Construction Technology of PHC Tube-pile in Typical Thick-dense Sand Layer in Nanchang Area

-

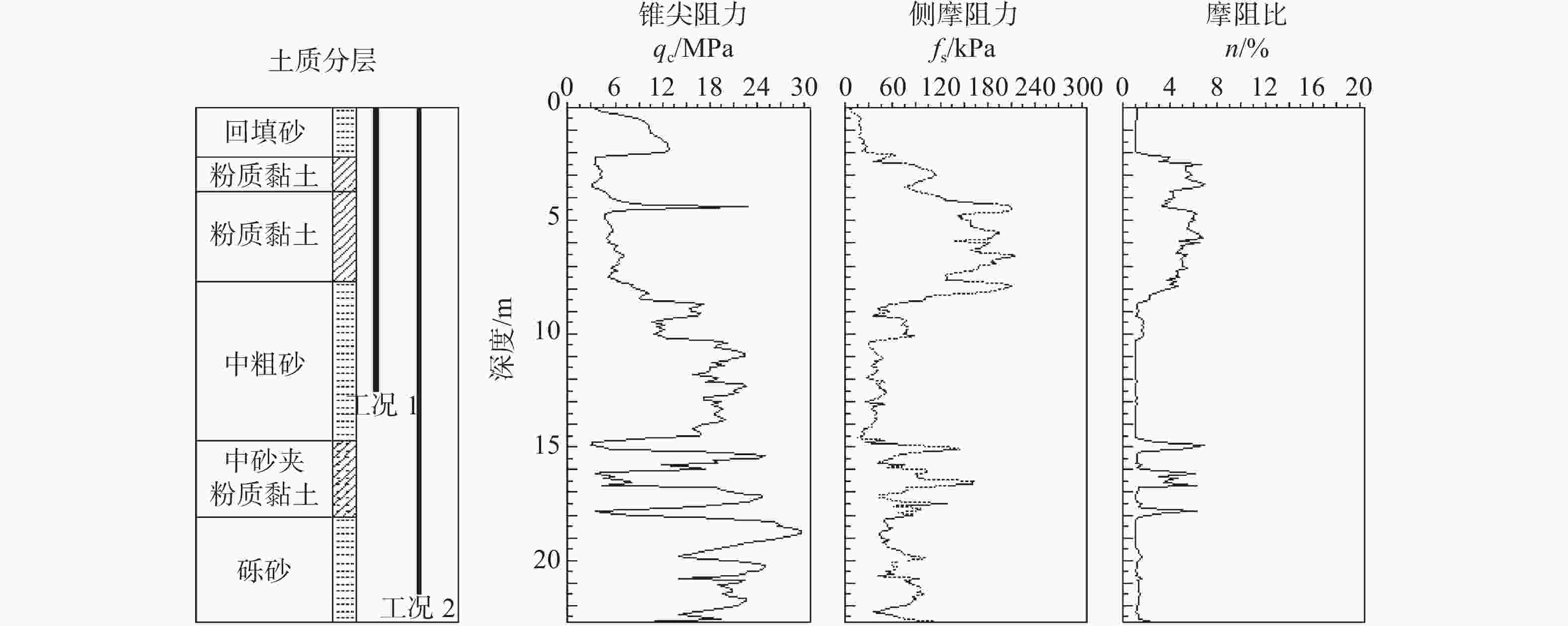

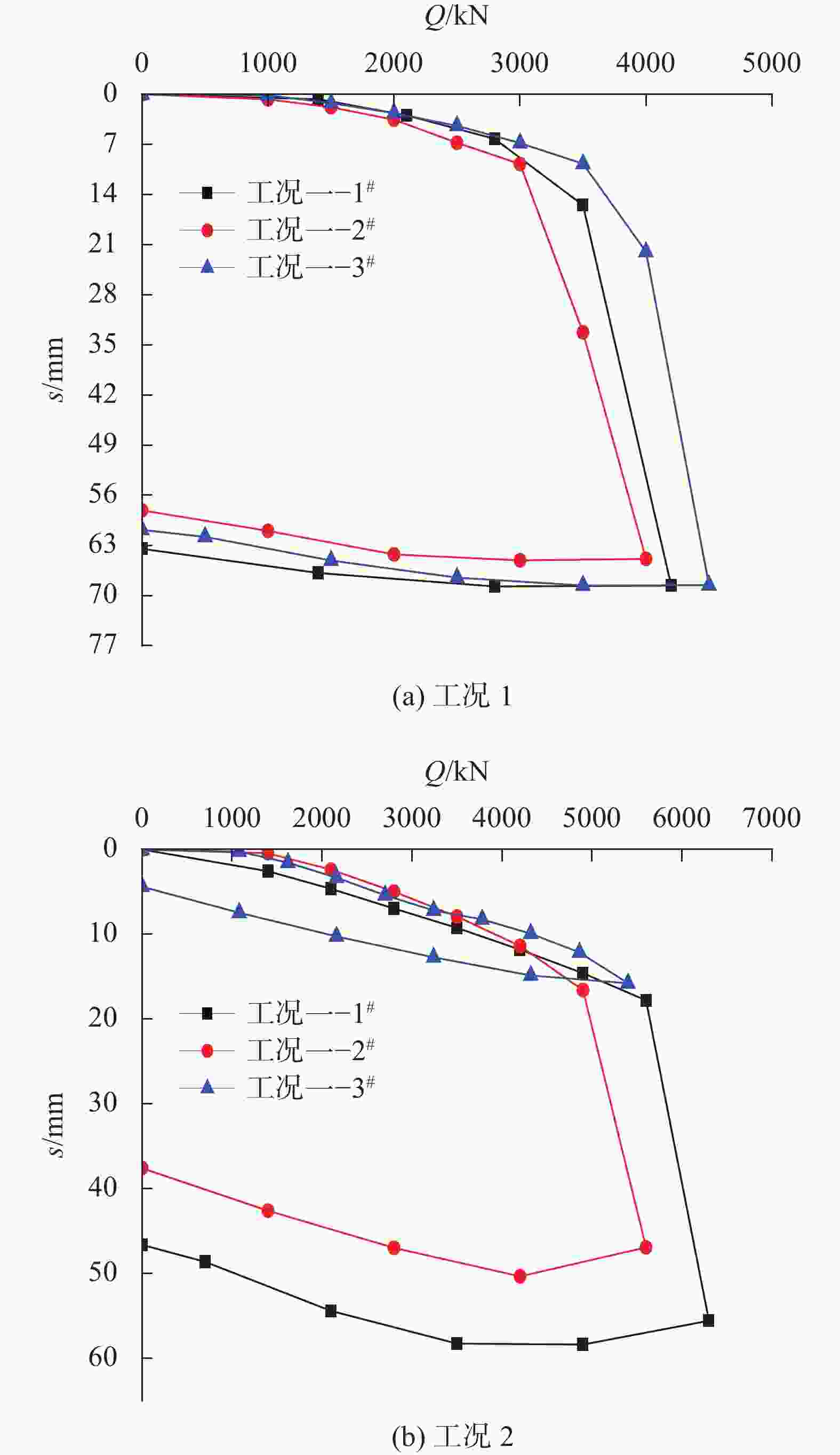

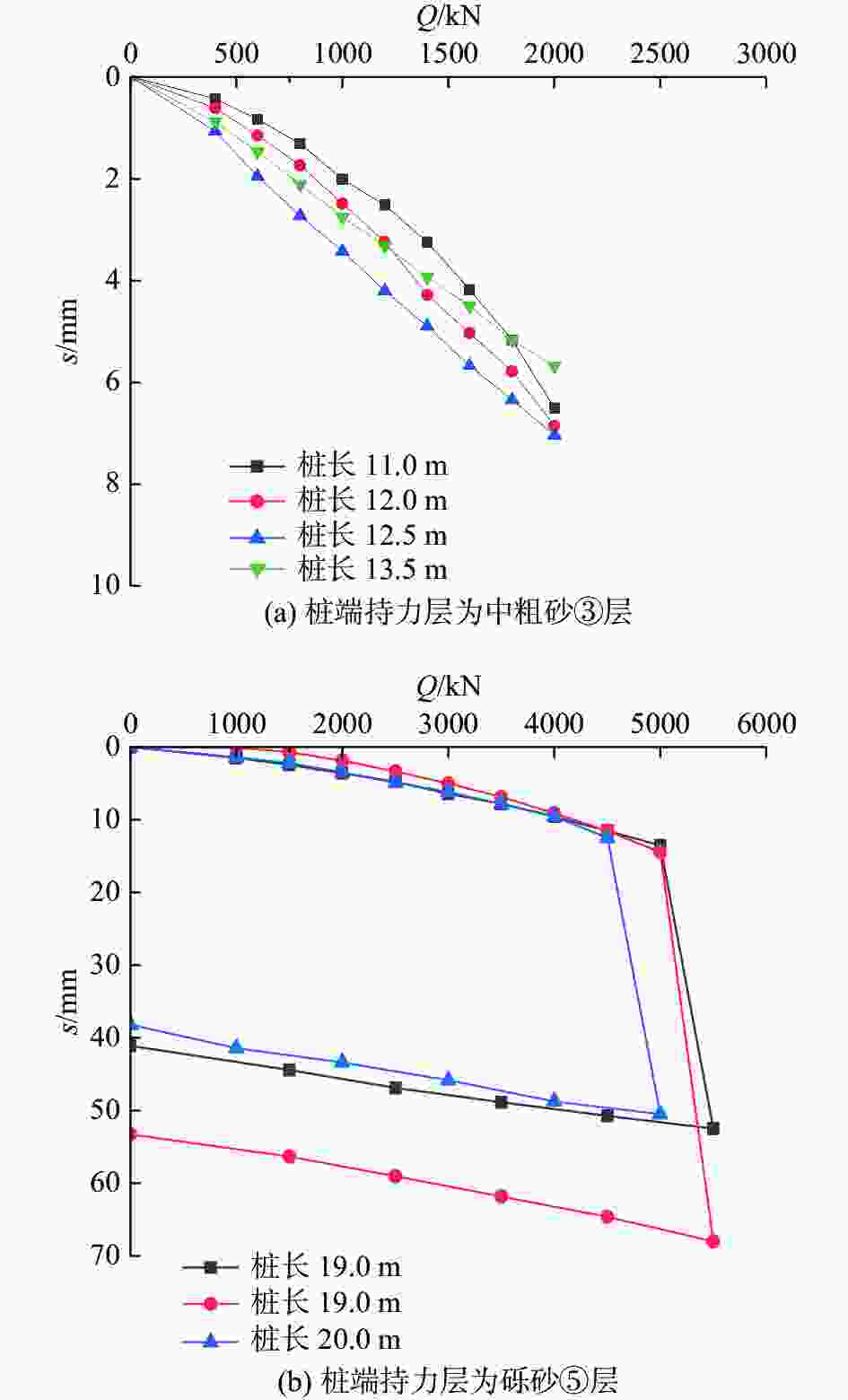

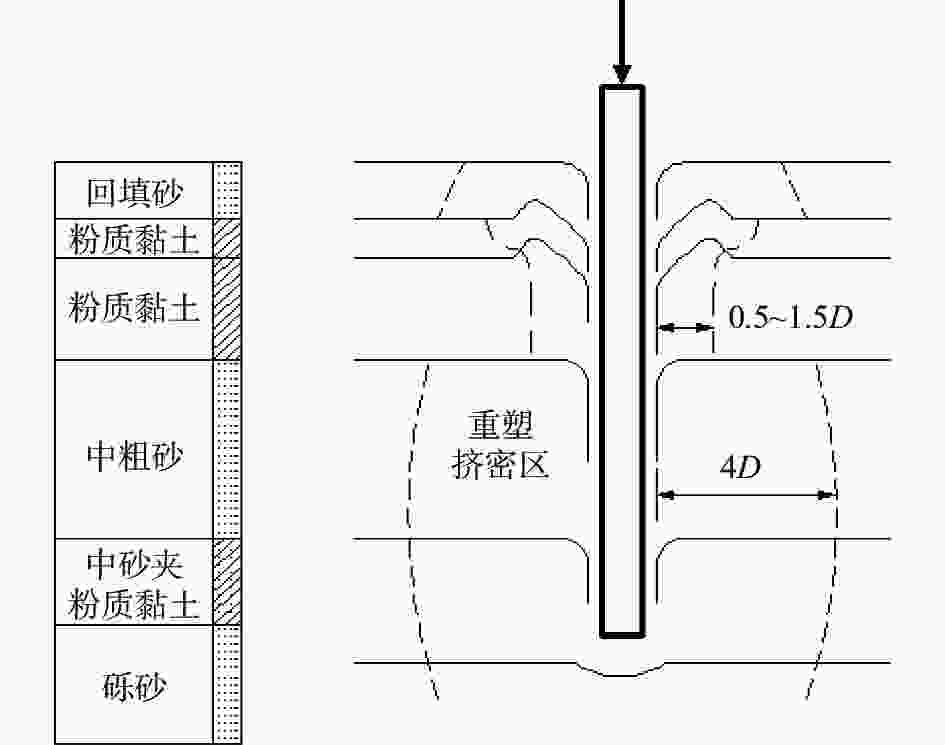

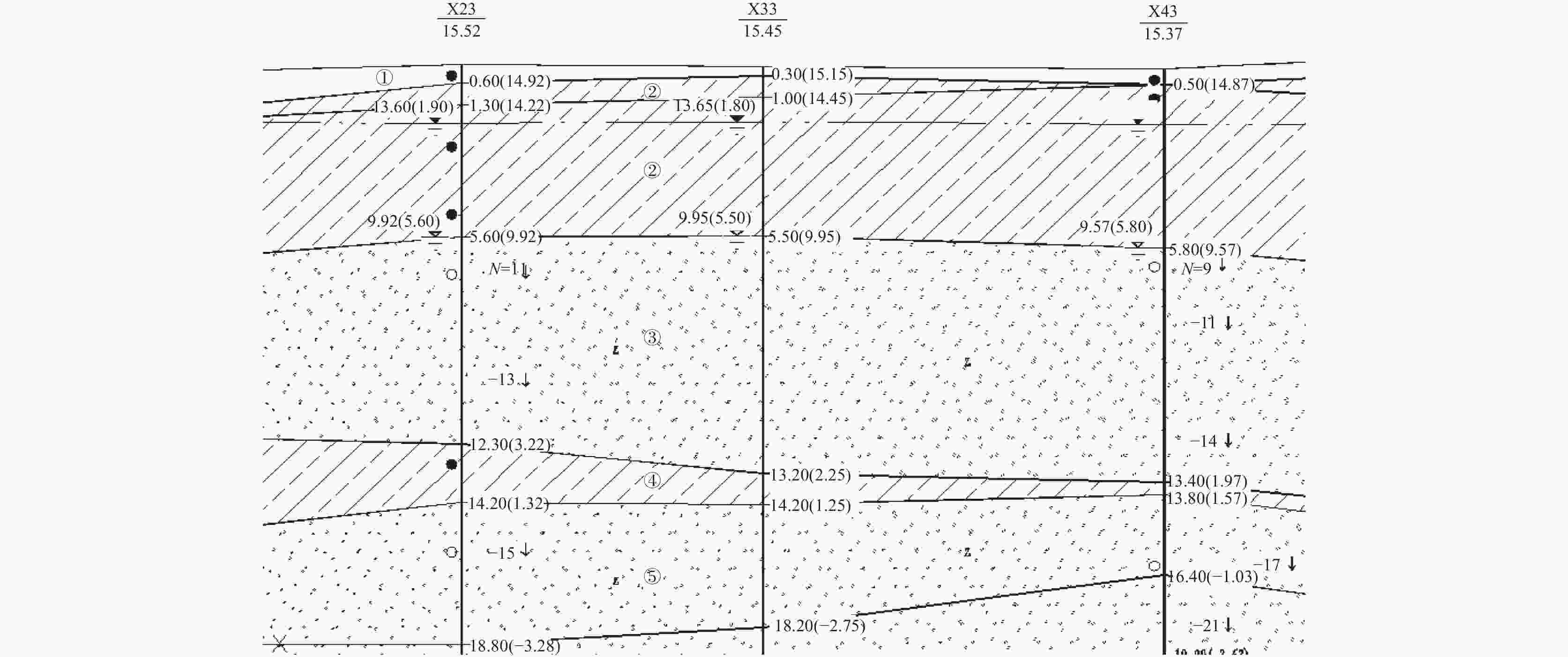

摘要: 依托南昌地区某桩基工程,采用静力触探原位试验分析该地区典型厚密砂层地质特征,结合理论计算及现场试验分析PHC管桩的锤击沉桩阻力及设计单桩极限承载力,对工程桩的设计及施工提出合理建议,同时总结该地层条件下锤击PHC管桩成桩的施工工艺。后续工程桩承载力检测结果表明,优化调整后的施工技术满足了工程设计要求,取得了良好的社会与经济效益,可在该区域推广应用。Abstract: Based on the example of pile foundation in Nanchang, static penetration in-situ test was used to analyze the geological characteristics of typical thick-dense sand layers in the area. Based on theoretical calculations and on-site tests, the hammer sinking resistance of PHC pipe piles and the ultimate bearing capacity of a single pile were analyzed. Reasonable suggestions were proposed for the design and construction of engineering piles, and the construction process of hammer driving PHC pipe piles under this geological condition was summarized. The subsequent pile bearing capacity testing results show that the optimized and adjusted construction technology meets the engineering design requirements and has achieved good social and economic benefits, which can be promoted and applied in this area.

-

表 1 地层土体主要物理力学指标表

地层

编号土性名称 层厚/m 含水率/% 孔隙比 塑限

指数液限

指数压缩系数/MPa−1 黏聚力/kPa 内摩擦角/(°) 标准贯入试验/击 ① 回填砂 2.20 14 ②1 粉质黏土 1.50 29.3 0.904 13.9 0.71 0.424 18.3 8.2 14.5 ② 粉质黏土 4.00 25.0 0.772 14.0 0.39 0.286 29.6 16.1 15.5 ③ 中粗砂 7.00 24 ④ 中砂夹粉质黏土 3.40 26.4 0.801 13.2 0.45 0.294 27.9 14.8 16 ⑤ 砾砂 4.60 36 表 2 桩锤冲击力参数[6]

锤型 冲击部分质量/t 总质量/t 冲击力/

(×100 kN)D25 2.5 6.5 20~25 D35 3.5 7.2 25~40 D45 4.5 9.6 40~50 D60 6.0 15.0 50~70 D72 7.2 18.0 70~100 D80 8.0 17.0 >100 D100 10.0 20.0 >120 表 3 沉桩阻力计算成果

地层

编号土性名称 平均值 $ {n_i} $ $ \rho $ $ m $ ${P_{\rm{h}}}$/kN ${P_{\rm{j}}}$/kN ${P_{\rm{d}}}$/kN ${P_{\rm{u}}}$/kN ${f_{{\rm{s}}i} }$/kPa ${q_{{\rm{c}}i} }$/MPa ① 回填砂 22.7 7.72 3 ②1 粉质黏土 87.8 1.96 3.5 ② 粉质黏土 176.9 4.51 3.5 ③ 中粗砂 58.1 14.47 3 0.6 1.5 1433.4 1094.6 2552.5 5080.5 ④ 中砂夹粉质黏土 84.3 11.68 3.5 ⑤ 砾砂 67.7 19.18 3.5 0.6 1.5 1844.9 1579.3 3383.4 6807.5 表 4 静力触探指标计算单桩承载力成果

地层

编号土性名称 层厚/m 平均值 $ {\beta _i} $ $ \alpha $ ${Q_{{\rm{sk}}} }$/kN ${Q_{{\rm{pk}}} }$/kN ${Q_{{\rm{uk}}} }$/kN ${f_{{\rm{s}}i} }$/kPa ${q_{{\rm{c}}i} }$/MPa ① 回填砂 2.20 22.7 7.72 1.69 ②1 粉质黏土 1.50 87.8 1.96 0.86 ② 粉质黏土 4.00 176.9 4.51 0.58 ③ 中粗砂 7.00 58.1 14.47 0.81 1/2 1697.3 1361.6 3058.9 ④ 中砂夹粉质黏土 3.40 84.3 11.68 0.88 1/2 ⑤ 砾砂 4.60 67.7 19.18 0.81 1/2 2089.6 1995.8 4085.5 表 5 静载荷试验成果

序号 桩号 桩长/m 桩径/mm 沉桩方式 锤击数/击 桩端持力层 极限承载力/kN 沉降量/mm 1# 12.5 500 锤击 792 3500 15.48 工况1 2# 12.5 500 锤击 825 ③中粗砂 3500 33.25 3# 12.5 500 锤击 804 4000 22.01 1# 21 500 锤击 1496 5600 17.79 工况2 2# 21 500 锤击 1362 ⑤砾砂 4900 16.59 3# 21 500 锤击 1405 5400 15.77 -

[1] 邢皓枫,赵红崴,叶观宝,等. PHC管桩工程特性分析[J]. 岩土工程学报,2009,31(1):36-39. [2] 刘细元,马振兴,杨永革,等. 南昌市地下水特征及其应急水源地分析[J]. 资源调查与环境,2006,27(1):33-38. [3] YU H S,MITCHELL J K. Analysis of cone resistance: review of methods[J]. Journal of Geotechnical & Geoenvironmental Engineering,1998,125(9):140-149. [4] 张忠苗,喻 君,张广兴. 根据不同桩长对比试验优化设计桩持力层的研究[J]. 岩石力学与工程学报,2007,26(S2):4251-4257. [5] 《桩基工程手册》编写委员会. 桩基工程手册[M]. 北京: 中国建筑工业出版社, 1995. [6] JGJ 94—2008 建筑桩基技术规范[S]. 北京: 中国建筑工业出版社, 2008. [7] 许 巍,梁书亭,戴国亮. 预应力管桩设计中的若干问题讨论[J]. 工业建筑,2005,35(S1):489-491. [8] 李晓柱,孙 海. 锤击管桩挤(土)密效应现场试验研究[J]. 土工基础,2015,29(5):62-66. [9] 施建勇,彭 劼. 沉桩挤土效应研究综述[J]. 大坝观测与土工测试,2001,25(3):5-9. -

下载:

下载: