Design of reinforced concrete linings of pressure tunnels and shafts[J]. International Journal on Hydropower & Dams, 1997, 4(3): 88-94. [22] 潘家铮. 水工隧洞和调压室[M]. 北京: 水利电力出版社, 1990. (PAN J Z. Design of hydraulic tunnels and surge chambers[M]. Beijing: Water Resources and Electric Power Press, 1990. (in Chinese)PAN J Z. Design of hydraulic tunnels and surge chambers[M]. Beijing: Water Resources and Electric Power Press, 1990. (in Chinese) [23] 刘秀珍. 关于圆形有压水工隧洞衬砌裂缝计算的探讨[J]. 水力发电,1983(12):37-44. (LIU X Z. An approach to crack calculation of lining of circular presssure tunnel[J]. Water Power,1983(12):37-44. (in Chinese)LIU X Z. An approach to crack calculation of lining of circular presssure tunnel[J]. Water Power, 1983(12): 37-44. [24] 沈 威, 徐世烺. 水工压力隧洞结构限裂设计研究现状[J]. 水电能源科学,2010,28(3):84-87. (SHEN W, XU S L. Review on crack limiting design of high pressure tunnel in hydraulic project[J]. Water Resources and Power,2010,28(3):84-87. (in Chinese) doi: 10.3969/j.issn.1000-7709.2010.03.027SHEN W, XU S L. Review on crack limiting design of high pressure tunnel in hydraulic project[J]. Water Resources and Power, 2010, 28(3): 84-87. (in Chinese) doi: 10.3969/j.issn.1000-7709.2010.03.027 [25] 丁旭柳, 伍鹤皋, 朱忠华. 钢筋混凝土压力隧洞裂缝宽度计算方法的探讨[J]. 武汉大学学报(工学版),2001,34(2):24-27. (DING X L, WU H G, ZHU Z H. Study on computational method of crack width of reinforced concrete pressure tunnels[J]. Engineering Journal of Wuhan University,2001,34(2):24-27. (in Chinese)DING X L, WU H G, ZHU Z H. Study on computational method of crack width of reinforced concrete pressure tunnels[J]. Engineering Journal of Wuhan University, 2001, 34(2): 24-27. (in Chinese) [26] 佘 磊, 王玉杰, 曹瑞琅, 等. 高压水工隧洞钢筋混凝土衬砌裂缝开度计算方法评析[J]. 水利水电技术,2018,49(8):142-149. (SHE L, WANG Y J, CAO R L, et al. Analysis on crack-opening calculation method for reinforced concrete lining of high pressure hydraulic tunnel[J]. Water Resources and Hydropower Engineering,2018,49(8):142-149. (in Chinese)SHE L, WANG Y J, CAO R L, et al. Analysis on crack-opening calculation method for reinforced concrete lining of high pressure hydraulic tunnel[J]. Water Resources and Hydropower Engineering, 2018, 49(8): 142-149. (in Chinese) [27] 陈 晨, 曹瑞琅, 姚磊华, 等. 考虑主筋约束作用的高压水工隧洞衬砌裂缝开度研究[J]. 水利水电技术,2018,49(11):75-81. (CHEN C, CAO R L, YAO L H, et al. Main reinforcement constraint effect-considered study on crack opening of lining for high-pressure hydraulic tunnel[J]. Water Resources and Hydropower Engineering,2018,49(11):75-81. (in Chinese)CHEN C, CAO R L, YAO L H, et al. Main reinforcement constraint effect-considered study on crack opening of lining for high-pressure hydraulic tunnel[J]. Water Resources and Hydropower Engineering, 2018, 49(11): 75-81. (in Chinese) [28] 王玉杰, 陈 晨, 曹瑞琅, 等. 高内水压力隧洞钢筋混凝土衬砌裂缝控制标准[J]. 水力发电学报,2020,39(9):111-120. (WANG Y J, CHEN C, CAO R L, et al. Study on crack control standards for reinforced concrete linings in high internal water pressure tunnels[J]. Journal of Hydroelectric Engineering,2020,39(9):111-120. (in Chinese) doi: 10.11660/slfdxb.20200911WANG Y J, CHEN C, CAO R L, et al. Study on crack control standards for reinforced concrete linings in high internal water pressure tunnels[J]. Journal of Hydroelectric Engineering, 2020, 39(9): 111-120. (in Chinese) doi: 10.11660/slfdxb.20200911 [29] 文喜雨. 透水衬砌设计方法与高压隧洞承载特性研究[D]. 武汉: 武汉大学, 2017. (WEN X Y. Design of permeable and load-bearing characteristics of high pressure tunnel[D]. Wuhan: Wuhan University, 2017. (in Chinese)WEN X Y. Design of permeable and load-bearing characteristics of high pressure tunnel[D]. Wuhan: Wuhan University, 2017. (in Chinese) [30] 李志龙. 水工高压隧洞衬砌计算方法研究[D]. 大连: 大连理工大学, 2015. (LI Z L. Study on structural analysis methods of hydraulic pressure tunnel linings[D]. Dalian: Dalian University of Technology, 2015. (in Chinese)LI Z L. Study on structural analysis methods of hydraulic pressure tunnel linings[D]. Dalian: Dalian University of Technology, 2015. (in Chinese) [31] 苏 凯, 伍鹤皋, 周创兵. 内水压力下水工隧洞衬砌与围岩承载特性研究[J]. 岩土力学,2010,31(8):2407-2412,2452. (SU K, WU H G, ZHOU C B. Study of combined bearing characteristics of lining and surrounding rock for hydraulic tunnel under internal water pressure[J]. Rock and Soil Mechanics,2010,31(8):2407-2412,2452. (in Chinese) doi: 10.3969/j.issn.1000-7598.2010.08.010SU K, WU H G, ZHOU C B. Study of combined bearing characteristics of lining and surrounding rock for hydraulic tunnel under internal water pressure[J]. Rock and Soil Mechanics, 2010, 31(8): 2407-2412,2452. (in Chinese) doi: 10.3969/j.issn.1000-7598.2010.08.010 [32] 卢兆康. 高压引水隧洞的有限元计算[J]. 人民珠江,1992(1):15-19. (LU Z K. The calcultion of high pressure tunnel by means of finite element method[J]. Pearl River,1992(1):15-19. (in Chinese)LU Z K. The calcultion of high pressure tunnel by means of finite element method[J]. Pearl River, 1992(1): 15-19. [33] 张 栋, 邰纯洁, 肖 明. 惠州抽水蓄能电站地下高压钢筋混凝土岔管三维有限元分析[J]. 湖北水力发电,2006(1):24-28. (ZHANG D, TAI C J, XIAO M. 3-D finite element analysis of underground high pressure R C Bifurcation of huizhou pumped storage power station[J]. Hubei water power,2006(1):24-28. (in Chinese)ZHANG D, TAI C J, XIAO M. 3-D finite element analysis of underground high pressure R C Bifurcation of huizhou pumped storage power station[J]. Hubei water power, 2006(1): 24-28. [34] 王 明. 广东阳江抽水蓄能电站高压隧洞钢筋混凝土衬砌结构设计[J]. 广东水利水电,2022(12):79-83. (WANG M. Structural design of reinforced concrete lining for high pressure tunnel of Yangjiang pumped storage station[J]. Guangdong Water Resources and Hydropower,2022(12):79-83. (in Chinese)WANG M. Structural design of reinforced concrete lining for high pressure tunnel of Yangjiang pumped storage station[J]. Guangdong Water Resources and Hydropower, 2022(12): 79-83. (in Chinese) -

下载:

下载: