Fluidized solidified soil and its workability and strength based on pumping construction

-

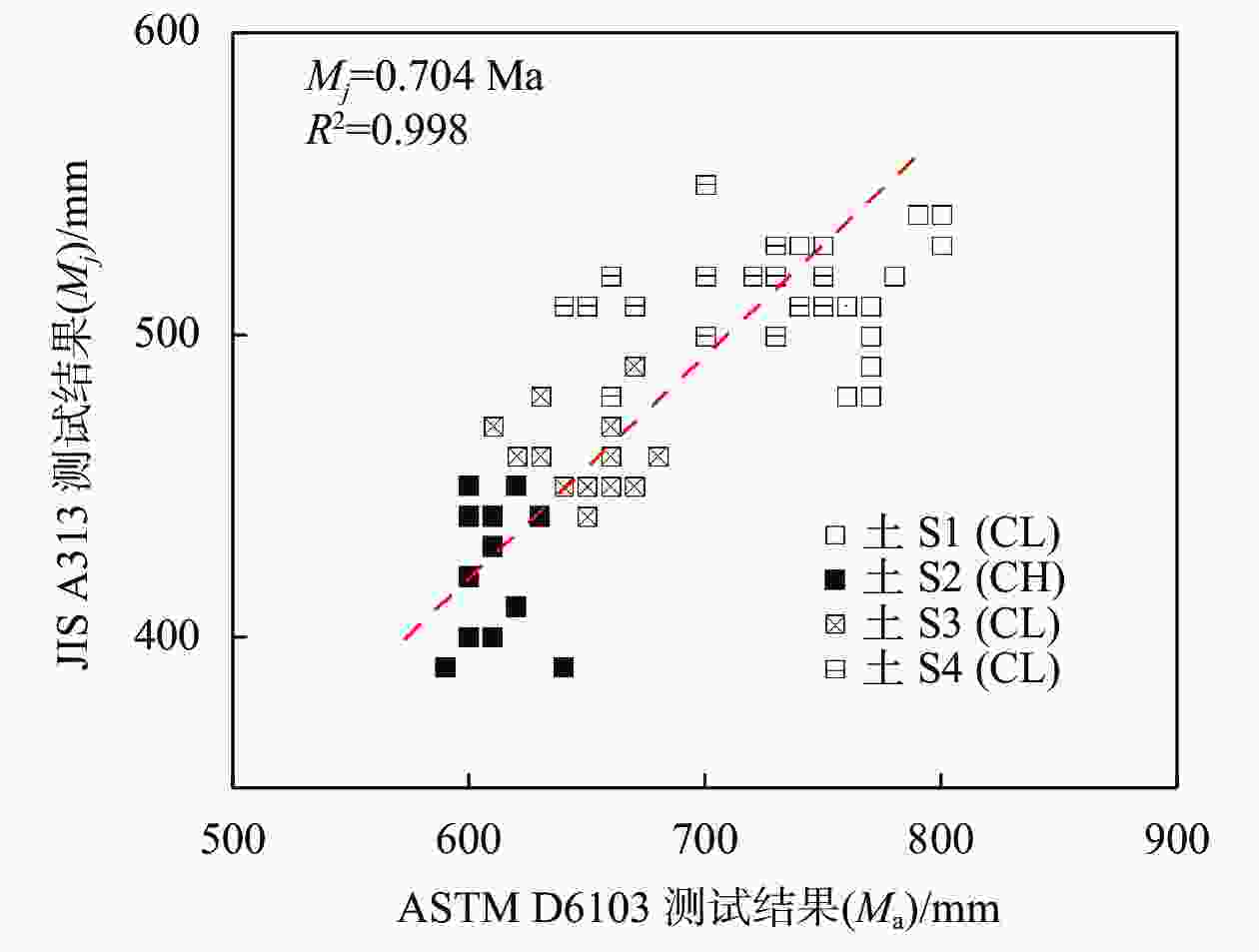

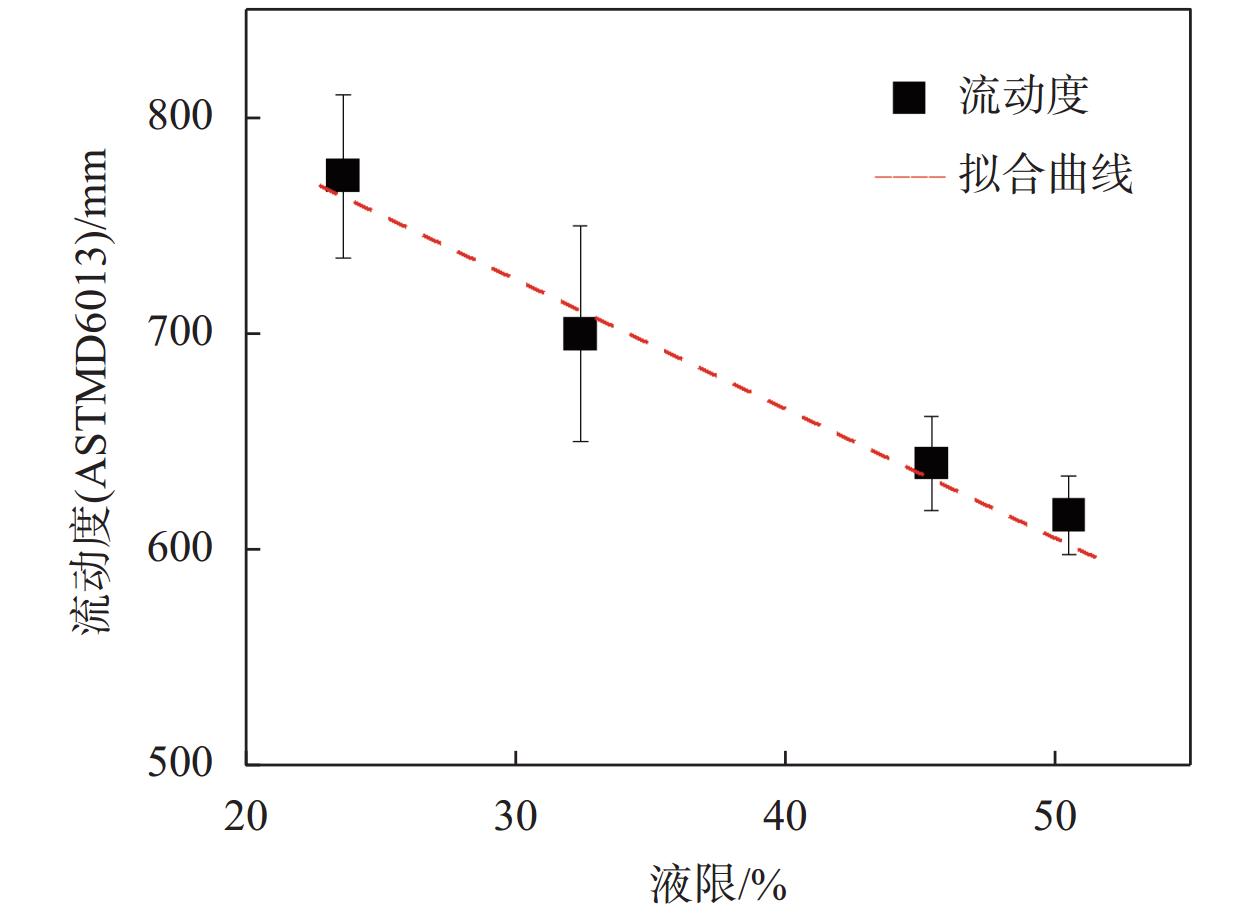

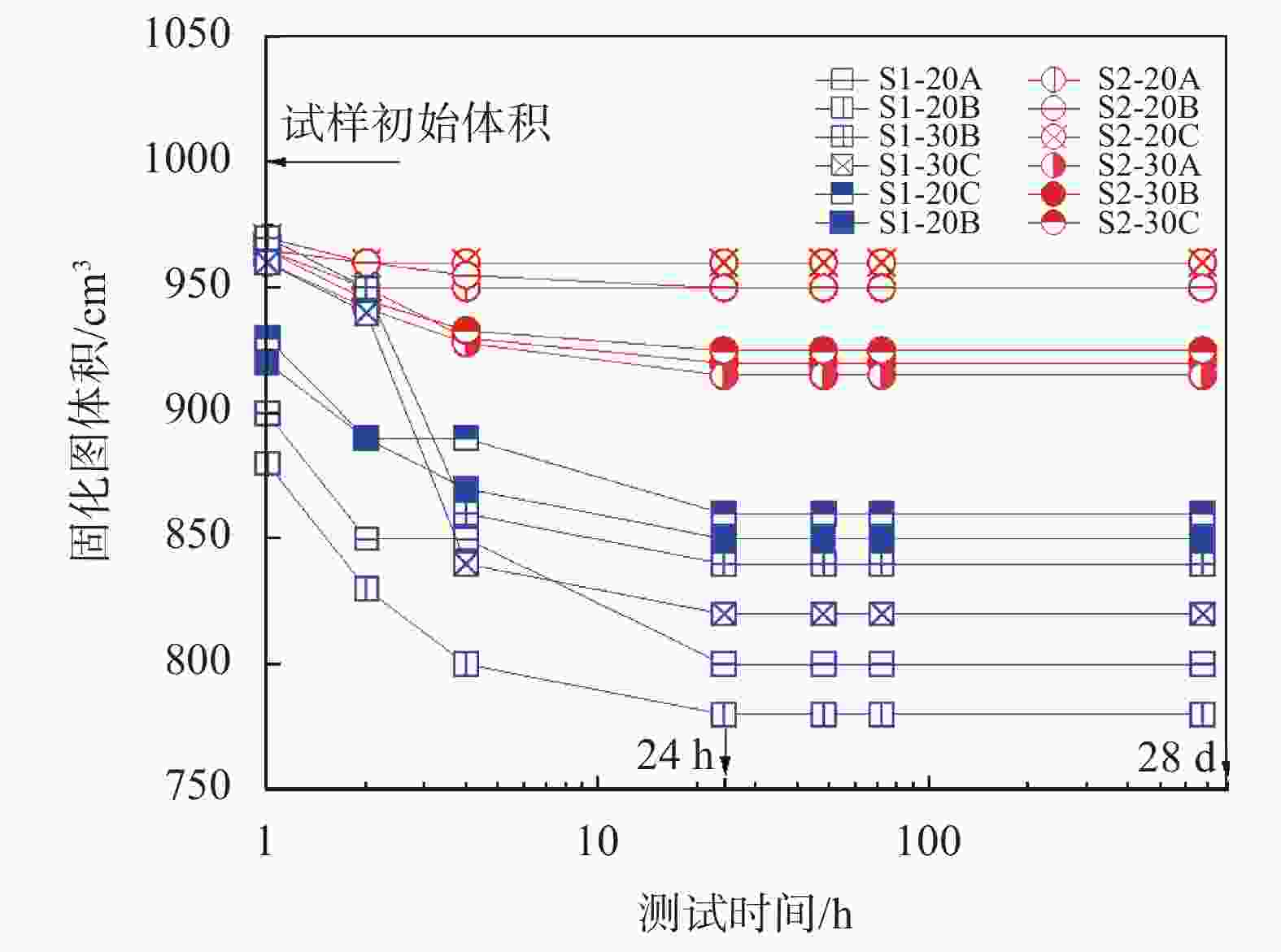

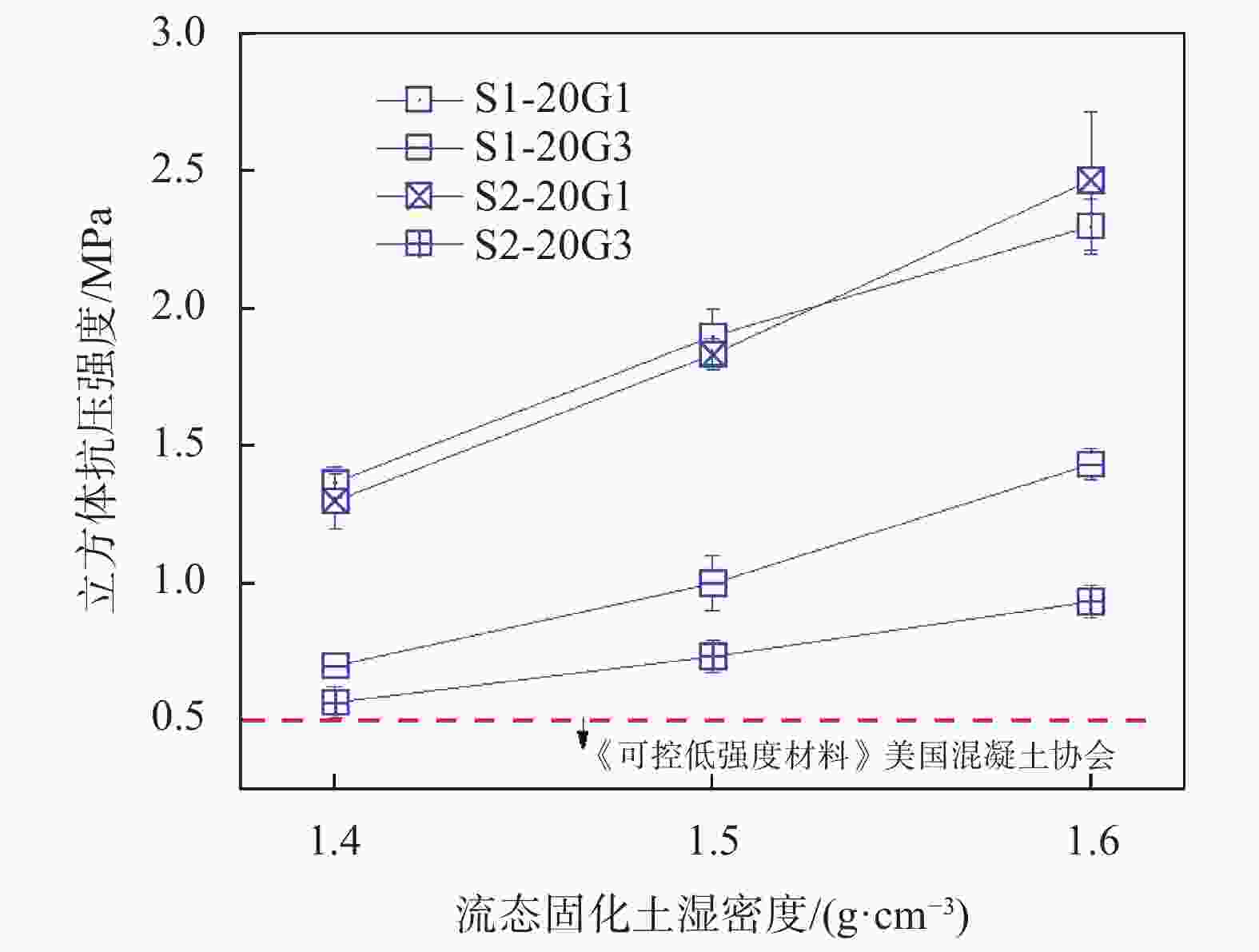

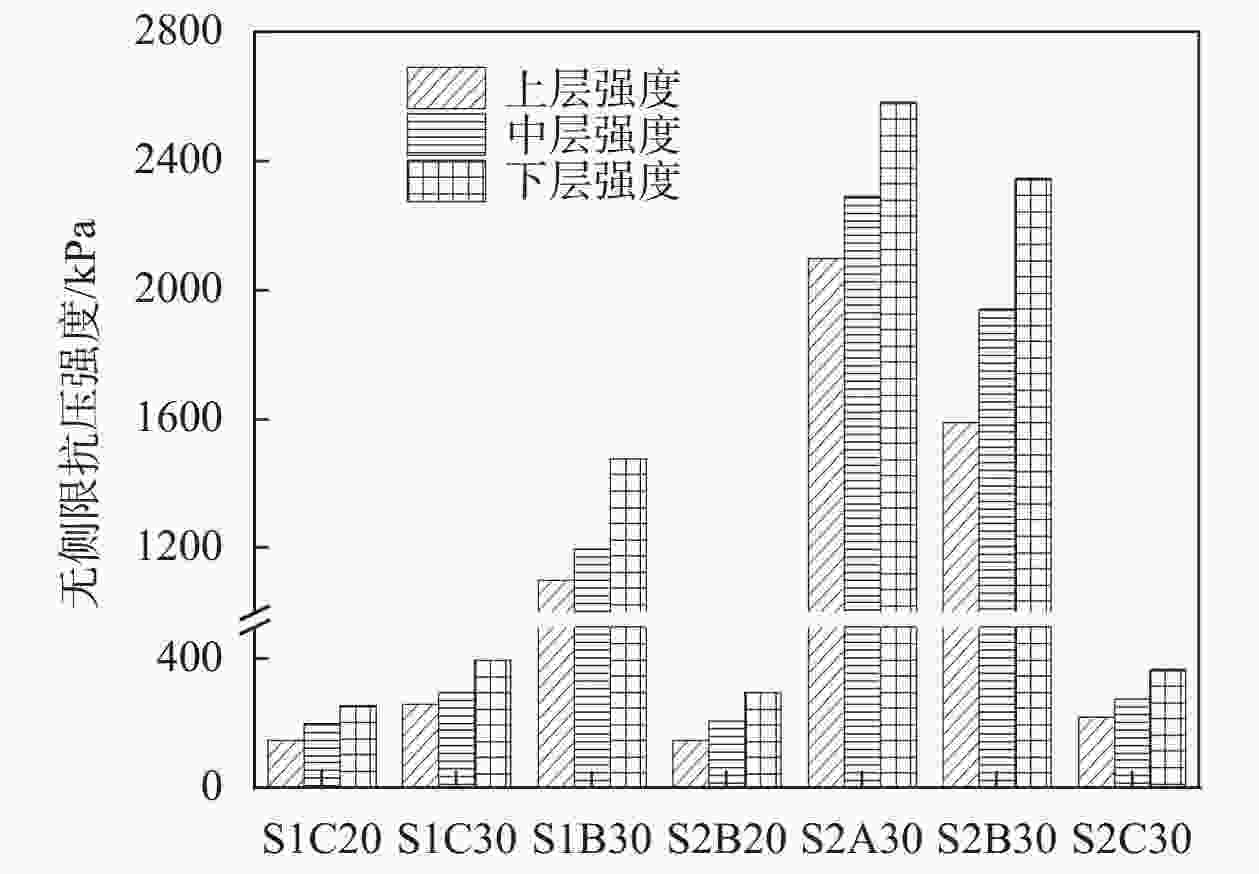

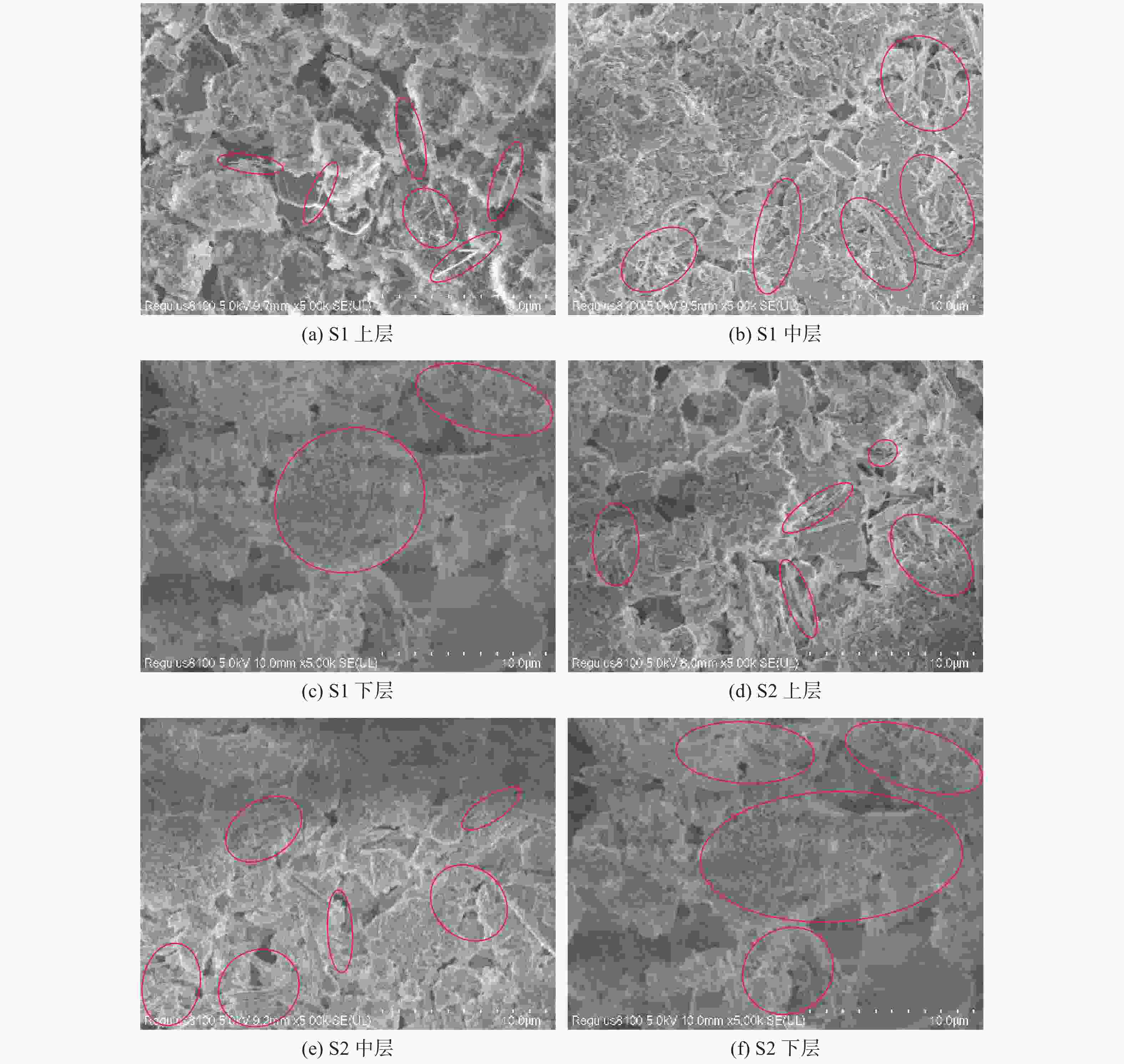

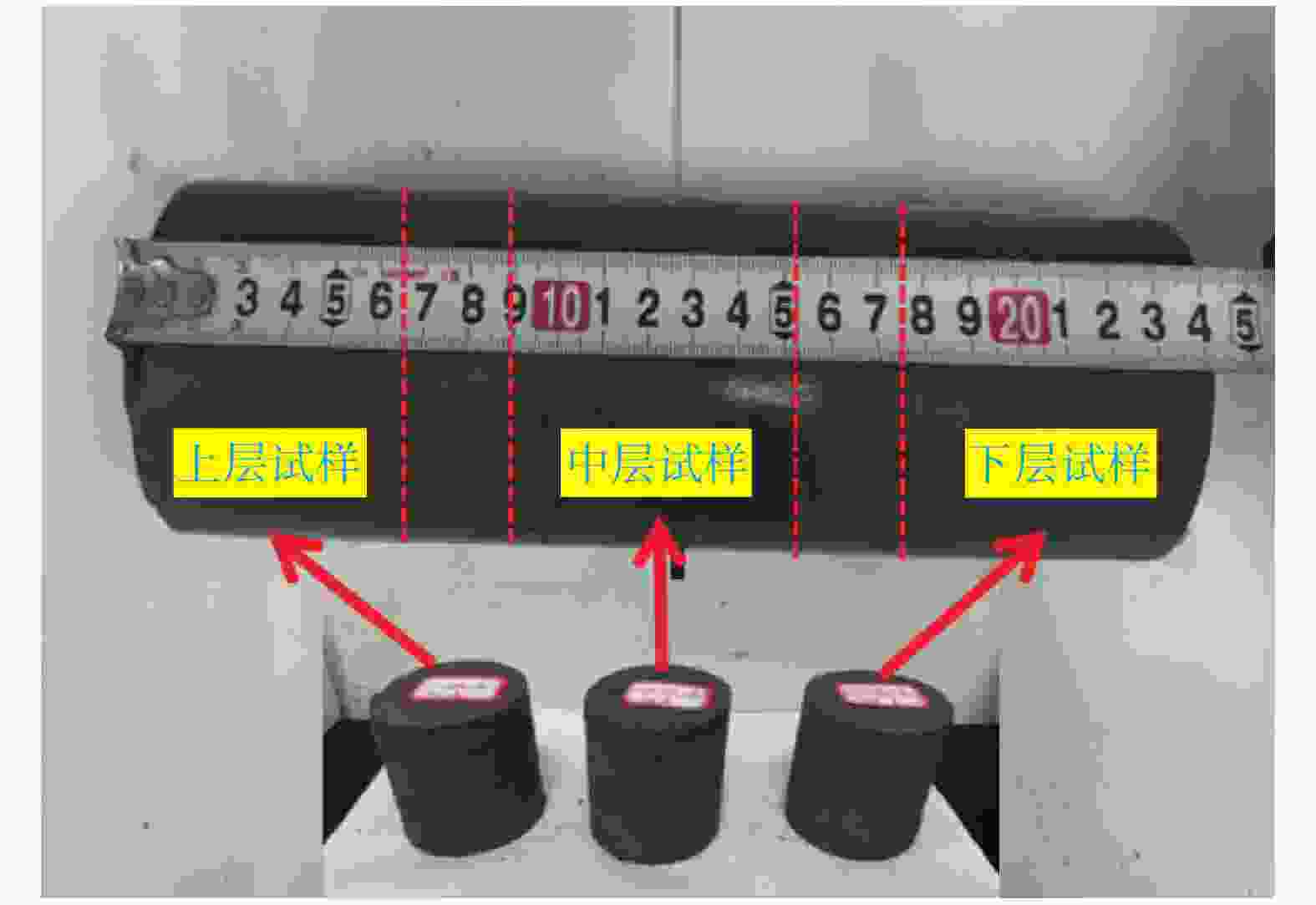

摘要: 流动性和抗压强度是流态固化土工程应用中的关键技术指标,决定了流态固化土的和易性和工作性能。泵送施工中可通过减小湿密度,适当提高流态固化土流动性,以满足设备要求。以两种土性的工程弃土为母土,控制湿密度在1.4~1.6 g/cm3,制备高流动性流态固化土,重点研究土性和湿密度对流态固化土流动度、泌水率、抗压强度的控制规律及作用机制。研究表明:流态固化土的流动度和泌水率主要受土性影响,母土液限越高,其流动度相对越低,泌水率相对越小,固化剂掺量和种类对其影响相对不显著;抗压强度主要受湿密度和固化剂影响,湿密度越高,流态固化土强度相对越大;高流动性流态固化土自凝阶段,因水化反应尚未充分,土颗粒、土−固化剂水化产物存在自重沉降,出现不同程度泌水,导致同一固化土试样抗压强度沿深度不均匀的现象,微观结构上表现为大孔隙逐渐被水化产物填充,胶结作用更为充分,中小孔隙依次增多,土体结构更为密实。Abstract: Liquidity and compressive strength are key technical indicators in the application of fluidized solidified soil engineering, which determine the construction and workability of fluidized solidified soil and its workability of construction. During pumping construction, reducing the wet density and appropriately improving the flowability of the solidified soil can meet equipment requirements. Using two types of engineering waste soil as parent soil, with a wet density controlled between 1.4 g/cm3 and 1.6 g/cm3, high flowability fluid-solidified soil was prepared. The focus was on investigating the control laws and mechanisms of soil properties and wet density on the flowability, bleeding rate, and compressive strength of fluid solidified soil. Research has shown that the flowability and bleeding rate of fluidized solidified soil are mainly affected by soil properties. The higher the liquid limit of the parent soil, the lower its flowability and bleeding rate. The dosage and type of solidifying agent have relatively insignificant effects on it; the compressive strength is mainly affected by the wet density and curing agent. The higher the wet density, the relatively greater the strength of the fluidized solidified soil. During the self-setting stage of highly fluid solidified soil, the hydration reaction has not yet been fully carried out. The soil particles and hydration products of the soil solidifying agent have self-weight settlement, resulting in varying degrees of bleeding. This leads to uneven compressive strength of the same solidified soil sample along the depth. The microstructure shows that large pores are gradually filled by hydration products, and the bonding effect is more complete. Small and medium-sized pores increase in sequence, and the soil structure is denser.

-

表 1 基本物理性质指标

Table 1. Basic physical property indicators

母土编号 工程分类 液限

wL/%塑限

wp/%塑性指数

Ip土粒的

相对密度GS黏粒

含量/%S1 粉土 23.6 14.0 9.6 2.71 31.0 S2 高液限黏土 50.5 24.8 32.1 2.66 46.1 S3 粉质黏土 45.4 19.8 15.6 2.68 39.8 S4 粉质黏土 32.4 20.3 12.1 2.62 35.7 表 2 固化剂化学成分

Table 2. Chemical composition of curing agent

固化剂

种类含量/% CaO SiO2 Al2O3 SO3 MgO TiO2 Fe2O3 其他 A 51.45 23.74 9.49 7.58 4.72 0.58 1.29 1.33 B 49.68 25.12 10.24 5.28 5.94 1.45 0.86 1.43 C 55.43 22.23 9.52 3.30 2.14 0.64 4.71 2.03 表 3 流态固化土基本性能试验汇总

Table 3. Summary of basic properties tests for fluid-consolidated soils

试样编号 流动度(ASTM D6103)/mm 流动度(JIS A313)/mm 7 d泌水率/% 初始湿密度

/(g∙cm−3)7 d表观密度

/(g∙cm−3)凝结时间/min 初凝 终凝 S1A20 730 530 20 1.44 1.51 1100 1430 S1B20 700 490 15 1.44 1.47 1250 1780 S1C20 720 500 14 1.45 1.53 1560 2420 S2A20 650 450 8 1.45 1.50 2020 2460 S2B20 660 460 5 1.43 1.46 2150 2670 S2C20 650 450 4 1.43 1.47 2960 3180 S1A30 720 510 21 1.44 1.51 1010 1320 S1B30 710 500 17 1.44 1.49 1180 1650 S1C30 720 500 15 1.45 1.52 1440 1880 S2A30 630 440 8 1.45 1.51 1880 2140 S2B30 640 460 6 1.43 1.46 1960 2230 S2C30 650 460 4 1.45 1.47 2540 2870 注:试样编号中,S1,S2分别表示试样母土类型;A,B,C分别表示所使用固化剂种类;20,30分别表示固化剂掺量(%)。 表 4 两种土不同层间强度试验结果

Table 4. Results of interlayer strength between two different soils

试样编号 抗压强度/kPa 上层 中层 下层 变异系数 S1C20 147.2 197.6 254.9 12.4 S1C30 258.20 297.90 397.92 18.3 S1B30 1100.87 1196.59 1479.61 15.6 S2C20 147.8 207.51 296.69 28.4 S2A30 2100.3 2290.6 2584.2 8.6 S2B30 1591.9 1941.88 2346.7 19.3 S2C30 217.7 277.2 367.2 26.2 -

[1] 周永祥, 王继忠. 预拌固化土的原理及工程应用前景[J]. 新型建筑材料, 2019, 46(10): 117-120. (ZHOU Y X, WANG J Z. Principle of ready-mixed solidified soil and its prospects for engineering application[J]. New Building Materials, 2019, 46(10): 117-120. (in Chinese) doi: 10.3969/j.issn.1001-702X.2019.10.027ZHOU Y X, WANG J Z. Principle of ready-mixed solidified soil and its prospects for engineering application[J]. New Building Materials, 2019, 46(10): 117-120. (in Chinese) doi: 10.3969/j.issn.1001-702X.2019.10.027 [2] 王英军, 黄昌乾. 肥槽回填土常见工程问题与处理方法. 岩土工程技术, 2019, 33(2): 84-88. (WANG Y J, HUANG C Q. Common engineering problems and treatment methods for backfilling soil in foundation trench[J]. Geotechnical Engineering Technique, 2019, 33(2): 84-88. (in Chinese)WANG Y J, HUANG C Q. Common engineering problems and treatment methods for backfilling soil in foundation trench[J]. Geotechnical Engineering Technique, 2019, 33(2): 84-88. (in Chinese) [3] 丁建文, 洪振舜, 刘松玉. 疏浚淤泥流动固化处理与流动性试验研究[J]. 岩土力学, 2011, 32(S1): 280-284. (DING J W, HONG Z S, LIU S Y, et al. Study of flow-solidification method and fluidity test of dredged clays[J]. Rock and Soil Mechanics, 2011, 32(S1): 280-284, (in Chinese) doi: 10.16285/j.rsm.2011.s1.123DING J W, HONG Z S, LIU S Y, et al. Study of flow-solidification method and fluidity test of dredged clays[J]. Rock and Soil Mechanics, 2011, 32(S1): 280-284, doi: 10.16285/j.rsm.2011.s1.123 [4] 郎瑞卿, 裴璐熹, 孙立强, 等. 新拌不同液限淤泥固化土流动性试验研究[J]. 岩土力学, 2023, 44(10): 2789-2797. (LANG R Q, PEI L X, SUN L Q, et al. Experimental study on the flowability of freshly mixed solidified muds with different liquid limits[J]. Rock and Soil Mechanics, 2023, 44(10): 2789-2797, (in Chinese) doi: 10.16285/j.rsm.2023.0867LANG R Q, PEI L X, SUN L Q, et al. Experimental study on the flowability of freshly mixed solidified muds with different liquid limits[J]. Rock and Soil Mechanics, 2023, 44(10): 2789-2797, doi: 10.16285/j.rsm.2023.0867 [5] 黄英豪, 戴济群, 徐 锴. 新拌固化淤泥的流动性和黏滞性试验研究[J]. 岩土工程学报, 2022, 44(2): 235-244. (HANG Y H, DAI J Q, XU K, et al. Flowability and viscosity of freshly solidified dredged materials[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(2): 235-244. (in Chinese) doi: 10.11779/CJGE202202004HANG Y H, DAI J Q, XU K, et al. Flowability and viscosity of freshly solidified dredged materials[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(2): 235-244. (in Chinese) doi: 10.11779/CJGE202202004 [6] 王 硕, 黄英豪, 王文翀, 等. 新拌固化淤泥流动性测试标准试验研究[J]. 水利水运工程学报, 2024(4): 89-100. (WANG S, HUANG Y H, WANG W C, et al. Experimental research on test standards for freshly mixed solidified sludge flowability[J]. Hydro-Science and Engineering, 2024(4): 89-100. (in Chinese) doi: 10.12170/20230805001WANG S, HUANG Y H, WANG W C, et al. Experimental research on test standards for freshly mixed solidified sludge flowability[J]. Hydro-Science and Engineering, 2024(4): 89-100. (in Chinese) doi: 10.12170/20230805001 [7] LEE JR L T. Method to rapidly assess the index properties of fine-grained dredged materials[J]. Geotechnical Testing Journal, 2004, 27(5): 464-468. doi: 10.1520/GTJ11812 [8] 丁建文, 刘铁平, 曹玉鹏, 等. 高含水率疏浚淤泥固化土的抗压试验与强度预测[J]. 岩土工程学报, 2013, 35(S2): 55-60. (DING J W, LIU T P, CAO Y P, et al. Unconfined compression tests and strength prediction method for solidified soils of dredged clays with high water content[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(S2): 55-60. (in Chinese)DING J W, LIU T P, CAO Y P, et al. Unconfined compression tests and strength prediction method for solidified soils of dredged clays with high water content[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(S2): 55-60. (in Chinese) [9] 纪文栋, 张宇亭, 颜容涛, 等. 高吸水材料改善高含水率淤泥流动性的试验研究[J]. 岩土力学, 2015, 36(S1): 281-286. (JI W D, ZHANG Y T, YAN R T, et al. An experimental study of decreasing fluidity of silt with high moisture content by high water absorbent material[J]. Rock and Soil Mechanics, 2015, 36(S1): 281-286. (in Chinese)JI W D, ZHANG Y T, YAN R T, et al. An experimental study of decreasing fluidity of silt with high moisture content by high water absorbent material[J]. Rock and Soil Mechanics, 2015, 36(S1): 281-286. (in Chinese) [10] 王东星, 陈政光. 氯氧镁水泥固化淤泥力学特性应变速率效应研究[J]. 岩土力学, 2021, 42(10): 2634-2646. (WANG D X, CHEN Z G. Strain rate effect on mechanical properties of magnesium oxychloride cement solidified sludge[J]. Rock and Soil Mechanics, 2021, 42(10): 2634-2646. (in Chinese)WANG D X, CHEN Z G. Strain rate effect on mechanical properties of magnesium oxychloride cement solidified sludge[J]. Rock and Soil Mechanics, 2021, 42(10): 2634-2646. (in Chinese) [11] 赵春彦, 黄启友, 郎 锋, 等. 单因素和多因素作用下的水泥土强度评估模型试验研究[J]. 铁道科学与工程学报, 2018, 15(11): 2788-2795. (ZHAO C Y, HUANG Q Y, LANG F, et al. Experimental study on strength evaluation model of cement soil under single factor and multi factors[J]. Journal of Railway Science and Engineering, 2018, 15(11): 2788-2795. (in Chinese)ZHAO C Y, HUANG Q Y, LANG F, et al. Experimental study on strength evaluation model of cement soil under single factor and multi factors[J]. Journal of Railway Science and Engineering, 2018, 15(11): 2788-2795. (in Chinese) [12] 冯志超, 朱 伟, 张春雷, 等. 黏粒含量对固化淤泥力学性质的影响[J]. 岩石力学与工程学报, 2007, 26(S1): 3052-3057. (FENG Z C, ZHU W, ZHANG C L, et al. Influence of clay content on mechanical properties of solidified silt[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(S1): 3052-3057. (in Chinese) doi: 10.3321/j.issn:1000-6915.2007.z1.070FENG Z C, ZHU W, ZHANG C L, et al. Influence of clay content on mechanical properties of solidified silt[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(S1): 3052-3057. (in Chinese) doi: 10.3321/j.issn:1000-6915.2007.z1.070 [13] UDDIN K, BALASUBRAMANIAM A S, BERGADO D T. Engineering behavior of cement-treated Bangkok soft clay[J]. Geotechnical Engineering, 1997, 28(1): 89-119. [14] 孙晓辉, 朱伟, 徐志荣. 污泥固化/稳定化处理中强度发生机理研究[C]//Proceedings of 2011 AASRI Conference on Information Technology and Economic Development. Kuala Lumpur: Intelligent Information Technology Application Association, 2011: 435-438. (SUN X H, ZHU W, XU Z R. A study on mechanism of strength in Solidification/Stabilization treatment of sludge[C]//Proceedings of 2011 AASRI Conference on Information Technology and Economic Development. Kuala Lumpur: Intelligent Information Technology Application Association, 2011: 435-438. (in Chinese)SUN X H, ZHU W, XU Z R. A study on mechanism of strength in Solidification/Stabilization treatment of sludge[C]//Proceedings of 2011 AASRI Conference on Information Technology and Economic Development. Kuala Lumpur: Intelligent Information Technology Application Association, 2011: 435-438. (in Chinese) [15] 朱 伟, 张春雷, 高玉峰, 等. 海洋疏浚泥固化处理土基本力学性质研究[J]. 浙江大学学报(工学版), 2005, 39(10): 1561-1565. (ZHU W, ZHANG C L, GAO Y F, et al. Fundamental mechanical properties of solidified dredged marine sediment[J]. Journal of Zhejiang University (Engineering Science), 2005, 39(10): 1561-1565. (in Chinese)ZHU W, ZHANG C L, GAO Y F, et al. Fundamental mechanical properties of solidified dredged marine sediment[J]. Journal of Zhejiang University (Engineering Science), 2005, 39(10): 1561-1565. (in Chinese) [16] 吴 俊, 征西遥, 杨爱武, 等. 矿渣-粉煤灰基地质聚合物固化淤泥质黏土的抗压强度试验研究[J]. 岩土力学, 2021, 42(3): 647-655. (WU J, ZHENG X Y, YANG A W, et al. Experimental study on the compressive strength of muddy clay solidified by the one-part slag-fly ash based geopolymer[J]. Rock and Soil Mechanics, 2021, 42(3): 647-655. (in Chinese)WU J, ZHENG X Y, YANG A W, et al. Experimental study on the compressive strength of muddy clay solidified by the one-part slag-fly ash based geopolymer[J]. Rock and Soil Mechanics, 2021, 42(3): 647-655. (in Chinese) [17] 周永祥, 刘 倩, 王祖琦, 等. 流态固化土用无熟料胶凝材料的性能研究[J]. 硅酸盐通报, 2022, 41(10): 3548-3555. (ZHOU Y X, LIU Q, WANG Z Q, et al. Properties of cementitious materials without clinker for fluid solidified soil[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(10): 3548-3555, (in Chinese) doi: 10.16552/j.cnki.issn1001-1625.2022.10.020ZHOU Y X, LIU Q, WANG Z Q, et al. Properties of cementitious materials without clinker for fluid solidified soil[J]. Bulletin of the Chinese Ceramic Society, 2022, 41(10): 3548-3555, doi: 10.16552/j.cnki.issn1001-1625.2022.10.020 [18] 李雅曦, 王 琴, 张秋臣, 等. 无机固化剂对流态固化土结构和性能的影响[J]. 材料导报, 2023, 37(S1): 23010106. (LI Y X, WANG Q, ZHANG Q C, et al. Effect of inorganic curing agents on the structure and properties of fluid cured soils[J]. Materials Reports, 2023, 37(S1): 23010106. (in Chinese)LI Y X, WANG Q, ZHANG Q C, et al. Effect of inorganic curing agents on the structure and properties of fluid cured soils[J]. Materials Reports, 2023, 37(S1): 23010106. (in Chinese) [19] MOHANTY S, ROY N, SINGH S P, et al. Strength and durability of flyash, GGBS and cement clinker stabilized dispersive soil[J]. Cold Regions Science and Technology, 2021, 191: 103358. doi: 10.1016/j.coldregions.2021.103358 [20] SHEEN Y N, ZHANG L H, LE D H. Engineering properties of soil-based controlled low-strength materials as slag partially substitutes to Portland cement[J]. Construction and Building Materials, 2013, 48: 822-829. doi: 10.1016/j.conbuildmat.2013.07.046 [21] IBRAHIM, RAHMAN M K, NAJAMUDDIN S K, et al. A review on utilization of industrial by-products in the production of controlled low strength materials and factors influencing the properties[J]. Construction and Building Materials, 2022, 325: 126704. doi: 10.1016/j.conbuildmat.2022.126704 -

下载:

下载: