| [1] |

ZHANG B, SHI L, YU X, et al. Assessing the water-sealed safety of an operating underground crude oil storage adjacent to a new similar cavern – a case study in China[J]. Engineering Geology, 2019, 249: 257-272. doi: 10.1016/j.enggeo.2019.01.008

|

| [2] |

王章琼, 晏鄂川, 季惠斌, 等. 我国环太平洋西海岸地区地下水封洞库选址区域稳定性研究[J]. 工程地质学报, 2013, 21(4): 626-633. (WANG Z Q, YAN E C, JI H B, et al. Regional stability of underground water sealed storage caverns around western pacific coastal area in China[J]. Journal of Engineering Geology, 2013, 21(4): 626-633. (in Chinese) doi: 10.3969/j.issn.1004-9665.2013.04.021WANG Z Q, YAN E C, JI H B, et al. Regional stability of underground water sealed storage caverns around western pacific coastal area in China[J]. Journal of Engineering Geology, 2013, 21(4): 626-633. (in Chinese) doi: 10.3969/j.issn.1004-9665.2013.04.021

|

| [3] |

王者超, 李术才, 梁建毅, 等. 地下水封石油洞库渗水量预测与统计[J]. 岩土工程学报, 2014, 36(8): 1490-1497. (WANG Z C, LI S C, LIANG J Y, et al. Prediction and measurement of groundwater flow rate of underground crude oil storage caverns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1490-1497. (in Chinese) doi: 10.11779/CJGE201408015WANG Z C, LI S C, LIANG J Y, et al. Prediction and measurement of groundwater flow rate of underground crude oil storage caverns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1490-1497. (in Chinese) doi: 10.11779/CJGE201408015

|

| [4] |

张 彬, 霍东平, 彭振华, 等. 基于GIS的中国东部沿海地区地下水封油库建造适宜性研究[J]. 工程地质学报, 2015, 23(4): 801-809. (ZHANG B, HUO D P, PENG Z H, et al. GIS-based approach for construction suitability evaluation of underground water-sealed oil storage caverns in east coast of China[J]. Journal of Engineering Geology, 2015, 23(4): 801-809. (in Chinese)ZHANG B, HUO D P, PENG Z H, et al. GIS-based approach for construction suitability evaluation of underground water-sealed oil storage caverns in east coast of China[J]. Journal of Engineering Geology, 2015, 23(4): 801-809. (in Chinese)

|

| [5] |

BARTON N, QUADROS E. Understanding the need for pre-injection from permeability measurements: what is the connection?[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2019, 11(3): 576-597. doi: 10.1016/j.jrmge.2018.12.008

|

| [6] |

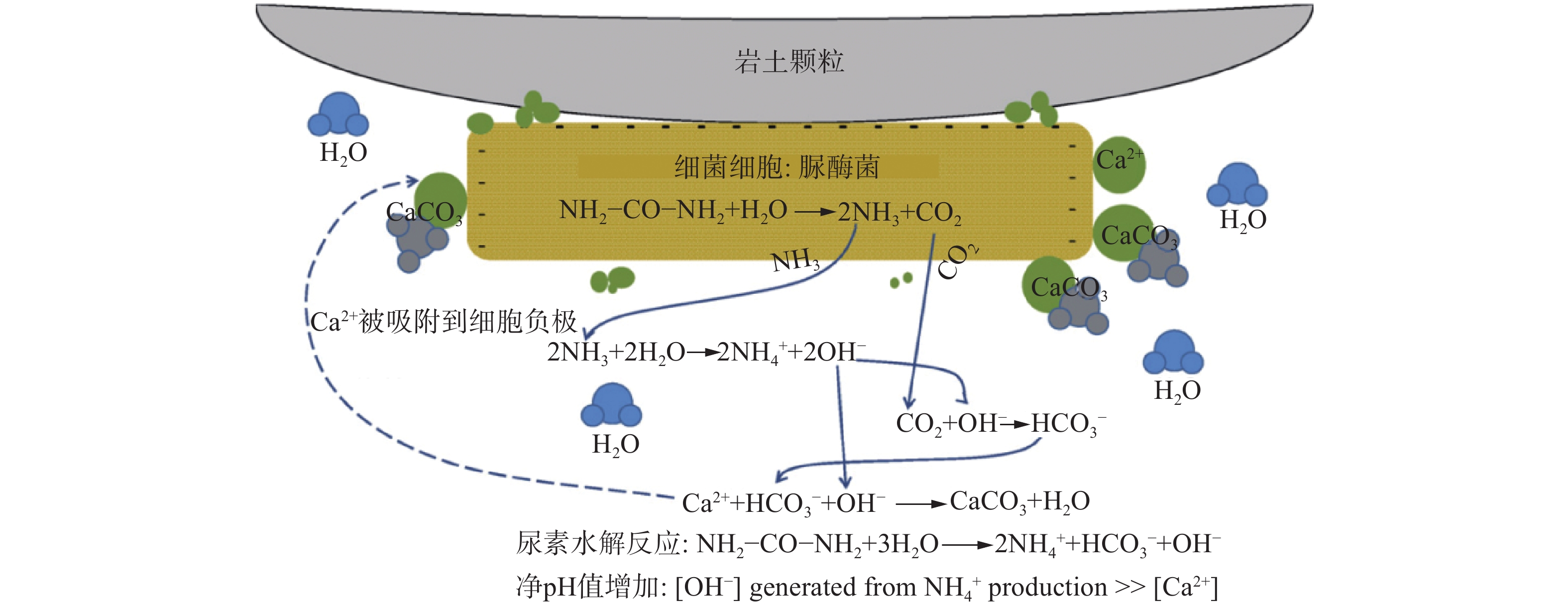

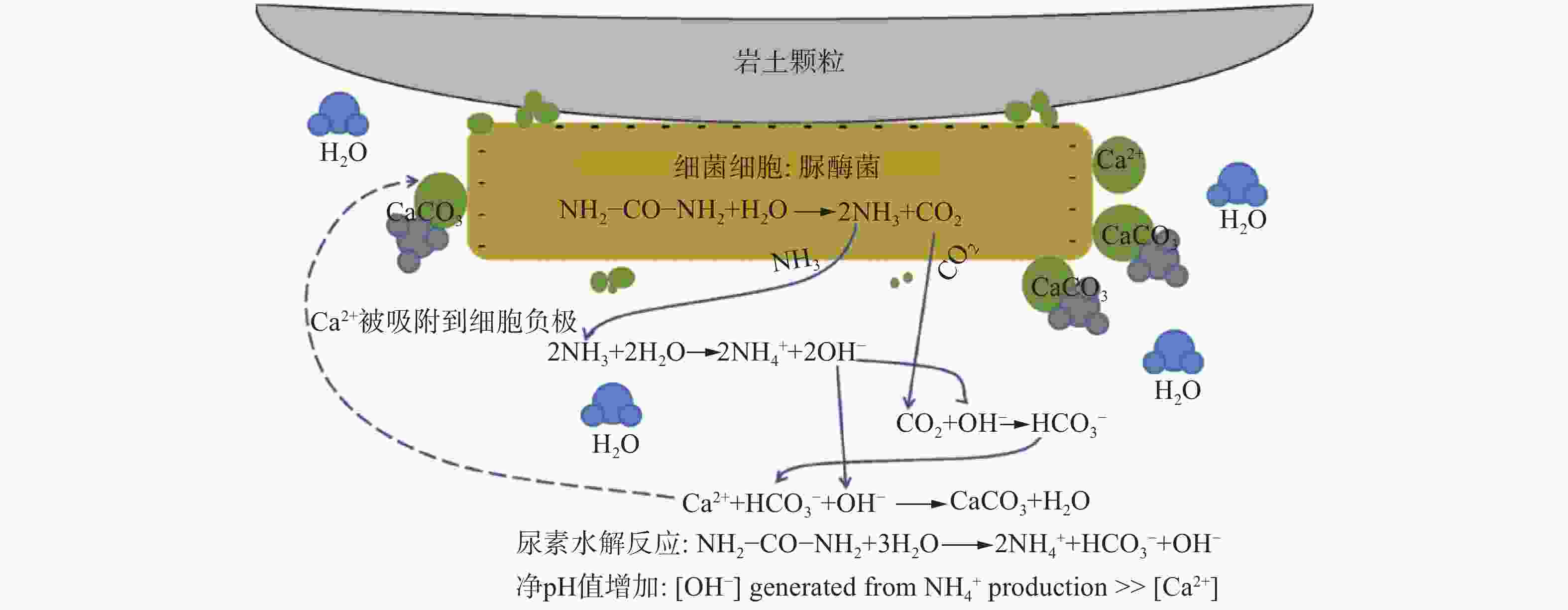

刘乾灵, 张 彬, 李玉涛, 等. MICP技术在地下水封油库渗控注浆中的应用潜力[J]. 工程地质学报, 2024, 32(4): 1412-1423. (LIU Q L, ZHANG B, LI Y T, et al. Application potential of MICP in seepage control grouting of underground water-sealed oil storage cavern[J]. Journal of Engineering Geology, 2024, 32(4): 1412-1423. (in Chinese)LIU Q L, ZHANG B, LI Y T, et al. Application potential of MICP in seepage control grouting of underground water-sealed oil storage cavern[J]. Journal of Engineering Geology, 2024, 32(4): 1412-1423. (in Chinese)

|

| [7] |

KIRKLAND C M, THANE A, HIEBERT R, et al. Addressing wellbore integrity and thief zone permeability using microbially-induced calcium carbonate precipitation (MICP): a field demonstration[J]. Journal of Petroleum Science and Engineering, 2020, 190: 107060. doi: 10.1016/j.petrol.2020.107060

|

| [8] |

BAGAL J, ONADEKO G, HAZEL P, et al. Annular barrier as an alternative to squeezes in challenging wells: technology review and case histories[C]//Proceedings of the Paper presented at the SPE/AAPG Africa Energy and Technology Conference. Nairobi: SPE, 2016.

|

| [9] |

WEIDEBORG M, KÄLLQVIST T, ØDEGÅRD K E, et al. Environmental risk assessment of acrylamide and methylolacrylamide from a grouting agent used in the tunnel construction of Romeriksporten, Norway[J]. Water Research, 2001, 35(11): 2645-2652. doi: 10.1016/S0043-1354(00)00550-9

|

| [10] |

白文军. 水封洞库工程预灌浆策略及实施要点[J]. 水利水电技术(中英文), 2022, 53(S2): 200-204. (BAI W J. Pre-excavation grouting strategy and implementation points of water sealed cavern project[J]. Water Resources and Hydropower Engineering, 2022, 53(S2): 200-204. (in Chinese)BAI W J. Pre-excavation grouting strategy and implementation points of water sealed cavern project[J]. Water Resources and Hydropower Engineering, 2022, 53(S2): 200-204. (in Chinese)

|

| [11] |

SHI L, ZHANG B, WANG H X, et al. Investigation on the causes of abnormal increase of water inflow in underground water-sealed storage system[J]. Tunnelling and Underground Space Technology, 2019, 87: 174-186. doi: 10.1016/j.tust.2019.02.013

|

| [12] |

LI N Y, FENG W T, YU J J, et al. Recent advances in geological storage: trapping mechanisms, storage sites, projects, and application of machine learning[J]. Energy & Fuels, 2023, 37(14): 10087-10111.

|

| [13] |

MOLNÁR Z, PEKKER P, DÓDONY I, et al. Clay minerals affect calcium (magnesium) carbonate precipitation and aging[J]. Earth and Planetary Science Letters, 2021, 567: 116971. doi: 10.1016/j.jpgl.2021.116971

|

| [14] |

WALL N A, MAULDEN E, GAGER E J, et al. Functionalized clays for radionuclide sequestration: a review[J]. ACS Earth and Space Chemistry, 2022, 6(11): 2552-2574. doi: 10.1021/acsearthspacechem.2c00098

|

| [15] |

王敬奎. 注浆堵水在地下水封洞库中的应用[J]. 西部探矿工程, 2020, 32(4): 41-44, 48. (WANG J K. Application of grouting for water blocking in underground water-sealed caverns[J]. West-China Exploration Engineering, 2020, 32(4): 41-44, 48. (in Chinese)WANG J K. Application of grouting for water blocking in underground water-sealed caverns[J]. West-China Exploration Engineering, 2020, 32(4): 41-44, 48. (in Chinese)

|

| [16] |

欧阳伟雄, 贺宝林. 复合材料注浆在地下水封石油洞库工程中的应用[J]. 油气田地面工程, 2022, 41(9): 106-111. (OUYANG W X, HE B L. Application of composite materials grouting in underground water-sealed oil storage in rock cavern engineering[J]. Oil-Gas Surface Engineering, 2022, 41(9): 106-111. (in Chinese)OUYANG W X, HE B L. Application of composite materials grouting in underground water-sealed oil storage in rock cavern engineering[J]. Oil-Gas Surface Engineering, 2022, 41(9): 106-111. (in Chinese)

|

| [17] |

DE MUYNCK W, DE BELIE N, VERSTRAETE W. Microbial carbonate precipitation in construction materials: a review[J]. Ecological Engineering, 2010, 36(2): 118-136. doi: 10.1016/j.ecoleng.2009.02.006

|

| [18] |

HE J, CHU J, GAO Y F, et al. Research advances and challenges in biogeotechnologies[J]. Geotechnical Research, 2019, 6(2): 144-155. doi: 10.1680/jgere.18.00035

|

| [19] |

刘汉龙, 肖 鹏, 肖 杨, 等. 微生物岩土技术及其应用研究新进展[J]. 土木与环境工程学报(中英文), 2019, 41(1): 1-14. (LIU H L, XIAO P, XIAO Y, et al. State-of-the-art review of biogeotechnology and its engineering applications[J]. Journal of Civil and Environmental Engineering, 2019, 41(1): 1-14. (in Chinese)LIU H L, XIAO P, XIAO Y, et al. State-of-the-art review of biogeotechnology and its engineering applications[J]. Journal of Civil and Environmental Engineering, 2019, 41(1): 1-14. (in Chinese)

|

| [20] |

MINTO J M, MACLACHLAN E, EL MOUNTASSIR G, et al. Rock fracture grouting with microbially induced carbonate precipitation[J]. Water Resources Research, 2016, 52(11): 8827-8844. doi: 10.1002/2016WR018884

|

| [21] |

SONG CP, ELSWORTH D, JIA Y Z, et al. Permeable rock matrix sealed with microbially-induced calcium carbonate precipitation: evolutions of mechanical behaviors and associated microstructure[J]. Engineering Geology, 2022, 304: 106697. doi: 10.1016/j.enggeo.2022.106697

|

| [22] |

孙 哲, 张 彬, 陈大伟, 等. 花岗岩裂隙岩体油水两相渗流可视化试验及数值模拟研究[J]. 地学前缘, 2023, 30(3): 465-475. (SUN Z, ZHANG B, CHEN D W, et al. Two-phase oil/water seepage in fractured granite rock mass: insight from seepage visualization experiment and numerical simulation[J]. Geoscience Frontiers, 2023, 30(3): 465-475. (in Chinese)SUN Z, ZHANG B, CHEN D W, et al. Two-phase oil/water seepage in fractured granite rock mass: insight from seepage visualization experiment and numerical simulation[J]. Geoscience Frontiers, 2023, 30(3): 465-475. (in Chinese)

|

| [23] |

CUTHBERT M O, MCMILLAN L A, HANDLEY-SIDHU S, et al. A field and modeling study of fractured rock permeability reduction using microbially induced calcite precipitation[J]. Environmental Science & Technology, 2013, 47(23): 13637-13643.

|

| [24] |

WU C Z, CHU J, WU S F, et al. Quantifying the permeability reduction of biogrouted rock fracture[J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 947-954. doi: 10.1007/s00603-018-1669-9

|

| [25] |

WU C Z, CHU J, WU S F, et al. 3D characterization of microbially induced carbonate precipitation in rock fracture and the resulted permeability reduction[J]. Engineering Geology, 2019, 249: 23-30. doi: 10.1016/j.enggeo.2018.12.017

|

| [26] |

WU C Z, CHU J, WU S F, et al. Microbially induced calcite precipitation along a circular flow channel under a constant flow condition[J]. Acta Geotechnica, 2019, 14(3): 673-683. doi: 10.1007/s11440-018-0747-1

|

| [27] |

TOBLER D J, MACLACHLAN E, PHOENIX V R. Microbially mediated plugging of porous media and the impact of differing injection strategies[J]. Ecological Engineering, 2012, 42: 270-278. doi: 10.1016/j.ecoleng.2012.02.027

|

| [28] |

TOBLER D J, MINTO J M, EL MOUNTASSIR G, et al. Microscale analysis of fractured rock sealed with microbially induced CaCO3 precipitation: influence on hydraulic and mechanical performance[J]. Water Resources Research, 2018, 54(10): 8295-8308. doi: 10.1029/2018WR023032

|

| [29] |

肖维民, 林 馨, 钟建敏, 等. 岩石节理微生物诱导碳酸钙沉积封堵渗流演化规律试验研究[J]. 岩土力学, 2023, 44(10): 2798-2808. (XIAO W M, LIN X, ZHONG J M, et al. Experimental study on rock joint permeability evolution during plugging process by microbially induced calcite precipitation[J]. Rock and Soil Mechanics, 2023, 44(10): 2798-2808. (in Chinese)XIAO W M, LIN X, ZHONG J M, et al. Experimental study on rock joint permeability evolution during plugging process by microbially induced calcite precipitation[J]. Rock and Soil Mechanics, 2023, 44(10): 2798-2808. (in Chinese)

|

| [30] |

EL MOUNTASSIR G, LUNN R J, MOIR H, et al. Hydrodynamic coupling in microbially mediated fracture mineralization: formation of self-organized groundwater flow channels[J]. Water Resources Research, 2014, 50(1): 1-16. doi: 10.1002/2013WR013578

|

| [31] |

CARDOSO R, ARBABZADEH E, DE LIMA J T, et al. The influence of stone joints width and roughness on the efficiency of biocementation sealing[J]. Construction and Building Materials, 2021, 283: 122743. doi: 10.1016/j.conbuildmat.2021.122743

|

| [32] |

ZAMBARE N M, LAUCHNOR E G, GERLACH R. Controlling the distribution of microbially precipitated calcium carbonate in radial flow environments[J]. Environmental Science & Technology, 2019, 53(10): 5916-5925.

|

| [33] |

WHIFFIN V S, VAN PAASSEN L A, HARKES M P. Microbial carbonate precipitation as a soil improvement technique[J]. Geomicrobiology Journal, 2007, 24(5): 417-423. doi: 10.1080/01490450701436505

|

| [34] |

DEJONG J T, MORTENSEN B M, MARTINEZ B C, et al. Bio-mediated soil improvement[J]. Ecological Engineering, 2010, 36(2): 197-210. doi: 10.1016/j.ecoleng.2008.12.029

|

| [35] |

WHIFFIN V S. Microbial CaCO3 precipitation for the production of biocement[D]. Perth: Murdoch University, 2004.

|

| [36] |

CHEN Y Q, WANG S Q, TONG X Y, et al. Towards the sustainable fine control of microbially induced calcium carbonate precipitation[J]. Journal of Cleaner Production, 2022, 377: 134395. doi: 10.1016/j.jclepro.2022.134395

|

| [37] |

IVANOV V, CHU J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ[J]. Reviews in Environmental Science and Bio/Technology, 2008, 7(2): 139-153. doi: 10.1007/s11157-007-9126-3

|

| [38] |

苏 飞. 微生物CaCO3固砂研究: 参数优化及技术改进[D]. 北京: 中国地质大学, 2022. (SU F. Research on microbial CaCO3 sand consolidation: parameter optimization and technological improvements[D]. Beijing: China University of Geosciences, 2022. (in Chinese)SU F. Research on microbial CaCO3 sand consolidation: parameter optimization and technological improvements[D]. Beijing: China University of Geosciences, 2022. (in Chinese)

|

| [39] |

RODEN E E, LEONARDO M R, FERRIS F G. Immobilization of strontium during iron biomineralization coupled to dissimilatory hydrous ferric oxide reduction[J]. Geochimica et Cosmochimica Acta, 2002, 66(16): 2823-2839. doi: 10.1016/S0016-7037(02)00878-5

|

| [40] |

AL QABANY A, SOGA K, SANTAMARINA C. Factors affecting efficiency of microbially induced calcite precipitation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2012, 138(8): 992-1001. doi: 10.1061/(ASCE)GT.1943-5606.0000666

|

| [41] |

HAN C. Modeling for the effect of in-situ bacteria growth on permeability reduction of a fractured medium[J]. Energy Sources, 2003, 25(3): 203-215. doi: 10.1080/00908310390142244

|

| [42] |

HOMMEL J, LAUCHNOR E, PHILLIPS A, et al. A revised model for microbially induced calcite precipitation: Improvements and new insights based on recent experiments[J]. Water Resources Research, 2015, 51(5): 3695-3715. doi: 10.1002/2014WR016503

|

| [43] |

WITHERSPOON P A, WANG J S Y, IWAI K, et al. Validity of Cubic Law for fluid flow in a deformable rock fracture[J]. Water Resources Research, 1980, 16(6): 1016-1024. doi: 10.1029/WR016i006p01016

|

下载:

下载: