Reinforcement effect and construction process of rapid impact compaction for highway reconstruction and expansion

-

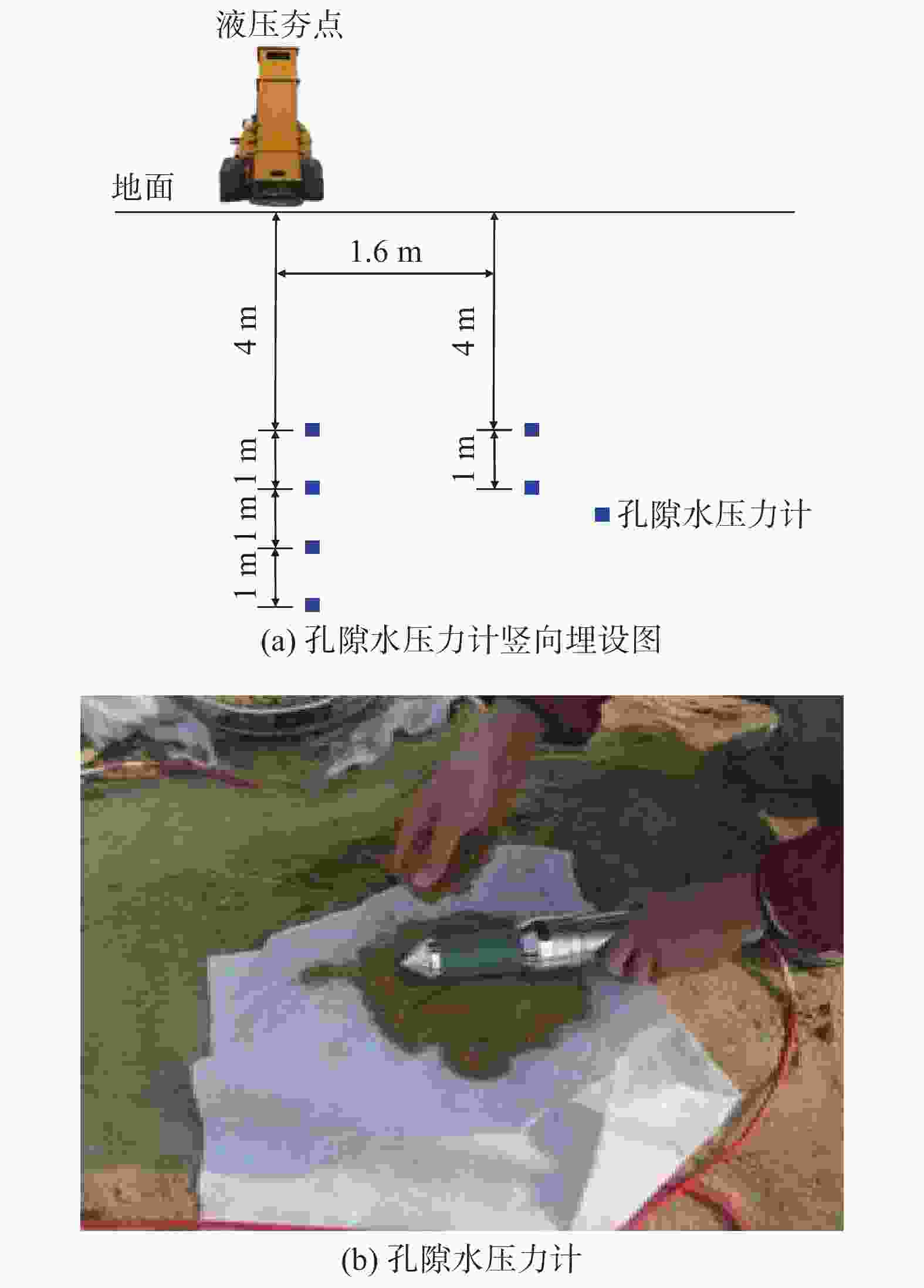

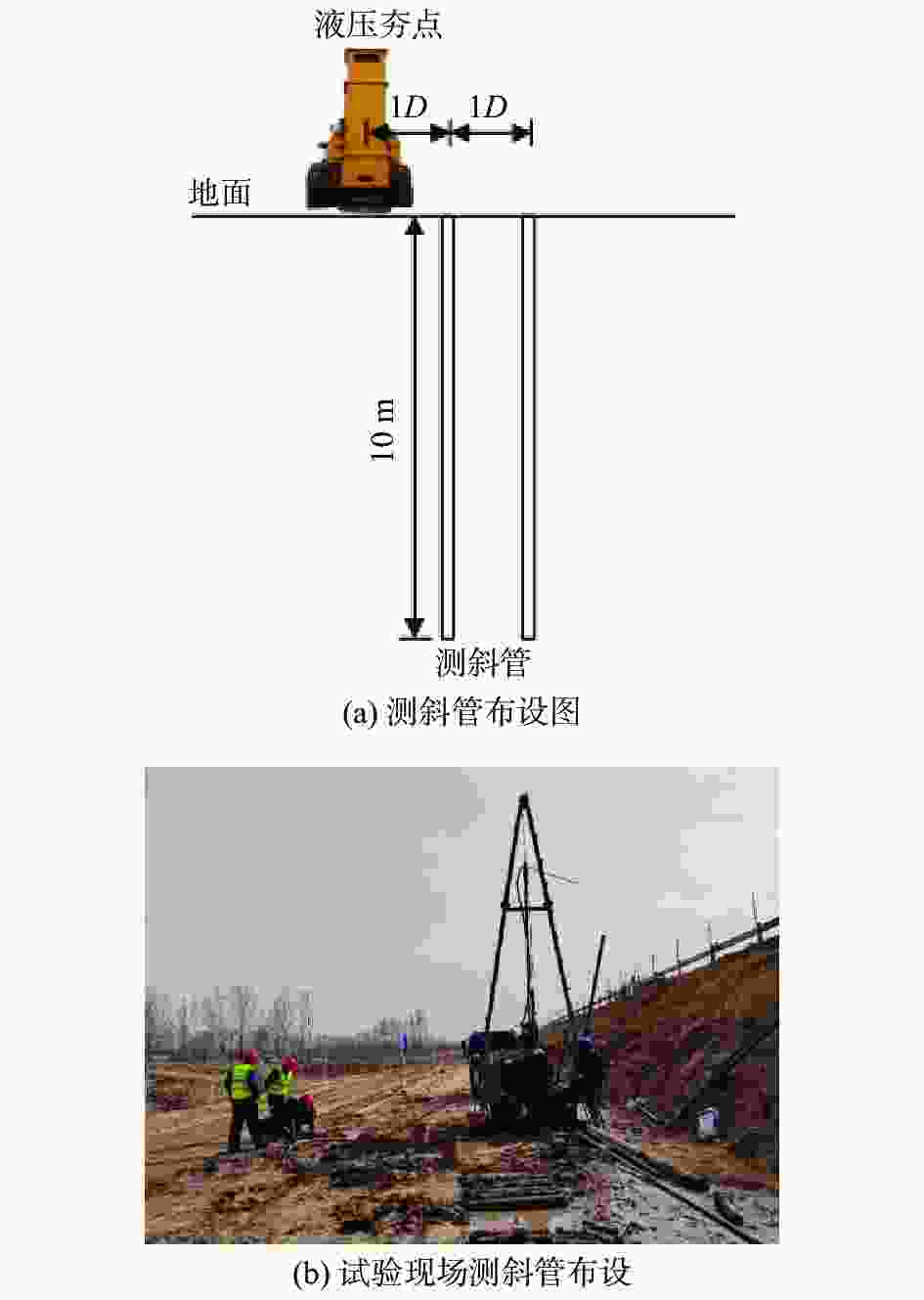

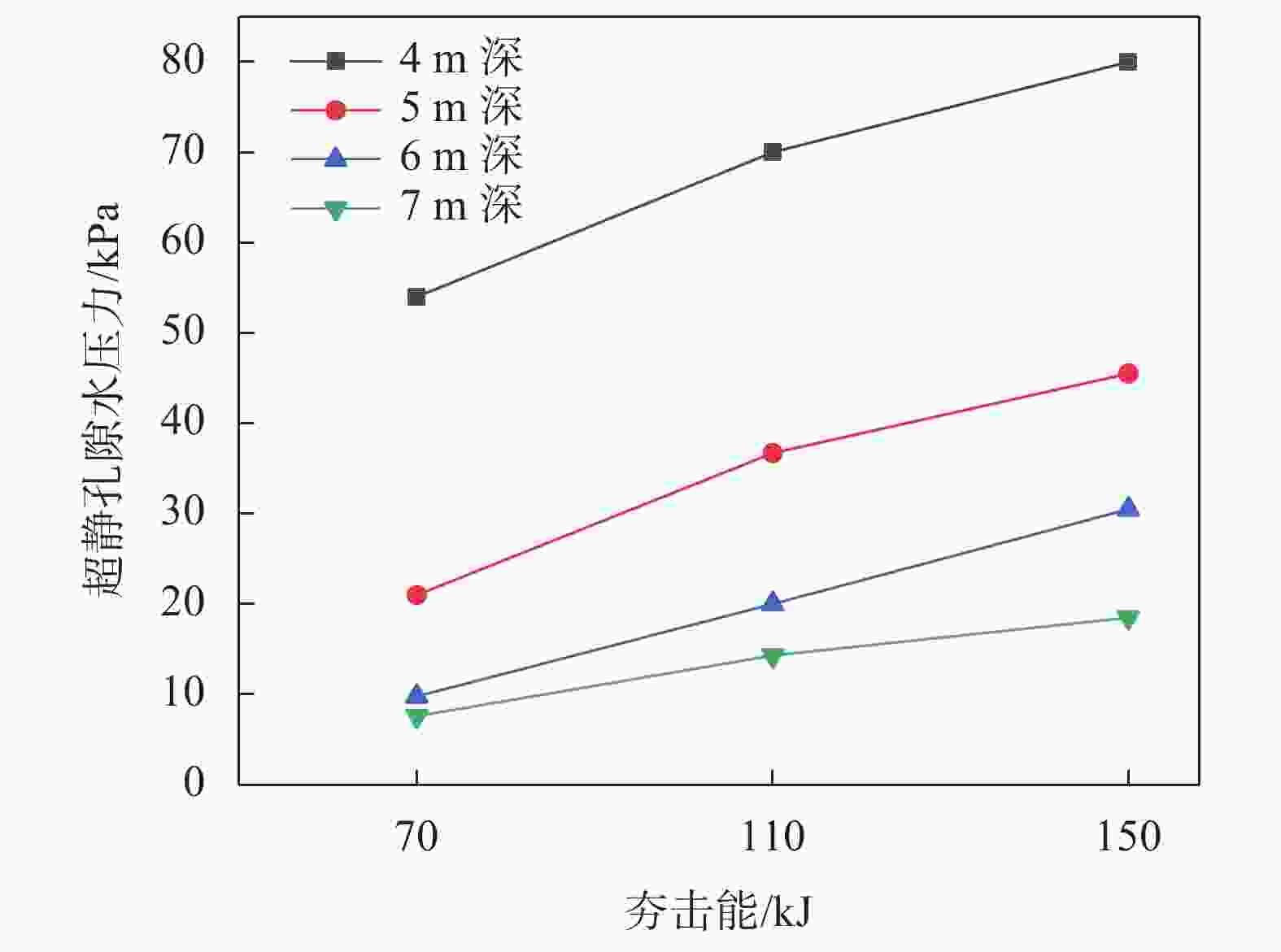

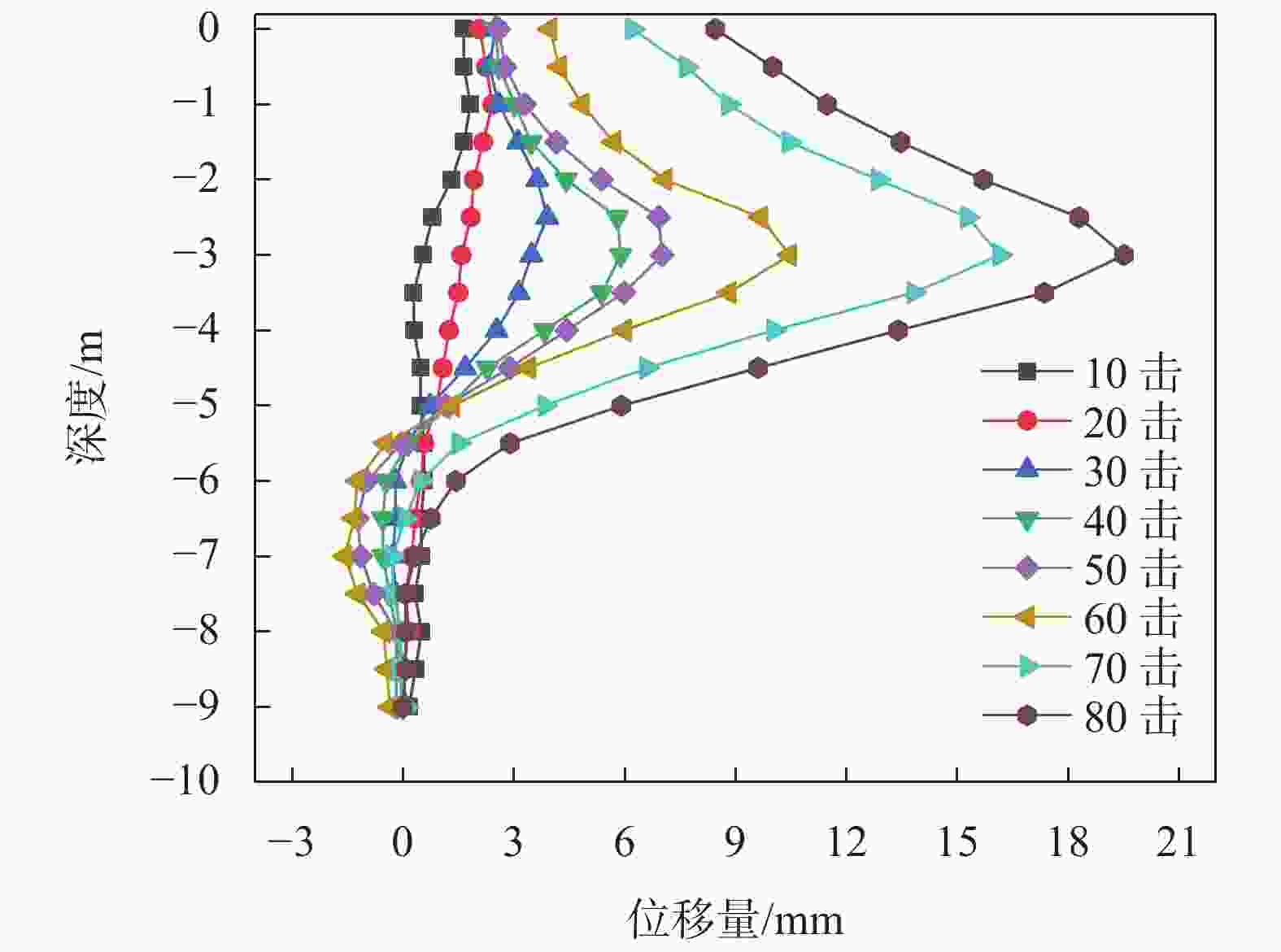

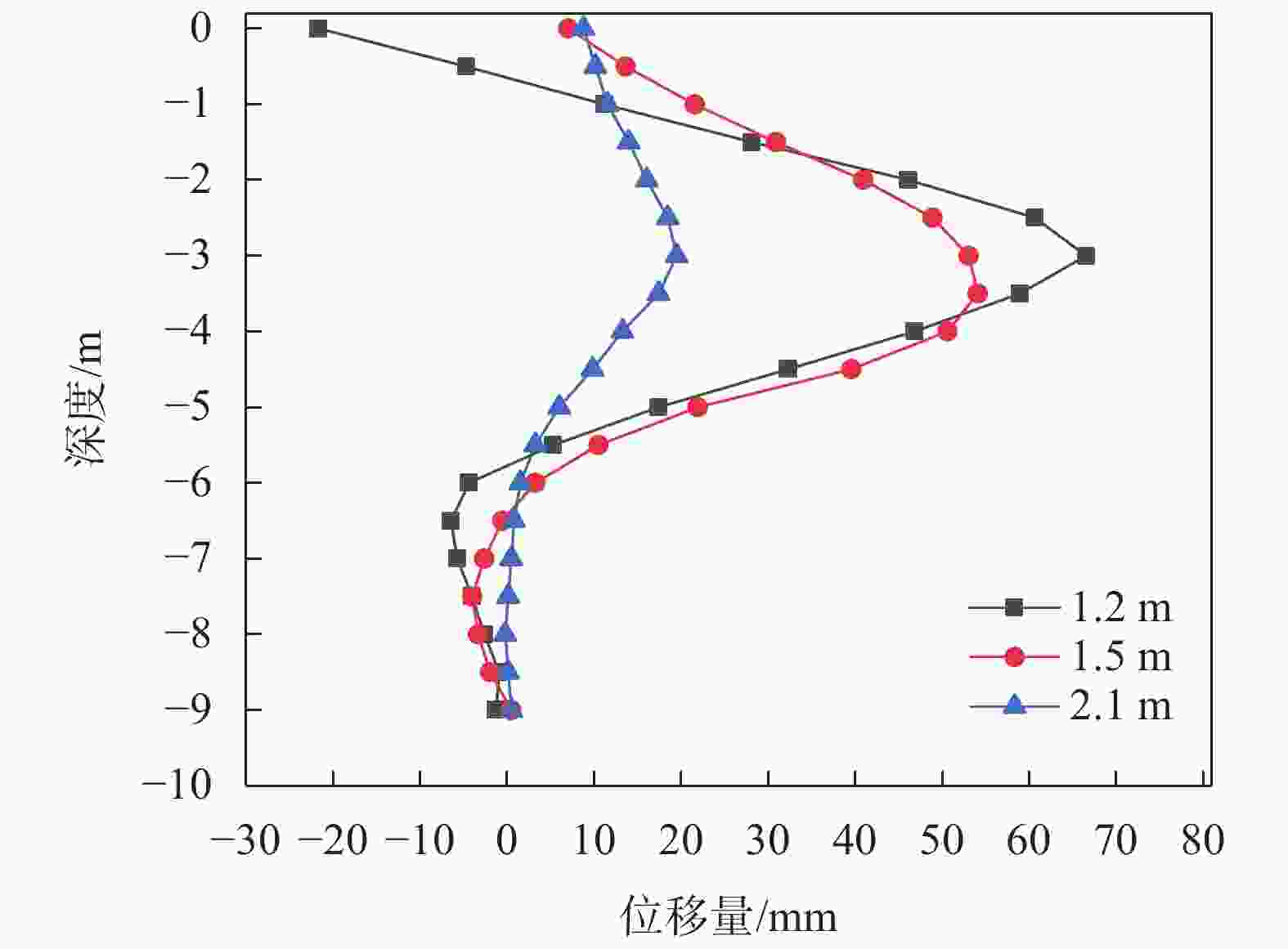

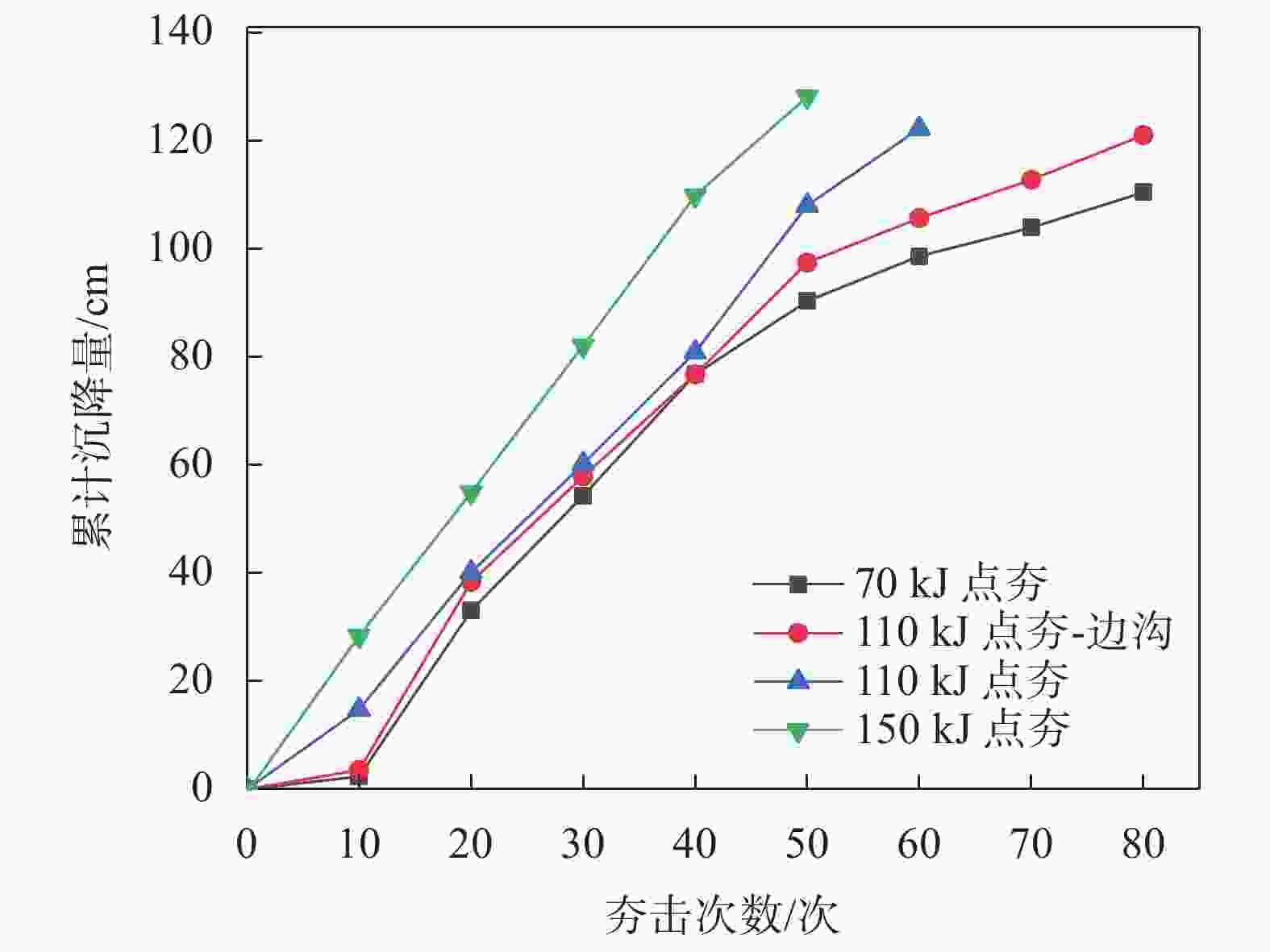

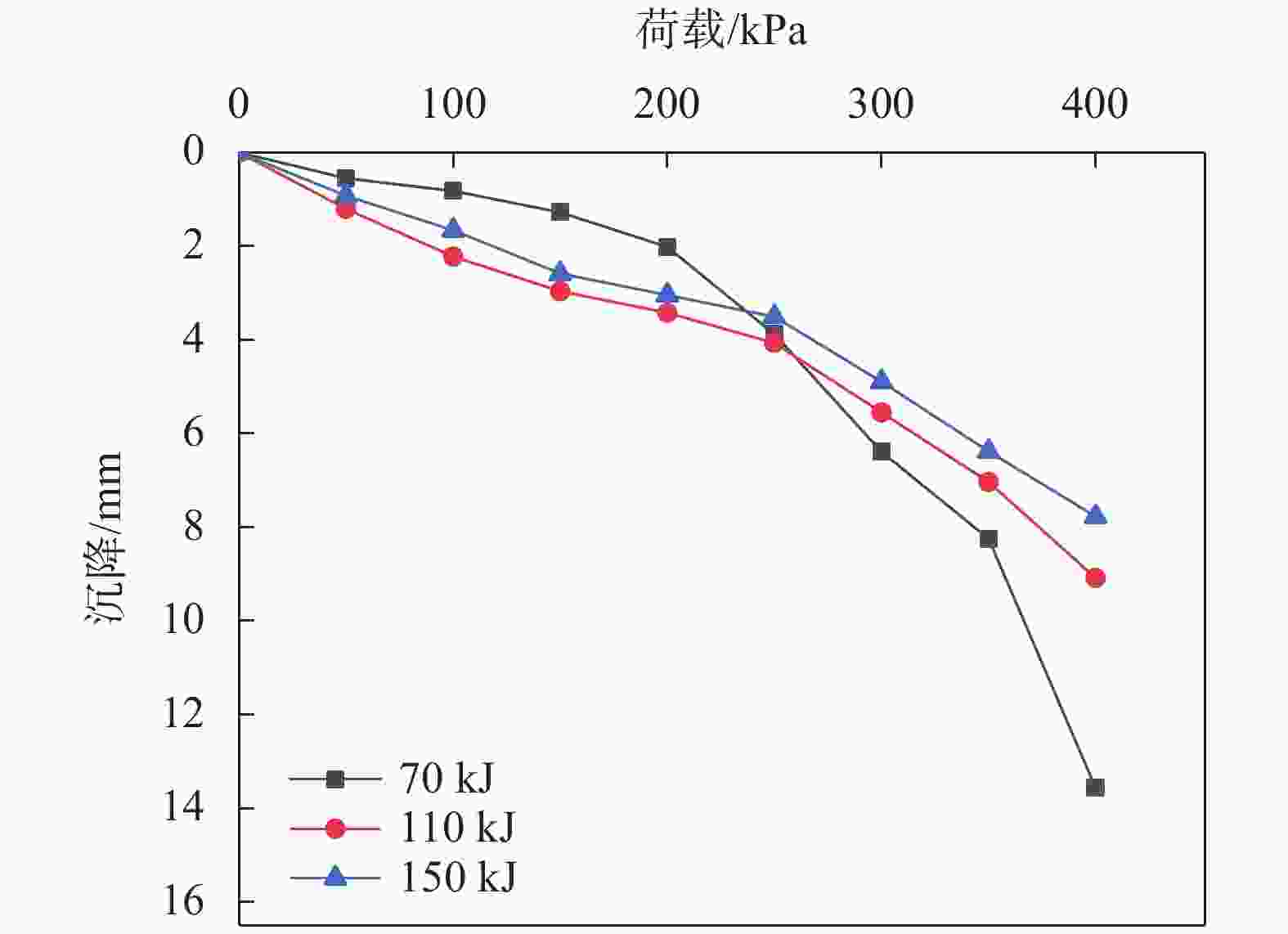

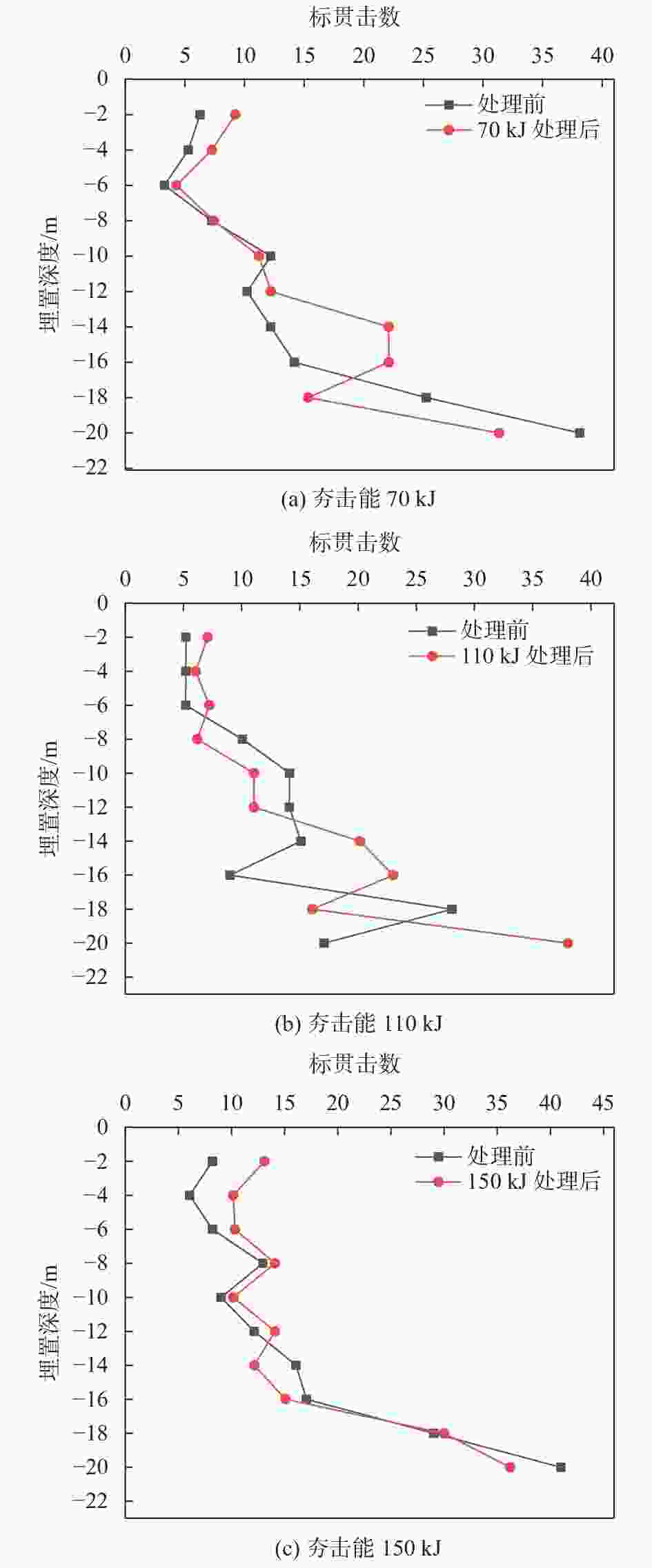

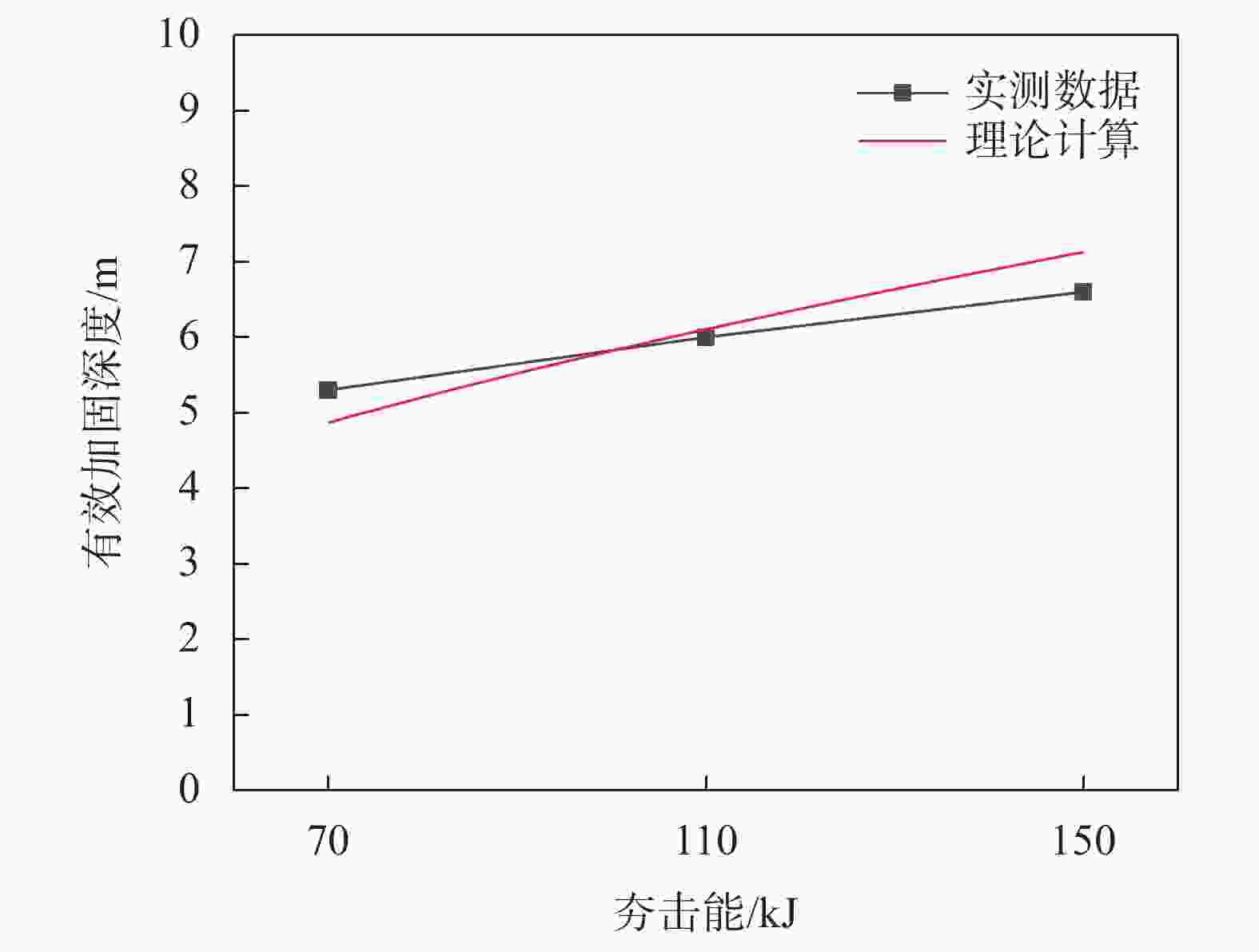

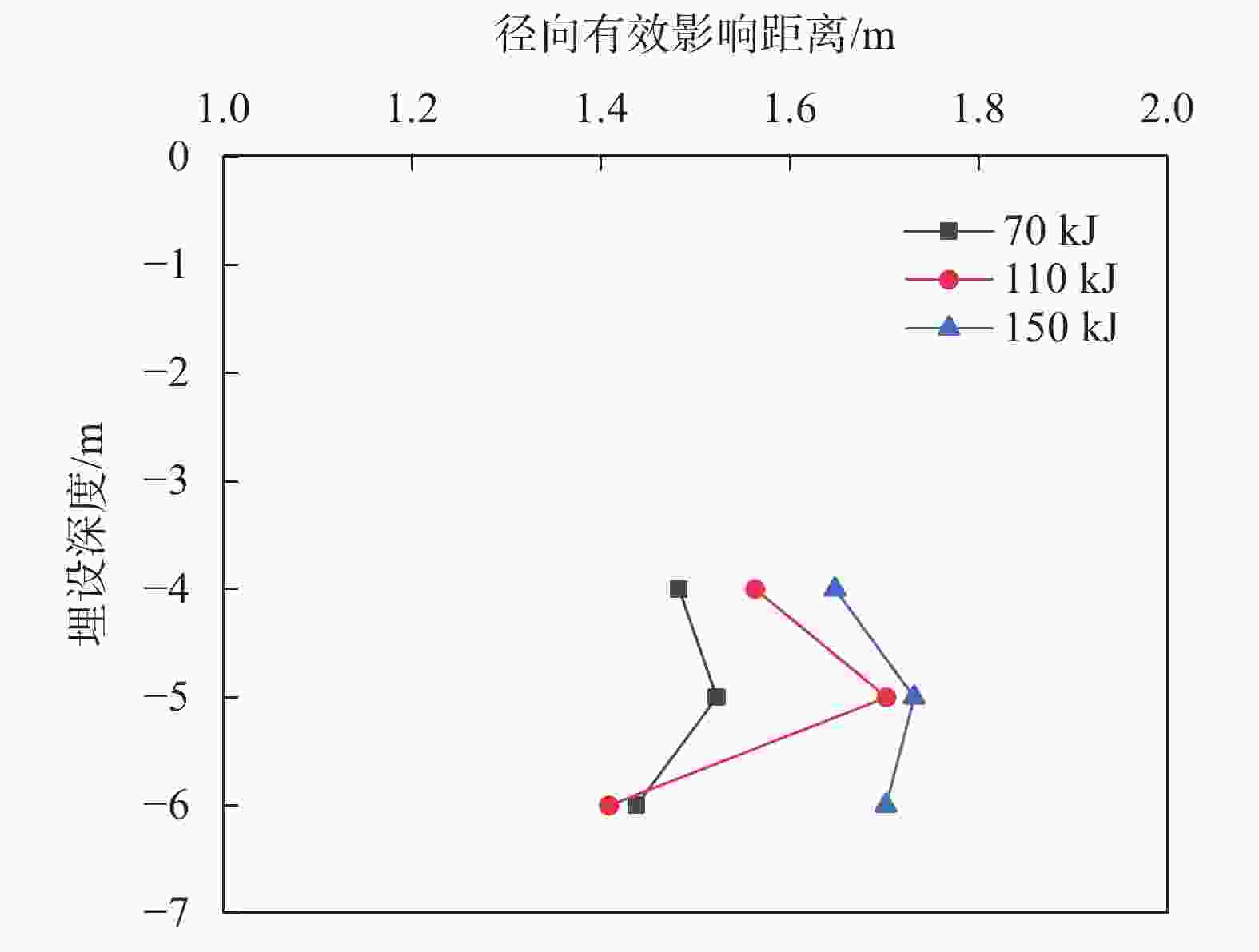

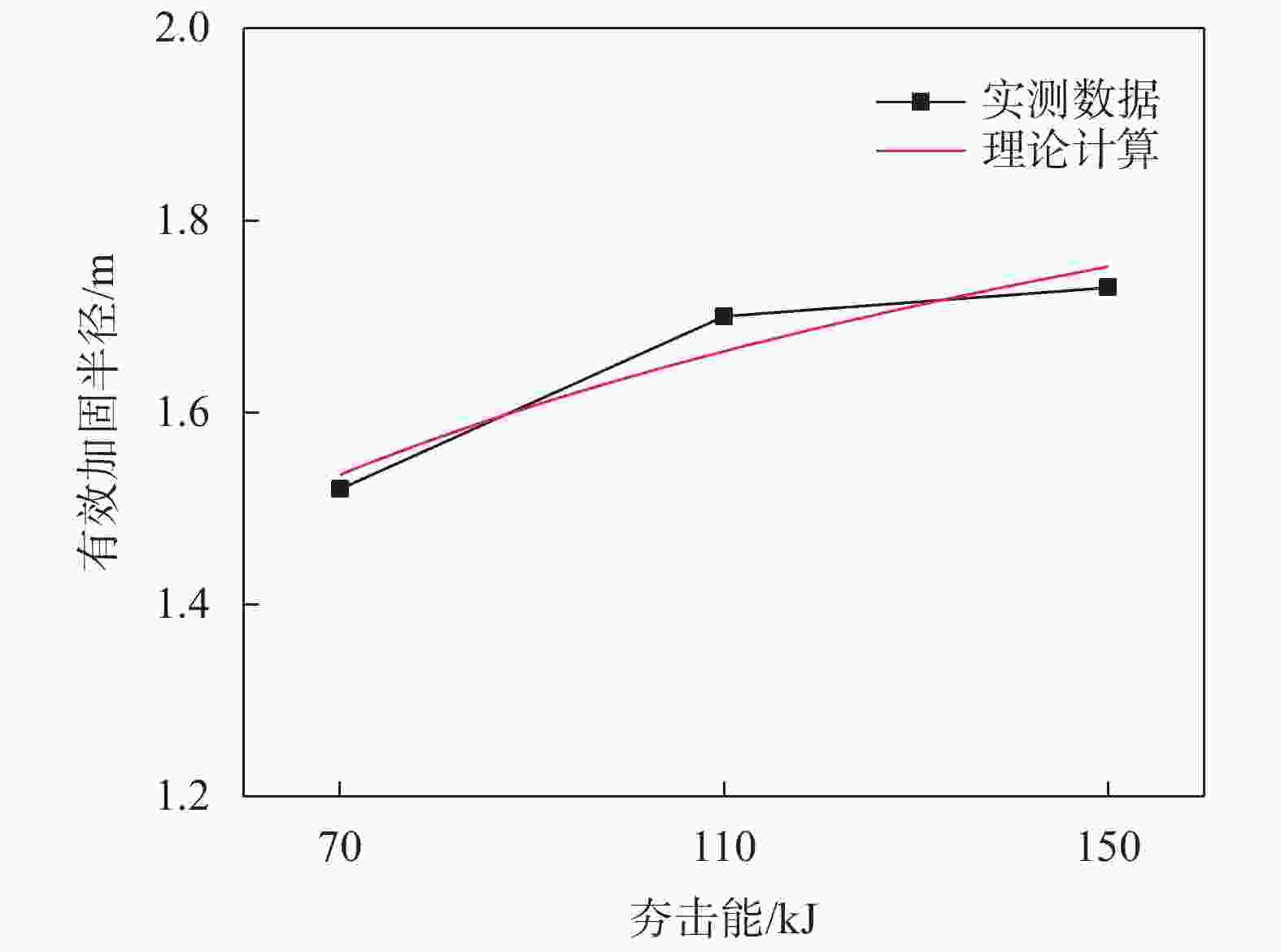

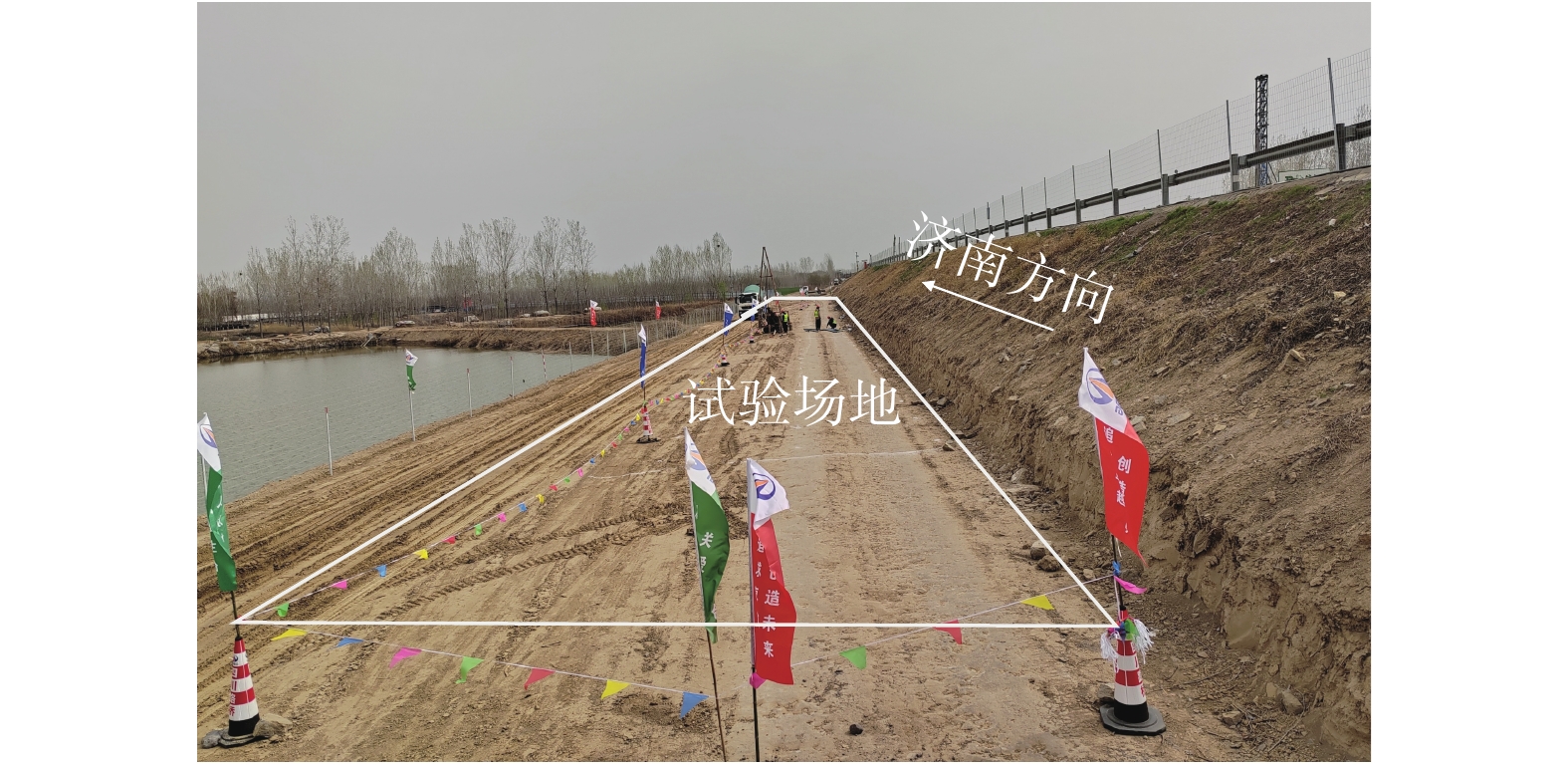

摘要: 针对高速液压夯处理改扩建公路地基的技术不确定性,依托济广高速改扩建工程,通过调整夯击能、夯击次数、夯间距等施工参数,对高速液压夯处理粉土地基的加固效果与施工工艺进行了研究。研究表明:高速液压夯技术可有效提高地基的加固深度及密实度;夯击能和夯击次数是影响加固效果的主要施工参数,夯后土体加固效果随夯击次数与夯击能的增加均呈线性增加趋势;夯后土体侧向位移量随深度呈现抛物线变化趋势,各夯间距工况下土体侧向位移量在3~4 m埋深处达到峰值;高速液压夯处理粉土地基的最佳夯点间距为1.5 m,最大有效加固深度约6 m,最大有效加固半径约1.6 m。综合试验数据与理论分析,建立了高速液压夯处理粉土地基的加固范围计算公式。Abstract: With the uncertainty in the technology of rapid impact compaction (RIC) for highway reconstruction and expansion, relying on the Ji-Guang Expressway project, the reinforcement effect and construction technology of RIC on loess foundations were studied by adjusting construction parameters such as compaction energy, compaction frequency, and compaction spacing. Meanwhile, the application effect and technical feasibility were verified. The study shows that the RIC can effectively improve the strength depth and compactness of the foundation. The compaction energy and frequency are the main construction parameters that affect the reinforcement effect. The reinforcement effect of the compacted soil shows a linear increase trend with the increase of compaction frequency and compaction energy. The lateral displacement of the soil after compaction shows a parabolic trend with depth, and reaches its peak at a burial depth of 3-4 meters under various compaction spacing conditions. The optimal spacing between compaction points for high-speed hydraulic compaction of loess foundation is 1.5 meters, with a maximum effective reinforcement depth of about 6 meters and a maximum effective reinforcement radius of about 1.6 meters. Based on comprehensive experimental data and theoretical analysis, a calculation formula for the reinforcement range of RIC treatment of loess foundation has been established.

-

表 1 试验点土质力学参数

土样名称 取土深度/m 含水率$ {w}_{0} $/% 湿密度$ {\rho }_{0} $/(g·cm−3) 孔隙比$ {e}_{0} $ 压缩系数a100-200/MPa−1 压缩模量$ E\mathrm{_s} $/MPa 渗透系数k/(cm·s−1) 低液限黏土 1.9~2.1 34.2 1.81 1.002 0.616 3.247 3.85×10−7 低液限黏土 3.1~3.3 41.9 1.78 1.184 0.542 4.025 1.12×10−4 低液限粉土 3.6~3.8 29.8 高液限黏土 5.3~5.5 43.2 1.82 1.168 0.513 4.239 1.60×10−6 高液限黏土 5.6~5.8 31.2 1.91 0.864 0.544 3.427 5.11×10−7 低液限粉土 7.4~7.6 27.5 1.97 0.765 0.108 16.305 1.93×10−5 粉土质砂 8.5~8.7 22.7 1.97 0.686 低液限黏土 10.8~11.0 28.2 1.94 0.796 0.161 11.028 8.87×10−6 低液限黏土 13.0~13.2 30.5 1.95 0.838 低液限黏土 14.8~15.0 24.0 2.03 0.652 0.228 7.221 8.56×10−7 低液限黏土 16.8~17.0 19.6 2.00 0.625 低液限粉土 19.6~19.8 18.1 2.02 0.575 0.083 18.575 8.47×10−5 表 2 高速液压夯加固范围试验设计

工况

(夯击能)夯点

型式夯点

间距/m夯点

布置夯击

次数夯击

遍数备注 70 kJ 点夯 3.2 正方形 40 2 连续夯击30次,

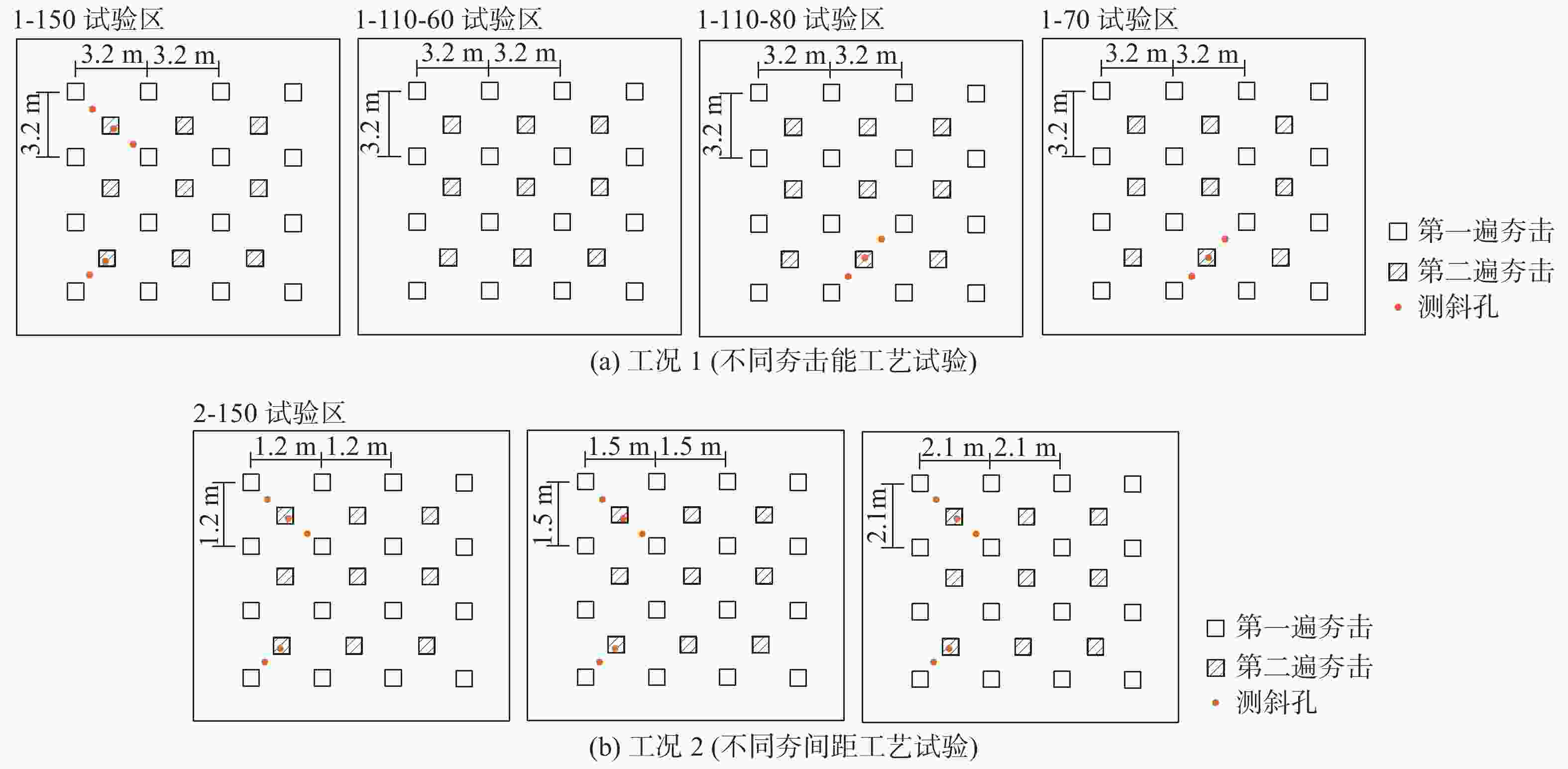

提锤1次110 kJ 点夯 3.2 正方形 40 2 150 kJ 点夯 3.2 正方形 40 2 表 3 高速液压夯施工工艺试验设计

试验类型 工况 夯击能量/kJ 布置形式 夯点间距/m 夯击次数 夯击遍数 试验段长度/m 夯击能工艺试验 1-150 150 正方形,第二遍夯点位于第一遍夯点之间 3.2 60 2 20 1-110-80 110 80 1-110-60 110 60 1-70 70 80 夯间距工艺试验 2-150 150 正方形,第二遍夯点位于第一遍夯点之间 1.2 60 2 20 2-150 1.5 2-150 2.1 表 4 不同深度处累计孔隙水压力值

测点埋深/m 累计孔隙水压力/kPa 10击 20击 30击 40击 4 18.10 38.25 56.06 68.61 5 16.06 26.28 32.41 39.41 6 9.34 16.93 21.61 24.23 7 4.09 8.47 12.26 16.06 -

[1] 段凌云. 高速液压夯在高速公路改扩建项目中的应用研究[J]. 四川水泥,2019(12):122. (DUAN L Y. Application research of high speed hydraulic tamper in expressway reconstruction and expansion project[J]. Sichuan Cement,2019(12):122. (in Chinese)DUAN L Y. Application research of high speed hydraulic tamper in expressway reconstruction and expansion project[J]. Sichuan Cement, 2019(12): 122. [2] 贾冬梅. 改扩建高速公路拓宽路基沉降规律分析[J]. 山西交通科技,2023(1):44-46. (JIA D M. Analysis of subsidence law of widened subgrade of reconstructed and expanded expressway[J]. Shanxi Science & Technology of Transportation,2023(1):44-46. (in Chinese)JIA D M. Analysis of subsidence law of widened subgrade of reconstructed and expanded expressway[J]. Shanxi Science & Technology of Transportation, 2023(1): 44-46. (in Chinese) [3] BO M W, NA Y M, ARULRAJAH A, et al. Densification of granular soil by dynamic compaction[J]. Proceedings of the Institution of Civil Engineers-Ground Improvement,2009,162(3):121-132. doi: 10.1680/grim.2009.162.3.121 [4] LEONARDS G A, HOLTZ R D, CUTTER W A. Dynamic compaction of granular soils[J]. Journal of the Geotechnical Engineering Division,1980,106(1):35-44. doi: 10.1061/AJGEB6.0000914 [5] TANG K, YUAN H W, LV J X, et al. Research on the method for analyzing the degree of impact acceleration and compaction of the impact roller[J]. IEEE Access,2020,8:73588-73600. doi: 10.1109/ACCESS.2020.2983425 [6] 赵建忠. 公路路基施工中冲击碾压技术的应用[J]. 交通建设与管理,2023(3):148-149. (ZHAO J Z. Application of impact crushing technology in highway roadbed construction[J]. Transport Construction & Management,2023(3):148-149. (in Chinese)ZHAO J Z. Application of impact crushing technology in highway roadbed construction[J]. Transport Construction & Management, 2023(3): 148-149. [7] 腊润涛, 张 荣. 强夯法处理湿陷性黄土地基的效果评价[J]. 公路,2020,65(1):54-57. (LA R T, ZHANG R. Evaluation of the effectiveness of strong ramming method in treating collapsible loess foundations[J]. Highway,2020,65(1):54-57. (in Chinese)LA R T, ZHANG R. Evaluation of the effectiveness of strong ramming method in treating collapsible loess foundations[J]. Highway, 2020, 65(1): 54-57. [8] 曹 斌, 刘 岩. 高速液压夯实机在高速公路路基填筑中的应用[J]. 公路,2016,61(11):71-75. (CAO B, LIU Y. Application of high-speed hydraulic rammer in highway roadbed filling[J]. Highway,2016,61(11):71-75. (in Chinese)CAO B, LIU Y. Application of high-speed hydraulic rammer in highway roadbed filling[J]. Highway, 2016, 61(11): 71-75. [9] 张凯乐. 高速夯实机在桥台背路基施工中的应用[J]. 交通世界,2022(27):75-77. (ZHANG K L. Application of high-speed rammer in the construction of bridge abutment backing roadbed[J]. TranspoWorld,2022(27):75-77. (in Chinese)ZHANG K L. Application of high-speed rammer in the construction of bridge abutment backing roadbed[J]. TranspoWorld, 2022(27): 75-77. [10] 董宝志, 徐文涛, 徐 晓, 等. 14000 kN·m超高能级强夯处理晋南地区湿陷性黄土的效果分析[J]. 地基处理,2023,5(5):414-420. (DONG B Z, XU W T, XU X, et al. Effect of 14000 kN·m ultra-high energy level dynamic compaction on collapsible loess in southern Shanxi[J]. Journal of Ground Improvement,2023,5(5):414-420. (in Chinese)DONG B Z, XU W T, XU X, et al. Effect of 14000 kN·m ultra-high energy level dynamic compaction on collapsible loess in southern Shanxi[J]. Journal of Ground Improvement, 2023, 5(5): 414-420. (in Chinese) [11] SIMPSON L A, JANG S T, RONAN C E, et al. Liquefaction potential mitigation using rapid impact compaction[M]//ZENG D, MANZARI M T, HILTUNEN D R. Geotechnical Earthquake Engineering and Soil Dynamics IV. Sacramento: ASCE, 2008: 1-10. [12] SUHENDRA A, FENDY. Rapid impact compaction method as an alternative ground improvement technology in infrastructure project[C]//IOP Conference Series: Earth and Environmental Science. IOP Publishing, 2023: 012012. [13] ADAM D, BRANDL H. Innovative dynamic compaction techniques & integrated compaction control methods[C]//Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering. IOS Press, 2009: 2216-2219. [14] SERRIDGE C J, SYNAC O. Application of the Rapid Impact Compaction (RIC) technique for risk mitigation in problematic soils[C]//The 10th IAEG International Congress. Nottingham, 2006: 1-13. [15] ALLOUZI R, BODOUR W A L, ALKLOUB A, et al. Finite-element model to simulate ground-improvement technique of rapid impact compaction[J]. Proceedings of the Institution of Civil Engineers-Ground Improvement,2019,172(1):44-52. doi: 10.1680/jgrim.18.00057 [16] KRISTIANSEN H, DAVIES M. Ground improvement using rapid impact compaction[C]//13th World Conference on Earthquake Engineering. Vancouver: WCEE, 2004: 496. [17] MOHAMMED M M, HASHIM R, SALMAN A F. Effective improvement depth for ground treated with rapid impact compaction[J]. Scientific Research and Essays,2010,5(18):2686-2693. [18] TARAWNEH B, MATRAJI M. Ground improvement using rapid impact compaction: case study in Dubai[J]. Građevinar,2014,66(11):1007-1014. [19] GHANBARI E, HAMIDI A. Numerical modeling of rapid impact compaction in loose sands[J]. Geomechanics and Engineering,2014,6(5):487-502. doi: 10.12989/gae.2014.6.5.487 -

下载:

下载: