Effects of pore spacing and pore diameter on mechanical properties of sandstone with uniformly distributed pores

-

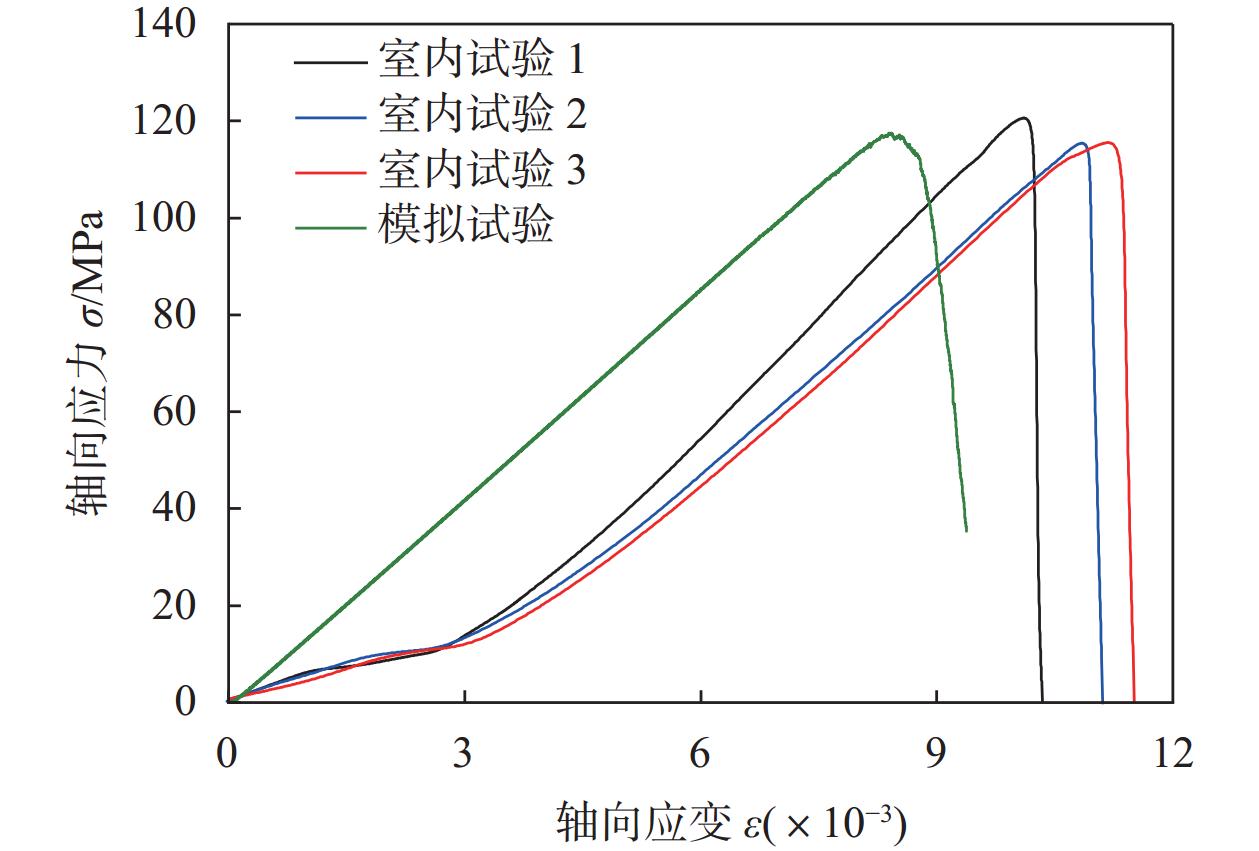

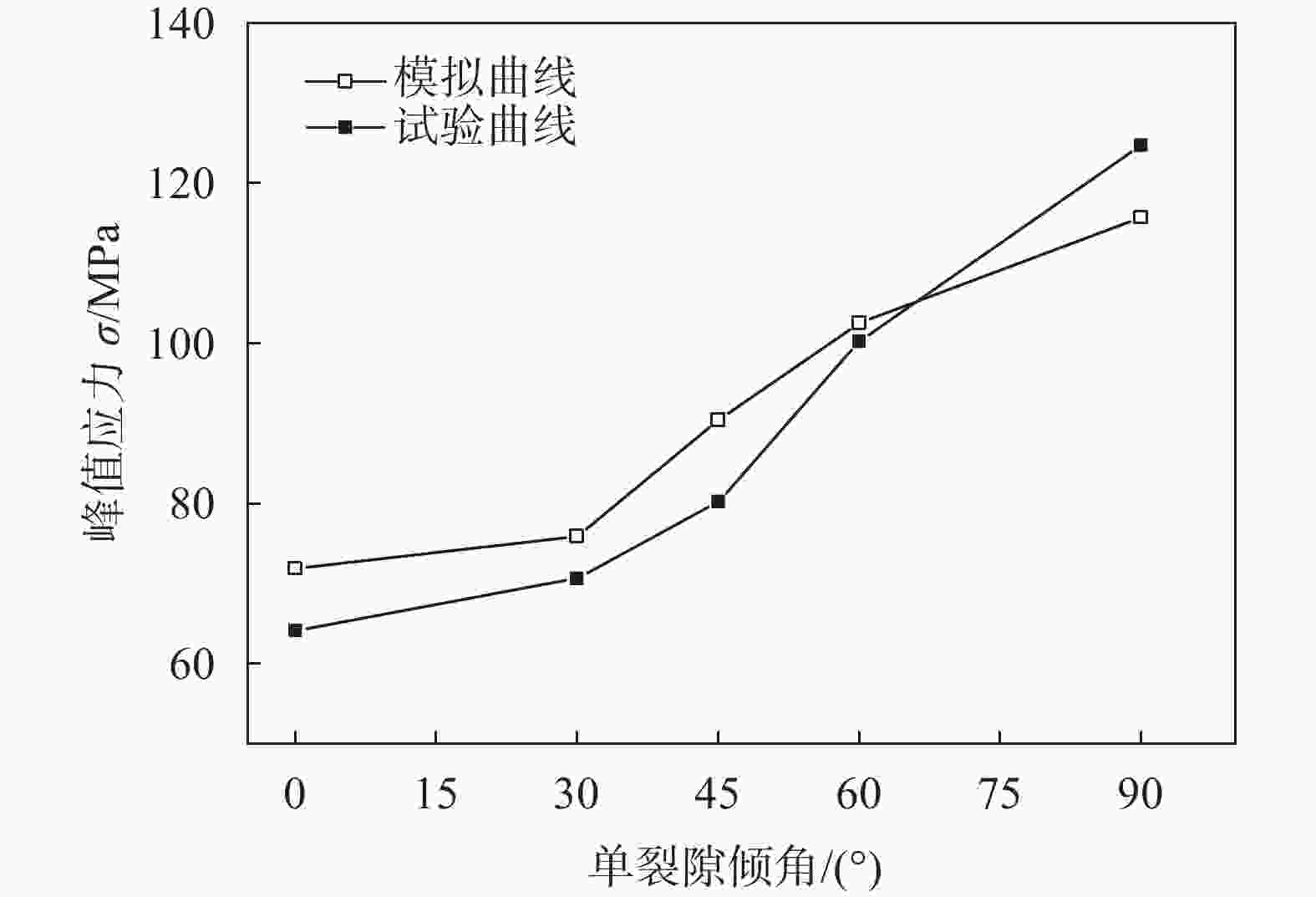

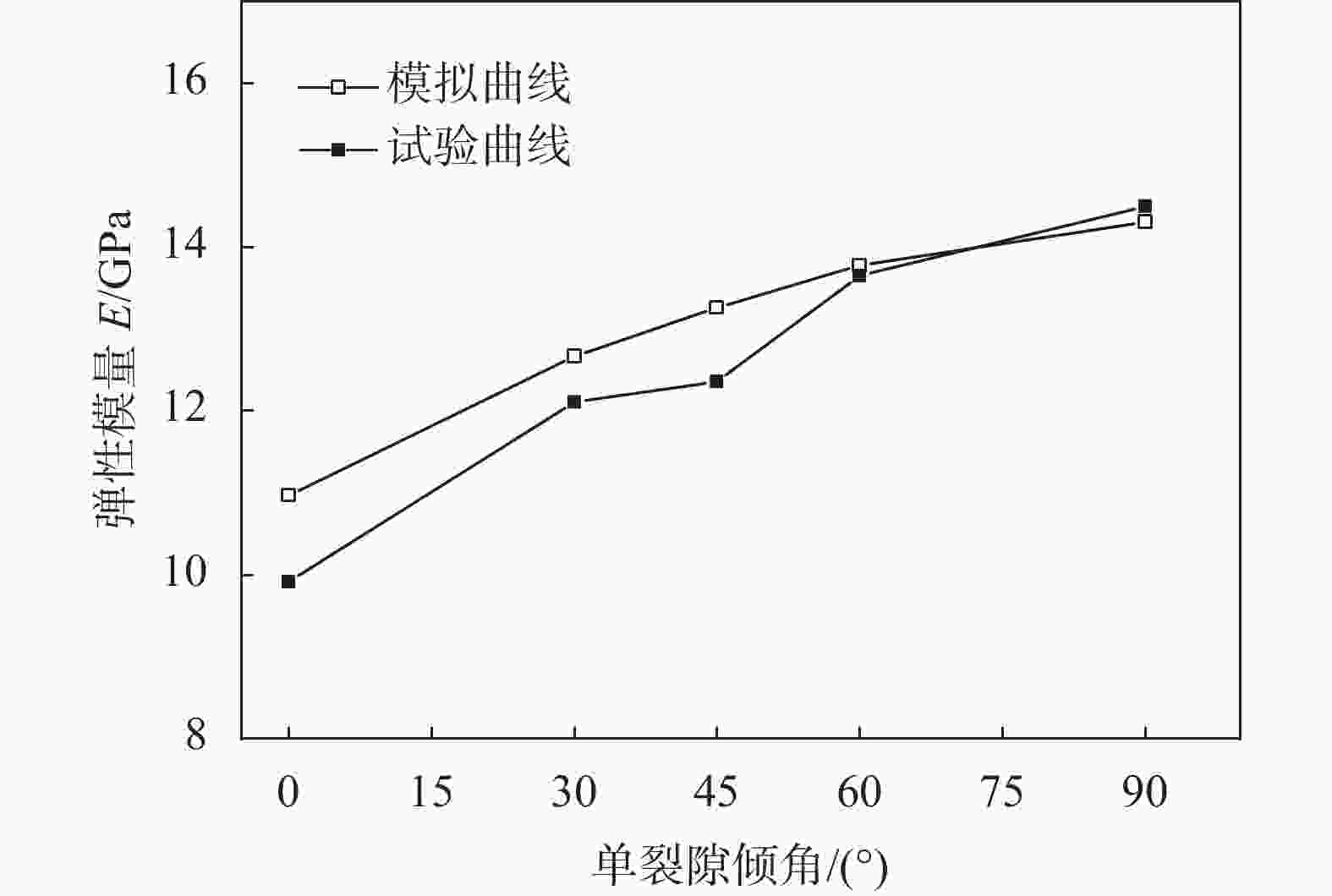

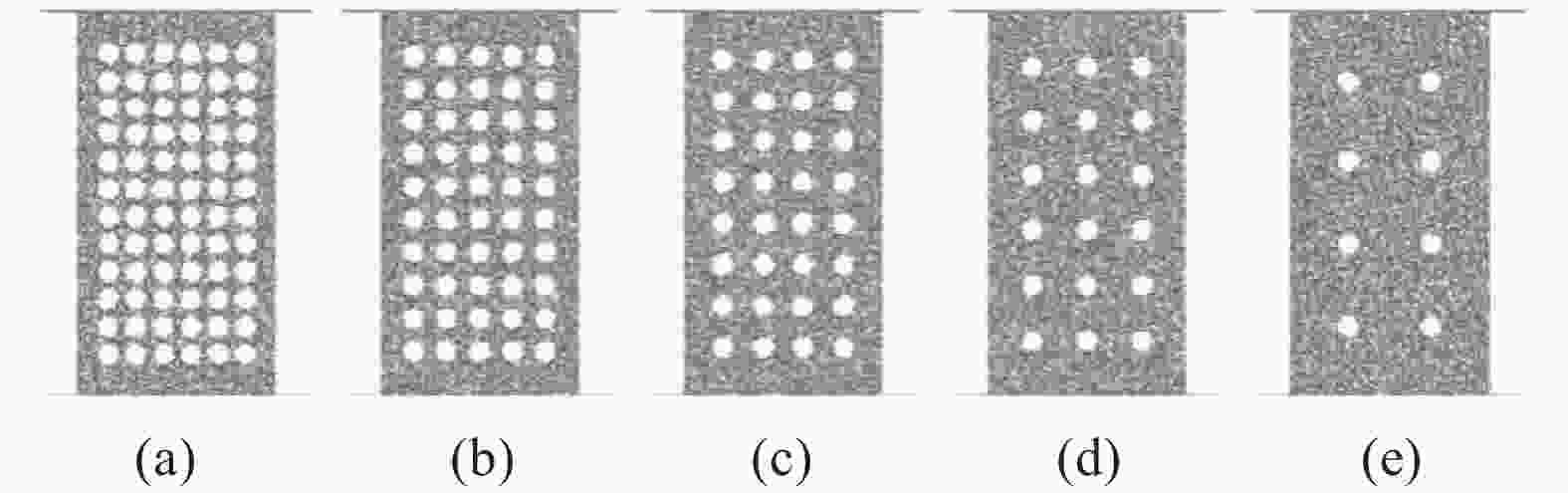

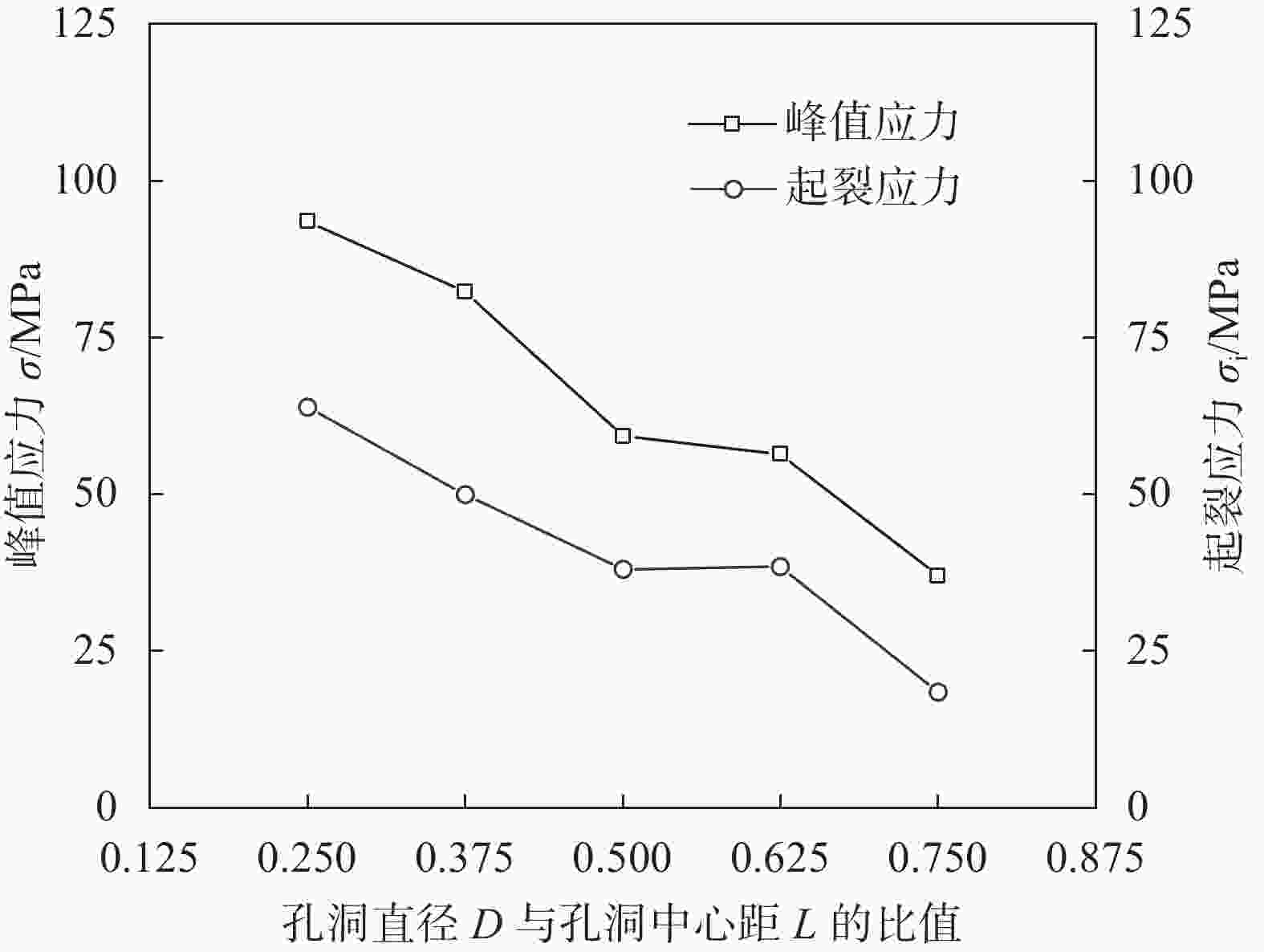

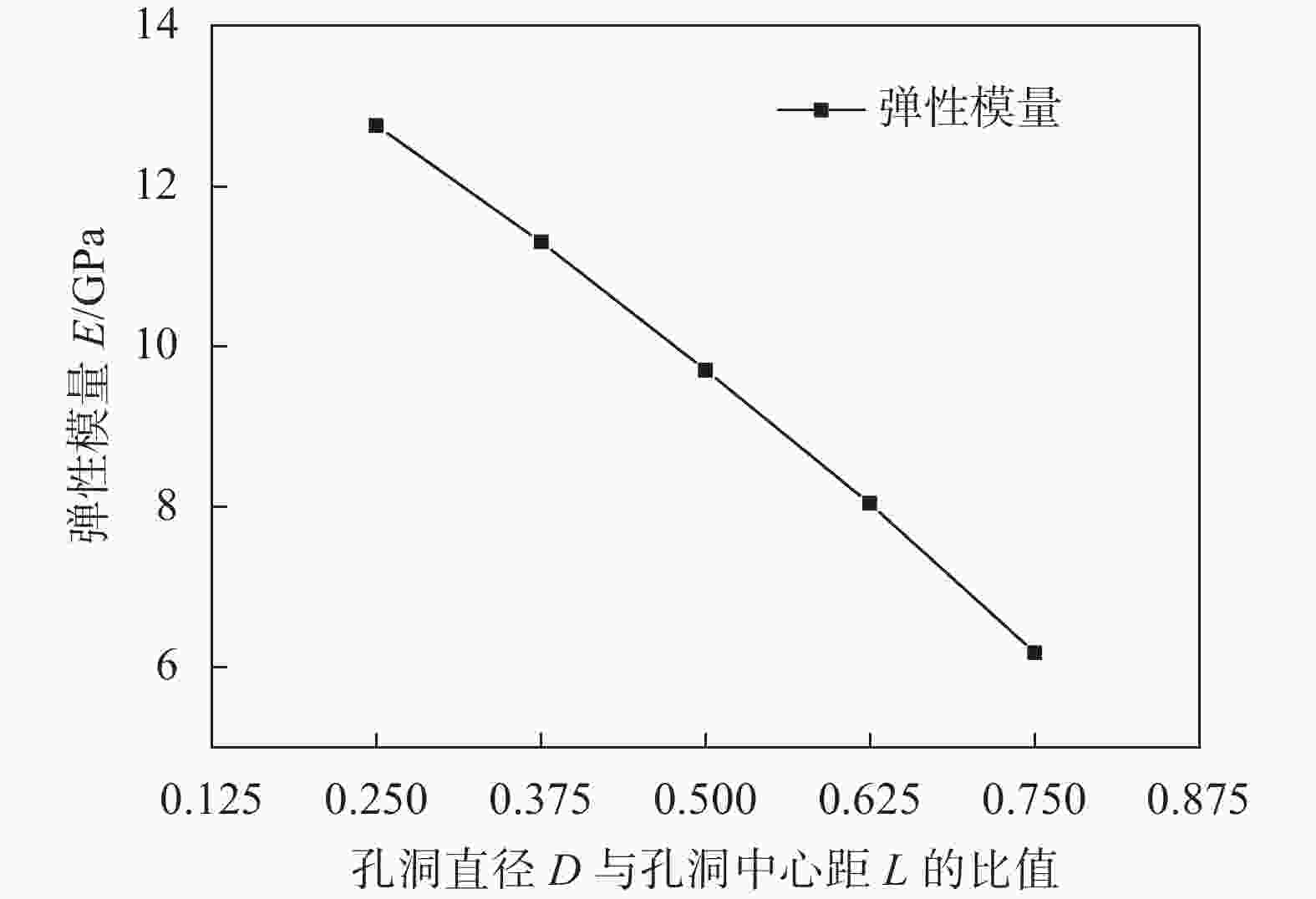

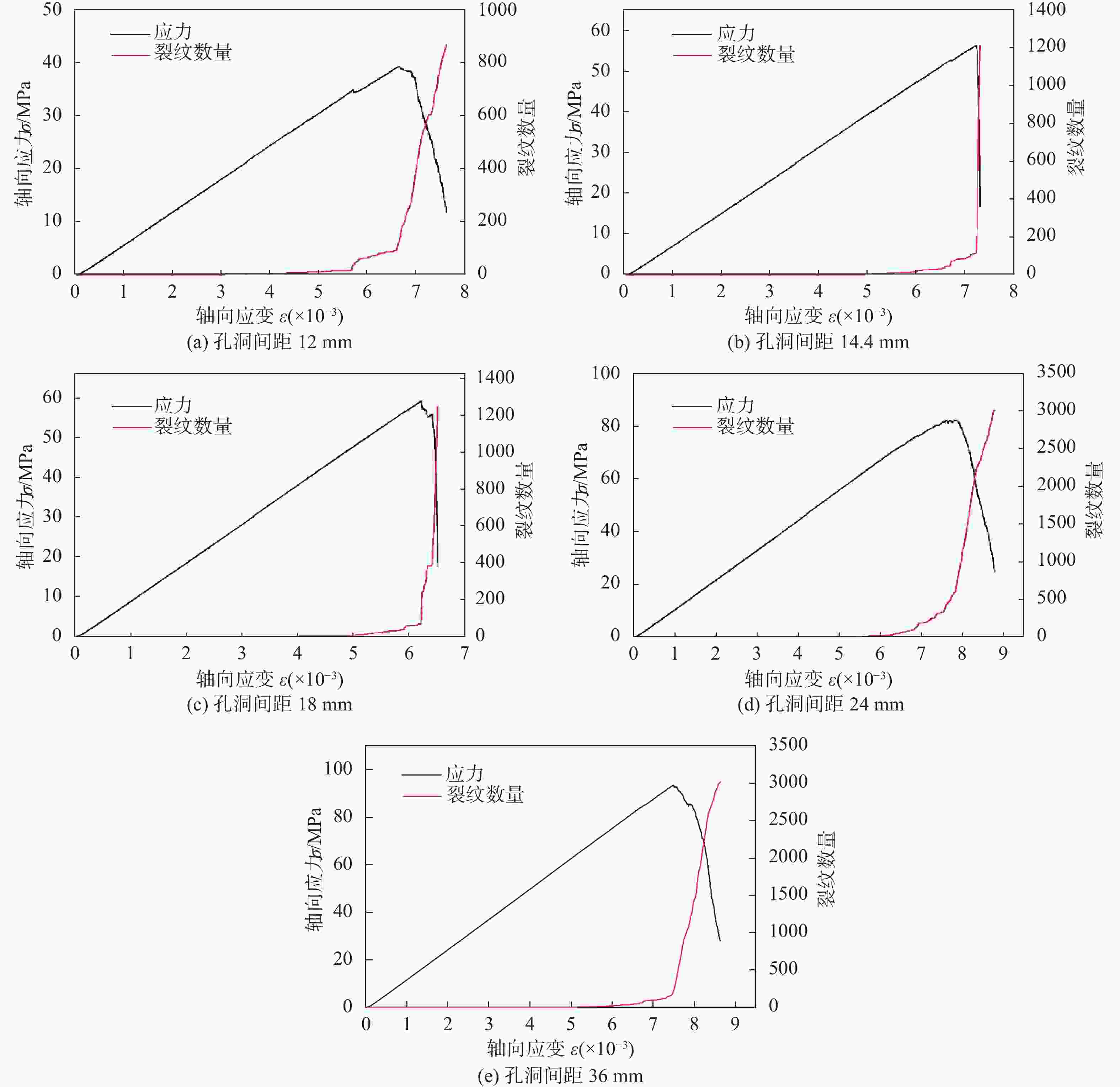

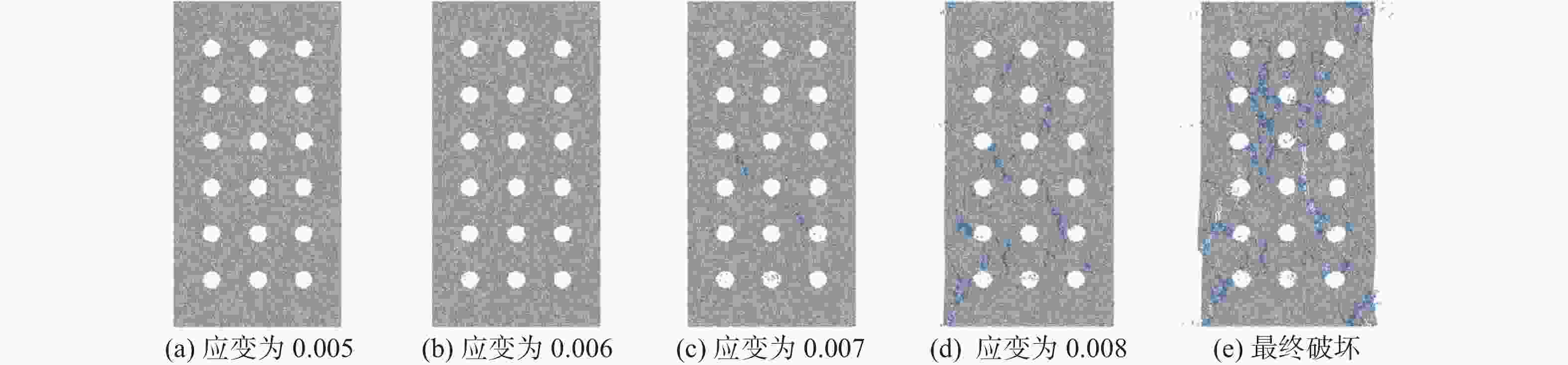

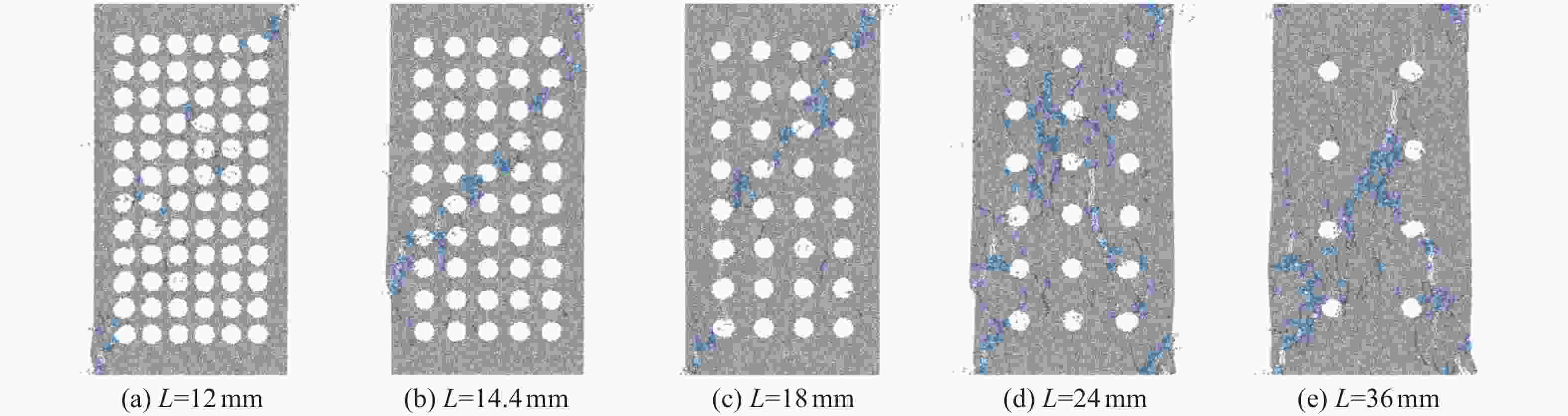

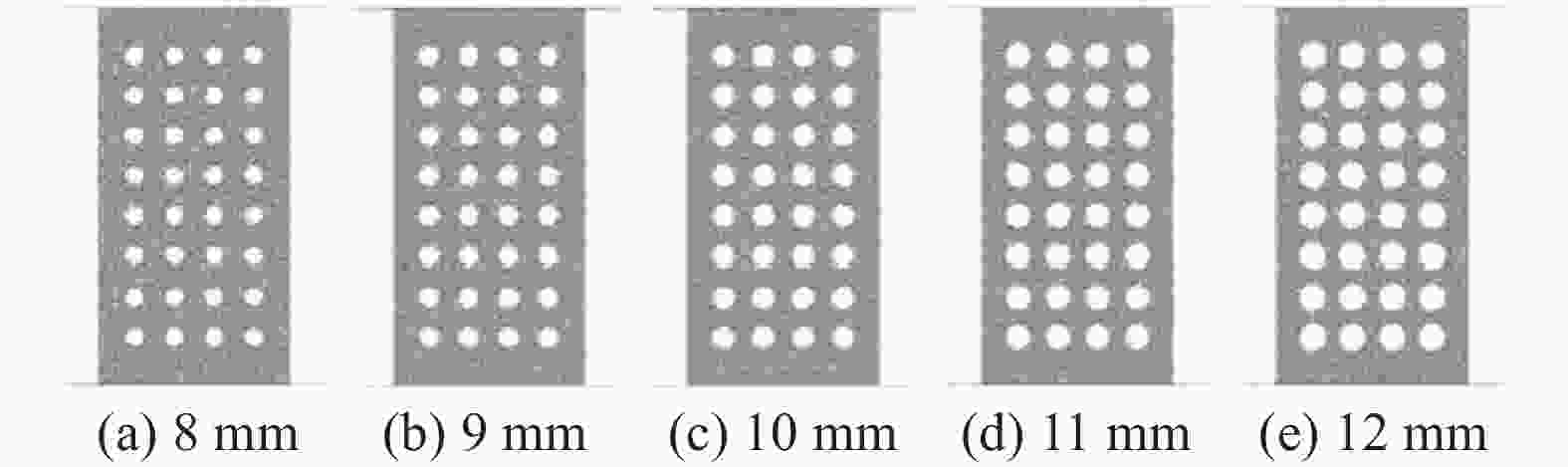

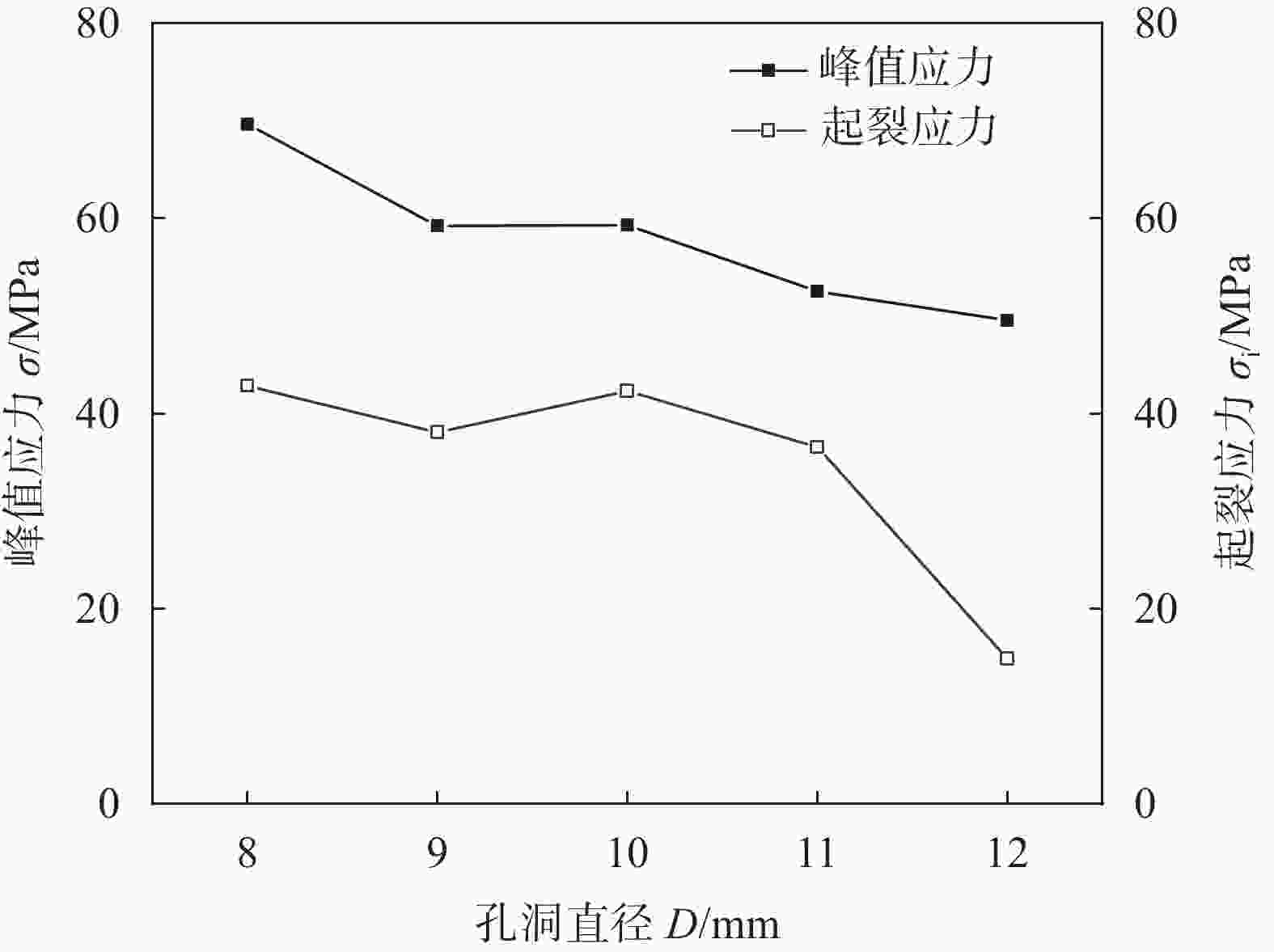

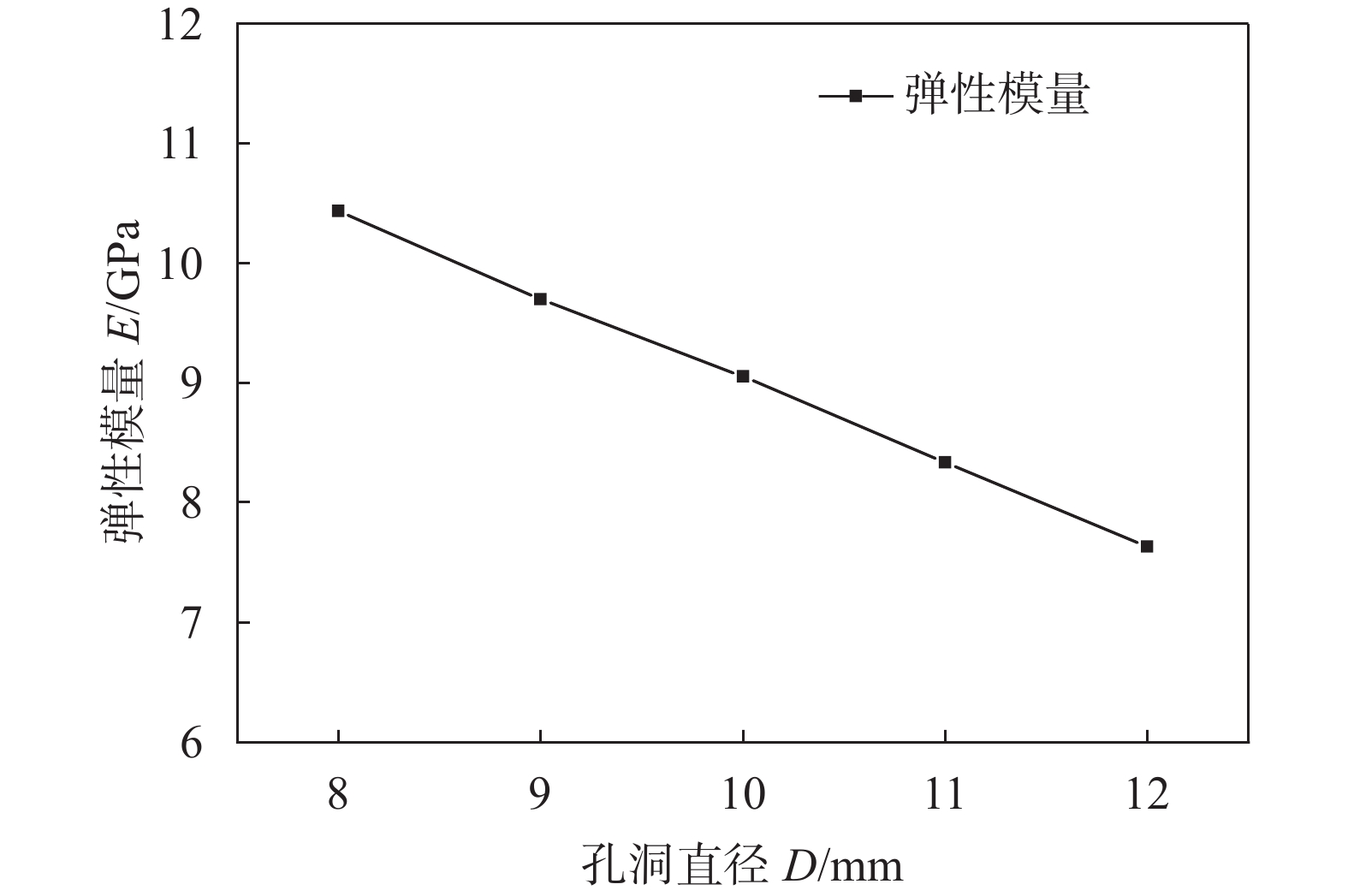

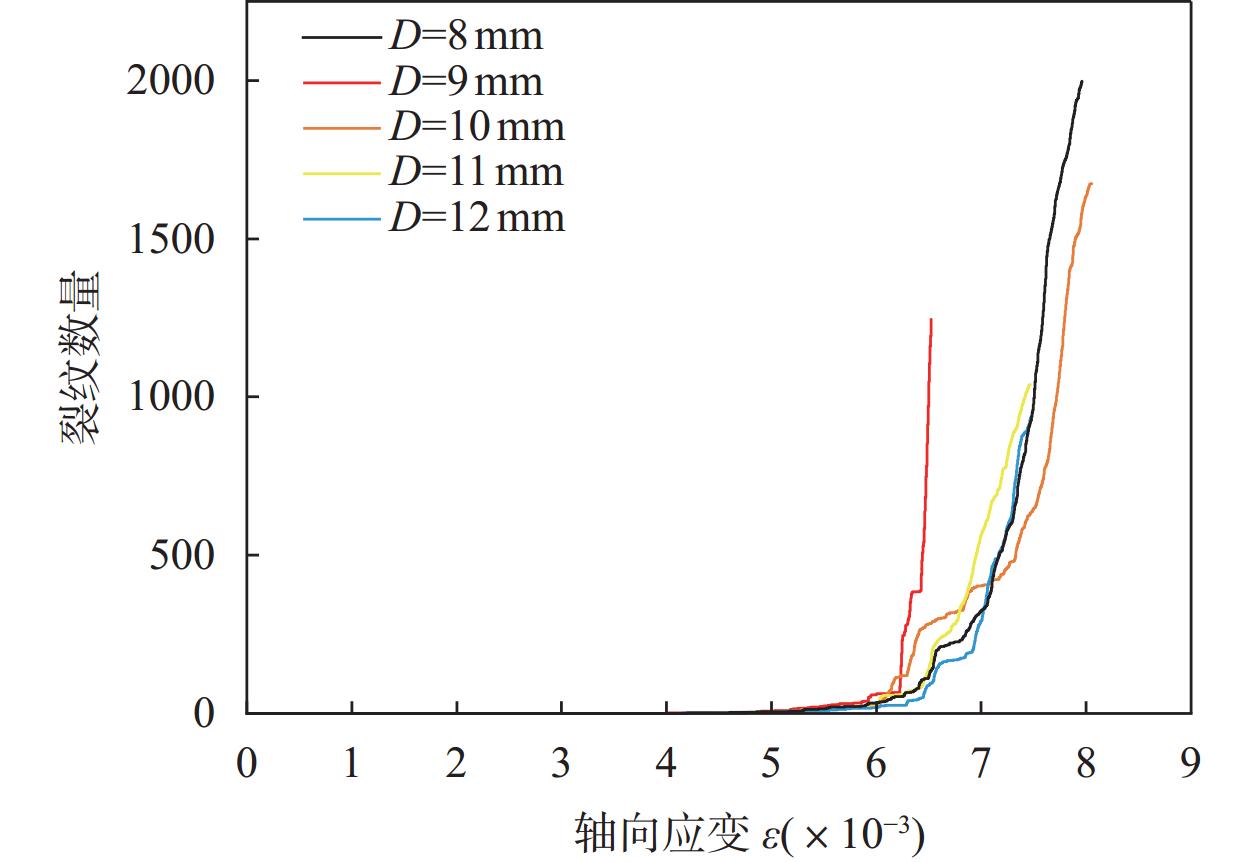

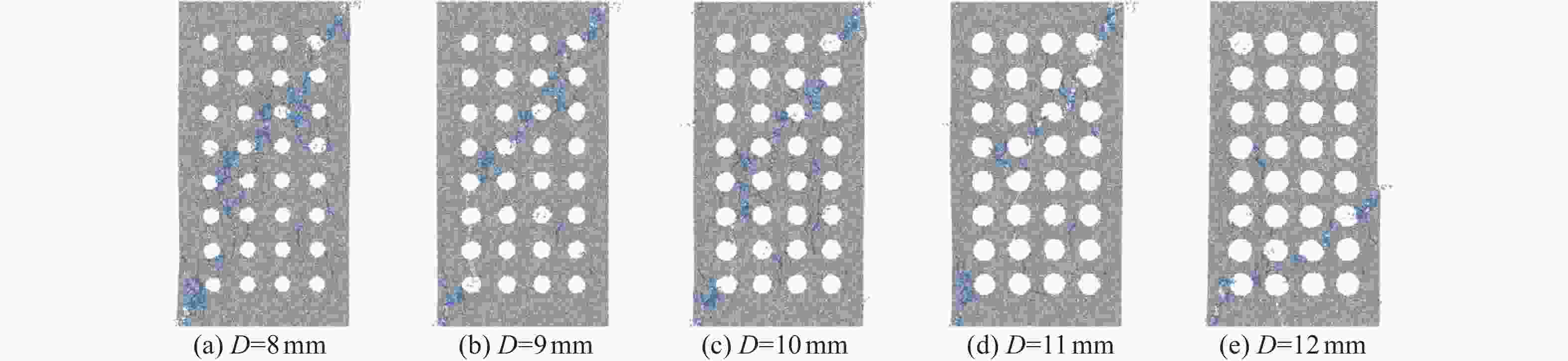

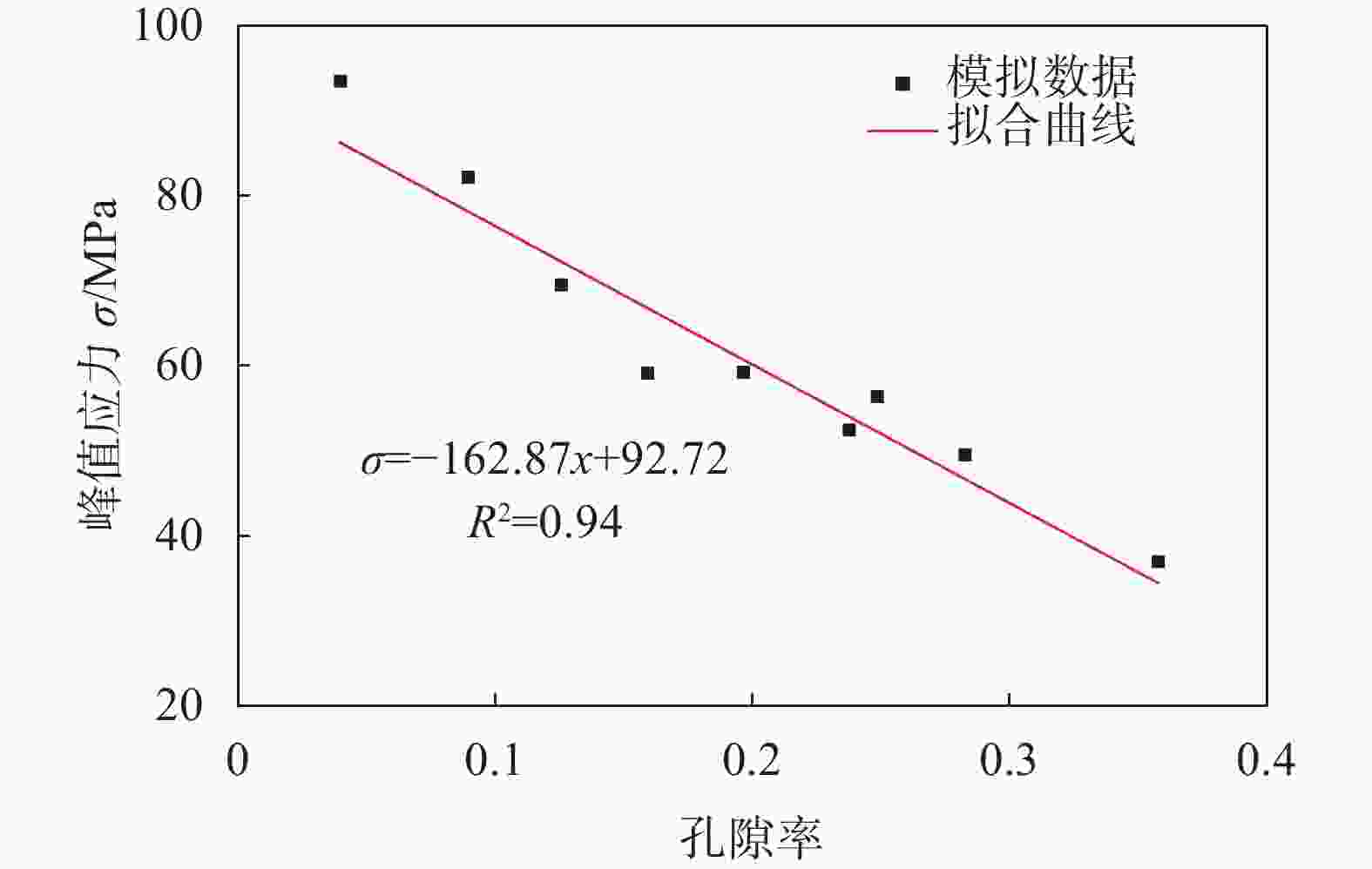

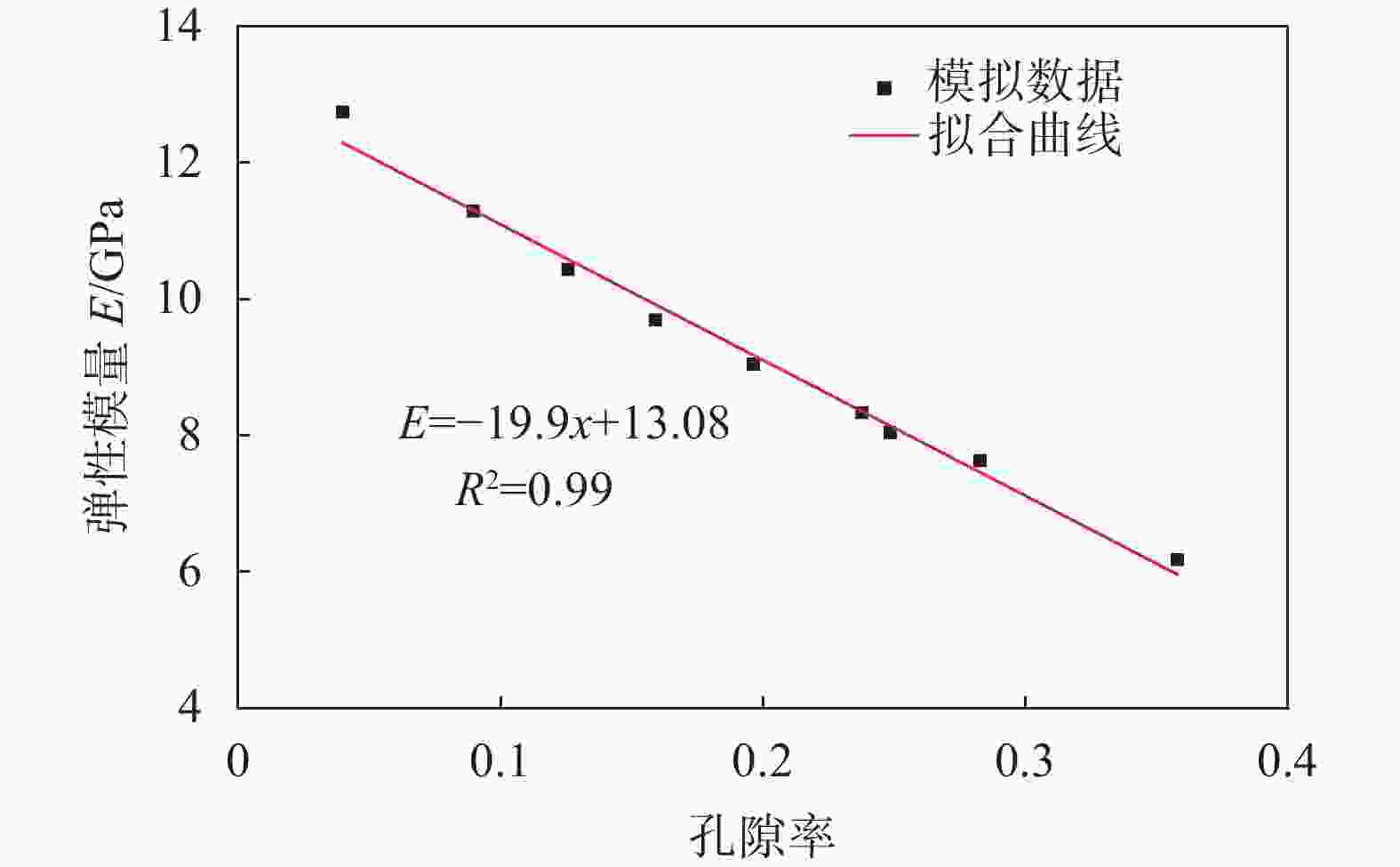

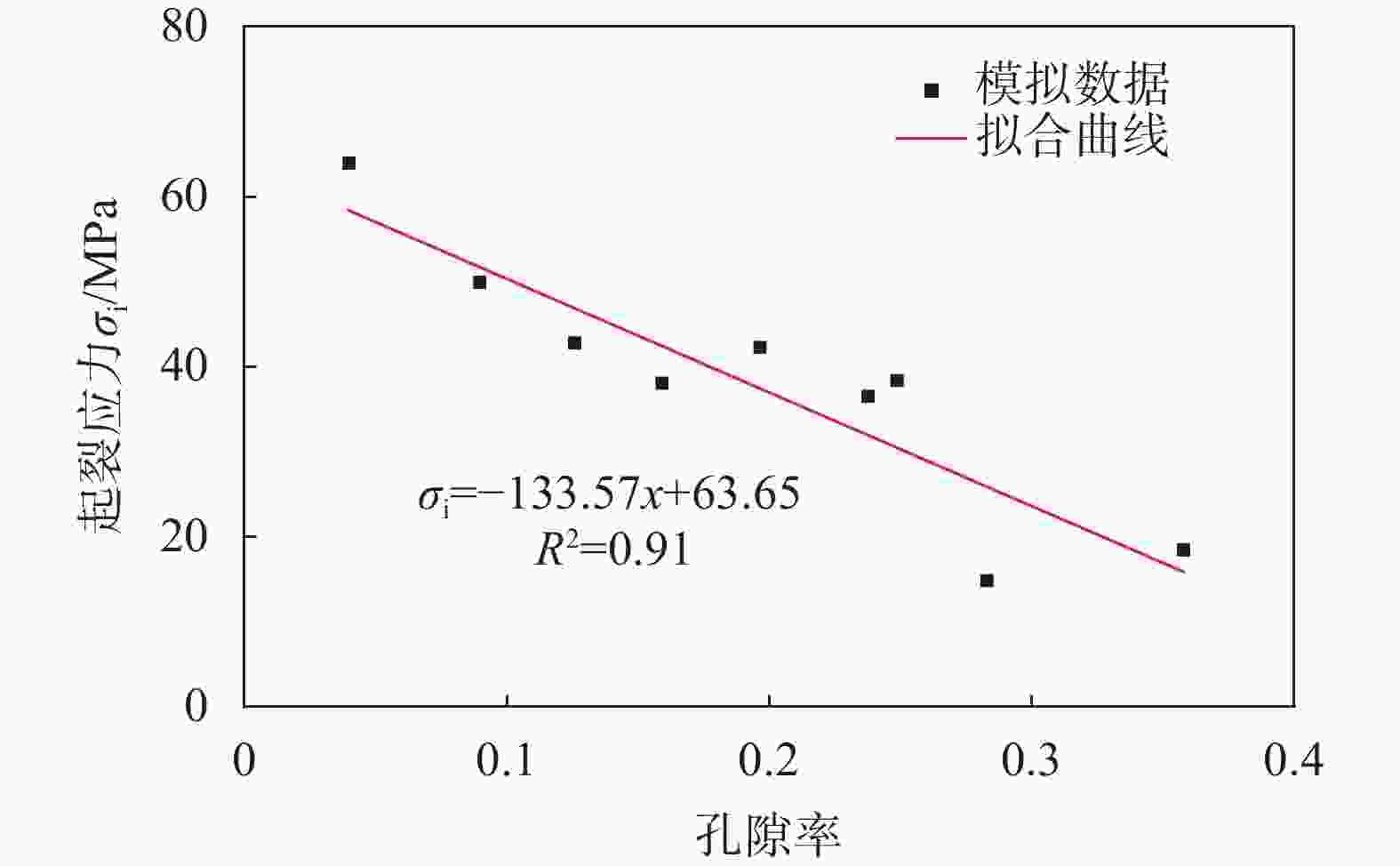

摘要: 为了研究孔洞间距和孔洞直径对于含均布孔洞岩石变形破坏的影响规律,基于完整砂岩试样和含有预制单一裂隙砂岩试样的室内单轴压缩试验数据,应用离散元颗粒流软件进行模拟,确定一组细观参数,并运用这组细观参数对含均布孔洞砂岩试样开展单轴压缩模拟试验。研究结果表明:当保持孔洞直径不变,随孔洞间距减小,试样的峰值应力、起裂应力和弹性模量均呈减小趋势,试样的破坏形式由剪切破坏逐渐变为劈裂破坏;当保持孔洞间距不变,随孔洞直径增大,试样的峰值应力、起裂应力和弹性模量呈减小趋势,试样破坏形式由劈裂剪切复合破坏转变为剪切破坏;试样加载破坏起于孔洞周围的应力集中,最终由于颗粒黏结断裂导致裂纹的扩展并贯通破坏,且试样的拉伸裂纹明显多于剪切裂纹。Abstract: To study the influence of pore spacing and pore diameter on the deformation and failure of rocks with uniformly distributed pores, a set of microscopic parameters was determined by using the indoor uniaxial compression test data of complete sandstone specimens and sandstone specimens with prefabricated single cracks and discrete element particle flow software simulation, and the uniaxial compression simulation test of sandstone specimens with uniformly distributed pores was carried out based on the microscopic parameters. The research results indicate that when the pore diameter is kept constant, the peak stress, crack initiation stress and elastic modulus of the specimen all show a decreasing trend with the decrease of pore spacing, and the failure form of the specimen changes from shear failure to splitting failure; when the pore spacing is kept constant, the peak stress, crack initiation stress and elastic modulus of the specimen show a decreasing trend with the increase of pore diameter, and the failure form of the specimen changes from splitting shear composite failure to shear failure; the failure of the specimen starts from the stress concentration around the pore, and finally, the cracks extend and penetrate due to the fracture of particle bonding. Notably, the tensile cracks of the specimen are significantly more than the shear cracks.

-

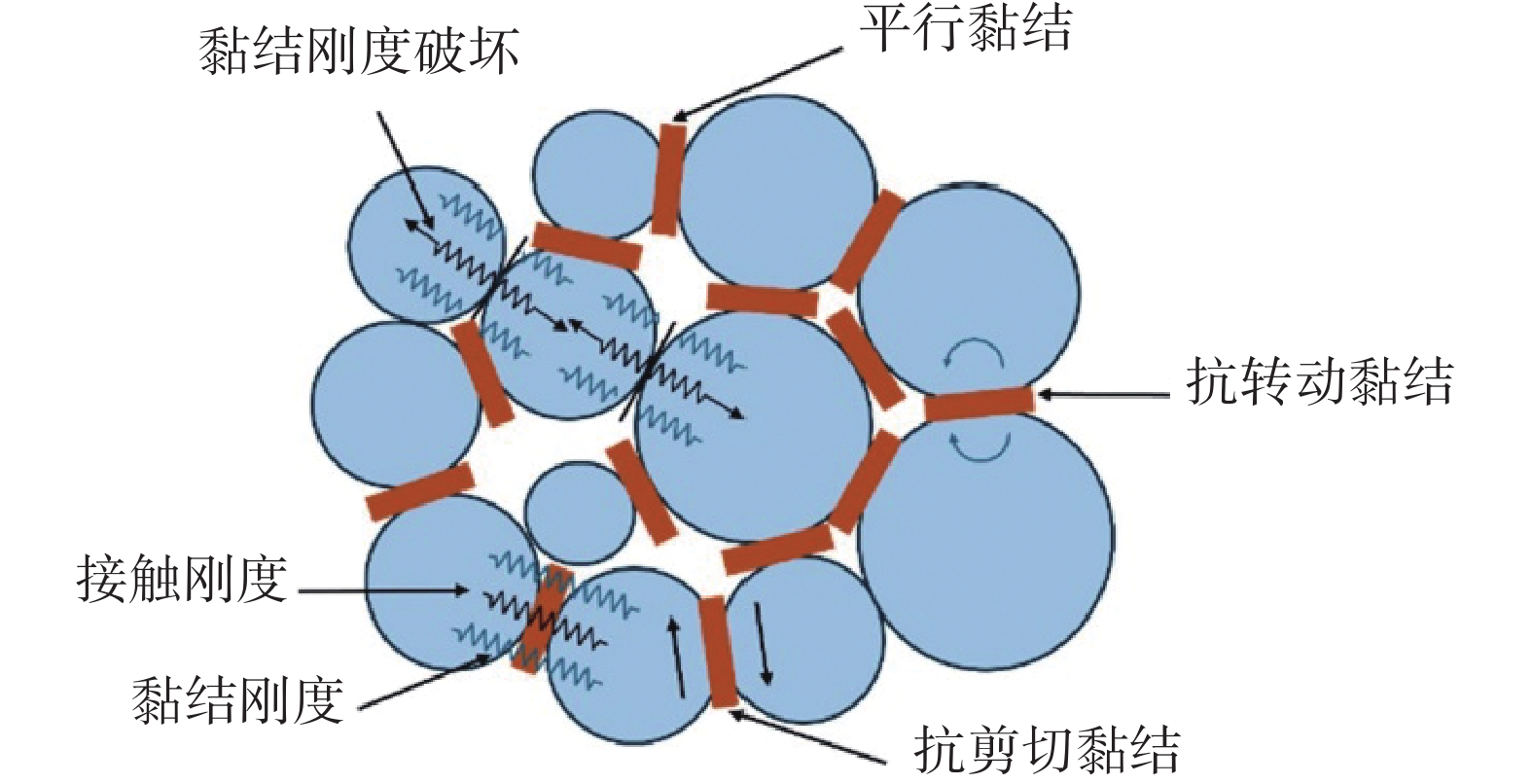

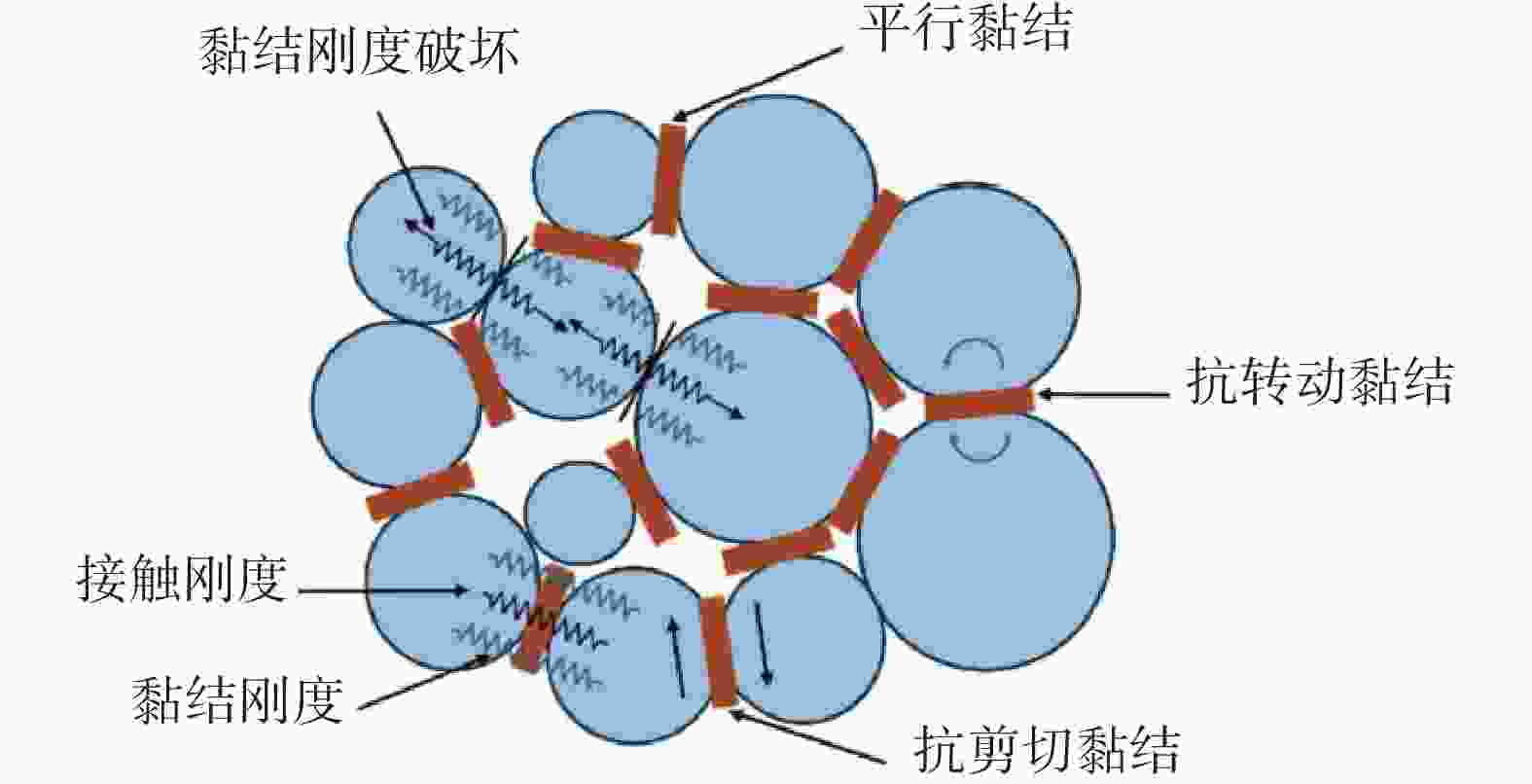

图 1 平行黏结模型[18]

表 1 砂岩试样细观参数

参数 取值 颗粒最小半径/mm 0.30 颗粒粒径比 1.60 颗粒密度/ (kg∙m−3) 2449 颗粒接触模量/GPa 9.5 颗粒刚度比 1.2 颗粒摩擦系数 0.9 平行黏结模量/GPa 1.0 平行黏结刚度比 1.2 法向黏结刚度/MPa 60±10 切向黏结刚度/MPa 80±30 表 2 砂岩断裂韧度试验数据统计[25]

岩石类型 $ K\mathrm{_{IC}} $/(MPa∙m1/2) 砂岩试样1 0.67 砂岩试样2 0.38 砂岩试样3 0.56 砂岩试样4 1.47 砂岩试样5 1.40 砂岩试样6 0.37 砂岩试样7 0.45 -

[1] 王志文, 赵海军, 马凤山, 等. 非均质共面断续节理岩体拉伸剪切破裂机制研究[J]. 工程地质学报, 2019, 27(5): 989-999. (WANG Z W, ZHAO H J, MA F S, et al. Numerical study on tension-shear failure mechanism of heterogeneous coplanar intermittent jointed rock mass[J]. Journal of Engineering Geology, 2019, 27(5): 989-999. (in Chinese)WANG Z W, ZHAO H J, MA F S, et al. Numerical study on tension-shear failure mechanism of heterogeneous coplanar intermittent jointed rock mass[J]. Journal of Engineering Geology, 2019, 27(5): 989-999. (in Chinese) [2] 刘享华, 张 科, 李 娜, 等. 含孔双裂隙3D打印类岩石试件破裂行为定量识别[J]. 岩土力学, 2021, 42(11): 3017-3028. (LIU X H, ZHANG K, LI N, et al. Quantitative identification of the failure behavior of the 3D printed rock-like specimen with one hole and two flaws[J]. Rock and Soil Mechanics, 2021, 42(11): 3017-3028. (in Chinese)LIU X H, ZHANG K, LI N, et al. Quantitative identification of the failure behavior of the 3D printed rock-like specimen with one hole and two flaws[J]. Rock and Soil Mechanics, 2021, 42(11): 3017-3028. (in Chinese) [3] 赵 娜, 孟利新, 张怡斌. 含单裂隙岩体蠕变破裂裂纹扩展演化规律研究[J]. 应用力学学报, 2023, 40(5): 1106-1116. (ZHAO N, MENG L X, ZHANG Y B. Study on the meso-crack propagation and evolution law of creep fracture in rock mass with single fissure[J]. Chinese Journal of Applied Mechanics, 2023, 40(5): 1106-1116. (in Chinese)ZHAO N, MENG L X, ZHANG Y B. Study on the meso-crack propagation and evolution law of creep fracture in rock mass with single fissure[J]. Chinese Journal of Applied Mechanics, 2023, 40(5): 1106-1116. (in Chinese) [4] 李学华, 牛志军, 姚强岭, 等. 孔洞式三叉裂隙砂岩裂纹扩展特征颗粒流分析[J]. 煤炭学报, 2020, 45(11): 3735-3747. (LI X H, NIU Z J, YAO Q L, et al. Particle flow analysis of crack propagation characteristics of hole-type trident cracks sandstone[J]. Journal of China Coal Society, 2020, 45(11): 3735-3747. (in Chinese)LI X H, NIU Z J, YAO Q L, et al. Particle flow analysis of crack propagation characteristics of hole-type trident cracks sandstone[J]. Journal of China Coal Society, 2020, 45(11): 3735-3747. (in Chinese) [5] 朱泉企, 李地元, 李夕兵. 含预制椭圆形孔洞大理岩变形破坏力学特性试验研究[J]. 岩石力学与工程学报, 2019, 38(S1): 2724-2733. (ZHU Q Q, LI D Y, LI X B. Experimental study on failure and mechanical characteristics of marble containing a prefabricated elliptical hole[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(S1): 2724-2733. (in Chinese)ZHU Q Q, LI D Y, LI X B. Experimental study on failure and mechanical characteristics of marble containing a prefabricated elliptical hole[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(S1): 2724-2733. (in Chinese) [6] WANG T, KANG Q R, ZHANG X Y, et al. Study on the influence of hole defects with different shapes on the mechanical behavior and damage law of coal and rock[J]. PLoS One, 2022, 17(3): e0265753. doi: 10.1371/journal.pone.0265753 [7] YANG S Q, LIU X R, JING H W. Experimental investigation on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression[J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 63: 82-92. doi: 10.1016/j.ijrmms.2013.06.008 [8] PAN W D, WANG X, LIU Q M, et al. Non-parallel double-crack propagation in rock-like materials under uniaxial compression[J]. International Journal of Coal Science & Technology, 2019, 6(3): 372-387. [9] HAERI H, SARFARAZI V, FATEHI MARJI M. Experimental and numerical investigation of uniaxial compression failure in rock-like specimens with L-shaped nonpersistent cracks[J]. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 2021, 45(4): 2555-2575. doi: 10.1007/s40996-020-00386-w [10] 朱谭谭, 靖洪文, 苏海健, 等. 含双圆形孔洞砂岩单轴压缩力学特性试验研究[J]. 岩土工程学报, 2015, 37(6): 1047-1056. (ZHU T T, JING H W, SU H J, et al. Mechanical behavior of sandstone containing double circular cavities under uniaxial compression[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(6): 1047-1056. (in Chinese) doi: 10.11779/CJGE201506011ZHU T T, JING H W, SU H J, et al. Mechanical behavior of sandstone containing double circular cavities under uniaxial compression[J]. Chinese Journal of Geotechnical Engineering, 2015, 37(6): 1047-1056. (in Chinese) doi: 10.11779/CJGE201506011 [11] TANG C A, WONG R H C, CHAU K T, et al. Modeling of compression-induced splitting failure in heterogeneous brittle porous solids[J]. Engineering Fracture Mechanics, 2005, 72(4): 597-615. doi: 10.1016/j.engfracmech.2004.04.008 [12] 蒋明镜, 张 宁, 申志福, 等. 含裂隙岩体单轴压缩裂纹扩展机制离散元分析[J]. 岩土力学, 2015, 36(11): 3293-3300,3314. (JIANG M J, ZHANG N, SHEN Z F, et al. DEM analyses of crack propagation in flawed rock mass under uniaxial compression[J]. Rock and Soil Mechanics, 2015, 36(11): 3293-3300,3314. (in Chinese)JIANG M J, ZHANG N, SHEN Z F, et al. DEM analyses of crack propagation in flawed rock mass under uniaxial compression[J]. Rock and Soil Mechanics, 2015, 36(11): 3293-3300,3314. (in Chinese) [13] ZHANG X P, ZHANG Q, WU S C. Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates[J]. Computers and Geotechnics, 2017, 83: 83-97. doi: 10.1016/j.compgeo.2016.11.003 [14] 吕学刚, 任梦梓, 杨维弘, 等. 条状缺陷倾角对砂岩力学特性影响的模拟研究[J]. 矿业安全与环保, 2020, 47(6): 43-47,53. (LYU X G, REN M Z, YANG W H, et al. Numerical study on the influence of strip defect angle on the mechanical properties of sandstone[J]. Mining Safety & Environmental Protection, 2020, 47(6): 43-47,53. (in Chinese)LYU X G, REN M Z, YANG W H, et al. Numerical study on the influence of strip defect angle on the mechanical properties of sandstone[J]. Mining Safety & Environmental Protection, 2020, 47(6): 43-47,53. (in Chinese) [15] YANG S Q, XU T, HE L, et al. Numerical study on failure behavior of brittle rock specimen containing pre-existing combined flaws under different confining pressure[J]. Archives of Civil and Mechanical Engineering, 2015, 15(4): 1085-1097. doi: 10.1016/j.acme.2015.03.005 [16] CUNDALL P A, STRACK O D L. Discussion: a discrete numerical model for granular assemblies[J]. Géotechnique, 1980, 30(3): 331-336. [17] 张 璇, 李之达, 张志华. 基于离散元的新拌混凝土流变性能分析[J]. 武汉理工大学学报, 2017, 39(6): 62-67. (ZHANG X, LI Z D, ZHANG Z H. Rheological properties analysis of fresh concrete based on discrete element method (DEM)[J]. Journal of Wuhan University of Technology, 2017, 39(6): 62-67. (in Chinese)ZHANG X, LI Z D, ZHANG Z H. Rheological properties analysis of fresh concrete based on discrete element method (DEM)[J]. Journal of Wuhan University of Technology, 2017, 39(6): 62-67. (in Chinese) [18] CHO N, MARTIN C D, SEGO D C. A clumped particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2007, 44(7): 997-1010. doi: 10.1016/j.ijrmms.2007.02.002 [19] 张鹏超. 单个非直裂隙红砂岩单轴压缩试验及颗粒流模拟研究[D]. 徐州: 中国矿业大学, 2020. (ZHANG P C. Experimental and particle flow simulation studies of red sandstone containing a single non-straight fissure under uniaxial compression[D]. Xuzhou: China University of Mining and Technology, 2020. (in Chinese)ZHANG P C. Experimental and particle flow simulation studies of red sandstone containing a single non-straight fissure under uniaxial compression[D]. Xuzhou: China University of Mining and Technology, 2020. (in Chinese) [20] 张社荣, 孙 博, 王 超, 等. 含孔洞硬岩破坏过程的离散元分析[J]. 岩石力学与工程学报, 2012, 31(S2): 3855-3863. (ZHANG S R, SUN B, WANG C, et al. Discrete element analysis of failure process of hard rock with a pre-existing circular opening[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S2): 3855-3863. (in Chinese)ZHANG S R, SUN B, WANG C, et al. Discrete element analysis of failure process of hard rock with a pre-existing circular opening[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S2): 3855-3863. (in Chinese) [21] 周志伟, 马雯波. 单轴压缩下含双圆孔类岩石材料破坏机理研究[J/OL]. 应用力学学报, 1-12[2024-06-22]. http://kns.cnki.net/kcms/detail/61.1112.O3.20240318.1626.002.html. (ZHOU Z W, MA W B. Study on the damage mechanism of rock-like materials containing bicircular holes under uniaxial compression[J/OL]. Chinese Journal of Applied Mechanics, 1-12[2024-06-22]. http://kns.cnki.net/kcms/detail/61.1112.O3.20240318.1626.002.html.(in Chinese))ZHOU Z W, MA W B. Study on the damage mechanism of rock-like materials containing bicircular holes under uniaxial compression[J/OL]. Chinese Journal of Applied Mechanics, 1-12[2024-06-22]. http://kns.cnki.net/kcms/detail/61.1112.O3.20240318.1626.002.html.(in Chinese)) [22] 张 闯, 唐建新, 腾俊洋, 等. 孔洞数量及孔径对大理岩力学特性影响的试验研究[J]. 岩土力学, 2017, 38(S2): 41-50. (ZHANG C, TANG J X, TENG J Y, et al. Experimental study of influences of pore number and pore size on mechanical properties of marble[J]. Rock and Soil Mechanics, 2017, 38(S2): 41-50. (in Chinese)ZHANG C, TANG J X, TENG J Y, et al. Experimental study of influences of pore number and pore size on mechanical properties of marble[J]. Rock and Soil Mechanics, 2017, 38(S2): 41-50. (in Chinese) [23] 王 宇, 李 晓, 武艳芳, 等. 脆性岩石起裂应力水平与脆性指标关系探讨[J]. 岩石力学与工程学报, 2014, 33(2): 264-275. (WANG Y, LI X, WU Y F, et al. Research on relationship between crack initiation stress level and brittleness indices for brittle rocks[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(2): 264-275. (in Chinese)WANG Y, LI X, WU Y F, et al. Research on relationship between crack initiation stress level and brittleness indices for brittle rocks[J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(2): 264-275. (in Chinese) [24] SAMMIS C G, ASHBY M F. The failure of brittle porous solids under compressive stress states[J]. Acta Metallurgica, 1986, 34(3): 511-526. doi: 10.1016/0001-6160(86)90087-8 [25] 邓华锋, 朱 敏, 李建林, 等. 砂岩Ⅰ型断裂韧度及其与强度参数的相关性研究[J]. 岩土力学, 2012, 33(12): 3585-3591. (DENG H F, ZHU M, LI J L, et al. Study of mode-I fracture toughness and its correlation with strength parameters of sandstone[J]. Rock and Soil Mechanics, 2012, 33(12): 3585-3591. (in Chinese)DENG H F, ZHU M, LI J L, et al. Study of mode-I fracture toughness and its correlation with strength parameters of sandstone[J]. Rock and Soil Mechanics, 2012, 33(12): 3585-3591. (in Chinese) -

下载:

下载: